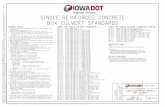

single precast reinforced concrete box culvert

Transcript of single precast reinforced concrete box culvert

6/28/2016 12:49:43 PM bkloss W:\Highway\Bridge\MethodsSection\CADD Concept Drafts\EnglishSignedPrecastCulverts.dgn PRCB G1-13 11x17_pdf.pltcfg

PRCB G1-13

BOX CULVERT STANDARDS

SINGLE PRECAST REINFORCED CONCRETE

GENERAL NOTES

INDEX AND

GENERAL NOTES:

SPECIFICATIONS:

DESIGN STRESSES:

CONSTRUCTION:

DESIGN:

INDEX FOR PRECAST CULVERT STANDARDS:

PEP 1-13

PES 4-13

PES 3-13-T3

PES 2-13-T3

PES 1-13-T3

PES 1-13-T1

PRCB 12-13

PRCB 10-13

PRCB 8-13

PRCB 6-13

PRCB G2-13

PRCB G1-13

EMBANKMENT PROTECTION DETAILS, 0° TO 45° SKEWS

ALTERNATE CURTAIN WALL DETAILS

TYPE 3 LINTEL BEAM DETAILS, 0° TO 45° SKEWS

TYPE 3 END SECTION DETAILS, 7.5° TO 45° SKEWS

TYPE 3 END SECTION DETAILS, UP TO 7.5° SKEWS

TYPE 1 END SECTION DETAILS, UP TO 7.5° SKEWS

CULVERT BARREL DETAILS, 12' SPANS

CULVERT BARREL DETAILS, 10' SPANS

CULVERT BARREL DETAILS, 8' SPANS

CULVERT BARREL DETAILS, 6' SPANS

TYPICAL CULVERT BARREL DETAILS

INDEX & GENERAL NOTES

DESIGN f'c = 5 ksi.

SECTIONS AS NOTED ON CULVERT BARREL DETAIL STANDARDS, FOR END SECTION

CONCRETE IN ACCORDANCE WITH AASHTO LRFD SECTION 5, f'c FOR BARREL

WELDED WIRE REINFORCEMENT IN ACCORDANCE WITH AASHTO LRFD SECTION 5.

BAR REINFORCEMENT IN ACCORDANCE WITH AASHTO LRFD SECTION 5, GRADE 60.

THE AASHTO LRFD BRIDGE DESIGN SPECIFICATIONS, 5TH ED., SERIES OF 2010:

DESIGN STRESSES FOR THE FOLLOWING MATERIALS ARE IN ACCORDANCE WITH

SUPPLEMENTAL SPECIFICATIONS AND SPECIAL PROVISIONS.

GENERAL SUPPLEMENTAL SPECIFICATIONS, DEVELOPMENTAL SPECIFICATIONS,

HIGHWAY AND BRIDGE CONSTRUCTION, CURRENT SERIES, PLUS APPLICABLE

IOWA DEPARTMENT OF TRANSPORTATION STANDARD SPECIFICATIONS FOR

AASHTO LRFD BRIDGE DESIGN SPECIFICATIONS, 5TH ED., SERIES OF 2010.

EN

GLIS

HSI

GN

ED

PR

EC

AS

TC

UL

VE

RT

S.D

GN - P

RC

B

G1-13 -

THIS

SH

EE

T IS

SU

ED 01-13.

Highway Division

15.

14.

13.

12.

11.

10.

9.

8.

7.

6.

5.

4.

3.

2.

1.

ENGLISH SIZE

BAR DESIGNATION 13

4

16

5

19

6

10

3

29

9

25

8

22

7

36

11

32

10

1 LAYER OF REINFORCEMENT BARS.

BARS OR

1 LAYER OF WELDED WIRE REINFORCEMENT AND I LAYER OF REINFORCEMENT

1 OR 2 LAYERS OF WELDED WIRE REINFORCEMENT OR

07-2016

RE

VIS

ED 07-2016 -

AD

DE

D

TH

E

DE

SI

GN

VE

RTIC

AL

AN

D

HO

RIZ

ON

TA

L

EA

RT

H P

RE

SS

UR

ES

AN

D

RE

NU

MB

ER

ED

TH

E

GE

NE

RA

L

NO

TE

S.

END SECTIONS AND ALLOW INLET AND OUTLET END SECTIONS TO BE SIMILAR.

SECTION MAY BE A DOUBLE GROOVE BARREL TO FACILITATE PLACEMENT OF OUTLET

THE FIRST PRECAST BARREL SECTION ADJACENT TO THE OUTLET PRECAST END

EQUIVALENT TO THE BAR DIAMETER IN MILLIMETERS.

DESIGNATION" IS THE STAMPED IMPRESSION ON THE REINFORCING BARS, AND IS

PRECAST PLANT MAY DISPLAY THE FOLLOWING "BAR DESIGNATION". THE "BAR

( #3 IS … INCH DIAMETER BAR ). ENGLISH REINFORCING STEEL RECEIVED AT THE

THESE CULVERT STANDARDS LABEL ALL REINFORCING STEEL WITH ENGLISH NOTATION

FOR THESE STANDARDS.

BOXCAR SOFTWARE VERSION 3.1 WAS USED FOR THE DESIGN OF THE BARREL SECTIONS

SIDES OF THE CUT MEMBER TO REPLACE OR EXCEED THE CUT REINFORCEMENT.

WHEN REINFORCEMENT IS CUT, ADDITIONAL REINFORCEMENT SHALL BE ADDED ON BOTH

THE WIRE REINFORCEMENT IS ACCEPTABLE.

REINFORCEMENT, EXCEPT THAT THE ORIGINAL WELDING REQUIRED TO MANUFACTURE

WELDING WILL NOT BE ALLOWED ON REINFORCEMENT BARS OR WELDED WIRE

LONGITUDINAL WIRES OR BARS SHALL NOT BE MORE THAN 8".

LESS THAN 2" NOR MORE THAN 4". THE SPACING CENTER TO CENTER OF THE

THE SPACING CENTER TO CENTER OF THE TRANSVERSE WIRES OR BARS SHALL NOT BE

(MAXIMUM OF 2 LAYERS).

THE MAXIMUM WELDED WIRE REINFORCEMENT SIZE SHALL BE A W23/D23 PER LAYER

REINFORCEMENT AS DETAILED.

THE MAXIMUM SIZE OF REINFORCEMENT BARS SHALL BE #6, EXCEPT FOR PARAPET

SPECIFICATIONS.

THE REINFORCEMENT SHALL BE DEVELOPED IN ACCORDANCE WITH AASHTO LRFD

C.

B.

A.

ANY OF THE FOLLOWING COMBINATIONS OF REINFORCEMENT MAY BE USED:

ALL DIMENSIONS ARE IN FEET AND INCHES UNLESS OTHERWISE NOTED OR SHOWN.

WERE DESIGNED WITH PLAIN WWR, Fy = 65 ksi.

AREAS SHALL BE INCREASED BY 8%. THE BARREL SECTIONS IN THESE STANDARDS

BARS ARE SUBSTITUTED FOR WELDED WIRE REINFORCEMENT, THE REINFORCEMENT

REINFORCEMENT AREAS ARE BASED ON WELDED WIRE REINFORCEMENT. IF REINFORCING

REINFORCING STEEL IN ACCORDANCE WITH THE STANDARD SPECIFICATIONS. THE

DEFORMED WELDED WIRE REINFORCEMENT (WWR) Fy = 65 ksi, AND/OR GRADE 60

THE REINFORCEMENT SUPPLIED FOR THIS STRUCTURE SHALL BE PLAIN AND/OR

REINFORCING BAR TO BE 1•" MIN. AND 2" MAX. UNLESS OTHERWISE NOTED.

THE CLEAR DISTANCE FROM FACE OF CONCRETE TO NEAR EDGE OR END OF

CONDITIONS.

THE PRECAST RCB CULVERT SECTIONS ARE DESIGNED FOR CLASS 2 EXPOSURE

HORIZONTAL EARTH PRESSURE, EHmax = 0.060 kcf MAX, EHmin = 0.030 kcf.

VERTICAL EARTH PRESSURE, EV=0.120 kcf.

EARTH FILLS OF VARYING HEIGHTS.

THE PRECAST RCB CULVERT SECTIONS ARE DESIGNED FOR HL-93 LIVE LOAD AND

LA

TE

ST

RE

VISI

ON

DA

TE

AP

PR

OV

ED

BY

BRI

DG

E

EN

GI

NE

ER

Highway Division

STANDARD DESIGN

CONCRETE BOX CULVERTS

SINGLE PRECAST REINFORCED

JANUARY, 2013

6/28/2016 12:49:45 PM bkloss W:\Highway\Bridge\MethodsSection\CADD Concept Drafts\EnglishSignedPrecastCulverts.dgn PRCB G2-13 11x17_pdf.pltcfg

"M""B"

"H"

"A"

"C""S""C"

TYP.

1" CL.

TY

P.

•"

4•"

3•

4 4

3#3 HAUNCH BARS @ 1'-0 MAX. SPACING3

4'-0 MINIMUM

FOR TRANSVERSE REINFORCEMENT

"B"

"H"

"A"

1" CL.

1" CL.

OR "C"

"A", "B"

SEE CULVERT BARREL DETAIL STANDARDS

("H"/2) - 6"

TIE

HO

LE

MAX.

2

MAX.

2

2

22

As3

As8

As4

As1

As7As5

As6As2

As6 As5

PRCB G2-13BARREL DETAILS

TYPICAL CULVERTTRANSVERSE BARREL SECTION

TONGUE AT CORNERS

NECESSARY TO FIT

CUT BARS AS

GROOVE SHOWN

TONGUE AND

TONGUE AND GROOVE JOINT DETAIL

OR BEVEL OPTIONAL

SMALL RADIUS

INSIDE FACE

OUTSIDE FACE

FABRIC LAYER DETAIL

WIRE FABRIC

LAYER OF WELDED

WIRE FABRIC

LAYER OF WELDED

LONGITUDINAL BARREL SECTION

NOTES:

1

3

FORMING DETAIL

SECTION

PLAN

SPACED AT A MAXIMUM OF 48 INCHES.

IN LIEU OF NYLON BOOTS WHEN

PLASTIC SPACERS MAY BE UTILIZED

NYLON BOOTS ON EVERY FOURTH WIRE.

TRANSVERSE REINFORCEMENT

REINFORCEMENT

LONGITUDINAL

BOTTOM OF FORM

SPACED AT A MAXIMUM OF 48 INCHES.

IN LIEU OF NYLON BOOTS WHEN

PLASTIC SPACERS MAY BE UTILIZED

NYLON BOOTS ON EVERY FOURTH WIRE.

BOTTOM OF FORM

REINFORCEMENT

LONGITUDINAL

STEEL FORM OR EQUAL

2

33

3

3

WELDED WIRE FABRIC SHALL BE PLACED AS SHOWN.

REINFORCEMENT AREAS, THE WIRES OF THE

FABRIC IS USED TO OBTAIN THE REQUIRED

WHEN MORE THAN ONE LAYER OF WELDED WIRE

NOTE:

As1, As7 OR As8 As5

As6

As2, As3 OR As4

#3 BAR

TO FIT TONGUE AT CORNERS

#3 BAR, CUT AS NECESSARY

As1

4‚

3ƒ

3•

EXTRA STRONG PIPE

MA

X.

2 M

AX.

2

MA

X.

2

MA

X.

2

MA

X.

2

MA

X.

2

TO BOLT

WELD COUPLER

APPROVED CONCRETE BOX TIES

ACCEPTABLE JOINT

REQUIRED TO PRODUCE

2'-8`} AS

2'-8 (ADJ. }1•" MIN.)

2'-8 (ADJ. }1•" MIN.)

2'-8 (ADJ. }1•" MIN.)

MA

X.

2

MA

X.

2

WELDED EYE OR APPROVED EQUAL *

PLACED INSIDE OF STRUCTURE.

DOWNSTREAM END WHEN THE CONNECTIONS ARE

*`THE CONNECTIONS SHALL BE PLACED AT THE

2'-8 (ADJ. }1•" MIN.)

MA

X.

2

MA

X.

2

MA

X.

2

MA

X.

2

2'-8 (ADJ. }1•" MIN.)

APPROVED EQUAL

WELDED EYE OR

PERMITTED WHEN PRECAST

TAPERED HOLES

1'-4

TYPICAL TIE LAYOUT

1'-4

@ 1'-0 SPACING (TYP.)

#3 HAUNCH BARS

RADIUS (TYP.)

1'-0 MAXIMUM

(REINFORCEMENT BAR OPTION SHOWN)

CORNER REQUIREMENTS

NECESSARY TO ACHIEVE

REINFORCEMENT AS

CUT OR BEND INSIDE

| HOLE | HOLE| JOINT

SHOWN FOR CLARITY

REINFORCEMENT NOT

ARE SET UP FOR 1'-4 SPACING FROM OUTSIDE OF JOINT.

CENTERLINE OF JOINTS AS SHOWN ABOVE, UNLESS FORMS

HOLES SHALL BE CAST OR DRILLED 1'-4 FROM

NOTE:

(REINFORCEMENT BAR OPTION SHOWN)

END

GROOVE

SEE FORMING DETAIL

4

5

As6As5

As5

As6

3

3

33

TONGUE END

6

5

4

3

2

1

6

ON FILL SIDE.

U BOLT TIES ARE REQUIRED FOR BIKE, PEDESTRIAN AND CATTLE PATHS WITH NUTS

OPTIONAL SQUARED CORNERS WITH ƒ" TO 2" CHAMFER.

CONNECTION TIE HOLE LOCATIONS.

REFER TO APPLICABLE END SECTION DETAIL SHEET FOR BARREL TO END SECTION

FLOOR, AND WALLS AND MUST BE 0.06 IN¢/FT. MIN.

LONGITUDINAL REINFORCEMENT DENOTED AS As5 & As6 MUST BE PLACED IN SLAB,

HAUNCH SIZES ARE TO BE 12" VERTICAL, 12" HORIZONTAL ON ALL BOX SIZES.

CULVERT TIES ARE TO BE 1"½ RODS. SEE THIS SHEET FOR CONNECTION DETAILS.

6

OUTSIDE REINFORCING (TYP.)

REINFORCING, BUT NOT PAST

MINIMUM OF 2" BEYOND INSIDE

HAUNCH BARS TO EXTEND A

EN

GLIS

HSI

GN

ED

PR

EC

AS

TC

UL

VE

RT

S.D

GN - P

RC

B

G2-13 -

THIS

SH

EE

T IS

SU

ED 01-13.

TOP VIEW

ADJUSTABLE TIE

U BOLT TIE

EYE BOLT TIE

DOUBLE EYE BOLT TIE DOUBLE WELDED PIPE TIE

WELDED PIPE TIE

CANOPY TIE

OPTIONAL

DETAIL "A"

SEE DETAIL "A" *

SEE DETAIL "A"

RE

VIS

ED 07-2016 -

CO

RR

EC

TE

D

TY

PO

S.

07-2016

LA

TE

ST

RE

VISI

ON

DA

TE

AP

PR

OV

ED

BY

BRI

DG

E

EN

GI

NE

ER

Highway Division

STANDARD DESIGN

CONCRETE BOX CULVERTS

SINGLE PRECAST REINFORCED

JANUARY, 2013

6/28/2016 12:49:46 PM bkloss W:\Highway\Bridge\MethodsSection\CADD Concept Drafts\EnglishSignedPrecastCulverts.dgn PRCB 6-13 11x17_pdf.pltcfg

"M"

"B"

"H"

"A"

"C""S""C"

TYP.

1'-0

TY

P.

1'-

0

NOTES:

DETAILS

CULVERT BARREL

TYPICAL BARREL SECTION

6' SPAN BARREL SECTIONS

PRCB 6-13

EN

GLIS

HSI

GN

ED

PR

EC

AS

TC

UL

VE

RT

S.D

GN - P

RC

B 6-13 -

THIS

SH

EE

T IS

SU

ED 01-13.

As1

As4

HAUNCH

As3

As8

HAUNCH BARAs7

As5

As6

As2

As6 As5

DIMENSIONS

(LB/FT)

WEIGHTAs1 As2 As3 As4 As7/As8

SIZE CLASS FILL S H A B C AREA LENGTH M AREA LENGTH AREA LENGTH AREA LENGTH AREA LENGTH

6x3

1 2-10 6 3 8 8 8 0.36 9'-2 2'-8 0.29 6'-6 0.27 6'-6 0.20 3'-6 0.20 3'-8 2370

2 11-19 6 3 8 8 8 0.48 9'-2 2'-8 0.40 6'-6 0.40 6'-6 0.20 3'-6 0.20 3'-8 2370

3 20-25 6 3 8 8 8 0.61 9'-2 2'-8 0.50 6'-6 0.50 6'-6 0.20 3'-6 0.20 3'-8 2370

6x4

1 2-11 6 4 8 8 8 0.31 10'-2 2'-8 0.35 6'-6 0.33 6'-6 0.20 4'-6 0.20 3'-8 2570

2 12-19 6 4 8 8 8 0.41 10'-2 2'-8 0.47 6'-6 0.48 6'-6 0.20 4'-6 0.20 3'-8 2570

3 20-25 6 4 8 8 8 0.52 10'-2 2'-8 0.59 6'-6 0.60 6'-6 0.20 4'-6 0.20 3'-8 2570

6x5

1 2-12 6 5 8 8 8 0.28 11'-2 2'-8 0.39 6'-6 0.38 6'-6 0.20 5'-6 0.20 3'-8 2770

2 13-19 6 5 8 8 8 0.36 11'-2 2'-8 0.51 6'-6 0.53 6'-6 0.20 5'-6 0.20 3'-8 2770

3 20-25 6 5 8 8 8 0.46 11'-2 2'-8 0.65 6'-6 0.66 6'-6 0.20 5'-6 0.20 3'-8 2770

6x6

1 2-12 6 6 8 8 8 0.26 12'-2 2'-8 0.43 6'-6 0.42 6'-6 0.20 6'-6 0.20 3'-8 2970

2 13-19 6 6 8 8 8 0.33 12'-2 2'-8 0.54 6'-6 0.56 6'-6 0.20 6'-6 0.20 3'-8 2970

3 20-25 6 6 8 8 8 0.41 12'-2 2'-8 0.68 6'-6 0.70 6'-6 0.20 6'-6 0.20 3'-8 2970

6x7

1 2-13 6 7 8 8 8 0.24 13'-2 2'-8 0.46 6'-6 0.46 6'-6 0.20 7'-6 0.20 3'-8 3170

2 14-19 6 7 8 8 8 0.30 13'-2 2'-8 0.55 6'-6 0.58 6'-6 0.20 7'-6 0.20 3'-8 3170

3 20-25 6 7 8 8 8 0.38 13'-2 2'-8 0.68 6'-6 0.71 6'-6 0.20 7'-6 0.20 3'-8 3170

6x8

1 2-13 6 8 8 8 8 0.23 14'-2 2'-8 0.49 6'-6 0.50 6'-6 0.20 8'-6 0.20 3'-8 3370

2 14-19 6 8 8 8 8 0.29 14'-2 2'-8 0.55 6'-6 0.59 6'-6 0.21 8'-6 0.20 3'-8 3370

3 20-25 6 8 8 8 8 0.36 14'-10 3'-0 0.68 6'-6 0.72 6'-6 0.25 8'-6 0.20 3'-0 3370

VARIABLE DIMENSIONS AND QUANTITIES FOR 6' SPAN BARREL SECTIONS

As6As5

As6

As5

BARS

REINFORCEMENT

REINFORCEMENT

WELDED WIRE

BENT BAR DETAILS

"M"`-`MIN. CL. "M"`-`MIN. CL.

D`=`4•"

FOR WIRE SIZE

D`=`ACCORDING TO ACI

NEEDED TO MAINTAIN CLEAR COVER.

PIN DIAMETER MAY BE INCREASED IF

D = PIN DIAMETER (MIN.).

ALL DIMENSIONS ARE OUT TO OUT.

REINFORCEMENT REQUIREMENTS (IN¢/FT)

f'c (ksi)

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

6.

5.

4.

3.

2.

1.

SEE PRCB G1-13 AND G2-13 FOR ADDITIONAL INFORMATION AND NOTES.

CORNERS.

WEIGHT OF SECTIONS ASSUMES A DENSITY OF 150 PCF AND SQUARED

LENGTH IS PROVIDED.

REINFORCEMENT SHALL BE ADJUSTED TO ENSURE ADEQUATE LAP

REINFORCING, DIMENSION "M" AND/OR LENGTH OF THE As7/As8

IF REINFORCING BARS ARE SUBSTITUTED FOR WELDED WIRE

REQUIREMENTS.

ALL REINFORCEMENT LENGTHS AND AREAS ARE MINIMUM

MINIMUM.

PLACED IN SLAB, FLOOR, AND WALLS AND MUST BE 0.06 IN¢/FT

LONGITUDINAL REINFORCEMENT DENOTED AS As5 AND As6 MUST BE

DIMENSIONS "A", "B" & "C" LISTED IN THE BAR LIST ARE IN INCHES.

LA

TE

ST

RE

VISI

ON

DA

TE

AP

PR

OV

ED

BY

BRI

DG

E

EN

GI

NE

ER

Highway Division

STANDARD DESIGN

CONCRETE BOX CULVERTS

SINGLE PRECAST REINFORCED

JANUARY, 2013

6/28/2016 12:49:48 PM bkloss W:\Highway\Bridge\MethodsSection\CADD Concept Drafts\EnglishSignedPrecastCulverts.dgn PRCB 8-13 11x17_pdf.pltcfg

TY

P.

1'-

0

TYP.

1'-0

"M"

"B"

"H"

"A"

"C""S""C"

DETAILS

CULVERT BARREL

TYPICAL BARREL SECTION

8' SPAN BARREL SECTIONS

PRCB 8-13

EN

GLIS

HSI

GN

ED

PR

EC

AS

TC

UL

VE

RT

S.D

GN - P

RC

B 8-13 -

THIS

SH

EE

T IS

SU

ED 01-13.

As1

As4

HAUNCH

As3

As8

As6 As5

HAUNCH BARAs5

As6

As7

As2

DIMENSIONS

(LB/FT)

WEIGHTAs1 As2 As3 As4 As7/As8

SIZE CLASS FILL S H A B C AREA LENGTH M AREA LENGTH AREA LENGTH AREA LENGTH AREA LENGTH

8x4

1 2-9 8 4 9 10 8 0.47 10'-9 2'-10 0.42 8'-6 0.40 8'-6 0.20 4'-6 0.24 5'-4 3320

2 10-19 8 4 9 10 8 0.65 10'-9 2'-10 0.66 8'-6 0.67 8'-6 0.20 4'-6 0.24 5'-4 3320

3 20-25 8 4 9 10 8 0.85 10'-9 2'-10 0.83 8'-6 0.85 8'-6 0.20 4'-6 0.24 5'-4 3320

8x5

1 2-9 8 5 9 10 8 0.41 11'-9 2'-10 0.46 8'-6 0.46 8'-6 0.20 5'-6 0.24 5'-4 3520

2 10-19 8 5 9 10 8 0.57 11'-9 2'-10 0.72 8'-6 0.74 8'-6 0.20 5'-6 0.24 5'-4 3520

3 20-25 8 5 9 10 8 0.74 11'-9 2'-10 0.91 8'-6 0.94 8'-6 0.20 5'-6 0.24 5'-4 3520

8x6

1 2-9 8 6 9 10 8 0.37 12'-9 2'-10 0.50 8'-6 0.50 8'-6 0.20 6'-6 0.24 5'-4 3720

2 10-19 8 6 9 10 8 0.51 12'-9 2'-10 0.76 8'-6 0.79 8'-6 0.20 6'-6 0.24 5'-4 3720

3 20-25 8 6 9 10 8 0.66 12'-9 2'-10 0.96 8'-6 0.99 8'-6 0.20 6'-6 0.24 5'-4 3720

8x7

1 2-10 8 7 9 10 8 0.34 13'-9 2'-10 0.53 8'-6 0.54 8'-6 0.20 7'-6 0.24 5'-4 3920

2 11-19 8 7 9 10 8 0.47 13'-9 2'-10 0.79 8'-6 0.82 8'-6 0.20 7'-6 0.24 5'-4 3920

3 20-25 8 7 9 10 8 0.60 13'-9 2'-10 1.00 8'-6 1.02 8'-6 0.20 7'-6 0.24 5'-4 3920

8x8

1 2-10 8 8 9 10 8 0.31 14'-9 2'-10 0.56 8'-6 0.57 8'-6 0.20 8'-6 0.24 5'-4 4120

2 11-19 8 8 9 10 8 0.43 14'-9 2'-10 0.81 8'-6 0.84 8'-6 0.20 8'-6 0.24 5'-4 4120

3 20-25 8 8 9 10 8 0.56 14'-9 2'-10 1.01 8'-6 1.04 8'-6 0.20 8'-6 0.24 5'-4 4120

8x9

1 2-11 8 9 9 10 8 0.30 15'-9 2'-10 0.59 8'-6 0.60 8'-6 0.20 9'-6 0.24 5'-4 4320

2 12-19 8 9 9 10 8 0.42 16'-1 3'-0 0.81 8'-6 0.85 8'-6 0.22 9'-6 0.24 5'-0 4320

3 20-25 8 9 9 10 8 0.54 16'-5 3'-2 1.01 8'-6 1.05 8'-6 0.26 9'-6 0.24 5'-0 4320

8x10

1 2-11 8 10 9 10 8 0.31 17'-1 3'-0 0.61 8'-6 0.63 8'-6 0.25 10'-6 0.24 5'-0 4520

2 12-20 8 10 9 10 8 0.48 17'-1 3'-0 0.84 8'-6 0.88 8'-6 0.34 10'-6 0.24 5'-0 4520

3 21-25 8 10 9 10 9 0.51 17'-5 3'-2 0.94 8'-6 0.99 8'-6 0.34 10'-6 0.24 5'-0 4810

VARIABLE DIMENSIONS AND QUANTITIES FOR 8' SPAN BARREL SECTIONS

As5 As6

As6

As5

BARS

REINFORCEMENT

REINFORCEMENT

WELDED WIRE

BENT BAR DETAILS

"M"`-`MIN. CL. "M"`-`MIN. CL.

D`=`4•"

FOR WIRE SIZE

D`=`ACCORDING TO ACI

NEEDED TO MAINTAIN CLEAR COVER.

PIN DIAMETER MAY BE INCREASED IF

D = PIN DIAMETER (MIN.).

ALL DIMENSIONS ARE OUT TO OUT.

NOTES:

6.

5.

4.

3.

2.

1.

SEE PRCB G1-13 AND G2-13 FOR ADDITIONAL INFORMATION AND NOTES.

CORNERS.

WEIGHT OF SECTIONS ASSUMES A DENSITY OF 150 PCF AND SQUARED

LENGTH IS PROVIDED.

REINFORCEMENT SHALL BE ADJUSTED TO ENSURE ADEQUATE LAP

REINFORCING, DIMENSION "M" AND/OR LENGTH OF THE As7/As8

IF REINFORCING BARS ARE SUBSTITUTED FOR WELDED WIRE

REQUIREMENTS.

ALL REINFORCEMENT LENGTHS AND AREAS ARE MINIMUM

MINIMUM.

PLACED IN SLAB, FLOOR, AND WALLS AND MUST BE 0.06 IN¢/FT

LONGITUDINAL REINFORCEMENT DENOTED AS As5 AND As6 MUST BE

DIMENSIONS "A", "B" & "C" LISTED IN THE BAR LIST ARE IN INCHES.

REINFORCEMENT REQUIREMENTS (IN¢/FT)

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

f'c (ksi)

LA

TE

ST

RE

VISI

ON

DA

TE

AP

PR

OV

ED

BY

BRI

DG

E

EN

GI

NE

ER

Highway Division

STANDARD DESIGN

CONCRETE BOX CULVERTS

SINGLE PRECAST REINFORCED

JANUARY, 2013

6/28/2016 12:49:49 PM bkloss W:\Highway\Bridge\MethodsSection\CADD Concept Drafts\EnglishSignedPrecastCulverts.dgn PRCB 10-13 11x17_pdf.pltcfg

TY

P.

1'-

0

TYP.

1'-0

"M"

"B"

"H"

"A"

"C""S""C"

DETAILS

CULVERT BARREL

TYPICAL BARREL SECTION

10' SPAN BARREL SECTIONS

PRCB 10-13

EN

GLIS

HSI

GN

ED

PR

EC

AS

TC

UL

VE

RT

S.D

GN - P

RC

B 10-13 -

THIS

SH

EE

T IS

SU

ED 01-13.

As3

As8

HAUNCH

As4

As1

As7As5

As6As2

As6 As5

HAUNCH BAR

DIMENSIONS

(LB/FT)

WEIGHTAs1 As2 As3 As4 As7/As8

SIZE CLASS FILL S H A B C AREA LENGTH M AREA LENGTH AREA LENGTH AREA LENGTH AREA LENGTH

10x4

1 2-11 10 4 9 10 8 0.72 10'-9 2'-10 0.62 10'-6 0.63 10'-6 0.20 4'-6 0.24 7'-4 3795

2 12-21 10 4 9 10 8 1.24 13'-9 4'-4 1.04 10'-6 1.05 10'-6 0.20 4'-6 0.24 7'-0 3795

3 22-25 10 4 10 11 9 1.23 12'-1 3'-5 1.03 10'-6 1.07 10'-6 0.22 4'-6 0.27 9'-0 4220

10x5

1 2-11 10 5 9 10 8 0.64 11'-9 2'-10 0.69 10'-6 0.71 10'-6 0.20 5'-6 0.24 7'-4 3995

2 12-22 10 5 9 10 8 1.15 12'-5 3'-2 1.20 10'-6 1.21 10'-6 0.20 5'-6 0.24 9'-0 3995

3 23-25 10 5 10 11 9 1.09 12'-7 3'-2 1.13 10'-6 1.19 10'-6 0.22 5'-6 0.27 9'-0 4445

10x6

1 2-11 10 6 9 10 8 0.58 12'-9 2'-10 0.74 10'-6 0.76 10'-6 0.20 6'-6 0.24 7'-4 4195

2 12-22 10 6 9 10 8 1.03 13'-1 3'-0 1.28 10'-6 1.30 10'-6 0.20 6'-6 0.24 9'-0 4195

3 23-25 10 6 10 11 9 0.98 13'-3 3'-0 1.21 10'-6 1.27 10'-6 0.22 6'-6 0.27 9'-0 4670

10x7

1 2-11 10 7 9 10 8 0.54 13'-9 2'-10 0.78 10'-6 0.81 10'-6 0.20 7'-6 0.24 7'-4 4395

2 12-22 10 7 9 10 8 0.94 13'-9 2'-10 1.34 10'-6 1.36 10'-6 0.20 7'-6 0.24 9'-0 4395

3 23-25 10 7 10 11 9 0.90 13'-11 2'-10 1.26 10'-6 1.34 10'-6 0.22 7'-6 0.27 9'-0 4895

10x8

1 2-10 10 8 9 10 8 0.50 14'-9 2'-10 0.76 10'-6 0.80 10'-6 0.20 8'-6 0.24 7'-4 4595

2 11-21 10 8 9 10 8 0.83 14'-9 2'-10 1.33 10'-6 1.36 10'-6 0.20 8'-6 0.24 9'-0 4595

3 22-25 10 8 10 11 8 0.83 14'-11 2'-10 1.41 10'-6 1.50 10'-6 0.20 8'-6 0.27 9'-0 4875

10x9

1 2-11 10 9 9 10 8 0.46 15'-9 2'-10 0.83 10'-6 0.88 10'-6 0.20 9'-6 0.24 7'-4 4795

2 12-21 10 9 9 10 8 0.78 17'-1 3'-6 1.35 10'-6 1.39 10'-6 0.20 9'-6 0.24 7'-0 4795

3 22-25 10 9 10 11 8 0.79 15'-11 2'-10 1.43 10'-6 1.52 10'-6 0.20 9'-6 0.27 9'-0 5075

10x10

1 2-11 10 10 9 10 8 0.46 17'-1 3'-0 0.85 10'-6 0.91 10'-6 0.20 10'-6 0.24 7'-0 4995

2 12-21 10 10 9 10 8 0.76 18'-1 3'-6 1.37 10'-6 1.41 10'-6 0.24 10'-6 0.24 7'-0 4995

3 22-25 10 10 10 11 9 0.75 18'-5 3'-7 1.35 10'-6 1.43 10'-6 0.22 10'-6 0.27 7'-0 5570

10x11

1 2-9 10 11 9 10 8 0.46 18'-1 3'-0 0.85 10'-6 0.85 10'-6 0.28 11'-6 0.24 7'-0 5195

2 10-16 10 11 9 10 8 0.63 19'-9 3'-10 1.12 10'-6 1.17 10'-6 0.34 11'-6 0.24 5'-10 5195

3 17-20 10 11 9 10 9 0.68 20'-1 4'-0 1.24 10'-6 1.29 10'-6 0.32 11'-6 0.24 5'-10 5510

4 21-25 10 11 10 11 11 0.72 19'-7 3'-8 1.19 10'-6 1.28 10'-6 0.27 11'-6 0.27 7'-0 6435

10x12

1 2-12 10 12 9 10 8 0.54 21'-3 4'-1 0.93 10'-6 1.00 10'-6 0.41 12'-6 0.24 5'-2 5395

2 13-19 10 12 9 10 10 0.61 21'-7 4'-3 1.12 10'-6 1.18 10'-6 0.39 12'-6 0.24 5'-4 6075

3 20-25 10 12 10 11 12 0.69 22'-1 4'-5 1.12 10'-6 1.22 10'-6 0.36 12'-6 0.27 5'-8 7050

VARIABLE DIMENSIONS AND QUANTITIES FOR 10' SPAN BARREL SECTIONS

As5 As6

As6

As5

BARS

REINFORCEMENT

REINFORCEMENT

WELDED WIRE

BENT BAR DETAILS

"M"`-`MIN. CL. "M"`-`MIN. CL.

D`=`4•"

FOR WIRE SIZE

D`=`ACCORDING TO ACI

NEEDED TO MAINTAIN CLEAR COVER.

PIN DIAMETER MAY BE INCREASED IF

D = PIN DIAMETER (MIN.).

ALL DIMENSIONS ARE OUT TO OUT.

NOTES:

6.

5.

4.

3.

2.

1.

SEE PRCB G1-13 AND G2-13 FOR ADDITIONAL INFORMATION AND NOTES.

CORNERS.

WEIGHT OF SECTIONS ASSUMES A DENSITY OF 150 PCF AND SQUARED

LENGTH IS PROVIDED.

REINFORCEMENT SHALL BE ADJUSTED TO ENSURE ADEQUATE LAP

REINFORCING, DIMENSION "M" AND/OR LENGTH OF THE As7/As8

IF REINFORCING BARS ARE SUBSTITUTED FOR WELDED WIRE

REQUIREMENTS.

ALL REINFORCEMENT LENGTHS AND AREAS ARE MINIMUM

MINIMUM.

PLACED IN SLAB, FLOOR, AND WALLS AND MUST BE 0.06 IN¢/FT

LONGITUDINAL REINFORCEMENT DENOTED AS As5 AND As6 MUST BE

DIMENSIONS "A", "B" & "C" LISTED IN THE BAR LIST ARE IN INCHES.

REINFORCEMENT REQUIREMENTS (IN¢/FT)

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

f'c (ksi)

LA

TE

ST

RE

VISI

ON

DA

TE

AP

PR

OV

ED

BY

BRI

DG

E

EN

GI

NE

ER

Highway Division

STANDARD DESIGN

CONCRETE BOX CULVERTS

SINGLE PRECAST REINFORCED

JANUARY, 2013

6/28/2016 12:49:50 PM bkloss W:\Highway\Bridge\MethodsSection\CADD Concept Drafts\EnglishSignedPrecastCulverts.dgn PRCB 12-13 11x17_pdf.pltcfg

TY

P.

1'-

0

TYP.

1'-0

"M"

"B"

"H"

"A"

"C""S""C"

DETAILS

CULVERT BARREL

TYPICAL BARREL SECTION

12' SPAN BARREL SECTIONS

PRCB 12-13

EN

GLIS

HSI

GN

ED

PR

EC

AS

TC

UL

VE

RT

S.D

GN - P

RC

B 12-13 -

THIS

SH

EE

T IS

SU

ED 01-13.

HAUNCH

As1

As4

As7As5

As6 As2

HAUNCH BAR

As5As6

As3

As8

DIMENSIONS

(LB/FT)

WEIGHTAs1 As2 As3 As4 As7/As8

SIZE CLASS FILL S H A B C AREA LENGTH M AREA LENGTH AREA LENGTH AREA LENGTH AREA LENGTH

12x4

1 2-9 12 4 9 10 8 0.98 12'-11 3'-11 0.74 12'-6 0.74 12'-6 0.20 4'-6 0.24 9'-0 4270

2 10-15 12 4 9 10 9 1.27 15'-1 5'-0 0.98 12'-6 0.96 12'-6 0.22 4'-6 0.24 7'-10 4410

3 16-19 12 4 11 11 9 1.39 14'-8 4'-8 1.11 12'-6 1.12 12'-6 0.22 4'-6 0.27 9'-0 4915

4 20-25 12 4 12 12 10 1.54 15'-0 4'-9 1.26 12'-6 1.27 12'-6 0.24 4'-6 0.29 9'-0 5400

12x5

1 2-10 12 5 9 10 8 0.94 13'-9 3'-10 0.88 12'-6 0.89 12'-6 0.20 5'-6 0.24 9'-0 4470

2 11-15 12 5 9 10 9 1.16 14'-7 4'-3 1.07 12'-6 1.07 12'-6 0.22 5'-6 0.24 9'-0 4635

3 16-21 12 5 11 11 9 1.35 13'-6 3'-7 1.33 12'-6 1.35 12'-6 0.22 5'-6 0.27 11'-0 5140

4 22-25 12 5 12 12 9 1.38 13'-4 3'-5 1.53 12'-6 1.55 12'-6 0.22 5'-6 0.29 11'-0 5475

12x6

1 2-10 12 6 9 10 8 0.84 14'-5 3'-8 0.95 12'-6 0.97 12'-6 0.20 6'-6 0.24 9'-0 4670

2 11-15 12 6 9 10 8 1.15 15'-5 4'-2 1.27 12'-6 1.28 12'-6 0.20 6'-6 0.24 9'-0 4670

3 16-19 12 6 10 11 9 1.19 15'-11 4'-4 1.30 12'-6 1.36 12'-6 0.22 6'-6 0.27 9'-0 5195

4 20-25 12 6 12 12 9 1.22 13'-10 3'-2 1.63 12'-6 1.65 12'-6 0.22 6'-6 0.29 11'-0 5700

12x7

1 2-10 12 7 9 10 8 0.77 15'-1 3'-6 1.00 12'-6 1.03 12'-6 0.20 7'-6 0.24 9'-0 4870

2 11-15 12 7 9 10 8 1.05 16'-1 4'-0 1.34 12'-6 1.36 12'-6 0.20 7'-6 0.24 9'-0 4870

3 16-20 12 7 10 11 8 1.18 14'-9 3'-3 1.63 12'-6 1.67 12'-6 0.20 7'-6 0.27 11'-0 5200

4 21-25 12 7 12 12 9 1.10 14'-6 3'-0 1.70 12'-6 1.73 12'-6 0.22 7'-6 0.29 11'-0 5925

12x8

1 2-11 12 8 9 10 8 0.76 16'-1 3'-6 1.11 12'-6 1.15 12'-6 0.20 8'-6 0.24 9'-0 5070

2 12-18 12 8 10 10 8 1.04 15'-2 3'-0 1.60 12'-6 1.65 12'-6 0.20 8'-6 0.24 11'-0 5235

3 19-21 12 8 11 11 9 1.02 15'-4 3'-0 1.56 12'-6 1.61 12'-6 0.22 8'-6 0.27 11'-0 5815

4 22-25 12 8 12 12 9 1.01 15'-2 2'-10 1.75 12'-6 1.79 12'-6 0.22 8'-6 0.29 11'-0 6150

12x9

1 2-10 12 9 9 10 8 0.67 16'-9 3'-4 1.09 12'-6 1.13 12'-6 0.20 9'-6 0.24 9'-0 5270

2 11-15 12 9 9 10 8 0.91 17'-7 3'-9 1.44 12'-6 1.54 12'-6 0.20 9'-6 0.24 9'-0 5270

3 16-20 12 9 10 11 9 1.00 18'-3 4'-0 1.60 12'-6 1.64 12'-6 0.22 9'-6 0.27 9'-0 5870

4 21-25 12 9 12 12 9 0.94 16'-2 2'-10 1.78 12'-6 1.84 12'-6 0.22 9'-6 0.29 11'-0 6375

12x10

1 2-11 12 10 9 10 8 0.66 17'-9 3'-4 1.18 12'-6 1.24 12'-6 0.20 10'-6 0.24 9'-0 5470

2 12-17 12 10 10 10 8 0.87 18'-6 3'-8 1.60 12'-6 1.68 12'-6 0.20 10'-6 0.24 9'-0 5635

3 18-20 12 10 11 11 9 0.86 18'-10 3'-9 1.57 12'-6 1.64 12'-6 0.22 10'-6 0.27 9'-0 6265

4 21-25 12 10 12 12 9 0.92 17'-2 2'-10 1.80 12'-6 1.87 12'-6 0.22 10'-6 0.29 11'-0 6600

12x11

1 2-11 12 11 9 10 8 0.67 18'-9 3'-4 1.21 12'-6 1.27 12'-6 0.23 11'-6 0.24 9'-0 5670

2 12-15 12 11 10 10 8 0.80 19'-4 3'-7 1.42 12'-6 1.57 12'-6 0.23 11'-6 0.24 9'-0 5835

3 16-20 12 11 11 11 10 0.85 20'-0 3'-10 1.49 12'-6 1.57 12'-6 0.24 11'-6 0.27 9'-0 6810

4 21-25 12 11 12 12 10 0.90 20'-0 3'-9 1.71 12'-6 1.79 12'-6 0.24 11'-6 0.29 9'-0 7150

12x12

1 2-10 12 12 9 10 8 0.66 21'-1 4'-0 1.18 12'-6 1.25 12'-6 0.32 12'-6 0.24 7'-8 5870

2 11-15 12 12 10 10 9 0.77 21'-8 4'-3 1.34 12'-6 1.44 12'-6 0.30 12'-6 0.24 7'-8 6375

3 16-20 12 12 11 11 11 0.84 21'-2 3'-11 1.40 12'-6 1.50 12'-6 0.27 12'-6 0.27 9'-0 7405

4 21-25 12 12 12 12 12 0.90 21'-4 3'-11 1.54 12'-6 1.62 12'-6 0.29 12'-6 0.29 9'-0 8100

VARIABLE DIMENSIONS AND QUANTITIES FOR 12' SPAN BARREL SECTIONS

As6As5

As6

As5

BARS

REINFORCEMENT

REINFORCEMENT

WELDED WIRE

BENT BAR DETAILS

"M"`-`MIN. CL. "M"`-`MIN. CL.

D`=`4•"

FOR WIRE SIZE

D`=`ACCORDING TO ACI

NEEDED TO MAINTAIN CLEAR COVER.

PIN DIAMETER MAY BE INCREASED IF

D = PIN DIAMETER (MIN.).

ALL DIMENSIONS ARE OUT TO OUT.

NOTES:

6.

5.

4.

3.

2.

1.

SEE PRCB G1-13 AND G2-13 FOR ADDITIONAL INFORMATION AND NOTES.

CORNERS.

WEIGHT OF SECTIONS ASSUMES A DENSITY OF 150 PCF AND SQUARED

LENGTH IS PROVIDED.

REINFORCEMENT SHALL BE ADJUSTED TO ENSURE ADEQUATE LAP

REINFORCING, DIMENSION "M" AND/OR LENGTH OF THE As7/As8

IF REINFORCING BARS ARE SUBSTITUTED FOR WELDED WIRE

REQUIREMENTS.

ALL REINFORCEMENT LENGTHS AND AREAS ARE MINIMUM

MINIMUM.

PLACED IN SLAB, FLOOR, AND WALLS AND MUST BE 0.06 IN¢/FT

LONGITUDINAL REINFORCEMENT DENOTED AS As5 AND As6 MUST BE

DIMENSIONS "A", "B" & "C" LISTED IN THE BAR LIST ARE IN INCHES.

5.0

f'c (ksi)

5.0

5.0

6.0

5.0

5.0

5.0

6.0

5.0

5.0

5.0

6.0

5.0

5.0

5.0

6.0

5.0

5.0

5.0

6.0

5.0

5.0

5.0

6.0

5.0

5.0

5.0

6.0

5.0

5.0

5.0

6.0

5.0

5.0

5.0

6.0

REINFORCEMENT REQUIREMENTS (IN¢/FT)

LA

TE

ST

RE

VISI

ON

DA

TE

AP

PR

OV

ED

BY

BRI

DG

E

EN

GI

NE

ER

Highway Division

STANDARD DESIGN

CONCRETE BOX CULVERTS

SINGLE PRECAST REINFORCED

JANUARY, 2013

6/28/2016 12:49:52 PM bkloss W:\Highway\Bridge\MethodsSection\CADD Concept Drafts\EnglishSignedPrecastCulverts.dgn PES 1-13-T1 11x17_pdf.pltcfg

RTb

8S8

4

VA

RIE

S

TYP.

1'-0

LEVEL

4

H

L

4'-0 MIN.6'-0 TYP. 1'-0

4'-

0

2'-

0Tb

H

TY

P.

1'-

8

TY

P.

1'-

6

6

6

4

OR GROOVE

4" TONGUE

Tb

TIE

HO

LE

1'-

6

TY

P.

TIE

HO

LE

1'-

8

TY

P.

1'-

1

3'-

0}

1'-4

S 88

CL.

5"

EDGE OF HAUNCH

0" T

O 3"

TYP.

1" CL.

TY

P.

•"

4•"

3•

OR

Tb

8

6

6

8

8

9

1'-0@ 6" O.C.

3a STIRRUPS

MI

N.

1'-

0

MI

N.

1'-

0

9

MIN.

1'-0

LONGIT. REINFORCING

SEE TABLE FOR

JOINT

END OF GROOVE

2'-

0

1'-

0R

2'-0

85

WELDED WIRE REINFORCING

CENTER OR EQUIVALENT

2'-6" LONG AT 1'-0" ON

#4 LONGITUDINAL BARS

ƒ"

•"

SIDE ELEVATION

(REINFORCEMENT NOT SHOWN)

PLAN VIEW

8

4

2'-

0

MA

X.

8

CL

4

2'-

0

MA

X.

S

SECTION Z-Z

SECTION Y-Y

3

2

1

CONSTRUCTION NOTES:

1'-

0

4

1

5

6

5

10

6

8

4

BOTTOM SLAB THICK. (IN)

INLET FLOW DIRECTION

OUTLET FLOW DIRECTION

DIMENS.

DIMENS.

APRON

R`(FT)

RISE

BOX

L`(FT)

LENGTH

APRON

S`(FT)

SPAN

H`(FT)

SECTION`HT.

Z

Z

Y

Y

TY

P

1" DIAMETER CULVERT TIES (TYP.)

As3 (SEE TABLE)

1:1 BEVEL

PRECAST CURTAIN WALL

As3 (SEE TABLE)

WALL MINIMUM 2

TWO PER CURTAIN

3" DIA. HOLES

3" ½ HOLES 2

3'-

0

MA

X.

SP

AC

ES

PR

EC

AS

T I

N

AP

RO

N

3" ½

HO

LE

S

BOTH DIRECTIONS

0.10 IN¢/FT E.F.

HEIGHT H IS LESS THAN 4'-0

TOP TIE NOT REQUIRED IF

REQUIRED

TIES ARE

TWO CULVERT

FOR SKEWS UP TO 7.5°

FENCE ANCHOR

5fa GALV. STEELD=3ƒ

5fa

BENT BAR DETAILS

D = PIN DIAMETER.

ALL DIMENSIONS ARE OUT TO OUT.

NOTE:

12

11

10

9

8

7

6

5

4

12

11

10

9

8

7

6

5

4

10

9

8

7

6

5

4

8

7

6

5

4

3

12

10

8

6

7

9

12

11

6

66

0.23 IN¢/FT FOR R = 12 FT

0.20 IN¢/FT FOR R = 4 FT - 11 FT

0.20 IN¢/FT

(IN¢/FT)

Ah

REQUIRED As3 (IN¢/FT)

---

---

---

---

---

---

---

---

---

8

---

---

---

---

---

---

---

---

---

8

---

---

---

---

---

---

---

8

0.31

0.23

0.20

0.20

0.20

0.20

8

0.65

0.53

0.42

0.34

0.26

0.24

0.24

0.24

0.24

10

0.62

0.50

0.40

0.31

0.24

0.24

0.24

0.24

0.24

10

0.37

0.29

0.24

0.24

0.24

0.24

0.24

10

---

---

---

---

---

---

10

0.90

0.67

0.49

0.34

0.24

0.24

0.24

0.24

0.24

0.94

0.70

0.51

0.36

0.24

0.24

0.24

0.24

0.24

0.67

0.49

0.34

0.24

0.24

0.24

0.24

0.46

0.31

0.20

0.20

0.20

0.20

7

71

TONGUE AND GROOVE JOINT DETAIL

INSIDE FACE

OUTSIDE FACEAh

LONGITUDINAL REINFORCING

7

7

7

NOTE: H IS THE LARGEST VERTICAL DIMENSION OF THE SECTION.

As3 OR As4

OR BEVEL OPTIONAL

SMALL RADIUS

SECTION DETAILS

TYPE 1 END

D=1•

3a

3

3

SECTION

TO BARREL

2 TIES

3

4 AND SLAB 2

IN CURB

3"½ HOLE

#7

REINFORCING

PARAPET LONGIT.

SPAN S (FT) REQUIRED BAR SIZE

6'

8'

10'

12'

#5

#6

#6

PES 1-13-T1

Ab

At

10'-3

13'-3

16'-3

19'-3

22'-3

25'-3

28'-3

31'-3

34'-3

Ah & As3 REINF.

(IN¢/FT)

Ab

At & Ab REINF.

(IN¢/FT)

At

12

10

8

6

0.38

0.31

0.24

0.22

0.74

0.59

0.46

0.33

TONGUE

(DETAIL SHOWN AT FLOOR; SIMILAR AT WALLS)

OUTSIDE REINFORCING (TYP.)

REINFORCING, BUT NOT PAST

MINIMUM OF 2" BEYOND INSIDE

HAUNCH BARS TO EXTEND A

WITH ƒ" TO 2" CHAMFER

OPTIONAL SQUARED CORNER

1'-0 MAXIMUM RADIUS (TYP.)

MA

X.

MI

N.

DOWEL SETTING NOTE :

B.

A.

MATERIALS I.M. 491.13.

HYDRAULIC CEMENT GROUT SHALL BE ONE OF THOSE APPROVED IN

COMPRESSED AIR IMMEDIATELY PRIOR TO PLACING GROUT. THE

TIMES THE DOWEL DIAMETER AND ARE TO BE BLOWN CLEAN WITH

HYDRAULIC CEMENT GROUT SYSTEMS. DRILLED HOLES ARE TO BE 2•

2301.03, E, OF THE STANDARD SPECIFICATIONS.

POLYMER GROUT SYSTEM SHALL BE IN ACCORDANCE WITH ARTICLE

AS A BONDING AGENT:

RECOMMENDATIONS. EITHER OF THE FOLLOWING SYSTEMS MAY BE USED

INSTALLED IN ACCORDANCE WITH THE MANUFACTURER'S

SHOWN IN THE "SIDE ELEVATION" DETAIL. THE DOWELS SHALL BE

BE DRILLED TO THE DEPTH REQUIRED TO ACHIEVE BAR EMBEDMENT AS

THE 5fa BARS MAY BE SET AS DOWELS IN DRILLED HOLES. HOLES SHALL

REINFORCING

LONGITUDINAL

S (FT)

SPANLAP @ |) 8

Ah (PERMISSIBLE

SPLICES ALLOWED AT | OF SPAN ONLY. 8

Ah REINFORCEMENT, SEE TABLE.

SPLICE 8

LAP

REFER TO FABRIC DETAIL ON SHEET PRCB G2-13 FOR MULTIPLE WWR LAYERS.

REFER TO SHEET PRCB G1-13 FOR ADDITIONAL NOTES.

STEEL SHALL NOT BE LESS THAN 1.5 INCHES OR GREATER THAN 2.0 INCHES.

MEETING THE REQUIREMENTS OF AASHTO LRFD SECTION 5. THE CONCRETE COVER OVER THE REINFORCING

REINFORCING FOR PRECAST END SECTIONS & CURTAIN WALLS SHALL BE WELDED WIRE REINFORCING (WWR)

AS SHOWN BELOW:

PRECAST BOX CULVERT END SECTIONS SHALL BE CONSTRUCTED IN ACCORDANCE WITH DETAILS AND NOTES,

8

EN

GLIS

HSI

GN

ED

PR

EC

AS

TC

UL

VE

RT

S.D

GN - P

ES 1-13-

T1 -

THIS

SH

EE

T IS

SU

ED 01-13.

3 7'-3

DETAIL "A"

BRIDGE DESIGN SPECIFICATIONS.

LAP SPLICES SHALL BE CLASS C AND SHALL BE DESIGNED ACCORDING TO THE AASHTO LRFD

ALL FACES OF THE END SECTION, EXCEPT IN THE TONGUE AND GROOVE AREA.

MINIMUM LONGITUDINAL REINFORCEMENT SHALL BE 0.06 SQ. INCHES PER PERIPHERAL FOOT ON

HAUNCH DIMENSION TO MATCH BARREL HAUNCH SIZE.

JOINT "OPTION B": PROVIDE JOINT IN WALLS, FLOOR AND HAUNCH.

DETAIL "A" ON THIS SHEET.

JOINT "OPTION A": PROVIDE JOINT IN WALLS AND FLOOR. TERMINATE JOINT AT HAUNCH. SEE

THICKNESS OF FLOOR, Tb = 8 IN. FOR 6' SPAN, Tb = 10 IN. FOR ALL OTHER SPANS.

AIR ENTRAINED PORTLAND CEMENT. GROUT MIX SHALL HAVE A MAXIMUM SLUMP OF 4 INCHES.

FILL HOLES WITH GROUT. GROUT SHALL CONSIST OF 1 PART CEMENT AND 2 PARTS SAND. USE

USE TONGUE ON INLET END SECTION AND GROOVE ON OUTLET END SECTION.

SHOWN 5

JOINT "OPTION B"

@ 1'-0 SPA.

#3 BARS

@ 1'-0 SPA.

#3 BARS

#8 DOWELS 1'-0 LONG

3"½ HOLE WITH

1'-0 LONG

#4 DOWELS

SHOWN 5

"OPTION B"

JOINT

SHOWN 4

JOINT "OPTION A"

"A" BELOW 4

SHOWN, SEE DETAIL

JOINT "OPTION A"

07-2016

RE

VIS

ED 05-13 -

AD

DE

D 3'

RIS

E

TO

TH

E

AP

RO

N

DI

ME

NSI

ON

S I

NF

OR

MA

TI

ON

TA

BL

E.

RE

VIS

ED 07-2016 -

CO

RR

EC

TE

D

TY

PO

S.

LA

TE

ST

RE

VISI

ON

DA

TE

AP

PR

OV

ED

BY

BRI

DG

E

EN

GI

NE

ER

Highway Division

STANDARD DESIGN

CONCRETE BOX CULVERTS

SINGLE PRECAST REINFORCED

JANUARY, 2013

6/28/2016 12:49:54 PM bkloss W:\Highway\Bridge\MethodsSection\CADD Concept Drafts\EnglishSignedPrecastCulverts.dgn PES 1-13-T3 11x17_pdf.pltcfg

6

RTb

8S8

4

VA

RIE

S

TYP.

1'-0

LEVEL

4

H

L

4'-0 MIN.6'-0 TYP. 1'-0

4'-

0

2'-

0Tb

R

H

TY

P.

1'-

8

TY

P.

1'-

6

63'-0

2'-6

6 1'-0 1'-0

4

4

OR GROOVE

4" TONGUE

Tb

TIE

HO

LE

1'-

6

TY

P.

TIE

HO

LE

1'-

8

TY

P.

1'-

1

3'-

0}

1'-4

S 88

CL.

5"

EDGE OF HAUNCH

0" T

O 3"

TYP.

1" CL.

TY

P.

•"

4•"

3•

OR

Tb

8

WELDED WIRE REINFORCING

CENTER OR EQUIVALENT

2'-6" LONG AT 1'-0" ON

#4 LONGITUDINAL BARS

JOINT

END OF GROOVE

85

ƒ"

•"

SIDE ELEVATION

(REINFORCEMENT NOT SHOWN)

PLAN VIEW

8

4

2'-

0

MA

X.

8

CL

4

2'-

0

MA

X.

S

SECTION Z-Z

SECTION Y-Y

3

2

1

CONSTRUCTION NOTES:

1'-

0

4

1

5

6

12

15

27

21

5

10

6

8

4 9

BOTTOM SLAB THICK. (IN)

INLET FLOW DIRECTION

OUTLET FLOW DIRECTION

DIMENS.

DIMENS.

APRON

R`(FT)

RISE

BOX

L`(FT)

LENGTH

APRON

S`(FT)

SPAN

H`(FT)

SECTION`HT.

Z

Z

Y

Y

TY

P

1" DIAMETER CULVERT TIES (TYP.)

As3 (SEE TABLE)

1:1 BEVEL

PRECAST CURTAIN WALL

As3 (SEE TABLE)

WALL MINIMUM 2

TWO PER CURTAIN

3" DIA. HOLES

3" ½ HOLES 2

3'-

0

MA

X.

SP

AC

ES

PR

EC

AS

T I

N

AP

RO

N

3" ½

HO

LE

S

BOTH DIRECTIONS

0.10 IN¢/FT E.F.

HEIGHT H IS LESS THAN 4'-0

TOP TIE NOT REQUIRED IF

REQUIRED

TIES ARE

TWO CULVERT

FOR SKEWS UP TO 7.5°

INFORMATION

DETAILS FOR ADDITIONAL

SEE LINTEL BEAM

FENCE ANCHOR

5fa GALV. STEEL

D=3ƒ

5fa

BENT BAR DETAILS

D = PIN DIAMETER.

ALL DIMENSIONS ARE OUT TO OUT.

NOTE:

12

11

10

9

8

7

6

5

4

12

11

10

9

8

7

6

5

4

10

9

8

7

6

5

4

8

7

6

5

4

3

12

10

8

6

7 18

9 24

12

11 30

33

6

66

0.23 IN¢/FT FOR R = 12 FT

0.20 IN¢/FT FOR R = 4 FT - 11 FT

0.20 IN¢/FT

(IN¢/FT)

Ah

REQUIRED As3 (IN¢/FT)

---

---

---

---

---

---

---

---

---

8

---

---

---

---

---

---

---

---

---

8

---

---

---

---

---

---

---

8

0.31

0.23

0.20

0.20

0.20

0.20

8

0.65

0.53

0.42

0.34

0.26

0.24

0.24

0.24

0.24

10

0.62

0.50

0.40

0.31

0.24

0.24

0.24

0.24

0.24

10

0.37

0.29

0.24

0.24

0.24

0.24

0.24

10

---

---

---

---

---

---

10

0.90

0.67

0.49

0.34

0.24

0.24

0.24

0.24

0.24

0.94

0.70

0.51

0.36

0.24

0.24

0.24

0.24

0.24

0.67

0.49

0.34

0.24

0.24

0.24

0.24

0.46

0.31

0.20

0.20

0.20

0.20

7

7

TONGUE AND GROOVE JOINT DETAIL

INSIDE FACE

OUTSIDE FACEAh

LONGITUDINAL REINFORCING

7

7

7

NOTE: H IS THE LARGEST VERTICAL DIMENSION OF THE SECTION.

SECTION

BARREL

2 TIES TO

As3 OR As4

OR BEVEL OPTIONAL

SMALL RADIUS

SECTION DETAILS

TYPE 3 ENDPES 1-13-T3

Ah & As3 REINF.

TONGUE

TOP OF WALL 2

6" DEEP INTO

2"½ HOLES,

2

3

3

3

2

1

(DETAIL SHOWN AT FLOOR; SIMILAR AT WALLS)

WITH ƒ" TO 2" CHAMFER

OPTIONAL SQUARED CORNER

1'-0 MAXIMUM RADIUS (TYP.)

OUTSIDE REINFORCING (TYP.)

REINFORCING, BUT NOT PAST

MINIMUM OF 2" BEYOND INSIDE

HAUNCH BARS TO EXTEND A

MA

X.

MI

N.

REINFORCING

LONGITUDINAL

DOWEL SETTING NOTE :

B.

A.

MATERIALS I.M. 491.13.

HYDRAULIC CEMENT GROUT SHALL BE ONE OF THOSE APPROVED IN

COMPRESSED AIR IMMEDIATELY PRIOR TO PLACING GROUT. THE

TIMES THE DOWEL DIAMETER AND ARE TO BE BLOWN CLEAN WITH

HYDRAULIC CEMENT GROUT SYSTEMS. DRILLED HOLES ARE TO BE 2•

2301.03, E, OF THE STANDARD SPECIFICATIONS.

POLYMER GROUT SYSTEM SHALL BE IN ACCORDANCE WITH ARTICLE

AS A BONDING AGENT:

RECOMMENDATIONS. EITHER OF THE FOLLOWING SYSTEMS MAY BE USED

INSTALLED IN ACCORDANCE WITH THE MANUFACTURER'S

SHOWN IN THE "SIDE ELEVATION" DETAIL. THE DOWELS SHALL BE

BE DRILLED TO THE DEPTH REQUIRED TO ACHIEVE BAR EMBEDMENT AS

THE 5fa BARS MAY BE SET AS DOWELS IN DRILLED HOLES. HOLES SHALL

SPLICES ALLOWED AT | OF SPAN ONLY. 8

Ah REINFORCEMENT, SEE TABLE.

LAP @ |) 8

Ah (PERMISSIBLE

REFER TO FABRIC DETAIL ON SHEET PRCB G2-13 FOR MULTIPLE WWR LAYERS.

REFER TO SHEET PRCB G1-13 FOR ADDITIONAL NOTES.

STEEL SHALL NOT BE LESS THAN 1.5 INCHES OR GREATER THAN 2.0 INCHES.

MEETING THE REQUIREMENTS OF AASHTO LRFD SECTION 5. THE CONCRETE COVER OVER THE REINFORCING

REINFORCING FOR PRECAST END SECTIONS & CURTAIN WALLS SHALL BE WELDED WIRE REINFORCING (WWR)

AS SHOWN BELOW:

PRECAST BOX CULVERT END SECTIONS SHALL BE CONSTRUCTED IN ACCORDANCE WITH DETAILS AND NOTES,

8

EN

GLIS

HSI

GN

ED

PR

EC

AS

TC

UL

VE

RT

S.D

GN - P

ES 1-13-

T3 -

THIS

SH

EE

T IS

SU

ED 01-13.

3 6

"A" BELOW 4

SHOWN, SEE DETAIL

JOINT "OPTION A"

SHOWN 5

JOINT "OPTION B"

DETAIL "A"

@ 1'-0 SPA.

#3 BARS

SHOWN 5

"OPTION B"

JOINT

SHOWN 4

JOINT "OPTION A"

1'-0 LONG

#4 DOWELS

@ 1'-0 SPA.

#3 BARS

BRIDGE DESIGN SPECIFICATIONS.

LAP SPLICES SHALL BE CLASS C AND SHALL BE DESIGNED ACCORDING TO THE AASHTO LRFD

ALL FACES OF THE END SECTION, EXCEPT IN THE TONGUE AND GROOVE AREA.

MINIMUM LONGITUDINAL REINFORCEMENT SHALL BE 0.06 SQ. INCHES PER PERIPHERAL FOOT ON

HAUNCH DIMENSION TO MATCH BARREL HAUNCH SIZE.

JOINT "OPTION B": PROVIDE JOINT IN WALLS, FLOOR AND HAUNCH.

DETAIL "A" ON THIS SHEET.

JOINT "OPTION A": PROVIDE JOINT IN WALLS AND FLOOR. TERMINATE JOINT AT HAUNCH. SEE

THICKNESS OF FLOOR, Tb = 8 IN. FOR 6' SPAN, Tb = 10 IN. FOR ALL OTHER SPANS.

AIR ENTRAINED PORTLAND CEMENT. GROUT MIX SHALL HAVE A MAXIMUM SLUMP OF 4 INCHES.

FILL HOLES WITH GROUT. GROUT SHALL CONSIST OF 1 PART CEMENT AND 2 PARTS SAND. USE

USE TONGUE ON INLET END SECTION AND GROOVE ON OUTLET END SECTION.

RE

VIS

ED 05-13 -

AD

DE

D

TH

E 3'

RIS

E

TO

TH

E

AP

RO

N

DI

ME

NSI

ON I

NF

OR

MA

TI

ON

TA

BL

E.

RE

VIS

ED 07-2016 -

CO

RR

EC

TE

D

TY

PO

S.

07-2016

LA

TE

ST

RE

VISI

ON

DA

TE

AP

PR

OV

ED

BY

BRI

DG

E

EN

GI

NE

ER

Highway Division

STANDARD DESIGN

CONCRETE BOX CULVERTS

SINGLE PRECAST REINFORCED

JANUARY, 2013

6/28/2016 12:49:55 PM bkloss W:\Highway\Bridge\MethodsSection\CADD Concept Drafts\EnglishSignedPrecastCulverts.dgn PES 2-13-T3 11x17_pdf.pltcfg

S

1'-0

4'-

0

8

1

LEVEL WALL SECTIONSLOPED

SECTIONS

WALL

(SEE TABLE)

N

(SEE TABLE)

LL

@ 3'-

0

MA

X.

3"½

HO

LES

MIN.

1'-6 4'-0 MIN.P

1'-

0

L (SEE TABLE)

2'-

0Tb

H TY

P.

1'-

6

TY

P.

1'-

8

CL.

5"

TYP.

1" CL.

TY

P.

•"

3•

OR

Tb

8

EDGE OF HAUNCH

END OF GROOVE JOINT

0" T

O 3"

WELDED WIRE REINFORCING

CENTER OR EQUIVALENT

2'-6" LONG AT 1'-0" ON

#4 LONGITUDINAL BARS

Tb

R

4

4

88

G (SHOWN ELSEWHERE IN PLANS)

•"

•"

ƒ"

END VIEW

SECTION A-A

ELEVATION

PLAN VIEW

NOTES:

LENGTH L

3'-0

2'-6

(SEE TABLE)

3

INLET FLOW DIRECTION

OUTLET FLOW DIRECTION

TO THE NEAREST WHOLE INCH.

DIMENSIONS SHOWN IN TABLES ARE ROUNDED

NOTE:

TO | OF ROADWAY.

L - BASED ON 3:1 FORESLOPE NORMAL15° & 30° SKEWS

45° SKEWS

2'-10

3'-4

DETAILS FOR RIGHT AHEAD SKEWS SIMILAR.

SEE SITUATION PLAN FOR ACTUAL DIRECTION OF SKEW.

DETAILS SHOWN ARE FOR LEFT AHEAD SKEW.

NOTE:

A

A

5

(SEE TABLE)

As3

BARREL HAUNCH SIZE

HAUNCH TO MATCH

BEAM

LINTEL

6

TO MATCH BARREL

TONGUE OR GROOVE

HEIGHT H IS LESS THAN 4'-0

TOP TIE NOT REQUIRED IFFOR ADDITIONAL INFORMATION

SEE LINTEL BEAM DETAILS

2

SECTION

BARREL

2 TIES TO

FOR SKEWS OF 7.5° TO 45°

LENGTH LL

LENGTH N

LENGTH P

As4 REINF.

BOTTOM SLAB THICK. (IN)

DIMENS.

S`(FT)

SPAN

H`(FT)

SECTION`HT.

12

10

8

6

12

11

10

9

8

7

6

5

4

12

11

10

9

8

7

6

5

4

10

9

8

7

6

5

4

8

7

6

5

4

3

REQUIRED As3 (IN¢/FT)(IN¢/FT)

Ah

---

---

---

---

---

---

---

---

---

8

---

---

---

---

---

---

---

---

---

8

---

---

---

---

---

---

---

8

0.31

0.23

0.20

0.20

0.20

0.20

8

S`(FT)

SPAN15° SKEW 30° SKEW 45° SKEW

S`(FT)

SPAN15° SKEW 30° SKEW 45° SKEW

S`(FT)

SPAN15° SKEW 30° SKEW 45° SKEW15° SKEW 30° SKEW 45° SKEW

(IN¢/FT)

R`(FT)

RISE

15° SKEW 30° SKEW 45° SKEWH (FT)

SECTION HT.

EXCEPT AS NOTED

0.20 IN¢/FT (TYP.)9

4

BOTH DIRECTIONS

0.10 IN¢/FT IN E.F.

0.65

0.53

0.42

0.34

0.26

0.24

0.24

0.24

0.24

10

0.62

0.50

0.40

0.31

0.24

0.24

0.24

0.24

0.24

10

0.37

0.29

0.24

0.24

0.24

0.24

0.24

10

---

---

---

---

---

---

10

12

10

8

6

4'-3

4'-0

3'-9

3'-6

6'-4

5'-9

5'-2

4'-7

9'-6

8'-6

7'-6

6'-6

12

10

8

6

5'-11

5'-4

4'-10

4'-3

9'-10

8'-8

7'-6

6'-4

15'-6

13'-6

11'-6

9'-6

12

10

8

6

1'-9

1'-6

1'-3

1'-0

3'-10

3'-3

2'-8

2'-1

6'-8

5'-8

4'-8

3'-812

11

10 OR LESS

0.25

0.20

0.20

0.27

0.21

0.20

0.29

0.22

0.20

0.97

0.73

0.53

0.37

0.29

0.24

0.24

0.24

0.24

15° SKEW

1.02

0.77

0.56

0.39

0.27

0.24

0.24

0.24

0.24

15° SKEW

0.73

0.53

0.37

0.25

0.24

0.24

0.24

15° SKEW

0.50

0.33

0.21

0.20

0.20

0.20

15° SKEW

1.05

0.78

0.57

0.40

0.29

0.24

0.24

0.24

0.24

30° SKEW

1.09

0.82

0.60

0.42

0.28

0.24

0.24

0.24

0.24

30° SKEW

0.78

0.57

0.40

0.27

0.24

0.24

0.24

30° SKEW

0.53

0.36

0.22

0.20

0.20

0.20

30° SKEW

1.10

0.83

0.60

0.42

0.29

0.24

0.24

0.24

0.24

45° SKEW

1.16

0.87

0.64

0.44

0.30

0.24

0.24

0.24

0.24

45° SKEW

0.83

0.60

0.42

0.28

0.24

0.24

0.24

45° SKEW

0.56

0.38

0.24

0.20

0.20

0.20

45° SKEW

INSIDE FACE

OUTSIDE FACEAh

OR BEVEL OPTIONAL

SMALL RADIUS

NOTE: H IS THE LARGEST VERTICAL DIMENSION OF THE SECTION.

PER CURTAIN WALL, MIN.

3" DIA. HOLES - TWO

11

10

10

As3 OR As4

PES 2-13-T3SECTION DETAILS

TYPE 3 END

Ah & As3 REINFORCEMENT

REINFORCING

LONGITUDINAL

TONGUE AND GROOVE JOINT DETAIL

REINFORCING

LONGITUDINAL

TONGUE

5

TOP OF WALL 4

INCH DEEP INTO

2"½ HOLES, 6

4

CURTAIN WALL DETAILS

SEE SECTION A-A FOR

4

(DETAIL SHOWN AT FLOOR; SIMILAR AT WALLS)

OUTSIDE REINFORCING (TYP.)

REINFORCING, BUT NOT PAST

MINIMUM OF 2" BEYOND INSIDE

HAUNCH BARS TO EXTEND A

WITH ƒ" TO 2" CHAMFER

OPTIONAL SQUARED CORNER

1'-0 MAXIMUM RADIUS (TYP)PERMISSIBLE LAP @ |) 12

Ah (SEE TABLE,

REFER TO FABRIC LAYER DETAIL ON SHEET PRCB G2-13 FOR MULTIPLE WWR LAYERS.

REFER TO SHEET PRCB G1-13 FOR ADDITIONAL NOTES.

INCHES.

COVER OVER THE REINFORCING SHALL NOT BE LESS THAN 1.5 INCHES OR GREATER THAN 2.0

REINFORCING (WWR) MEETING THE REQUIREMENTS OF AASHTO LRFD SECTION 5. THE CONCRETE

REINFORCING FOR PRECAST END SECTIONS AND CURTAIN WALLS SHALL BE WELDED WIRE

NOTES, AS SHOWN BELOW:

PRECAST BOX CULVERT END SECTIONS SHALL BE CONSTRUCTED IN ACCORDANCE WITH DETAILS AND

12

11

10

9

8

7

6

5

4

3

2

1

EN

GLIS

HSI

GN

ED

PR

EC

AS

TC

UL

VE

RT

S.D

GN - P

ES 2-13-

T3 -

THIS

SH

EE

T IS

SU

ED 01-13.

34'-1

30'-11

27'-10

24'-9

21'-8

18'-6

15'-5

12'-4

9'-3

6'-1

37'-8

34'-2

30'-9

27'-3

23'-9

20'-4

16'-10

13'-5

9'-11

6'-6

46'-1

41'-10

37'-7

33'-4

29'-1

24'-11

20'-8

16'-5

12'-2

7'-11

12

11

10

9

8

7

6

5

4

3

As4 = 0.20 IN¢/FT

OF THE SECTION. FOR ALL OTHER SECTIONS,

H IS THE LARGEST VERTICAL DIMENSION

FIRST SECTION ADJACENT TO THE BARREL ONLY.

As4 IS INSIDE FACE WALL STEEL FOR THE

NOTE:

@ 1'-0 SPA.

#3 BARS

1'-0 LONG

#4 DOWELS

DETAIL "A"

DETAIL "B"

SHOWN 8

JOINT "OPTION B"

SEE DETAIL "B"DETAIL "A" ABOVE 7

SHOWN, SEE

JOINT "OPTION A"

SHOWN 7

JOINT "OPTION A"

SHOWN 7

JOINT "OPTION A"

SHOWN 8

JOINT "OPTION B"

RE

VIS

ED 05-13 -

AD

DE

D

TH

E 3'

RIS

E

TO

TH

E

LE

NG

TH

L I

NF

OR

MA

TI

ON

TA

BL

E.

07-2016

| BARRELS

BRIDGE DESIGN SPECIFICATIONS.

LAP SPLICES SHALL BE CLASS C AND SHALL BE DESIGNED ACCORDING TO THE AASHTO LRFD

USE TONGUE ON INLET END SECTION AND GROOVE ON OUTLET END SECTION.

ALL FACES OF THE END SECTION, EXCEPT IN THE TONGUE AND GROOVE AREA.

MINIMUM LONGITUDINAL REINFORCEMENT SHALL BE 0.06 SQ. INCHES PER PERIPHERAL FOOT ON

FOR THE FIRST SECTION ADJACENT TO THE BARREL, SEE As4 TABLE

JOINT "OPTION B": PROVIDE JOINT IN WALLS, FLOOR AND HAUNCH.

DETAIL "A" ON THIS SHEET.

JOINT "OPTION A": PROVIDE JOINT IN WALLS AND FLOOR. TERMINATE JOINT AT HAUNCH. SEE

END OF WALL MAY BE CUT SQUARE AS SHOWN OR FOLLOW THE SKEW.

THICKNESS OF FLOOR, Tb = 8 IN. FOR 6' SPAN AND Tb = 10 IN. FOR ALL OTHER SPANS.

AIR ENTRAINED PORTLAND CEMENT. GROUT MIX SHALL HAVE A MAXIMUM SLUMP OF 4 INCHES.

FILL HOLES WITH GROUT. GROUT SHALL CONSIST OF 1 PART CEMENT AND 2 PARTS SAND. USE

37°30' UP TO 45°, USE A 45° SKEW END SECTION.

ANGLES OVER 22°30' UP TO 37°30', USE A 30° SKEW END SECTION. FOR SKEW ANGLES OVER

FOR SKEW ANGLES OVER 7°30' UP TO 22°30', USE A 15° SKEW END SECTION. FOR SKEW

CULVERT TIES ARE TO BE 1 INCH DIA. RODS.

8„" @ 15° ; 10†" @ 30° ; 1'-2 @ 45°

RE

VIS

ED 07-2016 -

CO

RR

EC

TE

D

TY

PO

S. A

DD

ED

DI

M. "G" A

LO

NG

CE

NT

ER

LI

NE

OF

SK

EW

ED

LI

NT

LE

BE

AM.

LA

TE

ST

RE

VISI

ON

DA

TE

AP

PR

OV

ED

BY

BRI

DG

E

EN

GI

NE

ER

Highway Division

STANDARD DESIGN

CONCRETE BOX CULVERTS

SINGLE PRECAST REINFORCED

JANUARY, 2013

6/28/2016 12:49:57 PM bkloss W:\Highway\Bridge\MethodsSection\CADD Concept Drafts\EnglishSignedPrecastCulverts.dgn PES 3-13-T3 11x17_pdf.pltcfg

ELSEWHERE IN PLANS

N - SHOWN

6 1'-03"½ HOLES

8

1'-0

1'-0

3" C

L.

S

+ 1'-

4

CL.

2

CL.

2

A1 B

OT

TO

M - S

EE

LI

NT

EL

5

TO

P-0.2

0 I

N¢/

FT

4 (T

YP.)

2'-6

2'-10

2

4

69

1'-

0

2•

4

2•

69

1'-

0

7

8

1'-

5

6 6

6

1'-

5

1'-0

1'-5 33

2'-6

(TY

P.)

4

S

+ 1'-

4

1•

1•

55

36

91'-

0

7

1'-0

2•

4

33

6

A2 BOTTOM REINFORCEMENT

SEE LINTEL BEAM REINF. TABLE

2"

CL.

2"

CL.

1'-0

A2 BOTTOM REINF.

SEE TABLE

4

3•

7

CL.

2"

7 1'-5

1'-0 1'-0 6

CL.

2"

CL.

2"

20.20 IN¢/FT

TOP REINFORCEMENT

25 TOP-0.20 IN¢/FT

A2 BOTTOM - SEE

2

SE

E

LI

NT

EL

BM.

REI

NF.

TA

BL

E-

A1 B

OT

TO

M

4b1

&

#4

BA

RS

@ 1'-

6

MA

X.

TO

P

#4 BARS

TABLE)

G (SEE

4b1 ALTERNATE 4b1(2 REQUIRED)

(TONGUE OPTION SHOWN)

SECTION A-A

PLAN OF SQUARE LINTEL BEAM

TOP BARS

0° SKEW LINTEL BEAM(FOR SKEWS UP TO 7°30')

BOTTOM REINFORCEMENT

A1 (IN¢/FT)

SECTION B-B

A1 A2

45° SKEW15° SKEW 30° SKEWREBAR OPTION

A2 (IN¢/FT)

NOTES:

REINFORCEMENT TABLE

LINTEL BEAM

PLAN VIEW

15° & 30° SKEWS

45° SKEWS

SKEWED LINTEL BEAM

(TONGUE OPTION SHOWN)

D=3

D=3

D=3

SECTION C-C

NOTE: ALL DIMENSIONS ARE OUT TO OUT. D = PIN DIAMETER.

BENT BAR DETAILS

FOR SKEWS 0° TO 45°

5

4

3

2

1B B

CC

LINTEL BM. TABLE

BE

AM

TA

BL

E

(FOR SKEWS OF 7°30' TO 45°)

A A

@ 1'-0 MAX.

4b1-SPACED

3"½ HOLES

PARAPET

CENTER ON

3

2

12 x 12 PARAPET

4b1

CONST. JOINT

PERMISSIBLE

2

3

SHOWN

OPTION

TONGUE

11

4

0.20 IN¢/FT4" BEVEL

4" BEVEL

12 x 12 PARAPET

4b1

CONST. JOINT

PERMISSIBLE

3

4

1

12 x 12 PARAPET

4b1

CONST. JOINT

PERMISSIBLE

3

4" BEVEL

1

THE ENGINEER

AS DIRECTED BY

CLEAR HOLES

BEND BARS TO

3

1

WWR OPTION

BOTTOM REINFORCEMENT

A1 (IN¢/FT) A1 A2

REBAR OPTION

A2 (IN¢/FT)

REINFORCEMENT TABLE

LINTEL BEAM

WWR OPTION

(TONGUE OPTION SHOWN)

0.20 IN¢/FT

(FT)

S

SPAN

(FT)

S

SPAN

S`(FT)

SPAN

12

10

8

6

0.25

0.20

0.16

0.13

0.49

0.40

0.32

0.26

#5 @ 12

#4 @ 12

#4 @ 12

#4 @ 12

4 - #5 @ 8

3 - #5 @ 12

4 - #4 @ 8

3 - #4 @ 12

12

10

8

6

#8 @ 12

#7 @ 12

#6 @ 12

#5 @ 12

#8 @ 6

#7 @ 6

#6 @ 6

#5 @ 6

12

10

8

6

2 - #7

2 - #7

2 - #6

3 - #4

2 - #8

2 - #7

2 - #6

2 - #5

3 - #8

3 - #7

2 - #7

2 - #6

REINFORCEMENT`TABLE

SKEWED PARAPET

FOR PRIMARY STEEL AND 8 INCHES FOR DISTRIBUTION STEEL.

ASTM A615 (60 KSI). WIRE SPACING FOR WWR SHALL NOT EXCEED 2 INCHES

LRFD SECTION 5 OR REINFORCING BARS MEETING THE REQUIREMENTS OF

WELDED WIRE REINFORCING (WWR) MEETING THE REQUIREMENTS OF AASHTO

REINFORCING FOR PRECAST LINTELS AND PARAPETS SHALL BE EITHER

MODIFIED BELOW:

PRECAST BARREL AND END SECTION DETAILS AND NOTES, EXCEPT AS

PRECAST LINTEL BEAMS SHALL BE CONSTRUCTED IN ACCORDANCE WITH

PES 3-13-T3BEAM DETAILS

TYPE 3 LINTEL0.65

0.49

0.36

0.25

1.30

0.98

0.72

0.50

EN

GLIS

HSI

GN

ED

PR

EC

AS

TC

UL

VE

RT

S.D

GN - P

ES 3-13-

T3 -

THIS

SH

EE

T IS

SU

ED 01-13.

#4

#4

BA

R

2 - #4 BARS

#4 BAR

#4 BARS

#4 BARS

BARS

#4

BARS

#4

#4 BAR

#4 BARS

BARS

#4

#4 BAR

MAX. OF 11 INCH SPACING SHOULD BE USED.

AREAS SHOWN ARE FOR WELDED WIRE FABRIC. IF REBAR IS USED, #4 AT A

SEE SKEWED PARAPET REINFORCEMENT TABLE.

USED. TONGUE AND GROOVE TO TERMINATE AT CULVERT RADIUS.

CHECK THE LOCATION TO DETERMINE WHETHER A TONGUE OR A GROOVE IS

SPACING

CAST ADDITIONAL 3 INCH HOLES TO MAINTAIN A 4 FOOT MAXIMUM HOLE

WITH GROUT.

WALL SECTION AND 3 INCH DIA. HOLE IN THE LINTEL BEAM. FILL HOLES

PLACE #8 DOWEL, 1'-0 LONG INTO 2 INCH DIA. HOLE IN THE TOP OF THE

(PARAPET)

2 - #4 BARS

OF PARAPET

#4 BARS TOP

#4

BA

R

07-2016

LENGTH G

15° SKEW 30° SKEW 45° SKEW

2'-2Œ

1'-11…

1'-8‰

1'-4•

4'-0•

3'-5Œ

2'-10†

2'-3•

6'-8ˆ

5'-8ˆ

4'-8ˆ

3'-8ˆ

S`(FT)

SPAN

12

10

8

6

RE

VIS

ED 07-2016 -

CO

RR

EC

TE

D

TY

PO

S. A

DD

ED

DI

M. "G" A

LO

NG

CE

NT

ER

LI

NE

OF

SK

EW

ED

LI

NT

LE

BE

AM. A

DD

ED

TA

BL

E

FO

R

LE

NG

TH "G".

ALONG BARREL | OF SKEWED LINTLE BM.

LA

TE

ST

RE

VISI

ON

DA

TE

AP

PR

OV

ED

BY

BRI

DG

E

EN

GI

NE

ER

Highway Division

STANDARD DESIGN

CONCRETE BOX CULVERTS

SINGLE PRECAST REINFORCED

JANUARY, 2013

6/28/2016 12:49:58 PM bkloss W:\Highway\Bridge\MethodsSection\CADD Concept Drafts\EnglishSignedPrecastCulverts.dgn PES 4-13 11x17_pdf.pltcfg

MIN.

3'-0

MIN.

3'-0VARIES

3'-

6

MIN.

3'-0 VARIES

MIN.

3'-0

3'-

6

33

6

2•

| OF †" WIDE x 1" LONG

SLOT IN THE ANGLE

END OF APRON FLOOR

6

2•

| OF †" WIDE x 1" LONG

SLOT IN THE ANGLE

END OF APRON FLOOR

4

2•

| OF †" WIDE x 1" LONG

SLOT IN THE ANGLE

END OF APRON FLOOR

4

2•

| OF †" WIDE x 1" LONG

SLOT IN THE ANGLE

END OF APRON FLOOR

4 4 4

T/2

(T)

FL

OO

R

THIC

KN

ES

S

4

T/2

(T)

FL

OO

R

THIC

KN

ES

S

8 8 8 8

FL

OO

R

THIC

KN

ES

S

FL

OO

R

THIC

KN

ES

S

SP

A.

2

EQ.

WALL DETAILS

ALTERNATE CURTAIN

ALTERNATES 3 & 4 (GALVANIZED STEEL SHEETS)

STEEL SHEET PILING SHOWN ON NEW OR OLD CONSTRUCTIONSTEEL SHEET PILING SHOWN

ALTERNATE 2

DETAIL "B"

ALTERNATE 1

DETAIL "A"

ALTERNATE 4

DETAIL "D"

ON NEW CONSTRUCTION ONLY

ALTERNATE 3

DETAIL "C"

ELEVATIONELEVATION ELEVATION

ELEVATION

PLANPLAN

PLANPLAN

END VIEW ELEVATION

END VIEW ELEVATION

3

TOP OF APRON FLOOR

3

TOP OF APRON FLOOR

3

TOP OF APRON FLOOR

3

TOP OF APRON FLOOR

4

1

2

1

3

5

8

3

7

8

SHEET LAP

3

6

1

8

4

3

1

8

2

5 OR 7

WINGWALL

GROUNDLINE

SEE DETAIL "A" OR "B"

WINGWALL

GROUNDLINE

SEE DETAIL "C" OR "D"

1

6

PLACEMENT OF CULVERT APRON

PLACE DROPWALL PRIOR TO

L8x4xƒ

L6x4x†

L8x4xƒ

L8x4xƒ

L6x4x†

L6x4x†

L8x4xƒ L8x4xƒ L6x4x† L6x4x†

9 9 9 9

PES 4-13

3

2

1

4

8

7

6

5

NOTES:

9

ALTERNATES 1 & 2 (GALVANIZED STEEL SHEET PILING)

SEALANT, AND CRAFCO ROAD SAVER SILICONE.

PRODUCTS MEETING THESE CRITERIA ARE DOW 888, CSL 342 JOINT

MATERIAL SHALL BE NEUTRAL CURE AND NON-SAG SILICONE. THREE

CAULK JOINT BETWEEN TOP OF APRON FLOOR AND ANGLE. CAULKING

APPROVED BY THE ENGINEER.

FILL THE VOIDS AS SHOWN, WITH CONCRETE OR CONCRETE GROUT, AS

GALVANIZED STEEL SHEET PILING, SECTION PS 27.5 OR EQUAL.

…"½x0'-1 BOLT WITH NUT, TO LAP STEEL SHEETS.

INTERLOCKING TYPE A.

GALVANIZED CORRUGATED (12 GAUGE OR HEAVIER) STEEL SHEET PILING,

TO THE NEAREST VALLEY).

x0'-5 BOLTS WITH NUT AND LOCK WASHER (10" CENTER TO CENTER,

FASTEN THE STEEL SHEETS TO THE FRONT EDGE OF THE APRON WITH …"½

AND AN APPROVED ANCHORAGE (2'-0 SPACING).

FASTEN THE L8x4xƒ OR L6x4x† WITH …"½x0'-4 BOLTS, 1" O.D. WASHER

TO THE NEAREST VALLEY).

x0'-4 BOLTS AND APPROVED ANCHORAGES (10" CENTER TO CENTER,

FASTEN THE STEEL SHEETS TO THE FRONT EDGE OF THE APRON WITH …"½

SHEETS.

2•"x•" OR 2"x•" CORRUGATED (12 GAGE OR HEAVIER) GALVANIZED STEEL

ANGLES SHALL BE GALVANIZED.

ALL CURTAIN WALL MATERIAL, INCLUDING BOLTS, NUTS, WASHERS, AND

USE OF ALTERNATE CURTAIN WALLS SHALL BE APPROVED BY THE ENGINEER.

EN

GLIS

HSI

GN

ED

PR

EC

AS

TC

UL

VE

RT

S.D

GN - P

ES 4-13 -

THIS

SH

EE

T IS

SU

ED 01-13.

LA

TE

ST

RE

VISI

ON

DA

TE

AP

PR

OV

ED

BY

BRI

DG

E

EN

GI

NE

ER

Highway Division

STANDARD DESIGN

CONCRETE BOX CULVERTS

SINGLE PRECAST REINFORCED

JANUARY, 2013

6/28/2016 12:50:00 PM bkloss W:\Highway\Bridge\MethodsSection\CADD Concept Drafts\EnglishSignedPrecastCulverts.dgn PEP 1-13 11x17_pdf.pltcfg

TYP.

3'-0

3'-0

2'-

0

MI

N.

6

3'-

0

TY

P.

3'-

0

TY

P.

3'-0

TYP.

2'-

0

6

3'-0

2'-

0

PERP. TO | RDWY.

*

*

*

PLAN VIEW

ELEVATION VIEW

NON-SKEW END SECTIONS

PLAN VIEW

ELEVATION VIEW

SKEWED END SECTIONS

SECTION C-C

SECTION A-A

SECTION B-B

TYPICAL DETAILS

CONSTRUCTION NOTES:

C

C

B

B

A A

C

C

B

B

A

A

WITH 0° TO 45° SKEWED END SECTIONS

PROTECTION DETAILS

EMBANKMENT

CURTAIN WALL

CURTAIN WALL

CLASS E REVETMENT

CLASS E REVETMENT

PARAPET

FABRIC

ENGINEERING

TOP OF WALL

CURTAIN WALL

CLASS E REVETMENT

END SECTION

INSIDE FACE OF

FABRIC

ENGINEERING

SPECIFICATIONS.

IN ACCORDANCE WITH ARTICLE 4196.01, B, 3 OF THE STANDARD

THE ENGINEERING FABRIC SHALL MEET THE MATERIAL REQUIREMENTS

ARTICLE 2507.03 OF THE STANDARD SPECIFICATIONS.

CLASS E REVETMENT SHOULD BE USED AND PLACED ACCORDING TO

REVETMENT

CLASS E

REVETMENT

CLASS E

PEP 1-13

EN

GLIS

HSI

GN

ED

PR

EC

AS

TC

UL

VE

RT

S.D

GN - P

EP 1-13 -

THIS

SH

EE

T IS

SU

ED 01-13.

FABRIC

ENGINEERING

12-15

RE

VIS

ED 10-14 -

CH

AN

GE

D

TH

E

AR

EA

OF

TH

E

RE

VE

TM

EN

T

TO I

NC

LU

DE

TH

E

AR

EA I

N

FR

ON

T

OF

TH

E

AP

RO

N. C

HA

NG

ED

TH

E

DE

PT

H

OF

RE

VE

TM

EN

T

TO 2'-

0.

REVETMENT AND ENGINEERING FABRIC.

* = SEE CULVERT PLANS FOR LIMITS OF

REVETMENT AND ENGINEERING FABRIC.

* = SEE CULVERT PLANS FOR LIMITS OF

REVETMENT AND ENGINEERING FABRIC.

* = SEE CULVERT PLANS FOR LIMITS OF

RE

VIS

ED 12-15 -

AD

DE

D

NO

TE "S

EE

CU

LV

ER

T

PL

AN

S

FO

R

LI

MIT

S

OF

RE

VE

TM

EN

T

AN

D

EN

GI

NE

ERI

NG

FA

BRIC."

LA

TE

ST

RE

VISI

ON

DA

TE

AP

PR

OV

ED

BY

BRI

DG

E

EN

GI

NE

ER

Highway Division

STANDARD DESIGN

CONCRETE BOX CULVERTS

SINGLE PRECAST REINFORCED

JANUARY, 2013