PR15 - Realizing Profitability and Efficiencies in Your Operations by Leveraging Model Predictive...

-

Upload

rockwell-automation -

Category

Technology

-

view

122 -

download

6

Transcript of PR15 - Realizing Profitability and Efficiencies in Your Operations by Leveraging Model Predictive...

Copyright © 2015 Rockwell Automation, Inc. All Rights Reserved. Rockwell Automation TechED 2015 @ROKTechED #ROKTechED

PUBLIC INFORMATION

PR15 - Realizing Profitability and Efficiencies in Your Operations by Leveraging Model Predictive Control (MPC)

Copyright © 2015 Rockwell Automation, Inc. All Rights Reserved. Rockwell Automation TechED 2015 @ROKTechED #ROKTechED

Agenda

Where Can it be applied most profitably?

How Does Model Predictive Control Increase Efficiencies?

What is Model Predictive Control?

Copyright © 2015 Rockwell Automation, Inc. All Rights Reserved. Rockwell Automation TechED 2015 @ROKTechED #ROKTechED 3

Regulatory

Supervisory/Advanced

Optimizer

Superheater/Dehydro Unit Styrene Distillation

DCS Controllers DCS Controllers

Sensors

(Inputs) Sensors

(Inputs)

Actuators

(Outputs)

Actuators

(Outputs)

20

CVs

20

MVs

12

MVs

23

CVs

Operator Operator Plant Manager

Plant

I just had the

splitter lined-out

Steam/EB Ratio EB Feed

Bed Temperatures

Increase

styrene

production

Process Engineer

Conventional Control Architecture

Copyright © 2015 Rockwell Automation, Inc. All Rights Reserved. Rockwell Automation TechED 2015 @ROKTechED #ROKTechED 4

Superheater/Dehydro Unit Styrene Distillation

Sensors (Inputs)

Sensors (Inputs)

Actuators (Outputs)

Actuators (Outputs)

DCS Controllers DCS Controllers

Operator Operator

Steady-state Global Optimizer

North MPC

South MPC

D123 MPC

D567 MPC

Optimal

targets

Raw materials prices

Fuel price

Steam price

Production rate

Other constraints

Process

Engineer What’s wrong

with the

analyzer?

Something

wrong with

the level?

Plant

DCS

Performance

monitor

Optimizer

CV

SP CV

SP

MVs MVs MVs MVs CVs CVs CVs CVs

APC and Online Optimization Answer

Supervisory/Advanced

Copyright © 2015 Rockwell Automation, Inc. All Rights Reserved. Rockwell Automation TechED 2015 @ROKTechED #ROKTechED

MPC versus PID Control

Coordinate multiple interacting PIDs

Predictably manage external disturbances

Handle long or complex process dynamics

Maximize performance up to process limits

PID tuning is subjective and requires time and experience

We do this because it makes

processors money:

Higher production, yields,

efficiency and product quality

Copyright © 2015 Rockwell Automation, Inc. All Rights Reserved. Rockwell Automation TechED 2015 @ROKTechED #ROKTechED

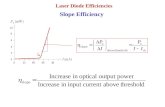

now

CV

MV

MV

1 Horizon

CVSP

MVSP

0

How a Receding Horizon works

7

measured

calculated (predicted)

calculated and sent out as MV

CV

Constraints

CV MV Process

Controller

Model

CV prediction MV prediction

MPC

Setpoints

1

0

2

1

0

2

1

2

)(

)()(

)()(

Horizon

k

MoveSupp

Horizon

k

SPCoef

Horizon

k

SPCoef

kMVMV

kMVkMVMV

kCVkCVCVJ

The Task: Minimize Error by calculating MVn over the Horizon

0

1 Horizon 0

Horizon 0 1

Copyright © 2015 Rockwell Automation, Inc. All Rights Reserved. Rockwell Automation TechED 2015 @ROKTechED #ROKTechED

MPC in Integrated Architecture

8

Production Center, FTHistorian, Pavilion® RTO …

Pavilion8® MPC, Software CEM®, VOA®, Asset Management, …

Rockwell Software Studio 5000®, PlantPAx™ MPCBuilder,

PlantPAx™ ModelBuilder

• PlantPAx® MPC

• IMC,CC,MMC

• FuzzyLogic

• SoftSensor® (AOI)

• PID,PIDE

• Motion

• Discrete

M P C

Copyright © 2015 Rockwell Automation, Inc. All Rights Reserved. Rockwell Automation TechED 2015 @ROKTechED #ROKTechED

Control Structure with MPC

Process

Soft Sensor® MPC

Lab

Pavilion8®

Server

Or Logix

PID PID PID PLC/DCS

Production Rate max

Higher Yields,

Lower energy

SP SP SP

Controlled Variables

Disturbance Variables

PV

Copyright © 2015 Rockwell Automation, Inc. All Rights Reserved. Rockwell Automation TechED 2015 @ROKTechED #ROKTechED

MPC Opportunities

Coating Oven

Distillation Column

Compressor

Chemical Reactor

Boiler

Furnace

Dryer

Drilling Rig

….

10

Copyright © 2015 Rockwell Automation, Inc. All Rights Reserved. Rockwell Automation TechED 2015 @ROKTechED #ROKTechED 11

MPC On MPC Off MPC On

100,000 Gal

Fermenter

Temperature

Control

Long or complex process dynamics

Copyright © 2015 Rockwell Automation, Inc. All Rights Reserved. Rockwell Automation TechED 2015 @ROKTechED #ROKTechED 12

Two Exchanger Passes FC132 FC133

Isomax Product

Fractionator T-1302

FC211 FC212 FC213 FC214

Heater Passes

Heater Passes FC382 FC383 FC384 FC385 FC386 FC387

FC 382

055 TI

052 TI

FC 211

FEED FROM iSOMAX REACTORS

051

FC 132

TI

30

TI 060

17

STRIPPING

H-1304

251 PC

254 TC

STEAM

FC378 FC379 FC380 FC381

305 FI

067 TI

37

FUEL GAS

257T FC

31

25

270 TC 24

H-1303

21

TI 069

12

PV 230

054 TI

Debutanizer T-1301

5

1

226 FC

053 TI

PC 230

FC 225

TC 396

9

1

435 FI

FC 310

269 TC

313 PC

FUEL GAS

Diesel Stripper

T-1303 079

LC 276

FC280 FC281 319

H-1305

FC 280 Heater

Passes

290 TC TI

FC

TI 070

FC 272

Kerosene Stripper

T-1304

TI 081

FC 301

PC 260

FRACTIONATOR BOTTOMS

DIESEL TO STORAGE

KEROSENE TO STORAGE

FC 308

475

HEAVY STRAIGHT RUN TO TANK 217

FC

FC 336

292 FC

Naphtha Splitter T-1305 TI

25

085

083 TI

1

338 TI

FUEL GAS

PV 313B

TC 325

PV 313A

FC 323

HEAVY STRAIGHT RUN TO PLATFORMER

FC 332

LIGHT STRAIGHT RUN TO BLENDING

FI 351

TO FLARE

LIGHT ENDS RECOVERY

LIGHT ENDS RECOVERY

LIGHT ENDS RECOVERY

Isomax Unit

Fractionation

Direct Quality Control with Soft Sensors

Copyright © 2015 Rockwell Automation, Inc. All Rights Reserved. Rockwell Automation TechED 2015 @ROKTechED #ROKTechED Copyright © 2011 Rockwell Automation, Inc. All rights reserved. 13

Diesel 95% Boiling Point Soft Sensor

Copyright © 2015 Rockwell Automation, Inc. All Rights Reserved. Rockwell Automation TechED 2015 @ROKTechED #ROKTechED Copyright © 2011 Rockwell Automation, Inc. All rights reserved. 14

Light Naphtha RVP Soft Sensor

Copyright © 2015 Rockwell Automation, Inc. All Rights Reserved. Rockwell Automation TechED 2015 @ROKTechED #ROKTechED

Distillation Column MPC Stability

Reduce Product Variability by 85%

EB - Before EB - After

15

Copyright © 2015 Rockwell Automation, Inc. All Rights Reserved. Rockwell Automation TechED 2015 @ROKTechED #ROKTechED

Reactor MPC Temperature Stability

Reduce Temperature Variability by 84% - 94%

RXC - Before RXC - After

16

Copyright © 2015 Rockwell Automation, Inc. All Rights Reserved. Rockwell Automation TechED 2015 @ROKTechED #ROKTechED 17

MPC for a Closed Circuit Cement Mill

Fineness (CV)

Fresh Feed (MV)

Reject Flow

(CCV)

Mill Level (CCV)

Water Injection (DV)

Damper

(MV) & (DV)

Motor Power (CCV)

Separator Speed (MV)

Elevator Power (CCV)

MV – Manipulated Variable

CV – Controlled Variable

CCV – Constraint Variable

DV – Disturbance Variable

Charge Wear Rate

(DV)

Feed Hardness

Grinding

Additives (DV)

Feed

Temperature

Mill Pressure

(CCV)

45um Residue (CV)

Product

Pump (CCV)

Mill Fan

(MV)

Copyright © 2015 Rockwell Automation, Inc. All Rights Reserved. Rockwell Automation TechED 2015 @ROKTechED #ROKTechED

Reduce Energy, Increase Capacity

18

Copyright © 2015 Rockwell Automation, Inc. All Rights Reserved. Rockwell Automation TechED 2015 @ROKTechED #ROKTechED

19

Dryer Line Optimization

MV – Manipulated Variable

CV – Controlled Variable

CCV – Constraint Variable

DV – Disturbance Variable

Evap Feed

TVR Steam (MV)

HPP Speed(MV)

Air Temp (MV)

Air Temp (MV)

Air Humidity (DV)

Moisture

Powder Rate (CV)

Exhaust Temp

Exhaust RH

(Sticky Point) (CCV)

Nozzle Pressure (CCV)

Damper Position (CCV)

Copyright © 2015 Rockwell Automation, Inc. All Rights Reserved. Rockwell Automation TechED 2015 @ROKTechED #ROKTechED

20

Dairy Spray Drying > 30 Installations

3.46 3.05 4.05

8.1

5.2

4.1

0

2

4

6

8

10

Rate Moisture Err x 100

D2 CV Means Typical Benefits

Improved capacity utilization

8% increase in throughput

16% increase in RH

40-60% reduction in moisture variability and

equivalent yield

Reduced variability

40-60% in outlet temp

40-50% in solids rate

30% in RH

50% in moisture

ROI Consistently greater than 60%