Ppk pp pc ingles

-

Upload

fer-echavarria -

Category

Business

-

view

1.081 -

download

1

description

Transcript of Ppk pp pc ingles

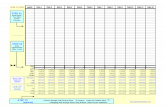

Process capability CPprocess capability compares the output of an in-control process to the specification limits by using capability indices. The comparison is made by forming the ratio of the spread between the process specifications (the specification "width") to the spread of the process values, as measured by 6 process standard deviation units (the process "width").

Process Capability Indices

We are often required to compare the output of a stable process with the process specifications and make a statement about how well the process meets specification. To do this we compare the natural variability of a stable process with the process specification limits.

A process where almost all the measurements fall inside the specification limits is a capable process.

What is cpk

nterpreting Cp, Cpk“Cpk is an index (a simple number) which

measures how close a process is running to its specification limits, relative to the natural variability of the process. The larger the index, the less likely it is that any item will be outside the specs.” Neil Polhemus

cpk measures how close you are to your target and how consistent you are to around your average performance

What is pp

n process improvement efforts, the process performance index is an estimate of the process capability of a process during its initial set-up, before it has been brought into a state of statistical control.[1]

Formally, if the upper and lower specifications of the process are USL and LSL, the estimated mean of the process is , and the estimated variability of the process (expressed as a standard deviation) is , then the process performance index is defined as:

is estimated using the sample standard deviation. Ppk may be negative if the process mean falls outside the specification limits (because the process is producing a large proportion of defective output). Some specifications may only be one sided (for example, strength). For specifications that only have a lower limit, ; for those that only have an upper limit, .

What is ppk

PPK is used for long term. When the Process Capability Index shows how a process will do in the future, the Process Performance Index shows how a process performed in the past. It can also be seen that the process will be in a state of control in CPK where as it is not like that in PPK.

PPK or Process Performance Index helps in verifying if the sample generated is capable to meet Customer CTQs.

When PPK stands for Process Performance Index, CPK stands for Process Capability Index.

Calculating the sigma quality level of the process

essential first step in "6 sigma" is to define clearly what the customer wants, needs explicit. We call these requirements "critical features of quality."The next step is to determine the probability of defects or failuresthat occur in relation to these characteristics.One way is through classical statistical methods, such as a 6 sigmaprocess will have a Cp = 2. That is, when it is centered, if one takesthe distance between the sample mean and the specification limits, this will 6 standard deviations (usually identified with the Greek lettersigma).