Powermag200909 2 Dl

-

Upload

orlando-barrios -

Category

Documents

-

view

28 -

download

4

Transcript of Powermag200909 2 Dl

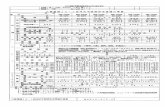

BUSINESS AND TECHNOLOGY FOR THE GLOBAL GENERATION INDUSTRYSeptember 2009 Vol. 153 No. 9Vol. 153No. 9September 2009 www.powermag.comTop Plants: Six Innovative Gas-Fired Plants10 Water Treatment Mistakes to AvoidGas Power Projects ThrivingCapturing Carbon: Options and Costs, Part ISpecial: Map of North AmericanGas-Fired PlantsCIRCLE 1 ON READER SERVICE CARDSeptember 2009 | POWER www.powermag.com1 Established 1882 Vol. 153 No. 9September 2009 www.powermag.comTKTKTKValve InventoryLarge (800) [email protected] THE COVERIn Italyfamous for Ferrari cars, Armani suits, and other symbols of sophisticated styleits no surprise that the Livorno Ferraris power plant building is an example of attractive, yet functional architectural design. Behind the sleek exterior is a brawny 800-MW combined-cycle plant. Courtesy: E.ONCOVER STORY:GAS-FIRED TOP PLANTS26Edward W. Clark Generating Station, Clark County, NevadaThis NV Energy plant has generated power since 1955, the year the Las Vegas Strip gotitsfirsthigh-rise,andhasgrownandevolvedwiththedesertdestination. The areas recent growth spurt and increasing renewable generation on the grid prompted the addition of peaking power capacity that promises to keep the lights hot and the rooms cool.30Goodman Energy Center, Hays, KansasWith 16% wind capacity, Midwest Energy blows away the competition among Kansas utilities. Both to back up that renewable generation and avoid the price penalty of pur-chasing peak power, this cooperative determined that the best way to face the future was with a gas-fired peaking plant. Nine Wrtsil engines give Midwest the ultimate in flexibility with next to no performance penalties.34Livorno Ferraris Power Plant, Vercelli Province, ItalyAnew800-MWSiemenscombined-cycleplant,thefirstplantbuiltbyanon-Italian operator, promises to keep Italys industrial north humming. Livorno Ferraris incorpo-rates not only the latest technologies for generation and environmental performance, but it also illustrates that Italians value design in all aspects of their culture. The facil-itys low visual impact and clean lines prove that power plants dont have to be purely utilitarian. 38Portlands Energy Centre, Ontario, CanadaYoud think a power project located at the edge of a major metropolitan area would take ages to build, but in this case youd be wrong. This 550-MW combined-cycle plant fed power to the grid less than two years after the EPC contract was signed. Of course, it helped that Portlands was developed on land with existing access to transmission andgaslines,demonstratingthatrecyclingworksforpowerplantsaswellasfor people.40Riverside Repowering Project, Minneapolis, MinnesotaXcel Energys Riverside Repowering Project is the last of three projects designed to significantly decrease power plant emissions in the Twin Cities area and lower costs for customers. Given the plants urban setting, a carefully orchestrated phased con-struction approach, reusing as much of the existing equipment and systems as pos-sible, and greater-than-usual utility involvement were the keys to success.46Royal Pride Holland Commercial Greenhouse Cogeneration Plant, Middenmeer, North Holland Province, NetherlandsOneoftheNetherlandslargestcommercialtomatogreenhousesisthesiteofthe worlds first installation of GE Energys new commercial 24-cylinder gas engine tech-nology from Jenbacher. The two 4-MW J624 units provide heat, power, and fertilizer from exhaust gas CO2.34CIRCLE 3 ON READER SERVICE CARDTKwww.powermag.comPOWER |September 2009 2INDUSTRY TRENDS50Map of Natural GasFired Generation in North AmericaSPECIAL REPORTCARBON CAPTURE TECHNOLOGIES52Combined-Cycle Carbon Capture: Options and Costs, Part IEuropeanregulatorsareconsideringthepossibilityofregulatingCO2emissions fromgas-firedplantsaswellascoal-firedones,andotherpartsoftheworldmay follow. But making CO2 capture choices in a nascent technology area is dangerous. A wiser approach is to consider accommodations available today that require little plant modification. Part I looks at the performance implications of the most promis-ing options.FEATURESFUELS56New Natural GasFired Projects on an UpswingIndustrialInfoResourcessummarizesthestatusofgas-firedpowerplantprojects that are in the pipeline and considers what the future may hold for gas-fired genera-tion in the U.S.INSTRUMENTATION & CONTROL59Pressure-Sensing Line Problems and SolutionsSensing lines in power plants may encounter a number of problems that can affect the accuracy and response time of the pressure-sensing system. Learn about a noise analysis technique for online detection of these problems that could make your job a little easier.HUMAN RESOURCES64Optimizing the Life-Cycle Cost of Human CapitalA Fluor executive director discusses an approach that can help power plants deter-mine which job functions are best handled by staff and which are best to outsource.DEPARTMENTS6SPEAKING OF POWERDead Mans HandGLOBAL MONITOR8Operation of Worlds First Supercritical CFB Steam Generator Begins in Poland10Report: Costs for First-Generation Carbon Capture Plants Will Soar12Nuclear Developments in Europe13Swiss Solar Plane Prototype Designed to Fly Day and Night13Scotland Officially Opens 100-MW Glendoe Hydro Plant15Biomass Electricity More Efficient than Ethanol, Researchers Say15DOE Funds Electrification of Transportation Sector15POWER DigestFOCUS ON O&M18Avoid These 10 Mistakes When Selecting Your New Water Treatment System20Accurate Online Silica Analyzers Ensure Boiler Performance, Add Boiler Life24LEGAL & REGULATORYSWEPCOs Construction Conundrum68NEW PRODUCTS76COMMENTARYTo Modernize the Grid, Think SmallerBy Kurt Yeager, executive director of the Galvin Electricity InitiativeVisit www.powermag.com/powerconnect to update or add your informationIf you have any questions or are interested in upgrading your listing, please contact Diane Hammes at [email protected] or at 713-343-1885ITS TIMEto renew or add yourcompanys listing in theMake the most of your listing and invest in upgrade options:Want to stand out from the other companies?DIncreased exposure year-round online and in the POWERmagazine December Buyers Guide issueDAdd your company logoDInclude additional categoriesDGain priority listing and jump to the top of selected categories5025 E. BUSINESS 20 ABILENE, TEXAS 79601 325.672.3400 [email protected] FOR PEOPLE WHO KNOW AND CARESourdough biscuits anchored chuck wagon meals, because biscuits keptthe cowboys fed and on the job. Just as biscuits kept things going on thefrontier, Rentech boilers can be depended upon today. Whatever trail yourcompany is riding, our boilers can fit. Your inspection of our engineeringand manufacturing facilities will show you why our boilers have earneda reputation for dependability from Dallas to Dubai. In a wide range ofapplications, our boilers improve efficiency, reduce shutdowns and addressenvironmental issues. Biscuits or boilers, reliability is paramount. Ours willleave a good taste in your mouth.Fired Package Boilers / Wasteheat Boilers / Heat Recovery Steam GeneratorsMaintenance & Service Strategies / Boiler Repair Services / SCR and CO SystemsSOURDOUGH BISCUITS WERE A STAPLE ON THE FRONTIER...Boilers & BISCUITS?www.rentechboilers.comCIRCLE 4 ON READER SERVICE CARDwww.powermag.comPOWER |September 2009 4Now incorporatingand EDITORIAL & PRODUCTIONEditor-in-Chief: Dr. Robert Peltier, PE480-820-7855, [email protected] Editor:Gail Reitenbach, PhDSenior Editor:Angela Neville, JDContributing Editors:Mark Axford;David Daniels;Bill Ellison, PE;Steven F. Greenwald; Tim Hurst; Jim Hylko; Kennedy Maize; Douglas Smith; Dick Storm; Dr. Justin ZacharySenior Writer:Sonal PatelSenior Designer:Leslie ClaireSenior Production Manager:Tracey Lilly, [email protected] Manager:Jamie ReesbyADVERTISING SALESNorth American OfficesSouthern & Eastern U.S./Eastern Canada/ Latin America:Matthew Grant, 713-343-1882, [email protected] & Western U.S./Western Canada:Dan Gentile, 512-918-8075, [email protected] OfficesUK/France/Benelux/Scandinavia:Peter Gilmore, +44 (0) 20 7834 5559, [email protected] Germany/Switzerland/Austria/Eastern Europe:Gerd Strasmann, +49 (0) 2191 931 497, [email protected]:Ferruccio Silvera, +39 (0) 2 284 6716, [email protected]/Portugal:Vibeke Gilland, +34 91 553 42 06, [email protected]:Katsuhiro Ishii, +81 3 5691 3335, [email protected]:Nartnittha Jirarayapong, +66 (0) 2 237-9471, +66 (0) 2 237 9478India:Faredoon B. Kuka, 91 22 5570 3081/82, [email protected] Korea:Peter Kwon, +82 2 416 2876, +82 2 2202 9351, [email protected]:Tony Tan, +60 3 706 4176, +60 3 706 4177, [email protected] AdvertisingDiane Hammes, 713-343-1885, [email protected] Buyers Guide SalesDiane Hammes, 713-343-1885, [email protected] DEVELOPMENTAudience Development Manager:Terry BestFulfillment Manager:George SeverineCUSTOMER SERVICEFor subscriber service:[email protected], 800-542-2823 or 847-763-9509Electronic and Paper Reprints:[email protected], 717-666-3052List Sales:Statlistics, Jen Felling, [email protected], 203-778-8700All Other Customer Service:713-343-1887BUSINESS OFFICE TradeFair Group Publications, 11000 Richmond Avenue, Suite 500, Houston, TX 77042Publisher:Brian K. Nessen, 713-343-1887, [email protected]:Sean GuerreACCESS INTELLIGENCE, LLC4 Choke Cherry Road, 2nd Floor, Rockville, MD 20850301-354-2000 www.accessintel.comChief Executive Officer:Donald A. PazourExec. Vice President & Chief Financial Officer:Ed PinedoExec. Vice President, Human Resources & Administration:Macy L. FectoDivisional President, Business Information Group:Heather FarleySenior Vice President, Corporate Audience Development:Sylvia SierraSenior Vice President & Chief Information Officer:Robert PaciorekVice President, Production & Manufacturing:Michael KrausVice President, Financial Planning & Internal Audit:Steve Barber BUSINESS AND TECHNOLOGY FOR THE GLOBAL GENERATION INDUSTRYVisit POWER on the web: www.powermag.comSubscribe online at: www.submag.com/sub/pwPOWER(ISSN0032-5929)ispublishedmonthlybyAccess Intelligence,LLC,4ChokeCherryRoad,SecondFloor, Rockville,MD20850.PeriodicalsPostagePaidatRockville, MD 20850-4024 and at additional mailing offices.POSTMASTER: Send address changes to POWER, P.O. Box 2182, Skokie, IL 60076. Email: [email protected] Post PM40063731. Return Undeliverable Canadian Addresses to: Station A, P.O. Box 54, Windsor, ONN9A 6J5.Subscriptions:Availableatnochargeonlyforqualified executivesandengineeringandsupervisorypersonnel inelectricutilities,independentgeneratingcompanies, consultingengineeringfirms,processindustries,andother manufacturingindustries.AllothersintheU.S.andU.S. possessions: $59 for one year, $99 for two years. In Canada: US$64 for one year, US$104 for two years. Outside U.S. and Canada: US$159 for one year, US$269 for two years (includes air mail delivery). Payment in full or credit card information is requiredtoprocessyourorder.Subscriptionrequestmust include subscriber name, title, and company name. For new or renewal orders, call 847-763-9509. Single copy price: $25. The publisher reserves the right to accept or reject any order. Allow four to twelve weeks for shipment of the first issue on subscriptions. Missing issues must be claimed within three months for the U.S. or within six months outside U.S.For customer service and address changes, call 847-763-9509orfax832-242-1971ore-mailpowermag@halldata.comorwritetoPOWER,P.O.Box2182,Skokie,IL60076. Please include account number, which appears above name on magazine mailing label or send entire label.PhotocopyPermission:Wherenecessary,permissionis grantedbythecopyrightownerforthoseregisteredwith the Copyright Clearance Center (CCC), 222 Rosewood Drive, Danvers,MA01923,978-750-8400,www.copyright.com, tophotocopyanyarticleherein,forcommercialuseforthe flatfeeof$2.50percopyofeacharticle,orforclassroom usefortheflatfeeof$1.00percopyofeacharticle.Send paymenttotheCCC.Copyingforotherthanpersonalor internalreferenceusewithouttheexpresspermissionof TradeFairGroupPublicationsisprohibited.Requestsfor special permission or bulk orders should be addressed to the publisher at 11000 Richmond Avenue, Suite 500, Houston, TX 77042. ISSN 0032-5929.Executive Offices of TradeFair Group Publications: 11000 Richmond Avenue, Suite 500, Houston, TX 77042. Copyright 2009 by TradeFair Group Publications. All rights reserved.www.rolls-royce.comStaying ahead of the pack.ReliableandaffordableperformanceputstheRolls-Royce Trent60attheheadofthepackwhenitcomestodeliveringindustrial power. With its class-leading 64MW output in powergeneration or mechanical drive applications, the Trent 60 is themostefficientandpowerfulaeroderivativegasturbineintheworld. And, builtupontheextensivelineageandglobalgasturbineexperienceofRolls-Royce, itcomescompletewithunparalleledcustomerservices. Forhighreliability, coupledwithindustry-leadingvalueandperformance, theTrent60isclearly at the head of the pack. Trusted to deliver excellenceCIRCLE 5 ON READER SERVICE CARDwww.powermag.comPOWER |September 2009 6SPEAKING OF POWERDead Mans HandThestageisbeingsetfornegotiatingasuccessoragree-menttotheKyotoProtocol.TheU.S.istryingtoexert some leadership in the international climate change debate byattemptingtobuildconsensusforbindingcarbonemission reductionspriortotheupcomingCopenhagenmeeting.Mean-while,carbonlegislationis,thankfully,stalledintheSenate, and developing countries are rejecting our entreaties. You cant win if other countries dont want to play.Trouble Begins at HomeTheCopenhagenmeetingscheduledforearlyDecemberbegins the formal negotiations of a follow-on agreement to the Kyoto Protocol,theinternationalagreementdedicatedtoreducing anthropogenicgreenhousegas(GHG)emissions.Developing nations, such as China and India, were not included in any nu-merical emissions limitations in the original Kyoto agreement.The Obama administration has signaled that it supports devel-oping a successor agreement to the Kyoto Protocol but will sign a new agreement only if China commits to making significant, robust reductions of carbon dioxide. However, President Barack Obama can strut his moral authority for demanding international reductions in carbon emissions at Copenhagen only if the Senate passes and he signs the bloated Waxman-Markey American Clean Energy and Security Act of 2009 (ACES) or some variant.However, ACES is a bad hand for one specific reason: It prom-isestoachieveonlytheslightestreductioninglobalambient temperatures0.05C to 0.2C through 2050, depending on which source you believeat the cost of trillions of dollar to the U.S. economy.JohnMcCain,coauthoroftheLieberman-McCainCli-mate Stewardship and Innovation Act that failed a 2007 Senate vote, is quoted in the August 1 issue of The Wall Street Journal as saying, [The Waxman-Markey] 1,400-page bill is a farce. They bought every industry offsteel mills, agriculture, utilities.I would not only not vote for it, he continued, I am op-posed to it entirely because it does damage to those of us who believe that we need to act in a rational fashion about climate change.EvenclimatescientistJamesHansenstatesinaneditorial published by Columbia University on July 13 titled Strategies to Address Global Warming that The truth is, the climate course set by Waxman-Markey is a disaster course. It is an exceedingly inefficient way to get a small reduction of emissions. It is less than worthless.India Points to Crisis of Credibility China and India do not get a pass in the upcoming negotiations as they did with Kyoto. U.S. carbon emissions have stabilized, yet the Center for Global Development estimates that China sur-passed the U.S. in carbon emissions from power generation fa-cilities in August 2008, and that country now emits a fifth of the worlds carbon. India, in third place behind the U.S., is rapidly closing the gap.There are widely disparate views about which countries should share the economic pain that would follow from the binding re-ductions in carbon emissions sought in Copenhagen. The July 20 WashingtonPostreportedonSecretaryofStateHillaryClintons three-day tour of India, during which she tried to arm-twist Indian Environment Minister Jairam Ramesh into agreeing to a binding limit on carbon emissions. First to speak to the reporters was Clin-ton during the post-meeting photo op. She described the meet-ings as very fruitful and so on. Next, as dozens of cameras rolled andClintonlookedon,Rameshplayedhistrumpcard:Indias position, let me be clear, is that we are simply not in the position to take legally binding emissions targets. Ramesh characterized hisstatementasIndiasofficialpositiononthesubjectandas not a debating strategy. China Says, You Buy, You PayChinaspositiononcappingcarbonemissionsissimilartoIn-dias, with a slight twist. China released a position paper on May 20 that describes its views on any future climate change agree-ment. The paper called on the richest countries in the world to reduce GHGs by 40% below 1990 by 2020, give up to 1% of their GDP to help poorer countries implement climate change mitiga-tion measures, and announced their opposition to any binding limits on its emissions. The paper also adds a new twist to the discussion: Countries that buy goods from China should be held responsible for the carbon dioxide emitted by the factories that make them. Rock and a Hard PlaceSowheredoesthatleavetheU.S.goingintotheCopenhagen negotiations?Ifthenegotiationswerepoker,thentheU.S.is all-in, and China and India are calling our bluff. It looks to me as if were likely to draw a pair of eights to go with ACES. Dr. Robert Peltier, PE, Editor-in-ChiefAtAmericanSocietyofBusinessPublicationEditorsbanquets inWashington,D.C.,inmid-July,POWERwonthefollowing awards:Managing Editor Gail Reitenbach and Senior Designer Leslie Claire won a national bronze for the July 2008 Table of Contents.Senior Writer Sonal Patel won the gold for feature stories in the Southeast Regional division for Whistling in the dark: Inside South Africas power crisis (Nov. 2008).Managing Editor Gail Reitenbach won the silver for feature sto-ries in the Southeast Regional division for Workforce manage-ment lessons from women in power generation (Nov. 2008).POWER Wins ASBPE AwardsGE EnergyI promise David Chapin, Lead Product Manager, Filtration TechnologiesBoiler cleaning outages whether planned or not are costly and disruptive. Now you can do something about it. The Powerwave+ impulse cleaning system helps reduce your annual outage time by keeping your boiler operating longer and more efciently. Which means you spend less time in scheduled outages, and maybe even eliminate unplanned outages due to buildup or tube leaks. And thats not just a promise. Its the promise of something better. Find out how Powerwave+ technology is already hard at work for your peers at ge-energy.com/powerwave.CIRCLE 6 ON READER SERVICE CARDwww.powermag.comPOWER |September 2009 8GLOBAL MONITORGLOBALMONI TORGLOBALMONI TORGLOBALMONI TORGLOBALMONI TORGLOBALMONI TORGLOBALMONI TORGLOBALMONI TORGLOBALMONI TORGLOBALMONI TORGLOBALMONI TORGLOBALMONI TORGLOBALMONI TORGLOBALMONI TORGLOBALMONI TORGLOBALMONI TORGLOBALMONI TORGLOBALMONI TORGLOBALMONI TORGLOBALMONI TORGLOBALMONI TOROperation of Worlds First Supercritical CFB Steam Generator Begins in PolandTheworldsfirstsupercriticalcirculating fluidized-bed(CFB)steamgeneratorbe-gansuccessfuloperationattheLagisza powerplantinPolandearlythisJuly, accordingtopowerequipmentanden-gineeringfirmFosterWheeler.Thenew CFBbelieved to be the worlds largestreplaced1960s-erapulverizedcoalunits at the power plant owned by Polish util-ityPoludniowyKoncernEnergetycznySA (PKE) (Figure 1). Foster Wheeler provided turnkey supply of the boiler island, including engineering and design, erection, civil work, start-up, andcommissioning.Manyexistingplant systems, including those for coal handling andwatertreatment,wererenovatedfor use with the new 460-MW CFB unit. The unit incorporates a number of ad-vanced design features, such as compact solidseparators,INTREXsuperheaters, andlow-temperaturefluegasheatre-coverythatcapturesvaluableheatthat wouldotherwisebelost.Italsoem-ploysfor the first time ever in a CFBBensonvertical-tubesupercriticalsteam technology. Specifically,inrelationtotheolder, de-commissionedboilers,thenewCFB burns less fuel and produces significantly lowerlevelsofcarbondioxideandother emissions for each megawatt generated, said Pertti Kinnunen, executive vice presi-dentofengineeringandtechnologyfor the Finnish subsidiary of Foster Wheelers GlobalPowerGroup.Kinnunenissaidto have been responsible for conceptual de-sign of the boiler in 2003. CFBtechnologyisacleaner-coalplat-form with a unique low-temperature com-bustion process that efficiently burns both traditional fuels and carbon-neutral fuels. Unlike conventional steam generators that burn the fuel in a large, high-temperature flame, CFB technology does not have burn-ers or a flame within its furnace. Instead, it uses fluidization technology to mix and circulatefuelparticleswithlimestoneas they burn in a lower-temperature combus-tionprocess.Thelimestonecapturesthe sulfuroxidesastheyareformed,while the lower burning temperature minimizes the formation of thermal-nitrogen oxides. Thefuelandlimestoneparticlesarere-cycled over and over back to the process, which results in high efficiency for burn-ing the fuel by extending the combustion residencetime,capturingpollutants,and transferringthefuelsheatenergyinto high-quality steam to produce power.Successful operation of the first large-scale supercritical CFB marks a milestone in the technologys history. The first com-mercial CFB was built by Foster Wheeler in 1979. The 5-MW boiler supplied to Suomen Kuitulevy in Pihlava, Finland, burned wood residues and peat. It was soon followed by a20-MWplantinKauttua,Finland.Over the years, CFB technology matured and its useexpanded.In2002,thefirst-genera-tiontechnologyreachedpeaksize,with twonominal300-MWboilersbeingin-stalledatJacksonvilleEnergyAuthoritys NorthsideGeneratingStationinFlorida, POWERs 2002 Plant of the Year. Thefluidizedcombustiontechnology optionscontinuetoevolve.Accordingto theU.S.DepartmentofEnergy,amajor efficiency-enhancing measure for second-generation pressurized fluidized bed com-bustors is the integration of a coal gasifier (carbonizer)toproduceafuelgas.This fuelgasiscombustedinatoppingcom-bustorandaddstothecombustorsflue gas energy entering the gas turbine, which is the more efficient portion of the com-bined cycle. The topping combustor must exhibit flame stability in combusting low-Btu gas and have low-NOx emission char-acteristics. To take maximum advantage of theincreasinglyefficientcommercialgas turbines, the high-energy gas leaving the 1.Polish power. The worlds first supercritical circulating fluidized-bed (CFB) steam gen-erator began operating this July at Poludniowy Koncern Energetycznys Lagisza power plant in Poland. The project marks a milestone in the technologys history. Courtesy: Foster WheelerSubscribe now to get your free subscription to the electronicnewsletter from POWER magazine.Just visit our web site www.powermag.comto subscribe.delivers headline news for powergenerators weeklyStart your freesubscription today!WANT POWER INDUSTRY NEWS MORE OFTEN?Chemical and Phamaceutical GroupSolvay Chemicals, Inc.1.800.SOLVAY C (800.765.8292)www.solvair.usCopyright 2009, Solvay Chemicals, Inc. All Rights ReservedPRODUCTSFrom the earth to the skyTrona is the natural way to clean the air. SOLVAir Select 200 trona is a naturally occurring mineral mined in Green River, Wyoming by Solvay Chemicals, Inc. When used to treat acid pollutants occurring in fue gases, this underground mineral helps clean the air. Utilizing simple chemistry, Select 200 efciently and cost-efectively removes a variety of acid gases such as SO2, SO3 or HCl. Used in a low capital cost injection system, Select 200 has shown the ability to remove over 90% of the acid gases present. Power plants, both large and small, have turned to the SOLVAir Group and its line of products to fght for cleaner air. For more detailed information on SOLVAir Select 200 trona and how it cleans acid gas in the stacks, go to www.solvair.us, or e-mail [email protected] 7 ON READER SERVICE CARDwww.powermag.comPOWER |September 2009 10GLOBAL MONITORtopping combustor must be nearly free of particulatematterandalkali/sulfurcon-tent.Also,releasestotheenvironment fromthepressurizedfluidbedcombus-tionsystemmustbeessentiallyfreeof mercury, an air pollutant for which federal regulations are in limbo. CFB research and developmentalsofocusonreductionsof bothcostandcarbondioxideemissions, so new sorbents are being evaluated. Sor-bent utilization has a major influence on operating costs, and carbon dioxide emis-sions streams can be used in the produc-tion of alkali-based sorbents. EffortsareongoingatthePowerSys-temsDevelopmentFacility(PSDF)in Wilsonville,Ala.,toensurethatcritical components and subsystems are ready for thedemonstrationofsecond-generation pressurized fluidized bed combustion. The PSDFisoperatedbySouthernCompany ServicesunderaDepartmentofEnergy contracttoconductcooperativeresearch and development with the industry.Report: Costs for First-Generation Carbon Capture Plants Will SoarCarboncaptureandstorage(CCS)has oflategainedsteamasthebestwayto mitigateemissionsofthegreenhouse gascarbondioxide(CO2)fromfossilfuel powerplants,despiteevidencethatthe approach would require much energy and increasethefuelneedsofacoal-fired plant by more than 25%. A new study from Harvard Universitys Belfer Center for Sci-ence and International Affairs now asserts thatlevelizedcostsforaprecombustion captureplantwithCO2compressionex-cluding costs of transport and storage and anyrevenuefromenhancedoilrecovery (EOR)aregoingtobemuchmorethan most people realize.TheJuly3report,RealisticCostsof Carbon Capture, finds that electricity pro-duced by the first coal power plants built toemployprecombustioncaptureand compressiontechnologycouldcostabout 10/kWh more with capture than conven-tional plants (which the report said ranged from 8 to 12/kWh). Costs of abatement werefoundtobeabout$150permetric ton of carbon dioxide (tCO2), with a range of $120 to $180/tCO2 avoided. But as the technology matures, signifi-cant cost reductions are expected because ofincreasedscale,lessonslearned,and technologicalinnovationsforplantinte-gration. The additional cost of electricity withCO2 capturecouldreportedlyplunge to about 2 to 5/kWh, with costs in the range of $35 to $75/tCO2. All costs in the report were based on 2008 data, with costs of abatement calculated with reference to conventional supercritical pulverized coal plantsforbothemissionsandelectricity costs.Theaveragetotalcostofelectric-ity produced from coal plants in 2008 was 2.75/kWh, according to energy analytics firm Ventyx.Thecostpremiumforgeneratinglow carbonelectricitywithCCSarefoundto bebroadlysimilartothecostpremiums forgeneratinglowcarbonelectricityby other means, where midcase estimates for costpremiumsoverconventionalpower generationatpresentaremainlyinthe rangeofapproximately1025/kWh (exceptforonshorewindpoweratgood siteswherecostpremiumsarelower), the report says. These cost premiums are all expected to decline in [the] future as technologies continue to mature.Thisstudyslevelizedcostsforcarbon capture and compression are significantly higherthanthoseestimatedinprevious studies.AccordingtoaMay2009survey bytheU.S.nonprofitgroupInstituteof EnergyResearch,theEnergyInformation AdministrationsAnnualEnergyOutlook 2009 puts levelized costs for an advanced coal-firedpowerplantwithpostcombus-tion capture and storage entering service in2016at$122.60/MWh(or12/kWh). Thiscompareswith$103.50/MWhforan advanced coal plant of the same capacity factor, but without CCS (Figure 2).TheHarvardstudyisoneofseveral significant CCS cost studies to have been releasedrecentlyfromaroundtheworld. In November 2008, McKinsey & Co. found fromitsassessmentofinformationgath-ered from industrial CCS stakeholders that costsfromthefirstdemonstrationCCS projectsbuiltin2015couldrangebe-tween 60 per tCO2 avoided. That cost can bereducedto30to40tCO2by2030 becauseoflessonslearnedfromdemon-2.CCScostcontroversy.AJulystudyfromHarvardsBelferCenterestimatesthat electricity produced by the first coal plants to employ precombustion carbon capture and se-questration technology could cost 10/kWh more than estimates for conventional plants, which range between 8 and 12/kWh. A survey of levelized costs in the Energy Information Admin-istrations Annual Energy Outlook 2009 by nonprofit group Institute of Energy Research finds that electricity from an advanced coal plant with carbon capture and sequestration (CCS) using postcombustion capture and entering service in 2016 will cost 12/kWh. Levelized costs for an advanced coal plant without CCS at the same capacity factor are estimated at 10/kWh. Note: Capacity factors for each technology differ. Courtesy: Institute of Energy Research 2007 dollars per MWhNatural gas advancedcombined cycle (CC)Natural gasconventional CCConventional coalAdvanced coalAdvanced nuclearBiomassGeothermalHydroNatural gas advancedCC with CCSAdvanced coalwith CCSNatural gas advancedcombustion turbineNatural gas conventionalcombustion turbineWindOffshore windSolar thermalSolar PV450400350300250200150100500Transmission investment Variable O&M (including fuel) Fixed O&M Levelized capital costL I Q U I D L E V E L M E A S U R E M E N Tesigned for use in external chambers, the all-new Model 7xGCaged Guided Wave Radar Probe is a single rod probe thatcombines the unimpeded performance of a coaxial with theviscosity immunity of a single rod.Engineered exclusively for Eclipse level transmitters, the Model 7xGprobe is available in three different diameters to dimensionally match eitherexisting or new 2", 3", or 4" chambers. This creates a perfectly matchedimpedance along the entire length of the probe for error-free signals. Theprobe measures dielectric constants as low as 1.4 in temperatures of up to+400 F (+200 C) and provides the capability of an overfill probe with accu-rate measurement up to the full point of a chamber. Because of its matchedimpedance characteristics, the Model 7xG probe is also ideal for interfacelevel measurement.To learn more about the all-new Caged Guided Wave Radar probe, callus or visit magnetrol.com.D1-800-624-8765 magnetrol.com [email protected] the all-newEclipse Caged GWR probeThe worlds only Guided Wave Radar Single Rodto combine all these features in one probe:SIL 2Worldwide Level and Flow Solutionssm The viscosity immunity of a Single Rod probe The unimpeded performance of a Coaxial probe Measurement to the very top of the chamber Measurement of dielectric constants as low as 1.4 Accurate measurement of liquid interface levelCIRCLE 8 ON READER SERVICE CARDwww.powermag.comPOWER |September 2009 12GLOBAL MONITORstrationprojects,findsthestudy,CarbonCapture&Storage: Assessing the Economics. Other studiesparticularly from companies that are conduct-ing demonstration CCS projectsput costs even higher than the Harvard study. Earlier this year, as an example, StatoilHydro con-cluded in a master plan for a CCS demonstration at Mongstad in Norway that CCS cost could up to 200 per tCO2. Nuclear Developments in Europe Recent months brought several developments in Europes much-touted nuclear renaissance. Spain Extends Life of Nations Oldest ReactorSpainsgovernmentonJuly2grantedafour-yearextensionto the operating permit of the 466-MW Santa Mara de Garoa nu-clear power plant (Figure 3). The decision follows a nonbinding recommendation by Spains nuclear regulator in June to issue a 10-year operating permit extension for the 38-year-old plant that wasscheduledtobedecommissionedin2011onthecondi-tion that it is modernized. That would cost operating companies Iberdrola and Endesa an estimated 50 million, but it is an in-vestment they are willing to make. The plant is by far the oldest remaining nuclear plant in Spain. Lobbyists in the country have been pushing to extend the plants operating life, saying that Spain needs nuclear power to support the nations rapidly growing renewable energy portfolio. Environ-mentalists,meanwhile,havedemandedtheplantstotalshut-downbecausetheyclaimthereactorhassufferedfromsevere cracking, and that corrosion has affected various components in the reactor vessel. Spanish Prime Minister Jose Luis Rodriguez Zapatero defended thegovernmentsdecision,sayingthatSpainneedstheenergy and the Garoa area needs the economic activityeven though the plant produces only about 1% of the countrys electricity, has aging technology, and produces 50% more high-level waste than Spains other five nuclear plants. Nuclear power produces 20% of Spains electricity, but permits for running most of the other plants will also expire by 2011or within the mandate of Zapateros government. A decision to pro-longthelifeoftheGaroaplantontheEbroRiverisamajor reversal for Zapatero, who, during general elections in 2004 and 2008, pledged to gradually phase out nuclear power.German Nuclear Policy Depends on Upcoming ElectionNuclear power in Germany may see new life following the Sept. 27generalelection.Thecountrysgovernmentin2000,under ChancellorGerhardSchroeder,agreedtophaseoutallofthe countrys17reactorsby2021.Buttheloomingpowergapof around 21 GWnearly 25% of the countrys overall power pro-ductioncouldstrong-armChancellorAngelaMerkelsChristian DemocratsandtheLiberalpartytopostponetheclosures.The Social Democrats continue to push for the phase-out, however, in favor of renewable energy such as wind and solar power. TheelectioninSeptembercould,therefore,decidewhether or not the phase-out continues. Reports from the nations po-litical media say the race is too close to call but that opinion polls show Merkels Christian Democrats and Liberals are gaining public favor. Bulgaria Desperate for Investors to Save BeleneBulgarias center-right government said in late July that if it does not find private investors for its majority stake in the planned Belenenuclearpowerplant,itwillbeforcedtoabandonthe project.Owingtotightgloballiquidityandtherecession,the government said it cannot afford to take on loans to fund its 51% stake in the 2,000-MW plant. The previous Socialist-led administration wanted to build Be-lene the countrys second nuclear planton the Danube River to recover Bulgarias position as a major power exporter in the 3.A half life. Spains government in July granted a four-year exten-sion to the 466-MW Santa Mara de Garoa nuclear power plant, a 38-year-old plant that is by far the countrys oldest nuclear plant. Spains primeministersaidthecountryneedstheenergy,eventhoughthe plantproducesabout1%ofthenationselectricity.Courtesy:Foro NuclearCIRCLE 9 ON READER SERVICE CARDSeptember 2009 | POWERwww.powermag.com13GLOBAL MONITORBalkans.ThecountryhadcontractedRussiasAtomstroyexport, Frances Areva, and Germanys Siemens to build Belene. Then it picked, with much fanfare, German utility RWE for the remaining 49% in the 4 billion Belene plant. Since then, analysts estimate that project costs have surged to more than 6 billion. The previous administration had even ne-gotiated a 3.8 billion state loan with the Russian government, but the new government says it is not willing to provide any state guarantees for loans. Financial Crisis Impacts Russias Grand Nuclear PlansRussian state nuclear corporation Rosatom said in mid-July that the global economic slowdown has affected its extensive nuclear powerplantconstructionprogram.Accordingtotheso-called Master layout plan for energy-producing capacities projected up to 2020, the current approved schedule in April 2007 (and then amended and re-endorsed in March 2008) calls for 36 new nuclear reactors to be built in the next decade. The program envisaged starting up one unit per year from 2009, two from 2012, three from 2015, and four from 2016. Nuclear capacity was expected to almost triple by 2020. Today, under crisis conditions, the time frame when we will need three to four [nuclear plant equipment] sets [per year] will be pushed back, but it will not be cancelled, just pushed back, taking into account the changing demand in energy. As we come out of the crisis, we will be needing all of this again, Rosatom headSergeiKiriyenkoreportedlytoldjournalistsinMarchthis year. This July, he confirmed that in the face of the financial crisis and declining energy demand, the nation had decided to put off thepeakoftheprogramforseveralyears.Wehadplannedto constructtworeactorsperyear,butwehavenowrevisedthe program and now, in the coming years, we will build one reactor per year, he said. Swiss Solar Plane Prototype Designed to Fly Day and NightThe first aircraft designed to fly day and night propelled solely by solar energy was unveiled at Dbendorf airfield, Switzerland, inlateJune.TheSolarImpulsehasthewingspanofaBoeing 747-400 and the weight of an average family car (1,600 kg) (Fig-ure4).Morethan12,000solarcellsmountedontothewings will power four electric motors with a maximum 10 horsepower each. During the day, the solar cells are designed to also charge lithium-polymer batteries (400 kg), which will allow the airplane to fly through the night. Adventurer Bertrand Piccard, who unveiled the Solar Impulse along with Solar Impulse CEO Andr Borschberg, retraced the his-toryoftheprojectsinceitwaslaunchedin2003.Theysaidit took six years of calculations, simulations, and tests for the 70-personteamtocompletetheaircraftprototypeHB-SIA.The prototypesmissionistodemonstratethefeasibilityofacom-plete day-night-day cycle, running on nothing but solar energy. This year and next year the plane will make its first test flightsincluding a complete night flight over Switzerland. Based on the results of those flights, the prototype will be improved. TheSolarImpulsesinventorshopethatstartingin2012, asecondexperimentalplane,HB-SIB,willcircumnavigatethe worldinfivestagesalbeitslowly.Withonly40horsepower, the aircraft takes off at 22 mph and then accelerates at altitude to an estimated speed of only 44 mphas fast as an average scooter. Scotland Officially Opens 100-MW Glendoe Hydro PlantInlateJune,ScotlandofficiallyopenedtheGlendoeHydro Scheme, a 100-MW project whose construction near Loch Ness in theScottishHighlandswastheregionsbiggestcivilengineer-ingprojectinrecenttimes.Planningfortheprojectbeganin 2001, and it took three years to build. Today, the project has the highestheadthedropfromthereservoirtotheturbineof 4.Soaringonsolar.AnaircraftprototypeunveiledthisJune runssolelyonsolarenergyvia12,000solarcellsmountedontothe wings. The plane, which features a wingspan of a Jumbo Jet and the weight of an average family car, has been designed to fly day and night. At40horsepower,itmovesslowlyhowever,acceleratingtoonly44 mph at altitude. Courtesy: Solar ImpulseCIRCLE 10 ON READER SERVICE CARDwww.powermag.comPOWER |September 2009 14GLOBAL MONITORanyhydrostationintheUK,allowingit to generate more energy from every cubic meterofwaterthananyotherfacilityin thecountry,saysprojectownerScottish and Southern Energy (SSE). Thereservoirwasformedbythecon-structionofa960-meter-long,35-m-highdamontheRiverTaff(Figure5). Theprojectsmorecomplexconstruction phasewasmarkedbydigginganexten-sivetunnelsystem,whichmeasures16 km in total. In order to carve the tunnels outoftheunderlyingbedrock,a200-m-longboringmachinewasused.SSEsays that in one instance, the machine entered the hillside in summer 2006 and emerged abouttwoyearslater,havingcreated8 km of tunnels. The actual power station is housed in a cavern 250 m below ground levelrough-ly 2 km from the banks of Loch Ness. This cavern stands adjacent to a smaller cavern that contains the main transformer. Theprojecthasbeenmuchpublicized andwell-receivedQueenElizabethher-self declared it openand SSE is already consideringtwonewlargepumpedstor-age schemes in the Great Glen, plans that the company is expected to make public in 2011. For those reasonalong with con-sideration of the UKs frenzied preparation to meet stringent carbon goalsthe Scot-tishmediaarespeculatingthatGlendoe may just be the beginning of a new era for hydropower in the Highlands. Some point toalistof102hydropowerdevelopment 5.Highland hydropower. The 100-MW Glendoe Hydro Scheme near Loch Ness in Scot-land officially opened in late June. The projects owner, Scottish and Southern Energy, says it has the highest drop from the reservoir to the turbine of any hydro station in the UK, which allows it to generate more energy from every cubic meter of water than any other facility in the country. Courtesy: ScotaviaBiomass Handling EquipmentComplete Engineered SystemsPulverized Coal Boiler ConversionsCFB Boiler Feed SystemsUSA: CORPORATE HEADQUARTERSJeffrey Rader Corporation398 Willis RoadWoodruff, SC, USA 29388Phone: 864.476.7523Fax: 864.476.7510CANADA: Montreal, QuebecJeffrey Rader Canada2350 Place Trans-CanadienneDorval, QuebecH9P 2X5 CanadaPhone: 514.822.2660Fax: 514.822.2699CANADA: Vancouver, BCJeffrey Rader CanadaUnit 2, 62 Fawcett RoadCoquitlam, BCV3K 6V5 CanadaPhone: 604.299.0241Fax: 604.299.1491SWEDEN: StockholmJeffrey Rader ABDomnarvsgatan 11, 163 53 SPNGAStockholm, SwedenPhone: +46 8 56 47 57 47Fax: +46 8 56 47 57 48For information on how Jeffrey Rader Corporation can solve your Biomass Handling needs, visit us at www.jeffreyrader.com/powSilosWood HogsDisc ScreensOpen StorageClosed StorageTruck DumpersChain ConveyorsBucket ElevatorsScrew ConveyorsScrew ReclaimersPneumatic ConveyingMaterial Handling for Biomass Power GenerationUNI TEDSTATESCANADASWEDEN UNITED STATES CANADA SWEDENSee our Biomass video at www.jeffreyrader.com/videoBCIRCLE 11 ON READER SERVICE CARDSeptember 2009 | POWERwww.powermag.com15GLOBAL MONITORprojects proposed by a 1946 regional hy-droelectric board. These ranged greatly in size,buttheyencompassedalmostevery water course in the region. Biomass Electricity More Efficient than Ethanol, Researchers SayBiomassplantmatterthatsgrownto generateenergyconvertedintoelec-tricitycouldresultin81%moretrans-portation miles and 108% more emissions offsetsthanethanol,accordingtoU.S. researchers.Inaddition,theelectricity option would be twice as effective at re-ducing greenhouse gas (GHG) emissions. The study, published in the May 22 is-sueofthejournalScience,wasbasedon two criteria: square miles of cropland and GHG offsets per area (in square miles) of cropland. In both cases, scientists consid-ered a range of feedstock crops (corn and switchgrass) and vehicle types (small car, midsize car, small SUV, and large SUV).University of California Merced Assistant Professor Elliott Campbell, along with Chris-topherFieldoftheCarnegieInstitutions DepartmentofGlobalEcologyandDavid LobellofStanfordUniversity,firstlooked athowmanymilesarangeofvehicles poweredbyethanolcouldtravelversusa range of electric vehicles fueled by electric-ity. Second, they examined offsets to GHG emissions for ethanol and bioelectricity.Theyalsoconsideredlandusewhen evaluatingeachmethod,sayingthat globally, the amount of land available to grow biomass crops is limited. Using ex-istingcroplandsforbiofuelscouldcause increases in food prices and clearing new land,ordeforestation,canhaveanega-tiveimpactontheenvironment,they said in a statement. Theauthorsarecarefultopointout that their study did not examine the per-formance of electricity and ethanol or oth-erpolicy-relevantcriteria.Wealsoneed to compare these options for other issues such as water consumption, air pollution, and economic costs, Campbell said. Theresultssuggestthatinvestment in an ethanol infrastructureeven if the ethanolisderivedfromamore-efficient cellulosic processmay be misguided. In addition, the study notes that it would be possible to capture and store carbon diox-ide emissions from biomass power plantsan option not available for ethanol. DOE Funds Electrification of Transportation Sector On August 5, President Barack Obama an-nouncedthat48newadvancedbattery and electric drive projects will receive $2.4 billion in funding from the Department of EnergyundertheAmericanRecoveryand ReinvestmentAct.Theannouncement marksthesinglelargestinvestmentin advancedbatterytechnologyforhybrid and electric-drive vehicles ever made. DOE funds will be matched by another $2.4 bil-lion from the award winners.Fourcompanieswereselectedinthe advanced vehicle electrification catego-ry. The largest amount, $99.8 million, will gotoElectricTransportationEngineering Corp.(eTec),asubsidiaryofECOtality Inc., to undertake the largest deployment of electric vehicles (EVs) and charging in-frastructure in U.S. history. In partnership with Nissan North Amer-ica, eTec will deploy EVs and the charging infrastructuretosupportthem.Theproj-ect, which will use the Nissan LEAFa ze-ro-emission electric vehicle, will develop, implement, and study techniques for opti-mizing the effectiveness of charging infra-structure that will support widespread EV deployment. The project will install elec-tricvehiclecharginginfrastructureand deploy up to 1,000 Nissan battery electric vehicles in strategic markets in five states: Arizona,California,Oregon,Tennessee, andWashington.TosupporttheNissan EV,theprojectwillinstallapproximately 12,500 Level 2 (220 V) charging systems and 250 Level 3 (fast-charge) systems.The project will collect and analyze data to characterize vehicle use in diverse top-ographic and climatic conditions, evaluate the effectiveness of charge infrastructure, and conduct trials of various revenue sys-tems for commercial and public charge in-frastructure. OnAugust2,Nissanintroducedthe LEAF (Figure 6), which the automaker calls the worlds first affordable, zero-emission car.Designedspecificallyforalithium-ionbattery-poweredchassis,theLEAFis amedium-sizehatchbackthatseatsfive adults and has a range of 100 miles. The carwilllaunchintheU.S.inlate2010. U.S. production will begin in 2012, at Nis-sansmanufacturingfacilityinSmyrna, Tenn.NissanchiefCarlosGhosnhassaid theLEAFwillcostaboutthesameasa gasoline-powered car.POWER DigestNewsitemsofinteresttopowerindustry professionals.Hitachi Power Systems to Supply Boil-erSystemsforMeigsCountyProject. AmericanMunicipalPower(AMP)on July 13 awarded a contract for the design and supply of two supercritical, coal-fired steam-electric generating power blocks to HitachiPowerSystemsAmericaforthe American Municipal Power Generating Sta-tion(AMPGS)projectunderdevelopment inMeigsCounty,Ohio.Eachpowerblock consists of a pulverized coal boiler power-ing a steam turbine generator and the as-sociatednitrogenoxideemissioncontrol equipment.Theboilersystemswillalso utilize Hitachis selective catalytic reduc-tion technology. The contract was award-ed following an extensive bid and analysis processthatincludedAMPstaff,Bechtel 6.The electric car, take two. When Nissan rolls out its all-electric LEAF in 2010, it will become part of the largest test project involving electric vehicles and charging infrastructure. Courtesy: Nissanwww.powermag.comPOWER |September 2009 16GLOBAL MONITORPower (the EPC contractor for the project), R.W. Beck (the proj-ects owners engineer), and Burns & Roe (an independent con-sultant reviewing the contract and bid evaluation). TheAMPGSfacilitywillalsousePowerspansECO-SO2emis-sion control technology for the control of sulfur dioxide (SO2), with co-benefits for the control of mercury and particulate mat-ter. The project will be the first large-scale commercial deploy-mentofthetechnology,which,inadditiontocontrollingSO2 at best available control technology standards, shows promise for the efficient capture of carbon dioxide (CO2) in the future. PowerspansCO2controltechnologyiscurrentlybeingtested withacommercialpilotatFirstEnergysR.E.Burgerplantin Shadyside, Ohio. GLE to Evaluate Laser-Based Uranium Enrichment Technol-ogy. Global Laser Enrichment (GLE) on July 30 announced the start-up of a test loop to evaluate the laser-based uranium en-richment technology that GLE is developing to increase the U.S. supply of enriched uranium for nuclear power plants worldwide. GLE, a business venture between GE Hitachi Ltd. and Canadian uraniumproducerCameco,planstousethetestloopsresults todeterminewhethertocommercializelaser-basedenrichment technology at a full-scale enrichment facility in Wilmington, N.C. GLE anticipates gleaning sufficient data from the test loop by the end of 2009. Start-up of the test loop comes less than a month after GLE announced it had completed its license application to the U.S. Nuclear Regulatory Commission (NRC) to build the full-scale facility. The NRCs estimated 30-month application review processofficiallybeginsoncetheagencyformallydockets,or accepts, the GLE application. AccionaInaugurates50-MWParabolicCylinderPlantin Spain. Spanish energy firm Acciona in late July inaugurated a 50-MW concentrating solar power (CSP) plant in Alvarado, Spain. The 236 million plant uses parabolic cylinder technologythe same as Accionas Nevadas Solar One CSP plant, which has been inoperationsinceJune2007.TheAlvaradoICSPplantcovers more than 130 hectares. Solar energy is reflected by 184,320 mir-rors aligned in rows to 768 solar collectors with a total length of around 75 km. Construction of the plant began in February 2008 and involved shifting more than a million cubic meters of earth. An average of 350 people worked throughout the 18-month con-struction period. A team of 31 will make up the plants operation and maintenance team. FluorCorp.toConductFEEDWorkforScottishandSouth-ern Plant in England. Fluor Corp. on July 21 said it had been selectedtoconductfront-endengineeringanddesign(FEED) work for a nitrogen oxide reduction program at the Fiddlers Ferry Power Station in Warrington, Cheshire, England. Fluor is currently performingpreliminaryengineeringandconstructionplanning services for selective catalytic reduction of emissions at Scottish and Southern Energys (SSE) four-unit coal-fired power plant as well as providing client technical support and project cost esti-mation. Fluor began a feasibility study in late 2008; FEED work isexpectedtobecompletedduringthethirdquarterof2009. SSE is competitively bidding the EPC contract for this clean air initiative. Wrtsil Wins Power Plant Orders from Greece and Cyprus.Wrtsil on July 20 said it won 40 million in separate orders to supply power generation equipment to the island of Lesvos, Greece, and to Cyprus from the Greek state-owned Public Power Corp. The contracts, representing a total of 72 MW, are for an extension to an existing power plant, with the extra 22 MW ca-pacity needed to meet the huge increase in demand that occurs during the tourist season. In addition, the Electricity Authority of Cyprus (EAC), a public utility, has ordered a power plant with threeWrtsil18V46engines,withacapacityof50MW.The new plant is located in Dhekelia, near the town of Larnaca, in Cyprus SCE&EPicksShaw,WestinghouseforNuclearPlantMain-tenanceandEngineering.TheSouthCarolinaElectric&Gas Co. (SCE&G), the principal subsidiary of SCANA Corp., on July 28 awarded the Shaw Groups power group and Westinghouse Electric Co. a long-term alliance contract. The group will provide nuclear maintenance, modification, refueling outage, and design engineering services to SCANAs V.C. Summer Nuclear Station Unit 1, in Jenkinsville, S.C. The contract is an extension of the rela-tionship established by Shaw and Westinghouse to provide EPC services for two new AP1000 nuclear power unitsV.C. Summer Units 2 and 3, operated by SCE&G and the South Carolina Public Service Authority (Santee Cooper). UKGovernmentGrantsVestas6MillionforWindEnergy R&D. The UKs Department of Energy and Climate Change on July 27 said Danish wind turbine maker Vestas Wind Systems would be granted over 6 million for research and development work on the Isle of Wight. The grant is made under the UK governments 1 billion program to set up onshore wind farms in the next three years. More than 3 million of Vestass total grant will come from theSouthEastEnglandDevelopmentAgency.Thesumwillbe paid out to the unit Vestas Technology UK Ltd., which runs an R&D center on the Isle of Wight. The Danish company will receive the subsidy despite its decision to close its wind-blade factory on the small island, which generated large media attention and protests against more than 600 job losses there. By Sonal Patel, POWERs senior writer.ASHROSS RUMig-Rail CarLow prole, high speed railcar unloading system.In-ground system meant for stationary use.ASHROSS RUM-Rail CarRailcar unloading machine, train drives over the RUM, walks off the track by itself.Unloads anywhere, anytime with speed and efciency.ASHROSS RC-ReclaimerCoal reclaimer.Use with dozer or other equipment.Moves the entire pile of coal and reclaims the coal in a fast and efcient manner.ASHROSS 1260 C-TruckSelf-propelled, mobile, towable drive over unloading system for belly dump and end dump trailers.ASHROSS ST-TruckStationary drive over unloading system for belly dump and end dump trailers. 530 South 250 West Pleasant Grove, Utah 84062801-785-6464 Fax; 801-785-6486 www.ashross.com email: [email protected] AvailableCOAL HANDLING EQUIPMENTUnload railcars fast and inexpensivelyCall today!801-785-6464CIRCLE 12 ON READER SERVICE CARDMAGENTA (MI) - ITALYvia Robecco, 20Tel. +39 02 972091Fax +39 02 9794977e-mail: [email protected] www.stf.itBURMEISTER & WAIN ENERGY A/SDK - 2820 Gentofte.Denmarkjaegersborg Alle 164Tel. +45 39 45 20 00Fax +45 39 45 20 05e-mail: [email protected] www.bwe.dkCIRCLE 13 ON READER SERVICE CARDwww.powermag.comPOWER |September 2009 18FOCUSONO&MFOCUSONO&MFOCUSONO&MFOCUSONO&MFOCUSONO&MFOCUSONO&MFOCUSONO&MFOCUSONO&MFOCUSONO&MFOCUSONO&MFOCUSONO&MFOCUSONO&MFOCUSONO&MFOCUSONO&MFOCUSONO&MFOCUSONO&MFOCUSONO&MFOCUSONO&MFOCUSONO&MFOCUSONO&MFOCUSONO&MFOCUSONO&MFOCUSONO&MFOCUS ON O&MWATER TREATMENTAvoid These 10 Mistakes When Selecting Your New Water Treatment SystemThereareanumberofreasonswhyyour plant might be looking at new water pre-treatmentequipmentinthenearfuture. Onecommonreasonistheadditionof newgeneratingcapacity.Formanyutili-ties, adding generation to an existing site has proven to be far simpler than obtain-ing the permits for a greenfield site. The added generation might be in the form of simple-cycle combustion turbines for peak powerdemands(seepp.26and30for examples) or a high-efficiency combined-cycle power plant. Regardless of the type ofnewgeneration,youcanbesurethat it will require additional high-purity water forprocessesrangingfromdirectsteam generationtopoweraugmentation,NOx control,andwashingthebladesofthe combustion turbines.Anotherreasontoconsidernewwater pretreatment equipment is that plant staff arefindingexistingionexchangeunits arebecomingincreasinglydifficultto maintain and expensive to operate. These problems may be compounded by a plant watersupplythathaschangedsincethe water treatment equipment was originally specified. Typically, the current water sup-plymayhavehigherlevelsofsuspended solids and dissolved solids than the equip-ment was originally designed to handle. Reverse osmosis (RO) systems have be-come a favorite in more and more installa-tions and are being successfully used with someverypoorquality(high-turbidity, high-salt, high-organic) waters. The major equipment companies continue to improve RO and ultrafiltration (UF) systems, increas-ing the water production rates and reduc-ing the equipment footprint (Figure 1). Ifyouareinthemarketforawater treatmentsystemretrofitorupgrade,or perhaps are preparing specifications for a new water treatment plant, it pays to learn fromothersmistakes.HereismyTop10 list of design mistakes made when new wa-ter treatment equipment is specified.1.Improperlyspecifyingorcharacteriz-ingthemakeupwatertotheequipmentparticularlythesiltdensityindex(SDI) onanRO.Icantoveremphasizetheim-portanceofproperlycharacterizingthe incomingwatersupplybeforepreparing equipmentspecifications.Takemultiple samples,atdifferenttimesoftheyear andundervariousoperatingconditions. Remembertomeasurethetemperature ofthewaterandtotalsuspendedsolids (TSS), or, better yet, SDI on each sample.2.Failingtomatchtheproductwater withtheneed.Noteverypieceofpower plantequipmentrequires18M(0.56 S/cm)waterwith10M (

![Dl-reamer Technical Presentation External[2]](https://static.fdocuments.in/doc/165x107/577cb4901a28aba7118c8803/dl-reamer-technical-presentation-external2.jpg)