Piedmont Aviation

Transcript of Piedmont Aviation

TAT Technologies Group

7 Decades within

the A&D Industry

Reputable

Customer Base

Employees600

5 Production

Sites

100M$

Annual Turnover

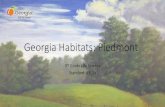

Global Presence

Tulsa, Oklahoma

175 Employees

OEM & MRO

________

Thermal Management Systems

Greensboro, North Carolina

140 Employees

MRO

________

APU, Landing Gear & MPG

Rio, Brazil

Partnership

MRO

________

Thermal Management Systems

Kiryat-Gat, Israel

110 Employees

MRO

________

Engine Components

Gedera, Israel

200 Employees

OEM & MRO

________

Thermal Management Systems

Flow Control Accessories

Novosibirsk, Russia

Open In April 2017

MRO

________

Thermal Management Systems

Thermal Management Solutions

Air to Oil CoolersAir to Air CoolersFuel to Oil CoolersLiquid Oxygen

Heat Exchangers

Liquid Air Heat

Exchangers

ECS Evaporators

and Condensers

ECS

Cold Plates

APU Capabilities

GTCP85 and GTCP95 Series

GTCP331-200/250 Series

GTCP36 Series

• CRJ100/200• Fokker 70/100• BAE 146• EMB 120• Black Hawk

• Boeing 757• Boeing 767• A310• A300

• 737 “Classics”• MD-80• C-130• P-3

• Emb170• Emb190

APS2300

• Combustion assemblies

• Fuel controls

• Starters

• Cooling fans

• Oil pumps

• Oil coolers

• Thermostats

• Fuel nozzles

• Speed switches

• Load control valve

• Pneumatic shutoff valve

• Fuel gear shaft

• VGD’s

• Oil pressure switch

• Air pressure regulator

• Solenoid valve

• Atomizer assembly

• Compressor and turbine assembly

• Transducer assembly

• Generator scavenge pump assembly

• Fuel check (run) valve

• Surge valve – pneumatic

• Oil tank assembly

Capabilities List – Clean, Repair, Overhaul & Test

ATR 42/72

Main & Nose

Landing Gear and

Accessories

Embraer E-170/190

Piedmont provides Repair & Overhaul Services for:

P3

CRJ-100/-200

Dash 8-100/200/300

Piedmont provides Repair & Overhaul Services for:

Main & Nose

Landing Gear and

Accessories

Machining & Grinding:

Norton CNC Gap Bed Grinder (48” swing)

HAAS CNC VF3 Machining Center

HAAS CNC SL-30 Lathe

Bridgeport CNC V10000

Bridgeport CNC Grinder

Coordinate Measuring Machine

Automated Shot Peen Machine

Manual Milling Machines

Manuals Lathes

OD Grinders

Surface Grinders

Machining & Electro Plating Capabilities Electroplating:

Hard Chrome Plate

Chrome Strip

Chromic Acid Anodize

Bright Cadmium

LHE Cadmium

Sulfamate Nickel

Nickel Strike

Copper

Nital Etch

Piedmont Overview

• 2 facilities –• 85,000 sqft main building – Greensboro

• 26,000 sqft additional building – Kernersville

• 130+ Employees• 15 yrs avg tenure

• Long history for APUs, LG & MPG (machining, plating, and grinding)

Partnerships in the Industry

Piedmont AdvantageComprehensive in house capability (one stop shop)

Better control over TAT

Industry leading quality

Historical work load experience to support volume

Close working relationship with OEM’s

Strong financial backing to support program investments

LEAN structure enables efficient communication

Lowest total cost of ownership, while improving reliability therefore, increasing total package value