Photoresist Derived Electrospun Carbon Nanofibers with ...cssharma/assets/pdf/4.pdf · carbon...

Transcript of Photoresist Derived Electrospun Carbon Nanofibers with ...cssharma/assets/pdf/4.pdf · carbon...

![Page 1: Photoresist Derived Electrospun Carbon Nanofibers with ...cssharma/assets/pdf/4.pdf · carbon gases] used for the synthesis of carbon fibers,1–9 PAN is the most commonly employed.](https://reader033.fdocuments.in/reader033/viewer/2022050121/5f51182f7e1faf2e5a672ccb/html5/thumbnails/1.jpg)

Seediscussions,stats,andauthorprofilesforthispublicationat:https://www.researchgate.net/publication/231390995

PhotoresistDerivedElectrospunCarbonNanofiberswithTunableMorphologyandSurfaceProperties

ArticleinIndustrial&EngineeringChemistryResearch·February2010

DOI:10.1021/ie901312j

CITATIONS

29

READS

90

6authors,including:

Someoftheauthorsofthispublicationarealsoworkingontheserelatedprojects:

ElectrospunpolymernanofibersforbiomedicalapplicationsViewproject

NanostructuredLiionelectrodematerialsynthesisbySol-gel/ElectrospinningViewproject

ChandraShekharSharma

IndianInstituteofTechnologyHyderabad

49PUBLICATIONS300CITATIONS

SEEPROFILE

RajeshVasita

UniversitàdegliStudidiMilano-Bicocca

13PUBLICATIONS585CITATIONS

SEEPROFILE

AshutoshSharmaIITK

IndianInstituteofTechnologyKanpur

385PUBLICATIONS8,899CITATIONS

SEEPROFILE

AllcontentfollowingthispagewasuploadedbyChandraShekharSharmaon30August2014.

Theuserhasrequestedenhancementofthedownloadedfile.Allin-textreferencesunderlinedinblueareaddedtotheoriginaldocument

andarelinkedtopublicationsonResearchGate,lettingyouaccessandreadthemimmediately.

![Page 2: Photoresist Derived Electrospun Carbon Nanofibers with ...cssharma/assets/pdf/4.pdf · carbon gases] used for the synthesis of carbon fibers,1–9 PAN is the most commonly employed.](https://reader033.fdocuments.in/reader033/viewer/2022050121/5f51182f7e1faf2e5a672ccb/html5/thumbnails/2.jpg)

Photoresist Derived Electrospun Carbon Nanofibers with Tunable Morphologyand Surface Properties

Chandra S. Sharma,†,‡ Rajesh Vasita,‡,§ Devendra K. Upadhyay,† Ashutosh Sharma,*,†

Dhirendra S. Katti,*,§ and R. Venkataraghavan|

Departments of Chemical Engineering and Biological Sciences and Bioengineering, Indian Institute ofTechnology, Kanpur-208016, India, UnileVer Research & DeVelopment Bangalore, 64, Main Road, Whitefield,Bangalore 560066, India

A new precursor, SU-8, which is a negative photoresist, was electrospun to produce ultrafine polymeric fiberswith a wide range of morphology and wettability characteristics. Electrospun nanofibers of SU-8 were pyrolyzedat 1173 K in an inert atmosphere to give carbon nanofibers. A set of parameters, including electric potential,distance between source and collector, polymer flow rate, and polymer concentration, was optimized forhigh-viscosity SU-8 photoresist to synthesize long continuous carbon fibers having diameters in the range of120-600 nm. However, for the same conditions, medium- and lower-viscosity SU-8 yielded beaded fibersand isolated beads, respectively. The wettability of the carbon web was significantly influenced by its surfacemorphology, as shown by water contact angle measurements. These SU-8-derived carbon nanostructures withtunable surface properties and morphologies could be especially suitable for integration with photoresist-based carbon-MEMS to produce multiscale hierarchal assemblies and could be of potential use in a broadrange of applications.

Introduction

Carbon nanofibers as a new material have the potential toplay a key role because of their physical dimensions, electricalconductivity, high mechanical strength, and low weight-to-strength ratio. Uses of carbon nanofibers are presently beingexplored in broad-ranging applications, including composites,filtration, protective clothing, agriculture, catalysis, defense, andsecurity.1–8 Recently, polymeric fibers including carbon fibershave also received attention in biomedical applications such asdrug delivery and orthopedic/dental implants.9,10 Among theprecursors [e.g., poly(acrylonitrile) (PAN), pitches, and hydro-carbon gases] used for the synthesis of carbon fibers,1–9 PANis the most commonly employed. We report here for the firsttime the use of an epoxy-based negative photoresist, SU-8, asa polymer precursor to carbon nanofibers prepared by theelectrospinning route. We also explore the conditions for tuningthe morphology (nanofibers/particles) and surface properties ofthe polymer and carbon nanostructures produced by electro-spinning of the SU-8 precursor.

SU-8 resist is the single most important material of choicefor the fabrication of opto-electronic and lab-on-a-chip devices,as well as a variety of microfluidics and microelectromechanicalsystems (MEMS) platforms.11 Recently, carbon-MEMS fabri-cated starting from the SU-8 precursor have also been shownto have potential applications in microbatteries and biologicalplatforms.12–16 Thus, a major motivation for SU-8-derivednanofibers is their ease of integration and compatibility withthe underlying device materials and processes. Further, use ofa photoresist material as a precursor to carbon fibers provides

a novel way to fabricate various kinds of high-aspect-ratiofibrous patterns by simple photolithography techniques that finddirect applications in C-MEMS and Bio-MEMS.13–16 Also, thepyrolysis of SU-8 nanofibers to produce carbon nanofibers couldallow their facile integration with other SU-8-derived carbonmesostructures to produce multiscale hierarchal assemblieswhere high external surface areas are of importance, forexample, in microbatteries and supercapacitors.13–15 Photoresist-derived carbon nanofibers could also be of potential use in abroad range of bulk applications such as filtration systems,composites, and biomedical applications. Biocompatibility ofSU-8-derived carbon16 also provides a motivation to producenanoscaffolds of this material, which could provide effectivebioplatforms for cell support and tissue repairs.

A number of methods, including drawing, phase separation,self-assembly, template synthesis, and electrospinning, havebeen employed in different contexts to fabricate polymernanofibers.17 The electrospinning process is a simple, versatile,and widely used method to produce nanofibers at large scale.A large number of polymers have been electrospun intonanofibers.1–5,7,17–21 During the electrospinning process, a highvoltage is used to create an electrically charged jet of polymer.22–29

Once the electric field overcomes a threshold value, this chargedjet is ejected from the tip of the electrospinning apparatus,forming a conical shape known as a Taylor cone.22–25 Thischarged polymer jet undergoes instabilities that lead to awhipping motion in which the liquid polymer jet traverses alengthy path that enables elongation as well as solvent evapora-tion, thereby leading to a charged and dry polymeric fiber withultrafine diameters. The trajectory of this charged polymer jetcan be controlled by the applied electric field.22–30

To the best of our knowledge, the study reported herein isthe first to consider the electrospinning of a negative photoresist,SU-8, to produce its nanofibers and particles and their pyrolysisto produce carbon nanostructures. The aim of the present workis to study the effects of various electrospinning parameters onfiber morphology and then to modulate and characterize thewetting behavior of variously prepared carbon nanostructures.

* To whom correspondence should be addressed. Tel.: +91-512-259 7026 (A.S.), +91-512-259 4028 (D.S.K.). Fax: +91-512-259 0104(A.S.), +91-512-259 4029 (D.S.K.). E-mail: [email protected] (A.S.),[email protected] (D.S.K.).

† Department of Chemical Engineering, Indian Institute of Technology.‡ These authors contributed equally to this work.§ Department of Biological Sciences and Bioengineering, Indian

Institute of Technology.| Unilever Research & Development Bangalore.

Ind. Eng. Chem. Res. 2010, 49, 2731–2739 2731

10.1021/ie901312j 2010 American Chemical SocietyPublished on Web 02/05/2010

![Page 3: Photoresist Derived Electrospun Carbon Nanofibers with ...cssharma/assets/pdf/4.pdf · carbon gases] used for the synthesis of carbon fibers,1–9 PAN is the most commonly employed.](https://reader033.fdocuments.in/reader033/viewer/2022050121/5f51182f7e1faf2e5a672ccb/html5/thumbnails/3.jpg)

Wettability is greatly affected by the surface texture of theelectrospun carbon nanofibers. We show that the surface texturealone can modulate the wetting behavior of SU-8-derived carbonfrom mildly hydrophilic to nearly superhydrophobic for a beadysurface. Further, we propose surface treatments to make thesurface very hydrophilic that can be employed to fabricatehydrophilic carbon nanofiber scaffolds. A precise tuning ofnanomorphology, roughness, and surface/wetting propertiesshould allow a greater flexibility in the use of SU-8-derivedcarbon nanostructures, including in biomedical devices, satellitedishes, solar energy panels, photovoltaics, and so on.31,32

Experimental Section

Materials. An epoxy-based negative photoresist, SU-8 2000series formulation (cyclopentanone-based), was obtained fromMicroChem, Newton, MA. It consists of eight epoxy groupsper molecule.33 This photoresist is available in many differentcompositions that provide a control on viscosity. Three differentresists of this series, namely, SU-8 2002, SU-8 2007, and SU-82015, with respective viscosities of 7, 140, and 1250 cSt at 25°C were used in this study. To dilute the photoresist, cyclo-pentanone (Sigma-Aldrich, St. Louis, MO) was used as athinner.

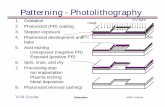

Electrospinning Setup. A schematic diagram of the elec-trospinning setup used in this study is shown in Figure 1. Itconsists mainly of three components: a high-voltage dc powersupply (Glassman High Voltage, Inc., High Bridge, NJ), asyringe pump (Harvard Apparatus, Holliston, MA) mounted witha needle, and a grounded collector plate. The flow rate of thepolymer solution could be modulated using a syringe pump.

Preparation of SU-8 Nanofibers. SU-8 nanofibers weresynthesized using the electrospinning process. Electrospinninguses an electric field to create a charged jet of polymer solution.The polymer solution was placed in a stainless steel needle(nozzle) connected to a glass syringe and held at the tip of thenozzle by its surface tension. Electrostatic charge was inducedon the solution by applying an external electric field betweenthe needle and a grounded plate. When the electric field wasincreased above a threshold value, a charged jet of the polymersolution formed. As this jet traversed the air, the solventevaporated, leaving behind a charged polymer fiber that wascollected on a silicon wafer attached to the grounded copperscreen. On the silicon wafer, continuous fibers were laid to forma nonwoven fiber mesh (fabric). Samples were then placed in avacuum desiccator for 6 h to ensure complete drying/removalof the solvent.

The applied electric potential and distance between the needleand collector screen were varied from 1.2 to 2.4 kV cm-1 and

from 6.0 to 20.0 cm, respectively, to examine the effects onthe diameter and morphology of as-spun SU-8 nanofibers. TheSU-8 feed rate was also varied from 0.1 to 0.5 mL/h to controlthe fiber diameter. In all experiments, a 26-gauge needle (internaldiameter of 0.26 mm) was used. Once the synthesis conditionsto yield continuous nanofibers were optimized with respect tothe three processing parameters mentioned above, the effectsof the SU-8 photoresist concentration and viscosity on morphol-ogy were studied.

Preparation of Carbon Nanofibers. After being dried,electrospun SU-8 nanofibers deposited on a silicon wafer wereexposed to 365-nm UV light for 1 min in order to cross-linkthe fibers. These cross-linked photoresist nanofibers sampleswere then placed in a quartz boat and heated to 1173 K underinert nitrogen (N2) atmosphere in a tubular high-temperaturefurnace for carbonization of the SU-8 polymer. Before thepyrolysis process started, nitrogen gas with a 0.5 L/min flowrate was purged for about 15 min into the quartz tube to displaceunwanted air or oxygen. The rate of heating was optimized tobe 5.0 K/min, and the N2 gas flow during the heating was keptconstant at 0.3 L/min. Once the maximum temperature wasreached, it was kept constant for 60 min. The furnace was thencooled to room temperature in about 10 h to obtain SU-8-derivedcarbon nanofibers. The inert atmosphere was maintained bypurging N2 gas until the furnace attained room temperature.

Surface Treatment. The chemical functionality of the carbonfabric was modified by exposing the fabric to ultraviolet ozone(UVO) for 30 min. The surface of these carbon nanofibers wasalso treated by low-temperature oxygen plasma with a plasmapower of 18 W. The flow rate of carrier gas (oxygen) wasmaintained at 0.3 mL/h at 0.2 mbar for 5 min.

Characterization. Scanning electron microscopy (SEM)(Quanta 200, FEI, Frankfurt am Main, Germany; SUPRA 40VP, Gemini, Carl Zeiss, Oberkochen, Germany) was used toobserve the surface morphology of the nonwoven fiber meshesand to determine the range of diameters produced for all of theabove studies. All samples were first sputter-coated with a thinlayer of Au-Pd to reduce the surface charging during electronbeam scanning. The average diameter of the nanofibers wasobtained for each sample by measuring the diameters of 50nanofibers in six different fields of view and calculating theiraverage. In the case of beaded fibers, both the nanofibers andbeads were measured (fibers were on the nanometer scale, andbeads were on the micrometer scale).

The wetting behavior of the carbon nanofiber surfaces wascharacterized by measuring static contact angles and contactangle hysteresis with a contact angle goniometer (Rame-Hart,Netcong, NJ). In most of the measurements, 5 µL (∼3-mmspherical drop diameter) water droplets were used.

The functional groups on the surface of the carbon nanofibersbefore and after plasma and UVO treatment were characterizedby Fourier transform infrared attenuated total reflection (FTIR-ATR) spectroscopy (Bruker Optik GmbH, Ettlingen, Germany).A confocal micro-Raman microscope (CRM 200, WiTec GmbH,Ulm, Germany, with λ ) 543 nm) was used to record the Ramanspectra of the carbon nanofibers before and after plasmatreatment. This technique allowed for the recording of theRaman spectra of individual fibers to characterize the types ofbonds between the elements constituting the material.

Results and Discussion

Effects of Applied Electric Potential on Polymer FiberMorphology and Size. The effects of the applied electricpotential on the average fiber diameter and morphology are

Figure 1. Schematic of electrospinning setup.

2732 Ind. Eng. Chem. Res., Vol. 49, No. 6, 2010

![Page 4: Photoresist Derived Electrospun Carbon Nanofibers with ...cssharma/assets/pdf/4.pdf · carbon gases] used for the synthesis of carbon fibers,1–9 PAN is the most commonly employed.](https://reader033.fdocuments.in/reader033/viewer/2022050121/5f51182f7e1faf2e5a672ccb/html5/thumbnails/4.jpg)

summarized in Figure 2a-d. For these experiments, SU-8 2015photoresist with the highest viscosity was used, and the appliedelectric potential was varied in the range of 1.2-2.4 kV cm-1.The volumetric feed rate of polymer and the distance betweenthe source and collector were fixed at 0.3 mL/h and 10 cm,respectively. At the lowest value of the electric potential,nonuniformly distributed fibers with large diameters (averagefiber diameter ) 1480 nm) were formed, as shown in Figure2a. At 2.0 kV cm-1, long continuous SU-8 electrospun fiberswith an average diameter of 800 nm were formed (Figure 2b).When the electric potential was increased to 2.4 kV cm-1,smaller-diameter fibers (average fiber diameter ) 190 nm) wereobtained. However, as shown in Figure 2c, these fibers werenot continuous and broke at shorter lengths.

Upon increasing the electric potential from 1.2 to 2.4 kVcm-1, the average SU-8 fiber diameter decreased from 1480 (90 to 190 ( 40 nm. A decrease in the average fiber diameterwith increasing applied electric potential, as shown in Figure2d, is generally consistent with the electrospinning process.28

The final diameter of the polymer jet is governed by the outcomeof a combination of forces generated by surface tension,viscosity, and electrical potential (field configuration and surfacecharges on the polymer solution that lead to electrostatic chargerepulsion).23,26 With increasing electric potential, the densityof charge on the polymer jet increases, thereby leading to ahigher electrostatic repulsion that enables larger drawing forcesand greater stretching of the jet and a reduction in the fiberdiameter. Interestingly, even though the applied electric potentialsignificantly influenced the fiber diameter of electrospun SU-8nanofibers, it did not seem to influence the morphology of thenanofibers.

Effects of Source-Collector Distance on Polymer FiberMorphology and Size. Based on the results for the effect ofelectric potential on fiber diameter, the applied electric potentialwas fixed at 2.0 kV cm-1. The volumetric flow rate of highlyviscous SU-8 2015-type photoresist was kept constant at 0.3mL/h, and the distance between the source needle and collectorscreen was varied from 6 to 20 cm. The effect of varying thedistance on fiber diameter is summarized in Figure 3.

At a distance of less than 6.0 cm, the polymer jet did nothave sufficient time for evaporation of the solvent, thus resultingin inadequate drying of the fibers. This led to spreading ofpartially dried fibers on the collector screen. Figure 3a showsthe as-electrospun fibers at a distance of 6.0 cm that had anaverage fiber diameter of 1600 ( 260 nm. Upon carefulobservation, it can be concluded that the fibers obtained werenot uniform and that the length of the path was not sufficientfor complete solvent evaporation, thereby leading to thick, fusedfibers. When the distance was increased to 10 cm, long,continuous, and uniform fibers with an average diameter of 285( 78 nm were obtained (Figure 3b). A further increase in thedistance to 12 cm reduced the diameter (155 nm) of the as-spun Su-8 fibers by 1 order of magnitude (Figure 3c) ascompared to the fibers obtained at 6.0 cm (1600 nm). A furtherincrease in the electrospinning distance did not produce anysignificant change in the fiber diameter. We also observed anuneven deposition of fibers once the distance became larger than12 cm because of different rates of drying before deposition onthe collector screen. At a distance of 20 cm (not shown in Figure3), the polymer jet became too short and unsteady, thus leadingto the formation of very short fibers.

Figure 2. SEM images showing the effect of applied electric potential on SU-8 fibers: (a) 1.2, (b) 2.0, and (c) 2.4 kV cm-1. (d) Graphical representation ofthe influence of the electrospinning voltage (V) on the average fiber diameter (d). The flow rate and distance between the source needle and collector were0.3 mL/h and 10 cm, respectively, for all cases.

Ind. Eng. Chem. Res., Vol. 49, No. 6, 2010 2733

![Page 5: Photoresist Derived Electrospun Carbon Nanofibers with ...cssharma/assets/pdf/4.pdf · carbon gases] used for the synthesis of carbon fibers,1–9 PAN is the most commonly employed.](https://reader033.fdocuments.in/reader033/viewer/2022050121/5f51182f7e1faf2e5a672ccb/html5/thumbnails/5.jpg)

Thus, in addition to its influence on the electric field intensity,the distance between the source needle and collector screen alsosignificantly influences the average diameter and uniformity ofthe fibers by changing their path length and solvent evaporation.Larger electrospinning distances enabled an increase in the totalpath length covered by the jet, which, in turn, allowed moretime for thinning of the polymer jet.2,22,26,29 At a fixed electricpotential, an increased distance also led to a reduction ofelectrostatic force, causing the jet to travel in linear path withoutany bending instability.23,25

Effects of SU-8 Volumetric Flow Rate on PolymerFiber Morphology and Size. The volumetric flow rate of highlyviscous SU-8 2015 photoresist was varied from 0.1 to 0.5 mL/hwhile the other parameters were held as optimized in theprevious sections: electric potential of 2.0 kV cm-1 and sourceneedle-collector screen distance of 10 cm. At very low flowrate of 0.1 mL/h, the yield of fibers was not significant. After

the flow rate had been increased to 0.2 mL/h, nanofibers withan average fiber diameter of 119 ( 18 nm were produced.However, these fibers were neither continuous nor sufficientlylong, as shown in Figure 4a. When the flow rate was increasedfurther to 0.3 mL/h, continuous long fibers with increasedaverage diameters (192 ( 16 nm) could be produced (Figure4b). A further increase in the flow rate to 0.4 mL/h yieldedfibers with a broad distribution of diameters, as shown in Figure4c. This resulted because of an increase in the mass throughputof the jet, which led to the formation of multiple jets of differentdiameters and different levels of instability. Highly nonuniform,thick fibers along with ultrathin fibers were produced at veryhigh flow rate, 0.5 mL/h (data not shown in Figure 4).

Based on the results presented in this section, the electricpotential and distance between the source needle and collectorwere found to play significant roles in controlling the averagediameter of electrospun fibers, whereas the polymer flow rate

Figure 3. SEM images showing the effect of the distance between the source needle and collector on the SU-8 fibers: (a) 6, (b) 10, and (c) 20 cm. (d)Graphical representation of the influence of the electrospinning distance (D) on the average fiber diameter (d). The flow rate and applied electric potentialwere 0.3 mL/h and 2.0 kV cm-1, respectively, for all cases.

Figure 4. SEM images showing the effect of the volumetric flow rate of the SU-8 photoresist on the SU-8 fibers: (a) 0.2, (b) 0.3, and (c) 0.4 mL/h. Theelectric potential and the distance between the source needle and collector were 2.0 kV cm-1 and 10 cm, respectively, for all cases.

2734 Ind. Eng. Chem. Res., Vol. 49, No. 6, 2010

![Page 6: Photoresist Derived Electrospun Carbon Nanofibers with ...cssharma/assets/pdf/4.pdf · carbon gases] used for the synthesis of carbon fibers,1–9 PAN is the most commonly employed.](https://reader033.fdocuments.in/reader033/viewer/2022050121/5f51182f7e1faf2e5a672ccb/html5/thumbnails/6.jpg)

had relatively less influence.28 The following set of parametersyielded continuous ultrathin uniform fibers with an averagediameter of 190 ( 40 nm: electric potential, 2.0 kV/cm;electrospinning distance, 10 cm; and flow rate, 0.3 mL/h. Thefiber diameter could be reduced by decreasing the flow rate,but the yield became poor.

Effects of Viscosity of SU-8 Solution on Polymer andCarbon Fiber Morphology and Size. Other than the afore-mentioned parameters, the influence of the viscosity of thephotoresist on nanofiber formation was also studied. Experi-ments were performed using two other solutions having viscosi-ties of 7 and 140 cSt while maintaining the other parameters atthe values that were optimized previously for the highestviscosity SU-8 (electric potential of 2.0 kV/cm, electrospinningdistance of 10 cm, and flow rate of 0.3 mL/h). The resultsdemonstrated that, for the lowest-viscosity SU-8 (7 cSt), clustersof beads were formed with an average diameter in the range of180-620 nm whereas, for the medium-viscosity SU-8 (140 cSt),long uniform carbon fibers connected through beads (beadedfibers) were produced. These results indicate that the viscosityof the solution used can significantly influence the fibermorphology.2,23,29 At very low viscosity, the Coulombic forcesthat tend to stretch the jet dominate the viscoelastic forces thatresist the jet breakup. Low viscosity thus aids in a rapid breakupof the charged polymer jet at shorter distances, thus leading tothe formation of nanometer-size beads rather than long fibers.2

At moderate viscosity (140 cSt), the charged polymer jet doesnot break up into beads completely because of the increasedviscoelasticity engendered by chain entanglements (as a con-sequence of the presence of an increased number of polymerchains per unit volume of polymer solution).2 As a result, beadedfibers form.

It was found that the morphology and diameters of the SU-8fibers were preserved during pyrolysis under the conditionsreported. This was because of the cross-linked nature of thephotoresist used. Figure 5 summarizes the findings for the effectsof viscosity on the morphology of carbon nanofibers that wereformed from as-electrospun SU-8 fibers after pyrolysis at 900°C in the presence of inert atmosphere. Figure 5a shows thecarbon nanofibers produced at optimized parameters with anaverage fiber diameter of 120 nm. Figure 5b shows a higher-magnification representation of smooth continuous carbon fibers.Whereas parts c and d of Figure 5 show the formation of beadedcarbon fibers for medium viscous SU-8 photoresist, part e showsthe formation of small clusters of uniform spherical beads only.By changing the applied electric potential to 1.0 kV cm-1 forthe lowest-viscosity SU-8, we observed that uniform and discretecarbon beads could also be produced, as shown in Figure 5f.This change in fiber morphology added a certain roughness tothe surface that was further characterized by the contact anglemeasurements discussed later in this study.

Figure 5. SEM images showing the effect of viscosity on the morphology of the carbon nanofibers: (a,b) highest viscosity, 1250 cSt; (c,d) medium viscosity,140 cSt; and (e,f) lowest viscosity, 7 cSt. The applied electric potential, flow rate, and distance between the source needle and collector were 2.0 kV cm-1,0.3 mL/h, and 10 cm, respectively, for a-e. The applied electric potential was 1.0 kV cm-1 for f, with the other conditions remaining the same. b and d arehigh-magnification images of a and c, respectively.

Ind. Eng. Chem. Res., Vol. 49, No. 6, 2010 2735

![Page 7: Photoresist Derived Electrospun Carbon Nanofibers with ...cssharma/assets/pdf/4.pdf · carbon gases] used for the synthesis of carbon fibers,1–9 PAN is the most commonly employed.](https://reader033.fdocuments.in/reader033/viewer/2022050121/5f51182f7e1faf2e5a672ccb/html5/thumbnails/7.jpg)

Effects of SU-8 Solvent Concentration on PolymerFiber Morphology. Cyclopentanone was used as a thinner todilute the SU-8. Two different solutions of SU-8 2015 with 20%and 40% (v/v) thinner were electrospun to observe the effectsof solvent concentration as summarized in Figure 6. Theoperating parameters were the same as optimized above.Interestingly, SU-8 resist with 20% (v/v) thinner producedbeaded fibers showing macropores on the surface (Figure 6a).The fibers appeared porous because of the evaporation and phaseseparation of solvent from SU-8. However, with the increasein dilution to 40% (v/v), porous beads were formed and thenbecame agglomerated to form clusters (Figure 6b). The mech-anism for the formation of porous fibers in a polymer-solventsystem undergoing solvent evaporation has been explainedtheoretically in literature.34 Such porous beaded fibers couldfind applications in filtration, drug delivery, and fuel cellmembranes, among others.

Wetting Properties of Carbon Fibers. To better understandthe effects of carbon nanofiber morphology on the surfaceroughness and thus on the wetting behavior of these fabrics,water contact angles (WCAs) and contact angle hysteresis(CAH) were measured. Smooth films of SU-8 2015 photoresistwere also prepared by spin coating at 3000 rpm and subsequentsoft baking at 333 K for 20 min for comparison with theelectrospun fabric. Smooth carbon films were obtained after UVexposure followed by pyrolysis at the same conditions asmentioned earlier.

Figure 7 shows images of water droplets on different surfaces(polymer or carbon) with different morphologies, namely, beads,beaded fibers, fibers, and smooth films, that are with and withoutsurface treatment. The first row of images is for the SU-8surfaces, the second row depicts untreated carbon surfaces, thirdrow is for the UV treated carbon and the fourth row is for theplasma-treated carbon. Images in the first to fourth columnscorrespond to different substrate morphologiessbeads, beadedfibers, fibers and smooth film, respectively. Thus, an under-standing of the effect of surface treatment on equilibrium watercontact angle can be developed by comparing the images indifferent rows of Figure 7, whereas the effect of substratemorphology can be seen by comparing the images in differentcolumns of Figure 7.

A smooth film of the SU-8 negative photoresist is weaklyhydrophilic. The water contact angle of SU-8-derived smoothcarbon film increased slightly to 70.8° ((1.6°) (Figure 7h) ascompared to that of an SU-8 photoresist film, 61.2° ((1.3°)(Figure 7d). There was a significant increase of the contact angleto 127.9° ((3.1°) (Figure 7g) for carbon fibers, and for carbon

beaded fibers, it increased further to 138.4° ((2.7°) (Figure 7f).The formation of carbon beads imparted even more hydropho-bicity, as shown by the contact angle of water on the carbonnanobead surface, 142.7° ((2.8°) (Figure 7e).

Thus, surface morphology and roughness were found to beimportant factors in controlling the wettability of the electrospunfabrics.20,32,35,36 Interestingly, tailoring of the carbon substratemorphology alone without any surface chemical modificationscould control the wetting properties in a large rangesfrommildly hydrophilic (<90° contact angle) on a smooth surface tonearly superhydrophobic on a beaded surface. There are only afew known instances of wettability transition across 90° contactangle with changing surface morphology.20,35,36

For a thorough understanding of the wetting character ofcarbon fabrics, contact angle hysteresis and sliding angles ofwater droplets were also measured.20 The complete wettabilityproperties of a surface can be understood in terms of twoequilibrium contact angles defined as the advancing and recedingcontact angles, which are different because of the surfaceroughness and heterogeneity. Contact angle hysteresis is definedas the difference between the advancing contact angle and thereceding contact angle.20,32,38 The propensity of a droplet tostick to a surface is related to contact angle hysteresis. Thesamples were first fixed on the goniometer stage, which couldbe tilted to a maximum of 40° from the vertical plane todetermine the contact angle hysteresis.

Figure 6. SEM images showing the effect of solvent concentration for (a) 20% and (b) 40% (v/v) solvent as a thinner. The high-magnification images inthe insets show the macropores on the surfaces.

Figure 7. Images of a water droplet on surfaces with various morphologyand chemical treatments: (a-d) SU-8, (e-h) SU-8-derived carbon, (i-l)SU-8-derived carbon after 30 min of UVO treatment, and (m-p) SU-8-derived carbon after 5 min of oxygen plasma treatment. Morphology changesoccurred in the following order (from left to right): beads, beaded fibers,fibers, and films. The drop volume was ∼5 µL for all samples.

2736 Ind. Eng. Chem. Res., Vol. 49, No. 6, 2010

![Page 8: Photoresist Derived Electrospun Carbon Nanofibers with ...cssharma/assets/pdf/4.pdf · carbon gases] used for the synthesis of carbon fibers,1–9 PAN is the most commonly employed.](https://reader033.fdocuments.in/reader033/viewer/2022050121/5f51182f7e1faf2e5a672ccb/html5/thumbnails/8.jpg)

On the carbon fiber substrates in the horizontal position, theadvancing and receding contact angles were measured to be127.9° ((3.1°) and 93.9° ((1.9°), respectively. This gives acontact angle hysteresis of 34° ((2.1°). On a substrate inclinedat 40° from the vertical, the contact angle hysteresis wasmeasured to be 65.1° ((1.8°). In this case, the advancing andreceding contact angles were measured to be 132.2° ((3.8°)and 67.1° ((2.9°), respectively. As a result of this high contactangle hysteresis, a water drop remains stuck on a tilted substratedespite gravity.37,38 This phenomenon is termed the “petaleffect”36 in which water droplets are unable to detach even onvery hydrophobic surfaces. In the case of carbon surfacescovered with beads, the advancing and receding contact angleswere found to be 146.3° ((2.7°) and 103.2° ((4.6°), respec-tively, at a sliding angle of 36°, where the drop started to slidedown. Such a nearly superhydrophobic behavior with a concur-rent high contact angle hysteresis is described as the Cassieimpregnating wetting state.36,37

As discussed above, weakly hydrophilic smooth carbonsurfaces could be made nearly superhydrophobic by thecontrol of surface morphology alone. Changes in the physicaltexture of carbon fabric were always accompanied by anincrease of the contact angle. We now show that the rangeon the hydrophilic side can also be greatly extended bysurface chemical modifications, which could be importantin using these substrates as bioplatforms and enhancing theircompatibility in aqueous solutions. In the case of carbonnanofibers, we found that they can be made stronglyhydrophilic by changing their surface chemistry. As anexample, the hydrophobic surface of carbon nanofibers wasvtreated by UVO for 30 min. The water contact angle ofUVO-treated carbon nanofibers was measured to be 17.7°((0.6°), which indicates a highly hydrophilic behavior ascompared to that of the untreated carbon counterpart,irrespective of the morphology. Similar behavior was ob-served after low-temperature oxygen plasma treatment underthe conditions specified earlier. The water contact angle ofplasma-treated carbon fabric was found to be 10.3° ((0.9°).However, the surface chemical changes induced by thesetreatments were found to be reversible. The hydrophobicrecovery of the treated fabrics was monitored after keepingthe carbon nanofiber samples under ambient conditions fora week. For the carbon nanofibers, the contact angle wasfound to be 110.8° ((3.6°) one week after the treatment ofthe surfaces with plasma and UVO, which indicates asignificant hydrophobic recovery. A slow hydrophobic re-covery for a film of SU-8 material after plasma treatment isknown.11

The surface chemistry of these carbon nanofibers was alsostudied by FTIR spectroscopy in the attenuated total reflectionmode to support the discussion above. Figure 8a,b showsFTIR-ATR spectra of plasma-treated and untreated carbonfibers, respectively. It is to be noted that the plasma or furtherUVO treatment of electrospun carbon nanofibers is a post-processing step applied after cross-linking and carbonizationin order to increase the hydrophilicity of these fibers. TheUV exposure of freshly spun SU-8 fibers mentioned earlierfor 1 min is a separate preprocessing step required to initiatethe acid-catalyzed cross-linking of the photoresist fibersbefore conversion into carbon fibers during pyrolysis. Thepresence of hydroxyl groups at 1410 cm-1 accompanied byO-H chelation at 3180, 3240, and 3450 cm-1 indicates ahigh density of hydroxyl surface groups after plasma treat-ment.16 Moreover, other oxygen-containing functional groups

such as carbonyl (1590-1760 cm-1), carboxylic (3500-3560cm-1), and phenolic (3610-3670 cm-1) were also evidentin the spectrum.2,16 In addition to these functional groups, astrong peak at 1500 cm-1 can be assigned to the presence ofaromatic CdC bonds in the SU-8 structure. Thus, based onthe FTIR-ATR analysis, it is clear that the number anddiversity of surface groups present on the surface of thecarbon fibers increased upon treatment with oxygen plasma.The increased peak intensity and presence of oxygen-richhydroxyl, carbonyl, carboxyl, and phenolic surface functionalgroups explains the extreme hydrophilic behavior of plasma-treated carbon fabrics as also verified by contact anglemeasurements.

Micro-Raman spectroscopy was used to analyze the surfacechemistry of SU-8-derived carbon before and after plasmatreatment. As shown in Figure 9, there were two broad peakscentered around 1350 and 1590 cm-1. These two peakscorrespond to the well-known D and G bands of graphite,respectively,3–6 indicating that a fraction of disorderedamorphous sp2 C-C bonding is present in the carbonnanofibers derived from electrospinning of SU-8 precursor.Although there were no significant differences in the peakpositions of the untreated and plasma-treated surfaces of thecarbon nanofibers, the peak intensities were significantly

Figure 8. FTIR-ATR spectra of (a) plasma-treated carbon fabric surfaceand (b) SU-8-derived carbon nanofibers without any further treatment.

Figure 9. Micro-Raman spectra of SU-8-derived carbon nanofibers beforeand after plasma treatment.

Ind. Eng. Chem. Res., Vol. 49, No. 6, 2010 2737

![Page 9: Photoresist Derived Electrospun Carbon Nanofibers with ...cssharma/assets/pdf/4.pdf · carbon gases] used for the synthesis of carbon fibers,1–9 PAN is the most commonly employed.](https://reader033.fdocuments.in/reader033/viewer/2022050121/5f51182f7e1faf2e5a672ccb/html5/thumbnails/9.jpg)

modified. The intensity ratio of the two first-order D and Gbands as denoted by ID/IG increased from 0.58 to 0.64 afterthe plasma treatment. This indicates6 an increase in thestructural disorder of the fibers because of the destruction ofbasal planes by oxygen plasma treatment.

Conclusions

SU-8 negative photoresist, which is widely used in conven-tional lithography, was chosen as a new polymer precursor tosynthesize carbon nanofibers and beads by electrospinning andsubsequent pyrolysis. Various processing parameters includingthe applied electric potential, source-collector distance, polymersolution concentration, and flow rate significantly influenced themorphology and size of the structure formed. Under optimizedconditions of electric field and flow rate, the morphology couldbe modulated from smooth nanofibers to beaded fibers and thento spherical beads simply by varying the viscosity of the SU-8solution. The formation of beaded fibers and beads was foundto impart significant hydrophobicity to the electrospun carbonweb, with the highest water contact angle of about 143° (beadonly) as compared to weakly hydrophilic smooth carbon film(contact angle ) 70.8°). Notwithstanding the hydrophobicityof these surfaces, water droplets could still be retained on themwhen tilted owing to a large contact angle hysteresis. This isan example of a recently observed petal effect in rough surfacesof polystyrene (PS) micromolded to resemble the microtextureof a rose petal.36 Thus, controlling the wetting properties frommildly hydrophilic on a smooth surface to nearly superhydro-phobic on a beaded surface could be achieved by tailoring thecarbon substrate morphology alone without any surface chemicaltreatment.

The development of SU-8-derived carbon nanostructures withdiverse fiber morphologies and tunable surface properties couldbe especially suitable for integration with photoresist-based high-aspect-ratio carbon-MEMS to produce multiscale hierarchalassemblies. These structures, because of their high surface areas,could also find potential use in a broad range of applicationssuch as filtration systems, composites, and biomedical applica-tions such as bio-MEMS, scaffolds, and implants.

Acknowledgment

We are thankful to Satinder Sharma, IIT, Kanpur, India, forhis help in Raman spectroscopic measurements. Helpful dis-cussions with Marc Madou and Manish M. Kulkarni areacknowledged. This work was supported by Unilever Research,Bangalore, and by a DST IRHPA project. R.V. acknowledgesthe Council of Scientific & Industrial Research (CSIR) for hisresearch fellowship, and D.S.K. acknowledges grant supportfrom the Department of Science & Technology, Governmentof India, and the Department of Biotechnology, Governmentof India.

Literature Cited

(1) Dzenis, Y. Spinning Continuous Fibers for Nanotechnology. Science2004, 304, 1917.

(2) Sutasinpromprae, J.; Jitjaicham, S.; Nithitanakul, M.; Meechaisue,C.; Supaphol, P. Preparation and Characterization of Ultrafine ElectrospunPolyacrylonitrile Fibers and Their Subsequent Pyrolysis to Carbon Fibers.Polym. Int. 2006, 55, 825.

(3) Wang, Y.; Serrano, S.; Santiago-Aviles, J. J. Conductivity Measure-ment of Electrospun PAN-based Carbon Nanofiber. J. Mater. Sci. 2002,21, 1055.

(4) Wang, Y.; Serrano, S.; Santiago-Aviles, J. J. Raman Characterizationof Carbon Nanofibers Prepared Using Electrospinning. Synth. Met. 2003,138, 423.

(5) Zussman, E.; Chen, X.; Ding, W.; Calabri, L.; Dikin, D. A.; Quintana,J. P.; Ruoff, R. S. Mechanical and Structural Characterization of ElectrospunPAN-Derived Carbon Nanofibers. Carbon 2005, 43, 2175.

(6) Montes-Moran, M. A.; Young, R. J. Raman Spectroscopy Study ofHM Carbon Fibers: Effect of Plasma Treatment on the Interfacial Propertiesof Single Fibre/Epoxy Composites. Carbon 2002, 40, 845.

(7) Peng, M.; Li, D.; Chen, Y.; Zheng, Q.; Wang, H. NanoporousStructured Submicrometer Carbon Fibers Prepared via Solution Electro-spinning of Polymer Blends. Langmuir 2006, 22, 9368.

(8) Brandl, W.; Marginean, G. Functionalisation of the Carbon Nanofi-bers by Plasma Treatment. Thin Solid Films 2004, 447-448, 181.

(9) Elias, K. L.; Price, R. L.; Webster, T. J. Enhanced Functions ofOsteoblasts on Nanometer Diameter Carbon Fibers. Biomaterials 2002, 23,3279.

(10) Katti, D. S.; Robinson, K. W.; Ko, F. K.; Laurencin, C. T.Bioresorbable nanofiber-based systems for wound healing and drug delivery:Optimization of fabrication parameters. J. Biomed. Mater. Res. 2004, 70B,286.

(11) Walther, F.; Davidovskaya, P.; Zurcher, S.; Kaiser, M.; Herberg,H.; Gigler, A.; Stark, R. W. Stability of the Hydrophilic Behaviour ofOxygen Plasma Activated SU-8. J. Micromech. Microeng. 2007, 17, 524.

(12) Ranganathan, S.; McCreery, R.; Majji, S. M.; Madou, M. Photo-resist-Derived Carbon for Microelectromechanical Systems and Electro-chemical Applications. J. Electrochem. Soc. 2000, 147, 277.

(13) Wang, C.; Jia, G.; Taherabadi, L. H.; Madou, M. J. A Novel Methodfor the Fabrication of High-Aspect Ratio C-MEMS Structures. J. MEMS2005, 14, 348.

(14) Teixidor, G. T.; Zaouk, R. B.; Park, B. Y.; Madou, M. J. Fabricationand Characterization of Three-Dimensional Carbon Electrodes for Lithium-Ion Batteries. J. Power Sources 2008, 183, 730.

(15) Park, B. Y.; Zaouk, R.; Wang, C.; Madou, M. J. A Case for FractalElectrodes in Electrochemical Applications. J. Electrochem. Soc. 2007, 154(2), P1.

(16) Teixidor, G. T.; Gorkin, R. A., III; Tripathi, P. P.; Bisht, G. S.;Kulkarni, M.; Maiti, T. K.; Battcharyya, T. K.; Subramaniam, J. R.; Sharma,A.; Park, B. Y.; Madou, M. Carbon-MEMS as a Substrate for Cell Growth.Biomed. Mater. 2008, 3, 034116.

(17) Jayaraman, K.; Kotaki, M.; Zhang, Y.; Mo, X.; Ramakrishna, S.Recent Advances in Polymer Nanofibers. J. Nanosci. Nanotechnol. 2004,4, 52.

(18) Huang, Z.-M.; Zhang, Y.-Z.; Kotaki, M.; Ramakrishna, S. A reviewon Polymer Nanofibers by Electrospinning and Their Applications inNanocomposites. Compos. Sci. Technol. 2003, 63, 2223.

(19) Ramakrishna, S.; Fujihara, K.; Teo, W.-E.; Yong, T.; Ma, Z.;Ramaseshan, R. Electrospun Nanofibers: Solving Global Issues. Mater.Today 2006, 9, 40.

(20) Ma, M.; Mao, Y.; Gupta, M.; Gleason, K. K.; Rutledge, G. C.Superhydrophobic Fabrics Produced by Electrospinning and Chemical VaporDeposition. Macromolecules 2005, 38, 9742.

(21) Dharmaraj, N.; Park, H. C.; Lee, B. M.; Viswanathamurthi, P.; Kim,H. Y.; Lee, D. R. Preparation and Morphology of Magnesium TitanateNanofibers via Electrospinning. Inorg. Chem. Commun. 2004, 7, 431.

(22) Doshi, J.; Reneker, H. D. Electrospinning Process and Applicationof Electrospun Fibers. J. Electrostat. 1995, 35, 151.

(23) Renekar, D. H.; Yarin, A. L.; Fong, H.; Koombhongse, S. BendingInstability of Electrically Charged Liquid Jets of Polymer Solutions inElectrospinning. J. Appl. Phys. 2000, 87, 4531.

(24) Shin, Y. M.; Hohman, M. M.; Brenner, M. P.; Rutledge, G. C.Electrospinning: A Whipping Fluid Jet Geenrates Submicron PolymerFibers. Appl. Phys. Lett. 2001, 78, 1149.

(25) Hohman, M. M.; Shin, M.; Rutledge, G.; Brenner, M. P. Electro-spinning and Electrically Forced Jets. II. Applications. Phys. Fluids 2001,13, 2221.

(26) Fridrikh, S. V.; Yu, J. H.; Brenner, M. P.; Rutledge, G. C.Controlling the Fiber Diameter During Electrospinning. Phys. ReV. Lett.2003, 90, 144502–1.

(27) Theron, S. A.; Zussman, E.; Yarin, A. L. Experimental Investigationof the Governing Parameters in the Electrospinning of Polymer Solutions.Polymer 2004, 45, 2017.

(28) Tan, S.-H.; Inai, R.; Kotaki, M.; Ramakrishna, S. SystematicParameter Study for Ultra-fine Fiber Fabrication via Electrospinning Process.Polymer 2005, 46, 6128.

(29) Thompson, C. J.; Chase, G. G.; Yarin, A. L.; Reneker, D. H. Effectsof Parameters on Nanofiber Diameter Determined from ElectrospinningModel. Polymer 2007, 48, 6913.

(30) Tan, S.; Huang, X.; Wu, B. Some Fascinating Phenomena inElectrospinning Processes and Applications of Electrospun Nanofibers.Polym. Int. 2007, 56, 1330.

2738 Ind. Eng. Chem. Res., Vol. 49, No. 6, 2010

![Page 10: Photoresist Derived Electrospun Carbon Nanofibers with ...cssharma/assets/pdf/4.pdf · carbon gases] used for the synthesis of carbon fibers,1–9 PAN is the most commonly employed.](https://reader033.fdocuments.in/reader033/viewer/2022050121/5f51182f7e1faf2e5a672ccb/html5/thumbnails/10.jpg)

(31) Jiang, L.; Zhao, Y.; Zhai, J. A Lotus-Leaf-like SuperhydrophobicSurface: A Porous Microsphere/Nanofiber Composite Film Prepared byElectrohydrodynamics. Angew. Chem., Int. Ed. 2004, 43, 4338.

(32) Ma, M.; Hill, R. M. Superhydrophobic Surfaces. Curr. Opin. ColloidInterface Sci. 2006, 11, 193.

(33) Sikanen, T.; Tuomikoski, S.; Ketola, R. A.; Kostiainen, R.;Franssila, S.; Kotiaho, T. Characterization of SU-8 for electrokineticmicrofluidics applications. Lab Chip 2005, 5, 888.

(34) Dayal, P.; Kyu, T. Porous Fiber Formation in Polymer-SolventSystem Undergoing Solvent Evaporation. J. Appl. Phys. 2006, 100, 043512.

(35) Yoon, Y.; Moon, H. S.; Lyoo, W. S.; Lee, T. S.; Park, W. H.Superhydrophobicity of PHBV Fibrous Surface with Bead-on-StringStructure. J. Colloid Interface Sci. 2008, 320, 91.

(36) Feng, L.; Zhang, Y.; Xi, J.; Zhu, Y.; Wang, N.; Xia, F.; Jiang, L.Petal Effect: A Superhydrophobic State with High Adhesive Force.Langmuir 2008, 24, 4114.

(37) Callies, M.; Quere, D. On Water Repellency. Soft Matter 2005, 1,55.

(38) Quere, D.; Azzopardi, M.-J.; Delattre, L. Drops at Rest on a TiltedPlane. Langmuir 1998, 14, 2213.

ReceiVed for reView August 22, 2009ReVised manuscript receiVed January 13, 2010

Accepted January 23, 2010

IE901312J

Ind. Eng. Chem. Res., Vol. 49, No. 6, 2010 2739

View publication statsView publication stats