PAVEMENT DESIGN DATA - ( C.R.C.P. ) TYPICAL DOWEL …0).pdf · 27/05/2020 · teora pat spacing...

Transcript of PAVEMENT DESIGN DATA - ( C.R.C.P. ) TYPICAL DOWEL …0).pdf · 27/05/2020 · teora pat spacing...

-

LONGITUDINAL CONSTRUCTION JOINT

DETAIL BDETAIL A

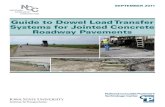

PAVEMENT DESIGN DATA - ( C.R.C.P. )

TRANSVERSE CONSTRUCTION HEADER JOINT

C

G P. C. CONCRETE FOR PAVEMENT

414 ( )

414 ( )

ITEM NO. ITEM UNIT

CONT. REINF. P. C. C. PAVT. ( PLACEMENT )

BASIS OF PAYMENT

CRCP PAVEMENT

24'-0" WIDE

BEFORE PAVING ADD-ON.

CURING COMPOUND JUST

APPLY SECOND COAT OF

SEE DETAIL ASEE DETAIL B

90

90

JOINTED CONCRE

TE OR

ASPHALT CONCR

ETE PAVEMENT

12''

JOINTED CONC.SHOULDER

12''90

( SEE PLANS )

JOINTED CONC.SHOULDER

SEE DETAIL A SEE DETAIL B

90

90

ON 12 INCH CENTERS SUCH THAT DOWEL BARS ARE NO

CLOSER THAN 12 INCHES OR FARTHER THAN 24 INCHES

FROM THE LONGITUDINAL SHOULDER JOINT. DOWEL BAR

DOWEL BARS LOCATED IN RAMP TAPER SHALL BE PLACED

JOINTED OR DOWEL JOINTED

CONCRETE PAVEMENT ( RAMP )

LONGIT. BARLONGIT. BAR

7.

8.

9.

11.

OR WORK STOPPAGE

END OF A DAYS RUN

OR SPLIT HEADER

SLOTTED ONE PIECE SEE GEN. NOTE

SHOULDER

NO. 11

3'' COVER (MIN.)

TO BE USED AT THE END OF EACH DAYS CONCRETE PLACEMENT

OR AT ANY WORK STOPPAGE OF 30 MINUTES OR LONGER.

2.

3.

4.

5.

6.

W Y

UPPER LIMIT = T/2

LOWER LIMIT = T/2

DETAILS ARE SHOWN ON ROADWAY STANDARD LTU-5.

CONCRETE PAVEMENT (SEE PLANS)

JOINTED CONCRETE OR ASPHALT

SPACING

TYPE

DESIGN

NESS

THICK-

SLAB

T

SIZE

BAR

BARS

OF

NO.

CONTRACTION JOINT.

THAN 24" TO AN EVENTUAL SAWED

TIE BARS SHALL NOT BE PLACED CLOSER

( SEE DETAIL THIS SHEET )

LONGITUDINAL CONSTRUCTION JOINT

CONCRETE PAVEMENT

CONTINUOUS REINFORCED

LA

NE

12'

( SEE DETAIL THIS SHEET )

LONGITUDINAL CONSTRUCTION JOINT

DOWEL JOINTED PCC

RAMP TAPER

DOWEL JOINTED PCC RAMP TAPER

JUNCTURE

RAMP

JUNCTURE

RAMP

CONCRETE PAVEMENT

CONTINUOUS REINFORCED

DIRECTION

OF TRAFFIC

DIRECTION

OF TRAFFIC

DIRECTION

OF TRAFFIC

DIRECTIONOF TRAFFIC

LA

NE

12'

DEPTH = T/4

SAWED AND SEALED JOINT

T

FOR DEPTH)

(REFER TO PLAN VIEW

LONGITUDINAL BARS.

OF SLAB TO CENTER OF

DIMENSION FROM TOP

LONGITUDINAL CONTRACTION JOINT

PCC RAMP TAPER

DOWEL JOINTED

SEE RDY. STD. LECS-5

CONTRACTION JOINTS

15' TYPICAL BETWEEN

SEE RDY. STD. LECS-5

CONTRACTION JOINTS

15' TYPICAL BETWEEN

PCC RAMP TAPER

DOWEL JOINTED

JOINT AT RAMP JUNCTURE

1 1/2" EXPANSION JOINT

RAMP IS ASPHALT.

REQUIRED WHEN

EXPANSION JOINT NOT

SEE RDY. STD. LTU-4

DOWEL BAR & SUPPORT

IN RAMP TAPER

DOWELED JOINTS

IN GORE

NON-DOWELED JOINTS

1.

10.

LONGITUDINAL JOINT

ED

GE O

F P

AV

EM

EN

T

6'' (M

IN.)

TY

PIC

AL

22" SP

LIC

E

BA

RS A

T 4

4''

CT

RS.

#5 D

EF

OR

ME

D T

RA

NS

VE

RS

E

SEE GENERAL NOTE NO. 8

BE APPROVED BY THE ENGINEER.

OPTIONAL PATTERN OF LAPS TO

STAGGER LONGIT. BAR SPLICES

TO S

PLIC

E

8'-0 MIN.JOINT, SEE NOTE 4

TRANSVERSE CONST.

24'-0" WIDE PAVEMENT PLAN

TO S

PLIC

E

8'-0"

MIN.

GENERAL NOTES

ODOT STANDARD SPECIFICATIONS.

ALL CONSTRUCTION AND MATERIALS REQUIREMENTS SHALL BE IN ACCORDANCE WITH THE 2019

STEEL.

WILL BE ALLOWED, IF THEIR TENSILE STRENGTH EQUALS OR EXCEEDS THAT OF THE REINFORCING

PURPOSE OF STARTING OR ENDING THE STAGGERED LAP PATTERN. MECHANICAL CONNECTORS

OF 30'-0''. LONGITUDINAL BARS SHORTER THAN THE 30'-0'' WILL BE NECESSARY FOR THE

ALL LONGITUDINAL BARS SHALL BE SPLICED A MINIMUM OF 22'' AND HAVE A MINIMUM LENGTH

FOR MAINLINE AND/OR SHOULDER PAVEMENT.

EXPANSION JOINTS WILL NOT BE USED, EXCEPT AT TERMINAL POINTS AS SHOWN IN THE PLANS,

ONLY WITH PRIOR APPROVAL OF THE ENGINEER.

TRANSVERSE CONSTRUCTION JOINTS MAY BE FORMED BY HEADERS OTHER THAN SHOWN, BUT

GIVEN AREA MEASURED 12'-0'' TRANSVERSELY BY 2'-6'' LONGITUDINALLY.

NOT OVER 30 PERCENT OF THE REGULAR LONGITUDINAL STEEL SHALL BE SPLICES WITHIN ANY

USED WHERE REQUIRED. COST TO BE INCLUDED IN OTHER ITEMS OF WORK.

'LEAVE OUT' SECTIONS ( OMISSIONS ) WILL NOT BE PERMITTED. TEMPORARY BRIDGES WILL BE

UNLESS OTHERWISE NOTED.

SHOULDERS ARE CALLED FOR, AS WELL AS RAMP TERMINALS AND STREET INTERSECTIONS,

LONGITUDINAL CONSTRUCTION JOINT IS TO BE USED ON PAVEMENT EDGES WHERE TIED

WITH HAND MANIPULATED MECHANICAL VIBRATORS.

ADJACENT TO TRANSVERSE CONSTRUCTION JOINTS AND EXPANSION JOINTS SHALL BE VIBRATED

CONSOLIDATION OF CONCRETE AROUND THE CLOSELY SPACED STEEL MEMBERS. THE CONCRETE

VIBRATORY EQUIPMENT WILL BE REQUIRED TO ENSURE COMPLETE AND UNIFORM

12.

TYPICAL DOWEL JOINTED ENTRANCE RAMP

TYPICAL DOWEL JOINTED EXIT RAMP

OF EACH BAR PLUS OR MINUS 2 INCHES.

TRANSVERSE PLACEMENT LIMITS EQUALS PLANS LOCATION

PLACEMENT IS MEASURED AT CENTERLINE OF BARS.

TOLERANCE FOR PLACEMENT OF LONGITUDINAL STEEL:

-1/2" (DOWN FROM T/2)

+1" (UP FROM T/2)

DIMENSIONS SHOWN TO C OF BAR UNLESS MARKED ''CLR.''L

26'-0" WIDE PAVEMENT SECTION

PA

VE

ME

NT

26'-0"

PA

VE

ME

NT

24'-0"

C

B1

B

A

A1

C

B1

B

A

A1

12"

11"

10"

9"

8"

12"

11"

10"

9"

8"

#7

#7

#7

#6

#6

#7

#7

#7

#6

#6

5 5/8"

5 1/4"

5 13/16"

5 5/8"

5 1/4"

4 3/16"

4 13/16"

5 11/16"

5 9/16"

4 7/8"

6 3/4"

7 1/2"

8 3/8"

6 3/4"

7 1/2"

7 1/16"

7 3/8"

8 1/8"

6 11/16"

7 3/4"

42

38

34

42

38

44

42

38

46

40

0.73

0.72

0.71

0.71

0.73

0.71

0.73

0.73

0.72

0.71

EXCEPT FOR WHEN OTHERWISE SHOWN IN THIS DETAIL.

TO BE AS SHOWN ON ROADWAY STANDARD LECS-4

APPROVED BY THE ENGINEER.

AND TIE BARS MAY BE ADJUSTED TO AVOID CONFLICT, AS

AND AS SHOWN IN THIS DETAIL. HEIGHT OF REINFORCING

TO BE AS SHOWN ON ROADWAY STANDARD LECS-5

CONTINUOUSLY REINFORCED P. C. C. PAVEMENT (PLACEMENT).

BE PAID FOR SEPARATELY, BUT WILL BE INCLUDED IN THE UNIT PRICE BID PER SQUARE YARD OF

COST OF ALL STEEL, INCLUDING ADDITIONAL STEEL REQUIRED AT TRANSVERSE JOINTS, WILL NOT

T

12'-0'' 12'-0''

Y

T /2

DIMENSIONS SHOWN TO C OF BAR UNLESS MARKED ''CLR.''L

24'-0''

24'-0" WIDE PAVEMENT SECTION

REIN

F. B

AR

SLIMIT

S F

OR L

ON

GIT.

VE

RTIC

AL P

LA

CE

ME

NT

JOINTLONGITUDINALW W

T

14'-0''

Y

T /2

REIN

F. B

AR

SLIMIT

S F

OR L

ON

GIT.

VE

RTIC

AL P

LA

CE

ME

NT

JOINTLONGITUDINALW W

12'-0''

26'-0''

L FIRST BAR L FIRST BAR

L FIRST BAR L FIRST BAR

C

CC

C

22'-11 7/8"

23'-0 5/8"

22'-11 1/2"

23'-0"

23'-0 3/4"

25'-2 13/16"

25'-1 1/2"

24'-11 3/4"

25'-0 3/16"

25'-1 1/2"

LENGTH

#5 BAR

TRANS.

TRANSVERSE BAR LENGTH

TRANSVERSE BAR LENGTH

FEEDERS WILL NOT BE ALLOWED.

CHAIR ASSEMBLIES. CHAIR ASSEMBLIES MUST BE USED. MECHANICAL PLACEMENT USING TUBE

RECOMMENDED PLACEMENT FOR LONGITUDINAL STEEL SUPPORTED ON TRANSVERSE STEEL &

IN ALL DETAILS THE TRANSVERSE STEEL IS SHOWN BELOW THE LONGITUDINAL STEEL. THIS IS THE

36.8

33.5

30.2

27.7

25.3

36.8

33.5

30.2

27.7

25.3

1/2 BAR DIA.W MINUS

1/2 BAR DIA.W MINUS

1/2 BAR DIA.W MINUS

1/2 BAR DIA.W MINUS

LONG AT 3'-0" CTRS.

#5 TIE BARS x 2'-6"

WILL BE REQUIRED FOR EACH 16 SQUARE FEET OF PAVEMENT.

CHAIR ASSEMBLIES SHALL BE OF A TYPE APPROVED BY THE ENGINEER AND AT LEAST ONE CHAIR

13.

CONTRACTION JOINTS IN THE SHOULDERS.THE CRCP SO THAT THE TIE BARS ARE NOT PLACED WITHIN 24" OF THE TRANSVERSECONT. REINF. CONC. PAVEMENT. THE JOINTS SHALL BE MARKED AND LOCATED PRIOR TO PLACINGSAW JOINTS FOR THE INSIDE AND OUTSIDE SHOULDERS WILL MATCH TRANSVERSELY ACROSS THE

(MIN.)24"

AT 3'-0" CTRS.

x 2'-6" LONG

NO. 5 TIE BARS

SAME SIZE AS LONGITUDINAL REINFORCING.

AS SHOWN IN PLAN VIEW. ALL BARS WILL BE

BETWEEN EVERY OTHER LONGITUDINAL BAR

PLACE A 6'-0" LONG REINFORCING BAR

0

R-16

CRCP1-4

PAVEMENT DETAILS

CONTINUOUSLY REINFORCED CONCRETE

(MIN.)24''

SY

CY

TO THE TEMPERATURE DROP.OF IT REMAINING THERE OVER 3 HOURS, SAWING THE JOINT MUST BE CARRIED OUT PRIOR DIFFERENTIAL OVER 20^ F, OR WILL MOVE THE AIR TEMPERATURE BELOW 40^ F WITH PROSPECTSIF A RAPID TEMPERATURE DROP IS EXPECTED, WHICH WILL CAUSE AN AIR TEMPERATURESAW CUTS SHOULD BE MADE AS SOON AS POSSIBLE, WITHOUT RAVELLING THE CUT JOINT EDGE.

SY

PER

LBS.

(%)

DES.

DATEDESCRIPTION

OKLAHOMA DEPARTMENT OF TRANSPORTATION

2019 SPECIFICATIONS

ROADWAY ENGINEER:

APPROVED BY

DATE:

STANDARD REVISIONS

ROADWAY DESIGN DIVISION STANDARD

5/27/20