PAINTING - IRON WORK

-

Upload

ansif-habib -

Category

Education

-

view

125 -

download

1

Transcript of PAINTING - IRON WORK

PAINTING

IRON WORK

BCMS

SEMINAR

Paint should be free from rust,grease,dust.

Wire brushes ,scrapers,etc are

equipment's used to remove all loose

scales, marks etc.

Water with caustic soda or lime is used to

remove grease .

The cleaned surface is provided with a

film of phosphoric acid.

The coats of paint then applied.

The paint suitable to iron and steel

surfaces should be selected for each

coat.

Precaution should be taken to avoid the

presence of brush marks on the final

painted surface.

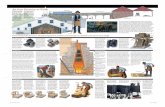

REPAINTING OLD IRONWORK

Old surface should be thoroughly

cleaned by the application of

soap-water

If grease is present it should be

removed by washing surface with

lime and water.

To remove old paint

the surface should

be burnt, usually by

blow lamp and then

old paint should be

scraped off or

dissolved and

removed by using

any paint solvent

GALVANIZED IRONWORK

It is a general rule not to paint the galvanized

ironwork until it has been exposed to weather

for a period of one year or so .

If it is necessary any one of the following two

solution is applied in the surface.

1. A solution containing .40N of copper

acetate to 1l of water.

2. A solution containing 0.13N each of muriatic

acid ,copper chloride , copper nitrate to a

litre of water .

The solution is taken in a glass vessel or

earthenware vessel.

This will prevent the precipitation of

copper salts.

When the solution is applied the surface is

turned black and after a period of about

12 hours, the coat of paint may be

applied on the surface.