Owner´s Manual - myHanse · 1 x highpressure pump CAT pump 1 Electric motor, protection class IP...

Transcript of Owner´s Manual - myHanse · 1 x highpressure pump CAT pump 1 Electric motor, protection class IP...

-

AQUAGIV SILVER-SERIE – Owner`s Manual Page 1 of 20

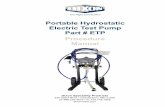

Owner´s Manual

AQUAGIV SILVER-SERIE Watermaker

27l-12/24V DC or 230V AC

40l-12/24V DC or 230V AC

75l-12/24 V DC or 230V AC

140l-230V AC

180l-230V AC

210l-230V AC

260l-230V AC

AQUAGIV is an international registrated trade mark

-

AQUAGIV SILVER-SERIE – Owner`s Manual Page 2 of 20

Introduction

Please read this owner´s manual carefully and make yourself familiar with all the components

of the watermaker.

The manual provided to you includes useful information about components of watermaker. It is

important and strongly advised that this information is read carefully before operation of the

watermaker.

Only by reading and understanding all the information on the manual, it can be ensured the

watermaker will operate safely and efficiently for a long time. The technical drawings, pictures

and details in the manual are guidelines for users.

-

AQUAGIV SILVER-SERIE – Owner`s Manual Page 3 of 20

Content

1. Introduction ........................................................................................................ 4

2. Technical Data .................................................................................................... 5

3. The reverse osmosis principle................................................................................ 6

4. Scope of components ........................................................................................... 7

5. Optionally accessories .......................................................................................... 8

6. Flow diagram ...................................................................................................... 9

7. Installation ....................................................................................................... 10

7.1 Seacock (not included in scope of delivery) ..................................................... 10 7.2 Sea strainer (not included in scope of delivery) ................................................ 10 7.3 Boost pump................................................................................................. 11 7.4 Prefilters ..................................................................................................... 11 7.5 Flush filter................................................................................................... 11 7.6 Watermaker ................................................................................................ 11 7.7 Membrane(s) ............................................................................................... 12 7.8 Electrical connections ................................................................................... 12

8. Operation ......................................................................................................... 13

8.1 Electric contol components ............................................................................ 14 8.2 First System Start ........................................................................................ 14 8.3 System Stop ............................................................................................... 14 8.4 Automated Flush .......................................................................................... 14 8.5 System Shut down ....................................................................................... 15 8.6 Membrane conservation ................................................................................ 15 8.7 Cleaning of the membrane(s) ........................................................................ 15 8.8 Flush interval .............................................................................................. 16

11. AQUAGIV Manufacturer´s Warranty ..................................................................... 19

12. Product registration ........................................................................................... 20

-

AQUAGIV PLATIN-Series modular – Owner`s Manual Page 4 of 20

1. Introduction

Thank you for choosing an AQUAGIV reverse osmosis watermaker. We trust that you will be

completely satisfied with our product.

AQUAGIV Watermakers are designed and manufactured to fulfill only the highest quality

standards and with components that have proven to withstand continuous duty in a harsh

marine environment.

The purpose of this manual is to allow you to become familiar with each component of your

AQUAGIV Watermaker. By understanding the function, importance and normal operation of

each part in the system, the operator can readily diagnose problems when they first develop.

Such problems are easily corrected and require minor adjustments. If left unattended, a small

problem in one component will affect the rest of the system and can lead to an expensive

repair. If you have any questions regarding the installation or operation of your watermaker

please contact us. We are happy to assist you.

AQUAGIV – watermakers

IRLI GmbH | Chiemseestr. 65 | 83233 Bernau

Tel. +49 8054 9999000 | Fax +49 8054 9999002

www.aquagiv-watermakers.com

http://www.aquagiv-watermakers.com

-

AQUAGIV PLATIN-Series modular – Owner`s Manual Page 5 of 20

2. Technical Data

Performance*:

Model Output

27l-12/24V DC 27 Litres/hour (7 Gall/hour)

40l-12/24V DC 40 Litres/hour (10.6 Gall/hour)

75l-24V DC, 230V AC 75 Litres/hour (20 Gall/hour)

140l-230V 140 Litres/hour (37 Gall/hour)

180l-230V 180 Litres/hour (48 Gall/hour)

210l-230V 210 Litres/hour (55 Gall/hour)

260l-230V 260 Litres/hour (69 Gall/hour)

* Reverse Osmosis performance varies with the feed water temperature and salinity. The rated performance is tested at 26°C / 80°F water temperature and 33g NaCl/ltr.

Product water quality: max. 1000 ppm TDS

Feedwater salinity: up to 50.000 ppm TDS ( NaCl )

Feedwater pressure: 0,1 – 1,0 Bar

Working pressure: 35 – 65 Bar

Feedwater temperature: 0.5°C - 45°C (32,0 – 113 ° Fahrenheit)

Energy consumption: 5 - 7 Amps./230V (80l – 210l)

Feedwater flow: 12-30 ltrs./Minute

-

AQUAGIV PLATIN-Series modular – Owner`s Manual Page 6 of 20

3. The reverse osmosis principle Reverse Osmosis (RO) systems, which are being used worldwide today, are one of the rapidly

growing technologies. Osmosis can be observed in nature, like vegetables absorbing the water

from the soil or kidneys distinguishing blood from urine. In the RO systems, fresh water is

gained by percolating minerals from the sea water getting through membranes with pinholes in

size of 1/1000 of micron, that is a molecular sieve, under high pressure (55-60 bars). Totally

dissolved solids (TDS) are thrown out of the system with a salty solution that can not get

through the membranes. The system is designed to reduce the salinity by 99%. The water

procuded on figure of 380 ppm in the Aegean Sea (salinity rate: 38000 ppm) is potable. The

water produced is disinfected from any microbe or viruses. According to World Health

Organization standards water with a TDS level of less than 700 ppm is drinkable. Tap waters in

many of theAegean Sea cost regions are higher than 1000 ppm.

Figure 1: Reverse osmosis membrane

-

AQUAGIV PLATIN-Series modular – Owner`s Manual Page 7 of 20

4. Scope of components 1. Prefilters

1 x 20 micron prefilter housing,

1 x 5micron prefilter housing

Prefilters mounted on the frame or at any other suitable position.

2. Watermaker in compact frame

1 x highpressure pump CAT pump

1 Electric motor, protection class IP 54, coupled to the high pressure pump

1 x electric control box for all pipes, sensors and valves

1 Flushing set, includes filter, electric flush walve

3. Membrane unit

Membrane(s) including mounting parts

Model Membrane(s) (diameter x length)

27l 1 x 2.5” x 21”

40l 2 x 2.5” x 21”

75l 2 x 2.5” x 21” or 1 x 2.5” x 40”

140l 2 x 2.5” x 40”

180l 3 x 2.5” x 40”

210l 4 x 2.5” x 40”

260l 5 x 2.5” x 40”

The membrane(s) can be mount either on the machine or any other appropriate place.

4. Hoses

2 metres reinforced hose ¾“, 19mm

3 metres PVC hose 10 mm

-

AQUAGIV PLATIN-Series modular – Owner`s Manual Page 8 of 20

5. Optionally accessories

Prefilter-Kit

10 Prefilters, 5 and/or 20 Micron

2 Charcoal filters (fresh water flush)

Cleaning/storage-Kit

1 x Alkaline cleaning compound

1 x Acid cleaning compound

1 x Storage compound

-

AQUAGIV PLATIN-Serie modular – Eignerhandbuch S. 9 � /20 �

6. Flow diagram

-

AQUAGIVSILVER-Series – Owner´s manual S. 10 � /20 �

7. Installation

7.1 Seacock (not included in scope of delivery)

For best results, we recommend the installation of an extra seacock (not included in the

standard scope of delivery) for your watermaker. Mount a suitable seacock including cut-off

valve close to the watermaker. Place the seacock as deep as possible before the boost pump.

Illustration: Seacock

Illustration: Seacock installation

7.2 Sea strainer (not included in scope of delivery)

Mount the sea strainer (not included in the standard scope of delivery) in a position easily to

reach in between the sea-cock and the boost pump. Connect the barbed fittings with the

reinforced 3/4” hose. Secure the hose with stainless steel hose clamps.

Illustration: example of a seastrainer (not included in scope of delivery)

Bow Stern

Water flow direction des Wassers Direction of

travel

-

AQUAGIVSILVER-Series – Owner´s manual S. 11 � /20 �

7.3 Boost pump

IN

Mount the boost pump below the waterline.

The pump has to be mounted in horizontal position.

The electrical installation should only be done by a professional electrician according to the

local regulations with regards to safety. Therefore electrical installation materials are not

supplied. It is essential to properly ground all components in contact with electricity.

Connect the boost pump with the PVC hose at the intake and the outtake side.

7.4 Prefilters

The prefilters are installed on the machine. They can be placed elsewhere. If so, follow the following steps: Assemble the prefilter(s) in an easily accessible place. Place the 20 Micron prefilter in the first cartridge and the 5 Micron filter in the second cartridge. Connect the prefilters to the boost pump at the intake side and to the high pressure pump at the outtake side.

7.5 Flush filter

The flush filter is installed on the machine. They can be placed elsewhere. If so, follow the following steps: Install the active carbon filter

housing at a serviceable location in between your freshwater system pump and the high

pressure pump. Use the delivered 10mms hose for the pipework. Connect the 2-way valve

cable to the control cabinet of the watermaker.

7.6 Watermaker

Place the watermaker at a deep, cool location. Connect the following hoses:

Seawater feed hose: Connect the delivered ¾” hose to the intake at the pump.

Seawater-discharge: Connect a 10mm John Guest Hose hose to reject water outlet.

A supplied connector can to used to connect it to a ½” standard-hose

Pump in, 3/4“ PVC hose connection Pump out, PVC hose connection ¾“ Out

-

AQUAGIVSILVER-Series – Owner´s manual S. 12 � /20 �

Product water outlet: Connect the product water outlet with your tank (10mms hose)

Flush intake: Connect your tank with the flush inlet at the high pressure pump (10mms hose)

7.7 Membrane(s)

The membrane housing(s) is (are) supplied pre-assembled backside of the watermaker rack.

Alternatively, the membranes can also be decreased and mounted at a suitable location.

The membrane is sealed within its housing by plugs at both ends. Inside is a small

amount of conservation liquid to keep the membrane moist and prevent bacterial growth.

The shelf life of the liquid, under best conditions, is one year. We recommend you install

and use your watermaker as soon as possible.

7.8 Electrical connections

Your system comes with all necessary cables which have been delivered connected as far

as possible. Further installation material and material for the sizing of the electrical

connections is not included. The electrical installation should only be done by a professional

electrician according to the local regulations with regards to safety. Therefore electrical

installation materials are not supplied. It is essential to properly ground all components in

contact with electricity.

15 Amp. Fuse has to be installed on site – this is not included in scope of delivery

Improper wiring extinguished the guarantee.

Raw water in

Brine oputlet | flush inlet | fresh water outlet (to tank)

-

AQUAGIVSILVER-Series – Owner´s manual S. 13 � /20 �

Connect all cables as follows:

- Connect the power supply cable to the power source.

- Connect the boost pump to the switchboard of the watermaker

Make sure, that the power supply is shut-off while installation of the electric connections.

8. Operation

The reverse osmosis membrane has a preservation solution, that may cause irritation of

the gastrointestinal tract. Therefore, the product water is allowed to be consumed earliest after

a half-hour running time.

Do not operate the system using contaminated feed water sources (oil, chlorine or other

chemicals).

Boost pump connection, marked with „B“ | power supply, marked with „E“

Prefilters | flow indictaor | pressure control | electric control panel | flush filter

-

AQUAGIVSILVER-Series – Owner´s manual S. 14 � /20 �

8.1 Electric contol components

Remote control unit can be connected by RS435 ethernet cable.

8.2 First System Start

- Open the seacock

- Make sure that the watermaker is connected to the power supply

- Push “Start” button and run the system without pressure (turn pressure knob clockwise).

Remove all air in the system.

- Never allow any leaks in your hose or tube connections

8.3 System Stop

- Push “Stop” button. The system will stop

- The “Flush” indication will start to BLINK and the automated flush will start after every use.

8.4 Automated Flush

The following steps must be followed, so that the automatic flush works:

- 230V Power supply must be switched ON

- Boats`s fresh water tank needs be filled with fresh water (ony flush cycle requires at

least 5 liters water)

- Boat`s pressure system needs tob e switched on

The flush cycle automatically starts after every product cycle and runs 4 minutes. During flush

sequence, the Flush indication lamp is flashing.

If the unit is not in use or during absence of the user, the flush cycle is repeated

Start | Stop | Flush

Power indication (light on when power available) Flow indication (feature will be available in Q3/2014) Pressure sensor (for landbased operation only) Salinity indication red: bad water quality – water overboard green: good water quality – water reaches tank

-

AQUAGIVSILVER-Series – Owner´s manual S. 15 � /20 �

once every 5 days fully automated. Make sure that the unit is connected to a 230V

Volt power supply and switched on.

Manual override:

The flush cycle can be started manually by pushing the FLUSH button.

The flush cycle can the stopped manually (when LED is flashing) by pushing the FLUSH button.

8.5 System Shut down

The following steps are to be considered for longer shutdown periods:

- Close the seacock (recommended after every use)

- Check the sea strainer

- Put the prefilters out of the cartridges and dry them

- Flush the watermaker extensive (use the manually flush modus)

We recommend a fresh water flush of the system after each operation. It prevents the

membrane from biological growth and prolongs the life and reliability of the entire plant. Your

Water Maker is equipped with an automatic flushing device.

8.6 Membrane conservation

If your watermaker is not operated for more than 10 days, the preservation of the

membrane(s) is recommended. This will preserve the membrane for longterm storage of up to

one year

- Flush the watermaker and remove prefilters and charcoal filters

- Close the seacock

- Mix 125 grams (1/2 of the capacity of AQUAGIV storage compound #3) into the Charcoal

filter housing.

- Start the manual flush by pushing the “Flush” button

- Make sure that the flush-water does not contain any chlorine.

Now the watermaker is conserved up to 10 moth. When temperatures may freeze during

absence, add an anti-freeze. Call Aquagiv watermakers for further information.

8.7 Cleaning of the membrane(s)

Your watermaker must be chemically cleaned when the product water output drops by

15% of the specified amount. The frequency of this occurring will vary greatly depending upon

feed water. Fouling of the membrane will naturally occur during normal usage of the

-

AQUAGIVSILVER-Series – Owner´s manual S. 16 � /20 �

watermaker. Increased amounts of fouling without proper cleaning of the membrane will

reduce the performance of your water maker. A drop in production of approximately 10% is

normal and expected during the first year.

The use of chemicals or cleaning methods other than those outlined in the

cleaning instructions will void theAQUAGIV warranty. Nonionic surfactants for membrane

cleaning or other chemicals not approved in writing by AQUAGIV will void the

element warranty.

Cleaning chemical #1 is an alkaline detergent. See warning label on side of the

container and observe all safety precautions on label.

Cleaning chemical #2 is an acid, a mineral scale remover. See warning label on side of

container and observe all safety precautions on label.

Do not mix different cleaning chemicals together. Do not use different cleaning

chemicals together at the same time. Mix the cleaning chemicals separately and use them

separately.

- Close the seacock

- Disconnect the intake and reject water hose and lead them in the plastic container. Re-

circulate the solution without pressure for up to 60 min. There will be no flow at the fresh

water outlet. For safety reasons we do not recommend to install a 3 way recirculation

valve.

- Mix 100 grams (1/3 of the capacity of AQUAGIV storage compound) of compound #1 or #2

into ten litres of water. Make sure that the water does not contain any chlorine. Use twice

of the total amount for the 180 litres and 210 litres watermakers.

- Start the manually flush procedure

- Repeat the flush procedure up to six times.

- Reconnect the watermaker to the connections and flush the system with fresh water

8.8 Flush interval

Flush Interval: If automated flush is activated (Fresh Water Flush light = steady on) the

membrane(s) are flushed automatically every 5 days. Make sure that you always have enough

fresh water in your tank.

-

AQUAGIVSILVER-Series – Owner´s manual S. 17 � /20 �

9. High pressure pump preventive service

Step Daily 50 hrs. 3000 hrs or

1 x year

If needed

Oil level/quality check X

Leakings X

Leaks at pumphead X

Regular oilchange X

Seal-replacement X

Valves-replacement X

Overheating X

unusual running noise X

Oil

Before use, check if the crankcase is filled with oil.

If not, fill the crankcase with engine oil HD-SAE 30 HD or multigrade-oil 15 W 40.

Remove the red hexagon cap (1) and fill the oil until the mid-sight glass (2) respectively until

the oil reaches the middle of the dipstick (3).

You will find the correct amount of oil on the first page of the pump`s instruction manual.

Remove the oil drain plug (4) and drain the oil for an oil change.

Fill with new oil as described above then.

The oil must be disposed properly.

Caution! Change oil only when electricity of the pump is cut-off (de-energize unit)!

4 – bottom of pump. To remove the oil, lift the watermaker

-

AQUAGIVSILVER-Series – Owner´s manual S. 18 � /20 �

10. Maintenance

Part Service Frequency

Sea strainer Clean the housing and the

inlet.

If clogged

Prefilters Cleaning of the prefilter

housings

1 x per year

Prefilters Change filter elements If becoming green.

Freshwater flush Change filter element After 6 month of use

High pressure pump Change o-rings and seals when leaking

High pressure pump Oil change Referring to pressure pump

Service manual (Pos. 9)

ro membrane Flush with fresh water After every production period

or after 5 days.

ro membrane Cleaning of the mambrane If product water output

decreases 15%-20%

Pipes, hoses Change of hoses and pipe If visible signs of wear or

leaks occur

-

AQUAGIVSILVER-Series – Owner´s manual S. 19 � /20 �

11. AQUAGIV Manufacturer´s Warranty

Standard warranty

Subject to the terms, conditions and limitations in this limited warranty (“warranty”), AQUAGIV new products are warranted to be free from defects in materials and workmanship for the following period (the “Warranty Period”):

24 months from Date of first purchase

“Date of first purchase” means the date on which the product was purchased by the first retail customer or where the product was installed and/or commissioned on a new vessel by a AQUAGIV certified original equipment manufacturer, the date on which the vessel was purchased by the first retail customer. For products installed by a AQUAGIV certified installer on a vessel already in the customer’s possession, the Warranty Period will begin on the date of product installation or commissioning.

AQUAGIV will (at its sole option) repair or replace any product which is (i) proven to be defective in materials or workmanship; and (ii) returned to AQUAGIV (or its agent) during the Warranty Period in accordance with this warranty. Replacement products may be new or refurbished. Such repair or replacement will be the sole remedy by AQUAGIV under this warranty. Any repaired or replacement product will be warranted in accordance with this warranty, for the unexpired balance of the Warranty Period on the original product.

Obtaining standard warranty service

To qualify for standard warranty service, the product must be returned to AQUAGIV or a AQUAGIV certified service agent within: (i) the Warranty Period; and (ii) 30 days of the alleged product failure. The product must be securely packaged and sent pre-paid, accompanied by:

• an original valid proof of purchase confirming the date of purchase and product supplier or a stamped warranty card completed by the product supplier; and • the product serial number.

It is recommended that the customer obtains postal insurance for products that are returned under this warranty. AQUAGIV will not be liable for loss or damage to products in transit to AQUAGIV.

Warranty limitations & exclusions

In addition to any other limitations and exclusions in this warranty, AQUAGIV is not responsible for, and this warranty does not cover:

• failure or defects due to accident, abuse or misuse, shipping damage, alterations, corrosion, incorrect and/or non-authorized service or improper installation (whether or not by a AQUAGIV certified service agent) or failure to comply with the Owner’s Handbook;

• products where the serial number has been altered, mutilated or removed; • costs associated with routine system checkouts, software revisions, alignment/calibration, sea trials or

commissioning unless required by replacement of parts in the area being aligned; • repair or replacement of consumable items including (without limitation) fuses, filters, membranes, o-rings. A

complete list of the consumable items relating to each product can be found in the Owner’s Handbook. • costs associated with overtime or premium labor work outside normal working hours; • differences in material, coloring or size that may exist between actual products and the pictures or descriptions of

such products in product advertising, literature or on the Internet; • replacement of missing components from the package of any product purchased through an Internet online auction

site; • fees associated with hauling, shipping or towing a vessel to a AQUAGIV certified service agent; • taxi fares, launch or docking fees, aircraft or vehicle rental, meals, customs, shipping, communication charges; • other travel or transport costs

-

AQUAGIVSILVER-Series – Owner´s manual S. 20 � /20 �

12. Product registration Personel Data Salutation ___________________________________________________ Prename* ___________________________________________________ Name* ___________________________________________________ Company ___________________________________________________ Adress* ___________________________________________________ Zip, City* ___________________________________________________ Country* ___________________________________________________ Tel ___________________________________________________ Fax ___________________________________________________ email ___________________________________________________ Boat ___________________________________________________ ( ) Sailboat ( ) Motorboat lenght ____________ Product data Model* ___________________________________________________ Serial number* ___________________________________________________ Date of purchase* ___________________________________________________ Dealer ___________________________________________________ * Mandatory field

Fax to AQUAGIV: +49 (0)8054 / 9999002