Pump - Electric Manual

Transcript of Pump - Electric Manual

-

8/2/2019 Pump - Electric Manual

1/18

Website: www.TBEI.com

E-mail: [email protected]

Phone: 1-800-869-9162 Rugby

1-800-255-4345 Heil

1-800-533-0494 CrysteelTRUCK BODIES & EQUIPMENT INTERNATIONAL, Inc.

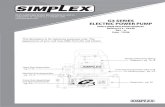

036226ELECTRIC MONARCH PUMP

INSTALLATION AND

OPERATION MANUALTo Be Filled In By Installer

Pump Model #:

Pump Serial #:

Hoist Model #:

In Service Date:

Dealer:

Address:

City, State ZIP:

Dealer Phone Number:

Use this manual ONLY if installing or operating a Monarch electric pump on a TBEI or Rugby hoist. This

manual should be kept in the glove compartment of the truck, or if installed on a trailer, the glovecompartment of the truck pulling the trailer or any weatherproof compartment on the trailer for reference

when needed.

Original Revision: June 9, 2006

Current Revision: G October 23, 2007

http://www.tbei.com/http://www.tbei.com/ -

8/2/2019 Pump - Electric Manual

2/18

Electric Monarch Pump Installation and Operation Manual

Stock No. 036226

Page 2 of 18

"INTRODUCTION"

This manual contains information necessary for the proper installation and operation of an electric

power unit. This manual applies only to a Monarch unit supplied from TBEI or Rugby. If you have a

different power unit, refer to that manufacturers directions. With proper installation, use, and regular

maintenance, this power unit will give many years of trouble free service.

"WARNINGS"

WARNING: Installing or operating this hoist without first understanding the proper installation and

operation procedures can lead to serious injury or death. Always read and understandfully all installation and operation manuals before installing or operating this

equipment.

WARNING: Being under a raised body can result in serious injury or death should the body

unexpectedly descend. Never position yourself or allow others to position themselvesunder a loaded body. Always prop the unloaded body up using the body prop or body

props supplied. Remember body props are to be used only on an unloaded body.When two props are provided, both props must be used.

WARNING: Malfunctioning equipment can cause property damage, injury or death. Always have

faulty equipment repaired before continuing its use. Consult the manufacturer ifrequired.

WARNING: Overloading of a truck or trailer can cause vehicle or trailer component damage or an

accident which may cause injury or death. Never exceed the gross vehicle weight

(GVW) or the gross axle weight (GAW) rating of your vehicle or trailer.

WARNING: The inadvertent shorting of the vehicle's electrical supply can cause a fire or equipment

damage that could lead to injury or death. Always disconnect the vehicle battery priorto installing, servicing, or repairing the power unit.

WARNING: Damage to brake lines during equipment installation, or installing bolts or equipment in

such a way that the line will rub and become damaged can lead to brake failure whichcan cause an accident and can lead to severe injury or death. Always take adequatesteps to prevent brake line damage during installation and isolate brake lines from

installed equipment.

-

8/2/2019 Pump - Electric Manual

3/18

Electric Monarch Pump Installation and Operation Manual

Stock No. 036226

Page 3 of 18

WARNING: Connecting the hoist to a hydraulic system with more pressure (psi) or flow (gpm) than

is recommended by the hoist manufacturer can cause the hoist to fail during thedumping of a load. This could lead to damage, serious injury, or death. Be sure you

have the correct pressure and flow. Consult the manufacturer if you do not know the

recommended pressure and flow.

WARNING: Adjusting the hydraulic pressure to more than the recommended setting may cause the

hoist to fail during the dumping of a load. This could cause damage, serious injury, ordeath. Never adjust the pressure on your own. Consult the manufacturer if the

hydraulic pressure is in question. Have only a qualified person set the hydraulic

pressure. Never adjust the pressure to more than the recommended amount.

WARNING: Fluid under pressure can pierce the skin and enter bloodstream, causing serious injury

or death. Always wear eye protection and protective clothing when working aroundhydraulic systems.

-

8/2/2019 Pump - Electric Manual

4/18

Electric Monarch Pump Installation and Operation Manual

Stock No. 036226

Page 4 of 18

"INSTALLATION INSTRUCTIONS"

POWER UNIT ATTACHMENTThe power unit should be mounted in a protected area near the hoist. For longevity of the unit and

related components, do not mount near exhaust system components or in the path of road splash from

the vehicles tires.

NOTE: Mount the unit horizontally so that the reservoir is level for full use of the reservoir

capacity.

WARNING: Check for potential clearance issues with vehicle brake lines, air lines, wire harnesses,

etc. before determining the power units location. Avoid damage to lines or installing

components that could rub against lines and cause system failures. Such failures couldlead to property damage, serious injury or death.

Securely attach the pump to the frame using two 3/8-16 x 1 flange bolts in the front, and one 3/8-16x 1 flange bolt at the back of the tank. Tighten to 33 ft.-lb. torque.

HOSE CONNECTIONS

NOTE: This manual contains descriptions of hydraulic fittings. In describing these fittings,

special designations are used. These designations and their meanings are as follows:

SPECIAL DESIGNATION MEANING

MB Male O-Ring Boss

FB Female O-Ring Boss

MJ Male JICFJ Female JIC

FJX Female JIC Swivel

FJX90 Female JIC Swivel ElbowMP Male Pipe Thread (NPT)

Fitting Designation Thread Size

4MB, 4FB, 4MJ, or 4FJ 7/16-20

6MB, 6FB, 6MJ, or 6FJ 9/16-18

8MB, 8FB, 8MJ, or 8FJ 3/4-16

4MP 1/4 NPT

12MP 3/4 NPT

-

8/2/2019 Pump - Electric Manual

5/18

Electric Monarch Pump Installation and Operation Manual

Stock No. 036226

Page 5 of 18

The type of fittings that are included will vary, depending on the model of hoist being installed. Referto Figures 1a thru 1f, depending on the type of hoist and pump model that is being installed.

For all of the units, a restricted fitting is supplied. This fitting reduces the speed at which the hoistcloses, to prevent damage to the truck or trailer frame. This fitting must be installed in the base end of

the hoist cylinder.

NOTE: All connections rely on O-ring or flare/face sealing methods. Therefore, no thread sealant or

tape of any kind is required to seal the joints.

Install all fittings and hoses. Tighten all of the connections, except the connection between the base

end port and the hose.

Leave the connection between the base end port and the hose loose at this time.

-

8/2/2019 Pump - Electric Manual

6/18

Electric Monarch Pump Installation and Operation Manual

Stock No. 036226

Page 6 of 18

HOSES

The following charts are included to aid in the identification of hoses. Please note that several

different lengths of hoses are available for each type.

Hose A

1/4" 6FJX-4FJX90

Part # LengthStandard Supply

(Base end of cylinder)

008238 5 LR-3510

008239 6

008240 8

008332 9

Hose B

1/4" 6FJX-6FJX

Part # LengthStandard Supply

(Base end of cylinder)

Standard Return

(Rod end of cylinder)

008172 4 HR-520

008173 5 LR-416/165/25, HR-540/550 LR-3510, HR-520

008174 6 LR-416/165/25

008176 8 HR-540/550

008320 9

008331 10

Hose C

3/8" 6FJX-6FJX

Standard Supply

(Base end of cylinder)

Standard ReturnPart # Length

(Rod end of cylinder)

008178 4

008179 5 LR-26/623/28

008180 6

008181 7 LR-26/623/28

008182 8

008325 9

008330 10

-

8/2/2019 Pump - Electric Manual

7/18

Electric Monarch Pump Installation and Operation Manual

Stock No. 036226

Page 7 of 18

FIGURE 1a

3.5 Cylinder

SINGLE-ACTING

-

8/2/2019 Pump - Electric Manual

8/18

Electric Monarch Pump Installation and Operation Manual

Stock No. 036226

Page 8 of 18

FIGURE 1b

4 Cylinder5 Cylinder

SINGLE-ACTING

-

8/2/2019 Pump - Electric Manual

9/18

Electric Monarch Pump Installation and Operation Manual

Stock No. 036226

Page 9 of 18

FIGURE 1c

6 Cylinder

SINGLE-ACTING

-

8/2/2019 Pump - Electric Manual

10/18

Electric Monarch Pump Installation and Operation Manual

Stock No. 036226

Page 10 of 18

FIGURE 1d

3.5 Cylinder

DOUBLE-ACTING

-

8/2/2019 Pump - Electric Manual

11/18

Electric Monarch Pump Installation and Operation Manual

Stock No. 036226

Page 11 of 18

FIGURE 1e

4 Cylinder5 Cylinder

DOUBLE-ACTING

-

8/2/2019 Pump - Electric Manual

12/18

Electric Monarch Pump Installation and Operation Manual

Stock No. 036226

Page 12 of 18

FIGURE 1f

6 Cylinder

DOUBLE-ACTING

-

8/2/2019 Pump - Electric Manual

13/18

Electric Monarch Pump Installation and Operation Manual

Stock No. 036226

Page 13 of 18

INSTALL ELECTRICAL

1. Route a copper American Wire Gage (AWG) #00 cable from the battery to the power unit.

Connect one end to the negative battery terminal. Connect the other end to the power units aluminumvalve block with a 5/16-18 x 3/4 hex cap screw as shown in Fig. 3.

CAUTION: The high current demands of the power unit require a direct connection between the

negative post of the battery and the power unit. Never rely on the vehicles groundingcircuit, which could lead to property damage or reduced hoist lifting capacity during

peak loads.

NOTE: Avoid routing locations where power cables my rub against any sharp edges of thevehicle, get pinched or be exposed to excessive heat. Install approved sheathing over

each cable in critical areas.

2. Route a copper AWG #00 cable from the battery to the power unit. At the power unit, insert the

supplied rubber terminal boot over the end of the cable and the black wire as shown in Fig. 2. Fasten

the cable end and black wire to Point A on the solenoid start switch. Tighten to 35 in.-lb. torque.Snap rubber terminal boot over stud to complete connection. Make sure all connections on solenoid

start switch are secure. Do not connect the cable to the battery at this time to prevent a dry start.

WARNING: Never tighten battery cable stud, marked Point A, to more than 35 in.-lb. torque andnever tighten control stud, marked Point B, to more than 15 in.-lb. torque. Exceedingtorque rating for either stud can cause unit to malfunction, which could lead to property

damage, serious injury or death.

3. (Double-Acting or Single-Acting if equipped) Place the solenoid cover over the solenoid andsecure in place with the tie strap provided.

4. The hoist should only be used with the operator in a safe location. Locate the hoist control stationin a safe location.

-

8/2/2019 Pump - Electric Manual

14/18

Electric Monarch Pump Installation and Operation Manual

Stock No. 036226

Page 14 of 18

FIGURES 2a & 3a

SINGLE-ACTING SCHEMATICS

-

8/2/2019 Pump - Electric Manual

15/18

Electric Monarch Pump Installation and Operation Manual

Stock No. 036226

Page 15 of 18

FIGURES 2b & 3b

DOUBLE-ACTING SCHEMATICS

-

8/2/2019 Pump - Electric Manual

16/18

Electric Monarch Pump Installation and Operation Manual

Stock No. 036226

Page 16 of 18

FILL & PRIME

Fill the reservoir with automatic transmission fluid (ATF), such as Dexron II Type A. Secure the

units power cable to the positive battery terminal to complete the electrical installation and allowoperation of the unit. Place a drip pan or other suitable container below loose hose fitting at base endof cylinder. Press UP pushbutton on control station to begin priming the unit. Once oil begins

flowing steadily from loose fitting, release pushbutton. Tighten fitting. Operate unit several times

starting with short cylinder strokes and increasing length with each successive stroke. Recheck oillevel often and add as necessary to keep pump from picking up air. After hoist has been fully raised

and lowered repeatedly to purge air from cylinder, lower hoist and check oil level in reservoir. With

the hoist down, the reservoir should be full within 2 of the top. DO NOT OVERFILL! Install

filler/breather cap in reservoir fill hole.

-

8/2/2019 Pump - Electric Manual

17/18

Electric Monarch Pump Installation and Operation Manual

Stock No. 036226

Page 17 of 18

OPERATION INSTRUCTIONS

WARNING: Being under or near a raised body can result in injury or death should the body

unexpectedly descend or tip. Hoist must be activated with operator in control at a safelocation. No one must be allowed to enter the area under a raised body while the hoistis in operation.

WARNING: Being under a raised body can result in serious injury or death should the bodyunexpectedly descend. Never position yourself or allow others to position themselves

under a loaded body. Always prop the unloaded body up using the body prop or body

props supplied. Remember body props are to be used only on an unloaded body.When two props are provided, both props must be used.

DANGER: 1. Stay out from under body when hoist is operating.

2. During dumping operations, no one must be allowed to stand in or move through thearea where the body and hoist operate or into an area where an upset load might fall.

3. Controls must be in a safe location and operator must remain at controls during the

dumping operation. Controls must be located in a location where it is not possible to beunder body during dumping operation.

4. Never leave body raised or partly raised while the truck or trailer is unattended or

while performing maintenance or service under body, unless body is braced to preventaccidental lowering.

5. Do not attempt to raise a loaded body when the truck or trailer is on un-level ground.6. Never jerk or shock a raised body to loosen a stuck load.

WARNING: Freeing a stuck load during dumping, with the body raised, by jerking or shocking thetrailer, may cause damage to the truck or trailer, serious injury or death. Never drive

forward or rearward and stop quickly with the load up or otherwise shock the load. If a

load is stuck in the body, lower the body, then free the load.

WARNING: Attempting to dump a load on un-level ground may cause the truck or trailer to over

turn, and can result in damage, serious injury or death. Always dump the load on

ground that is level front to rear as well as level side to side.

WARNING: Overloading a hoist can cause component damage or an accident which may cause

injury or death. Never exceed the hoists rated lift capacity.

WARNING: Damaged or malfunctioning equipment may cause injury or death. Repair or replace

any damaged or malfunctioning equipment before continuing its use.

NOTE: Always use clean automatic transmission fluid (ATF) in the power unit. Do not mix

types. Check oil level often and add as needed to prevent unit from pumping air.

Change fluid annually to remove condensation and entrapped debris.

-

8/2/2019 Pump - Electric Manual

18/18

Electric Monarch Pump Installation and Operation Manual

Stock No. 036226

Page 18 of 18

2006, 2007 TBEI

NOTE: Grease the hoist at regular intervals, at least every time the vehicle is serviced. See

Hoist Owners Manual for specific details and locations.

SINGLE-ACTING

Raise the hoist by pressing and holding the UP pushbutton on the control station. This activates thepower unit and directs oil to the base end of the hoist cylinder. Releasing the pushbutton will stop

raising the hoist and it will hold its position.

NOTE: The power unit is equipped with a factory-set hydraulic relief valve that will bypass at3200 PSI when the hoist reaches a fully raised position or whenever the load being

lifted exceeds the hoist capacity. Care should be taken not to let the pump bypass for

long periods of time, as this will put stress on the whole hydraulic and electrical system.To stop the pump from bypassing, release the UP button on the control station.

Lower the hoist by pressing and holding the DOWN pushbutton on the control station. Thisactivates the solenoid valve and directs oil from the cylinder back to the power units reservoir.

Releasing the pushbutton will stop lowering the hoist and it will hold its position.

DOUBLE-ACTING

Raise the hoist by pressing and holding the UP pushbutton on the control station. This activates thepower unit and directs oil to the base end of the hoist cylinder. Releasing the pushbutton will stop

raising the hoist and it will hold its position.

NOTE: The power unit is equipped with a factory-set hydraulic relief valve that will bypass at3200 PSI when the hoist reaches a fully raised position or whenever the load being

lifted exceeds the hoist capacity. Care should be taken not to let the pump bypass for

long periods of time, as this will put stress on the whole hydraulic and electrical system.To stop the pump from bypassing, release the UP button on the control station.

Lower the hoist by pressing and holding the DOWN pushbutton on the control station. This will

activate the pump and start the hoist down. Releasing the pushbutton will stop lowering the hoist andit will hold its position.

NOTE: When the hoist reaches its DOWN limit, the pump will bypass. Care should be

taken not to let the pump bypass for long periods of time, as this will put stress on the

whole hydraulic and electrical system. To stop the pump from bypassing, release the

DOWN button on the control station.

S:\acaddwg\MANUALS\P65\036226g doc