OWNER’S MANUAL - Colby College Compass/Yamaha Motor.pdf · E Thank you for choosing a Yamaha...

Transcript of OWNER’S MANUAL - Colby College Compass/Yamaha Motor.pdf · E Thank you for choosing a Yamaha...

-

F50A/T50A

LIT-18626-04-72

F50AT50A

OWNERS MANUAL

U.S.A.Edition

62Y-9-18 \ 01.5.9 10:00 AM y [ W 1 (2,1)

-

62Y-9-18 \ 01.5.9 10:00 AM y [ W 2 (1,1)

-

E

Thank you for choosing a Yamaha out-board motor. This Owners manual con-tains information needed for proper oper-ation, maintenance and care. A thoroughunderstanding of these simple instruc-tions will help you obtain maximumenjoyment from your new Yamaha. If youhave any question about the operation ormaintenance of your outboard motor,please consult a Yamaha dealer.

In this Owners Manual particularlyimportant information is distinguished inthe following ways.

QThe Safety Alert Symbol meansATTENTION! BECOME ALERT!YOUR SAFETY IS INVOLVED!

wFailure to follow WARNING instructionscould result in severe injury or death tothe machine operator, a bystander, or aperson inspecting or repairing the out-board motor.

cCA CAUTION indicates special precautionsthat must be taken to avoid damage tothe outboard motor.

NOTE:

A NOTE provides key information to makeprocedures easier or clearer.

* Yamaha continually seeks advance-ments in product design and quality.Therefore, while this manual containsthe most current product informationavailable at the time of printing, theremay be minor discrepancies betweenyour machine and this manual. If thereis any question concerning this manual,please consult your Yamaha dealer.

NOTE:

The F50TR, T50TR and their standardaccessories are used as a base for theexplanations and illustrations in this man-ual. Therefore, some items may not applyto every model.

EMU01449

TO THE OWNER

EMU01446

F50A/T50AOWNER'S MANUAL

2001 by Yamaha Motor Corporation, USA 1st Edition, April 2001

All rights reserved. Any reprinting or unauthorized use without the written permission of Yamaha Motor Corporation, USA

is expressly prohibited.Printed in Japan

P/N LIT-18626-04-72

62Y-9-18-1 5/16/01 10:18 AM Page 1

-

62Y-9-18-1 5/16/01 10:18 AM Page 2

-

E

GENERAL INFORMATION

BASIC COMPONENTS

OPERATION

MAINTENANCE

TROUBLE RECOVERY

INDEX

READ THIS OWNERS MANUAL CAREFULLYBEFORE OPERATING YOUR OUTBOARD MOTOR.

1

2

3

4

5

6

EMA20010

CONTENTS

62Y-9-18-1 5/16/01 10:19 AM Page 3

-

62Y-9-18-1 5/16/01 10:19 AM Page 4

-

E

2

3

4

5

6

EMB00010

Chapter 1

GENERAL INFORMATION

IDENTIFICATION NUMBERS RECORD ..1-1Outboard motor serial number...........1-1Key number...........................................1-1

EMISSION CONTROL INFORMATION...1-2

SAFETY INFORMATION..........................1-4

IMPORTANT LABELS ..............................1-6

BASIC BOATING RULES .........................1-7

FUELING INSTRUCTIONS.....................1-11Gasoline (Petrol).................................1-11

ENGINE OIL ............................................1-13

BATTERY REQUIREMENT ....................1-14

PROPELLER SELECTION .......................1-14

START-IN-GEAR PROTECTION ............1-16

1

62Y-9-18-1 5/16/01 10:19 AM Page 5

-

E

1-1

EMU00005

IDENTIFICATION NUMBERSRECORD

EMU00007

OUTBOARD MOTOR SERIALNUMBER

The outboard motor serial number isstamped on the label attached to the portside of the clamp-bracket.Record your outboard motor serial num-ber in the spaces provided to assist you inordering spare parts from your Yamahadealer or for reference in case your out-board motor is stolen.

1 Outboard motor serial number

EMU00008

KEY NUMBER

If a main key switch is equipped with themotor, the key identification number isstamped on your key as shown in theillustration. Record this number in thespace provided for reference in case youneed a new key.

1 Key number

1

401012

904011*

123

YAMAHAq

YAMAHA MOTOR CO., LTD.MADE IN JAPANPAYS D'ORIGINE JAPON

62Y-9-18-1 5/16/01 10:19 AM Page 6

-

E

1-2

******

q

w

EMU01385

EMISSION CONTROLINFORMATION

EMU01444

NORTH AMERICAN MODELSThis engine conforms to U.S. Environ-mental Protection Agency (EPA) regula-tions for marine SI engines. See the labelaffixed to your engine for details.

Approval label of Emission control certificateThis label is attached to the bottom cowl-ing.

1 Emission control information label

New Technology ; (4-stroke/HPDI) EM

Manufactured date labelThis label is attached to the clamp brack-et.

2 Manufactured date label

EMISSION CONTROL INFORMATIONENGINE FAMILY : THIS ENGINE CONFORMS TO 2001 U.S. EPA REGULATIONS FOR MARINE SI ENGINES.THIS ENGINE CONFORMS TO 2001 CALIFORNIA EMISSION REGULATIONS FOR SI MARINE ENGINES.REFER TO THE OWNERS MANUAL FOR MAINTENANCE SPECIFICATIONS AND ADJUSTMENTS.

FELs :SPARK PLUG :DISPLACEMENT :ADVERTISED POWER :

IDLE SPEED :SPARK PLUG GAP (mm) :FUEL : GASOLINEVALVE LASH (mm) : IN EX

cmkw

g/kw-hr rpm IN NEUTRAL

3

EM

Manufactured:

62Y-9-18-1 5/16/01 10:19 AM Page 7

-

1-3

E

EMU01389

STAR LABELSYour outboard motor is labeled with aCalifornia Air Resources Board (CARB)star label. See below for a description ofyour particular label.

1 Star label

One Star - Low EmissionThe one-star label identifies engines thatmeet the Air Resources Boards 2001exhaust emission standards. Enginesmeeting these standards have 75% loweremissions than conventional carburetedtwo-stroke engines. These engines areequivalent to the U.S. EPAs 2006 stan-dards for marine engines.

Two Stars - Very Low EmissionThe two-star label identifies engines thatmeet the Air Resources Boards 2004exhaust emission standards. Enginesmeeting these standards have 20% loweremissions than One Star-Low-Emissionengines.

Three Stars - Ultra Low EmissionThe three-star label identifies engines thatmeet the Air Resources Boards 2008exhaust emission standards. Enginesmeeting these standards have 65% loweremissions than One Star-Low-Emissionengines.

000957

q

62Y-9-18-1 5/16/01 10:19 AM Page 8

-

1-4

E

8 This product emits exhaust gases whichcontain carbon monoxide, a colorless,odorless gas which may cause braindamage or death when inhaled. Symp-toms include nausea, dizziness, anddrowsiness. Keep cockpit and cabinareas well ventilated. Avoid blockingexhaust outlets.8 Check throttle, shift, and steering for

proper operation before starting theengine.8 Attach the engine stop switch lanyard

to a secure place on your clothing, oryour arm or leg while operating. If youaccidentally leave the helm, the lanyardwill pull from the switch, stopping theengine.8 Know the marine laws and regulations

where you will be boating - and obeythem. Refer to the RULES OF THEROAD section for basic boating rules.8 Stay informed about the weather.

Check weather forecasts before boating.Avoid boating in hazardous weather.8 Tell someone where you are going:

leave a Float Plan with a responsibleperson. Be sure to cancel the Float Planwhen you return.8 Use common sense and good judgment

when boating. Know your abilities, andbe sure you understand how your boathandles under the different boatingconditions you may encounter. Operatewithin your limits, and the limits of yourboat. Always operate at safe speeds,and keep a careful watch for obstaclesand other traffic.8 Always watch carefully for swimmers

during the engine operation.8 Stay away from swimming areas.

EMU00917

SAFETYINFORMATION

8 Before mounting or operating the out-board motor, read this entire manual.Reading it should give you an under-standing of the motor and its operation.8 Before operating the boat, read any

owners or operators manuals suppliedwith it and all labels. Be sure you under-stand each item before operating.8 Do not overpower the boat with this

outboard motor. Overpowering theboat could result in loss of control. Therated power of the outboard should beequal to or less than the rated horse-power capacity of the boat. If the ratedhorsepower capacity of the boat isunknown, consult the dealer or boatmanufacturer.8 Do not modify the outboard. Modifica-

tions could make the motor unfit orunsafe to use.8 Never operate after drinking alcohol or

taking drugs. About 50% of all boatingfatalities involve intoxication.8 Have an approved personal flotation

device (PFD) on board for every occu-pant. It is a good idea to wear a PFDwhenever boating. At a minimum, chil-dren and non-swimmers should alwayswear PFDs, and everyone should wearPFDs when there are potentially haz-ardous boating conditions.8 Gasoline is highly flammable, and its

vapors are flammable and explosive.Handle and store gasoline carefully.Make sure there are no gas fumes orleaking fuel before starting the engine.

Q

62Y-9-18-1 5/16/01 10:19 AM Page 9

-

1-5

E

8When a swimmer is in the water nearyou shift into neutral and shut off theengine.8 Be informed about boating safety. Addi-

tional publications and information canbe obtained from many organizations,including the following:

United States Coast Guard

Consumer Affairs Staff (G-BC)Office of Boating, Public, and ConsumerAffairsU.S. Coast Guard HeadquartersWashington, D.C. 20593-0001Boating Safety Hotline: 1-800-368-5647

National Marine Manufacturers

Association (NMMA)

401 N. Michigan Ave.Chicago, Il 60611

Marine Retailers Association of America

155 N. Michigan Ave.Chicago, Il 60601

62Y-9-18-1 5/16/01 10:19 AM Page 10

-

1-6

E

EMB30011

IMPORTANT LABELS

WARNING LABELS1

CAUTION LABELS2

202011**

q

w

WARNINGBe sure shift control is in neutral before starting engine. (except 2HP)Do not touch or remove electrical parts when starting or during operation.Keep hands,hair,and clothes away from flywheel and other rotating parts while engine is running.

6A1-83625-41

CAUTION

62Y-13444-40

Transport and store the engine only as shown. Otherwise, engine damage could result from leaking oil.

62Y-9-18-1 5/16/01 10:19 AM Page 11

-

1-7

E

EMB40010*

BASIC BOATING RULES(Rules of the road)

Just as there are rules which apply whenyou are driving on streets and high ways,there are waterway rules which applywhen you are driving your boat. Theserules are used internationally, and arealso enforced by the United States CoastGuard and local agencies. You should beaware of these rules, and follow themwhenever you encounter another vesselon the water.

Several sets of rules prevail according togeographic location, but are all basicallythe same as the International Rules of theRoad. The rules presented here in yourOwners Manual are condensed, and havebeen provided for your convenience only.Consult your local U.S. Coast Guard Aux-iliary or Department of Motor Vehicles fora complete set of rules governing thewaters in which you will be using yourboat.

STEERING AND SAILING RULES ANDSOUND SIGNALSWhenever two vessels on the water meetone another, one vessel has the right-of-way; it is called the stand-on vessel.The vessel which does not have the right-of-way is called the give-way or bur-dened vessel. These rules determinewhich vessel has the right-of-way, andwhat each vessel should do.

Stand-on vesselThe vessel with the right-of-way has theduty to continue its course and speed,except to avoid an immediate collision.When you maintain your direction andspeed, the other vessel will be able todetermine how best to avoid you.

Give-way vesselThe vessel which does not have the right-of-way has the duty to take positive andtimely action to stay out of the way of theStand-On vessel. Normally, you shouldnot cross in front of the vessel with theright-of-way. You should slow down orchange directions briefly and pass behindthe other vessel. You should always movein such a way that the operator of theother vessel can see what you are doing.

The general prudential ruleThis rule is called Rule 2 in the Interna-tional Rules and says,

In obeying and construing these rulesdue regard shall be had to all dangers ofnavigation and collision, and to any spe-cial circumstances, which may render adeparture from the above rules necessaryin order to avoid immediate danger.

In other words, follow the standard rulesexcept when a collision will occur unlessboth vessels try to avoid each other. Ifthat is the case, both vessels becomeGive-Way vessels.

62Y-9-18-1 5/16/01 10:19 AM Page 12

-

1-8

E

RULES WHEN ENCOUNTERING VESSELSThere are three main situations which youmay encounter with other vessels whichcould lead to a collision unless the Steer-ing Rules are followed:

Meeting (you are approaching anothervessel head-on)Crossing (you are travelling across theother vessels path)Overtaking (you are passing or beingpassed by another vessel)

In the following illustration, your boat isin the center. You should give the right-of-way to any vessels shown in white area(you are the Give-Way vessel). Any ves-sels in the shaded area must yield to you(they are the Give-Way vessels). Both youand the meeting vessel must alter courseto avoid each other.

MeetingIf you are meeting another power vesselhead on, and are close enough to run therisk of collision, neither of you has theright-of-way! Both of you should altercourse to avoid an accident. You shouldkeep the other vessel on your port (left)side. This rule doesnt apply if both of you

will clear one another if you continue onyour set course and speed.

CrossingWhen two power driven vessels arecrossing each others path close enoughto run the risk of collision, the vesselwhich has the other on the starboard(right) side must keep out of the way ofthe other. If the other vessel is on yourright, you must keep out of its way; youare the Give-Way vessel. If the other ves-sel is on your port (left) side, rememberthat you should maintain course anddirection, provided the other vessel givesyou the right-of-way as it should.

OvertakingIf you are passing another vessel, you arethe Give-Way vessel. This means thatthe other vessel is expected to maintain

102045

102044

102046

62Y-9-18-1 5/16/01 10:19 AM Page 13

-

1-9

E

its course and speed. You must stay outof its way until you are clear of it. Like-wise, if another vessel is passing you, youshould maintain your speed and directionso that the other vessel can steer itselfaround you.

OTHER SPECIAL SITUATIONSThere are three other rules you should beaware of when driving your boat aroundother vessels.

Narrow channels and bendsWhen navigating in narrow channels, youshould keep to the right when it is safeand practical to do so. If the operator of apower-driven vessel is preparing to goaround a bend that may obstruct the viewof other water vessels, the operatorshould sound a prolonged blast on thewhistle (4 to 6 seconds). If another vesselis around the bend, it too should soundthe whistle. Even if no reply is heard,however, the vessel should still proceedaround the bend with caution. If you navi-gate such waters with your boat, you willneed to carry a portable air horn, avail-able from local marine supply stores.

Fishing vessel right-of-wayAll vessels which are fishing with nets,lines or trawls are considered to be fish-ing vessels under the InternationalRules. Vessels with trolling lines are notconsidered fishing vessels. Fishing ves-sels have the right-of-way regardless ofposition. Fishing vessels cannot, howev-er, impede the passage of other vessels innarrow channels.

Sailing vessel right-of-waySailing vessels should normally be giventhe right-of-way. The exceptions to thisare:1. When the sailing vessel is overtaking

the power-driven vessel, the power-driven vessel has the right-of-way.

2. Sailing vessels should keep clear ofany fishing vessel.

3. In a narrow channel, a sailing vesselshould not hamper the safe passageof a power-driven vessel which cannavigate only in such a channel.

Reading buoys and other markersThe waters of the United states aremarked for safe navigation by the lateralsystem of buoyage. Simply put, buoysand markers have an arrangement ofshapes, colors, numbers and lights toshow which side of the buoy a boatershould pass on when navigating in a par-ticular direction. The markings on thesebuoys are oriented from the perspectiveof being entered from seaward (theboater is going towards the port). Thismeans that red buoys are passed on thestarboard (right) side when proceedingfrom open water into port, and blackbuoys are to port (left) side. When navi-gating out of port, your position withrespect to the buoys should be reversed;red buoys should be to port and blackbuoys to starboard.Many bodies of water used by boaters areentirely within the boundaries of a partic-ular state. The Uniform State WaterwayMarking System has been devised forthese waters. This system uses buoys andsigns with distinctive shapes and colorsto show regulatory or advisory informa-

62Y-9-18-1 5/16/01 10:19 AM Page 14

-

1-10

E

1 11

A

1 11

Proceeding toward headof navigation from seaward

CAN BUOY

Odd number. Leave to port.

OR

SECONDARY CHANNEL BUOYSSTARTS NEW NUMBERING SYSTEM

old new

C " 1"

NUN BUOY

Even number. Leave to starboard

N " 2"

No change

BUOYCOLOR CODE

BLACK

RED

GREEN

" A"

" 2"

" 1"

" 3"

" 4"

" 5"

" 7"

N " 2"

" 6"C " 1"

RB " L"

RG " L"or

SECO

NDAR

YCH

ANNE

L

MAIN

CHANNEL

old new

22

22 22

AA

LLLL

Odd number. increasing toward head of naviga-

MAIN CHANNEL BUOYS

" 1" " 3" " 5" " 7"

tion.Leave to port (left) proceeding upstream.

LIGHTED BUOY (Port Hand)`

White Light Green Light

old new

old new

old new

LIGHTED BUOY (Starboard Hand)`

" 2" " 4" " 6"

Even number,increasing toward head of naviga-tion. Leave to starboard (right) proceeding up-stream.

White Light Red Light

" A"

LIGHTED SAFE WATER BUOY

No number. Marks midchannel, pass on eitherside. Letter has no lateral significance, used for

No number . Topmost band red - prefer red

Top Mark

White LightWhite Light

OR

OR

LIGHTED PREFERRED CHANNEL TO

RB " L" RG " L"

PORT BUOY

identification and location purposes.

channel is to left of buoy. Letter has no lateralsignificance, used for identification and locationpurposes.

Red LightRed orWhite Light

OR

102052

tion. These markers are white with blackletters and orange boarders. They signifyspeed zones, restricted areas, dangerareas, and general information.Remember, markings may vary by geo-graphic location. Always consult localboating authorities before driving yourboat in unfamiliar waters.

62Y-9-18-1 5/16/01 10:19 AM Page 15

-

1-11

E

EMB50410

FUELING INSTRUCTIONS

wGASOLINE AND ITS VAPORS ARE HIGH-LY FLAMMABLE AND EXPLOSIVE!8 Do not smoke when refueling, and

keep away from sparks, flames, orother sources of ignition.8 Stop engine before refueling.8 Refuel in a well-ventilated area. Refuel

portable fuel tanks off the boat.8 Take care not to spill gasoline. If gaso-

line spills, wipe it up immediately withdry rags.8 Do not overfill the fuel tank.8 Tighten the filler cap securely after

refueling.8 If you should swallow some gasoline

inhale a lot of gasoline vapor, or getgasoline in your eyes, get immediatemedical attention.8 If any gasoline spills onto your skin,

immediately wash with soap andwater. Change clothing if gasoline spillson it.8 Touch the fuel nozzle to the filler open-

ing or funnel to help prevent electrosta-tic sparks.

GASOLINE (PETROL)

Recommended gasoline:Regular unleaded gasoline with a minimum octane rating of 86 (Pump octane number): (R+M)/2

62Y-9-18-1 5/16/01 10:19 AM Page 16

-

1-12

E

If knocking or pinging occurs, use a differ-ent brand of gasoline or premium unlead-ed fuel. Unleaded fuel will give youlonger spark plug life and reduced main-tenance cost. If unleaded gasoline is notavailable, then leaded regular gasolinecan be used. If leaded gasoline is usuallyused, engine valves and related partsshould be inspected after every 300 hoursof operation.

Gasohol

There are two types of gasohol: gasoholcontaining ethanol and that containingmethanol. Gasohol containing ethanolcan be used if ethanol content does notexceed 10% and the fuel meets minimumoctane ratings. Gasohol containingmethanol is not recommended by Yama-ha because it can cause fuel system dam-age or engine performance problems.

cCUse only new clean gasoline which hasbeen stored in clean containers and is notcontaminated with water or foreign mat-ter.

62Y-9-18-1 5/16/01 10:19 AM Page 17

-

1-13

E

EMU01149

ENGINE OIL

Recommended engine oil;Use a combination of corresponding SAEand API shown in the chart below;

cCAll four-stroke engines are shipped fromthe factory without engine oil.

NOTE:

If the recommended engine oil is notavailable, then a multigrade type engineoil such as SF-CC/CD,SG-CC/CD or SH-CDcan be used.

SAE APISESFSGSH

_ 4 32 68 104F

_ 20 0 20 40C

10W-30, 10W-40

20W-40

Engine oil quantity:Refer to SPECIFICATIONS, Page 4-1.

000292

62Y-9-18-1 5/16/01 10:19 AM Page 18

-

1-14

E

EMU00031

BATTERY REQUIREMENT

cCDo not use the battery that does notmeet the specified capacity. If differentbattery from the specification is used, theelectric system may perform poorly or beoverloaded, causing electrical systemdamage.

Choose battery which meets the followingspecifications for Electric start model.

Minimum cold crank performance380 Amps at -17.8C (0F)Minimum reserve capacity124 minutes at 26.7C (80F)

EMU01395

PROPELLER SELECTION

The performance of your outboard motorwill be critically affected by your choice ofpropeller, as an incorrect choice couldadversely affect performance and couldalso seriously damage the motor. Enginespeed depends on the propeller size andboat load. If engine speed is too high ortoo low for good engine performance,this will have an adverse effect on theengine.

62Y-9-18-1 5/16/01 10:19 AM Page 19

-

1-15

E

Yamaha outboard motors are fitted withpropellers chosen to perform well over arange of applications, but there may beuses where a propeller with a differentpitch would be more appropriate. For agreater operating load, a smaller-pitchpropeller is more suitable as it enablesthe correct engine speed to be main-tained. Conversely, a larger-pitch pro-peller is more suitable for a smaller oper-ating load.

Yamaha dealers stock a range of pro-pellers, and can advise you and install apropeller on your outboard that is bestsuited to your application.NOTE:

At full throttle and under a maximumboat load, the engines rpm should bewithin the upper half of the full throttleoperating range, as listed in SPECIFICA-TIONS on page 4-1. Select a propellerwhich fulfills this requirement.If operating under conditions which allowthe engines rpm to rise above the maxi-mum recommended range (such as lightboat loads), reduce the throttle setting tomaintain the rpm in the proper operatingrange.

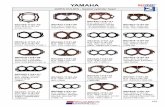

1 Propeller diameter (in inches)2 Propeller pitch (in inches)3 Type of propeller (propeller mark)

Refer to the section CHECKING PRO-PELLER for instructions on propellerremoval and installation.

602011

10-3/4x17-G

1 23

F50

13 x 17 - K

q w e

000933

T50

62Y-9-18-1 5/16/01 10:19 AM Page 20

-

1-16

E

EMU01209

START-IN-GEAR PROTECTION

Yamaha outboard motors or Yamahaapproved remote control units areequipped with start-in-gear protectiondevice(s). This feature permits the engineto be started only when it is Neutral.Always select Neutral before starting theengine.

62Y-9-18-1 5/16/01 10:19 AM Page 21

-

E

-MEMO-

62Y-9-18-1 5/16/01 10:19 AM Page 22

-

EMC00010

Chapter 2

BASIC COMPONENTS

MAIN COMPONENTS..............................2-1

OPERATIONS OF CONTROLS ANDOTHER FUNCTIONS ................................2-2

Fuel tank ................................................2-2Remote control .....................................2-3Trim tab .................................................2-7Power trim/tilt switch ...........................2-8Trim angle adjusting rod .....................2-8Digital tachometer................................2-9Tilt support lever ................................2-12Top cowling lock lever.......................2-12Flushing device...................................2-12

WARNING SYSTEM ..............................2-13Overheat warning...............................2-13Low oil pressure warning..................2-14

1

2

3

4

5

6

E

62Y-9-18-2 5/16/01 10:23 AM Page 1

-

!6

!5

i

!0

o

ty

r

r

u

!2

!1

q

w

e

!3

!4

!1

2-1

E

EMU01206

MAIN COMPONENTS

1 Top cowling2 Cowling lock lever3 Oil drain bolt4 Anodes5 Anti-cavitation plate6 Trim tab (Anode)7 Propeller8 Cooling water inlet9 Trim angle adjusting-rod

0 Clamp bracketq Tilt support leverw Power trim and tilt switche Flushing devicer Fuel jointt Remote control boxy Digital tachometer

* May not be exactly as shown; also may notbe included as standard equipment on allmodels.

*

**

62Y-9-18-2 5/16/01 10:23 AM Page 2

-

2-2

E

EMC20010

OPERATIONS OF CONTROLSAND

OTHER FUNCTIONS

EMC21012

FUEL TANKIf your model was equipped with aportable fuel tank, its function is as fol-lows.

1 Fuel hose joint2 Fuel meter (If equipped)3 Fuel tank cap4 Air vent screw (If equipped)

EMC31010

Fuel hose jointThis connector is provided for connectingor disconnecting fuel hose.EMC41110

Fuel meterThis meter is on the fuel tank cap. Itshows current fuel quantity in the fueltank approximately.EMC51010

Fuel tank capThis cap is for filling fuel. To remove it,turn it counterclockwise.EMC61010

Air vent screwThis screw is on the fuel tank cap. Toloosen it, turn it counterclockwise.

q wr

902051*

e

62Y-9-18-2 5/16/01 10:23 AM Page 3

-

E

2-3

701011*

wqe

r

tu

y

RN

Fqw er

ty

u

ut

r

y

701031

000323

UP

DN

EMC80612

REMOTE CONTROLBoth the shifter and the throttle are actu-ated by the remote control lever. In addi-tion, this control also has the electricalswitches.

1 Remote control lever2 Neutral interlock trigger3 Neutral throttle lever4 Main switch5 Engine stop lanyard switch6 Power trim and tilt switch7 Throttle friction adjusting screw

EMC50010

Remote control leverMoving the lever forward from the Neu-tral position engages Forward gear.Pulling the lever back from Neutralengages Reverse. The engine will contin-ue to run at idle until the lever is movedabout 35 (a detent can be felt). Movingthe lever farther opens the throttle, andthe engine will begin to accelerate.

1 Neutral2 Forwar3 Reverse4 Shift5 Fully closed6 Throttle7 Fully open

EMC50110

Neutral interlock triggerTo shift out of Neutral, the neutral inter-lock trigger of the remote control levermust first be pulled up.

62Y-9-18-2 5/16/01 10:23 AM Page 4

-

E

2-4

N

701033*

q

w

ONSTARTOFF

701021

EMC50210

Neutral throttle leverTo open the throttle without shifting intoeither Forward or Reverse, place theremote control lever in the Neutral posi-tion and lift the neutral throttle lever.NOTE:

The neutral throttle lever will operate onlywhen the remote control lever is in Neu-tral. The remote control lever will operateonly when the neutral throttle lever is inthe closed position.

1 Fully open2 Fully closed

EMC48110

Main switchThe main switch controls the ignition sys-tem; its operation is described below.8 OFFElectrical circuits switched off.(The key can be removed.)8 ONElectrical circuits switched on.(The key cannot be removed.)8 STARTStarter-motor will turn and start engine.(When the key is released, it returns auto-matically to ON.)

62Y-9-18-2 5/16/01 10:23 AM Page 5

-

E

2-5

000569

q

w

EMC28210

Engine stop lanyard switchThe lock-plate on the end of the lanyardmust be attached to the engine stopswitch for the engine to run. The lanyardshould be attached to a secure place onthe operators clothing, or arm or leg.Should the operator fall overboard orleave the helm, the lanyard will pull outthe lock plate, stopping ignition to theengine. This will prevent the boat fromrunning away under power.

w8 Attach the engine stop switch lanyard

to a secure place on your clothing, yourarm or leg while operating.8 Do not attach the lanyard to clothing

that could tear loose. Do not route thelanyard in such a way that it couldbecome entangled, preventing it fromfunctioning.8 Avoid accidentally pulling the lanyard

during normal operation. Loss ofengine power means the loss of moststeering control. Also, without enginepower, the boat could slow rapidly.This could cause people and objects inthe boat to be thrown forward.

NOTE:

The engine cannot be started with thelock-plate removed.

1 Lock-plate2 Lanyard

62Y-9-18-2 5/16/01 10:23 AM Page 6

-

E

2-6

UPDN

701034*

UP

DN

701035

EMU01331

Power Trim/Tilt SwitchThe power trim/tilt adjusts the motorangle in relation to the transom. Thepower trim/tilt switch is located on theremote control lever grip. Pushing theswitch UP trims the motor up, then tiltsthe motor up. Pressing the switch DNtilts the motor down and trims the motordown. When the switch button isreleased, the motor will stop in its currentposition.NOTE:

Refer to the sections ADJUSTING TRIMANGLE and TILTING UP/DOWN inChapter 3 for instructions on usage.

EMU01155

Throttle Friction Adjusting ScrewA friction device in the remote control boxprovides adjustable resistance to move-ment of the remote control lever, and canbe set according to operator preference.An adjusting screw is located on the frontof the remote control box.

wDo not overtighten the friction adjustingscrew. If there is too much resistance, itmay be difficult to move the lever, whichcould result in an accident.

Resistance Screw

Increase Turn clockwise

Decrease Turn counterclockwise

62Y-9-18-2 5/16/01 10:23 AM Page 7

-

EMU00113

TRIM TABThe trim tab should be adjusted so thatthe steering control can be turned toeither the right or left by applying thesame amount of force.

wAn improperly adjusted trim tab maycause difficult steering. Always test runafter the trim tab has been installed orreplaced to be sure steering is correct. Besure you have tightened the bolt afteradjusting the trim tab.

1 Trim tab2 Bolt3 Cap (If equipped)

cCThe trim tab also serves as an anode toprotect the engine from electrochemicalcorrosion. Never paint the trim tab as itwill become ineffective as an anode.

E

2-7

Boat tends to veer The fin of trim tab

To the left Turn to the left (port side) (A in the figure)

To the right Turn to the right (starboard side) (B in the figure)

q

w603011

A

B

q

w

e

603014*

A

B

F50

T50

62Y-9-18-2 5/16/01 10:23 AM Page 8

-

E

2-8

EMU01125

POWER TRIM/TILT SWITCHThe power trim/tilt adjusts the motorangle in relation to the transom. Thepower trim/tilt switch is located on theside of the bottom engine cowling. Push-ing the switch UP trims the motor up,then tilts the motor up. Pressing theswitch DN tilts the motor down andtrims the motor down. When the switchbutton is released, the motor will stop inits current position.

wUse the power trim/tilt switch located onthe bottom engine cowling only whenthe boat is at a complete stop with theengine off. Attempting to use the cowl-ing-mounted power trim/tilt switch whilethe boat is moving could increase the riskof falling overboard and could distractthe operator, increasing the risk of colli-sion with another boat or an obstacle.

NOTE:

Refer to the section Adjusting TrimAngle and Tilting Up/Down for instruc-tions on usage.

302011

UP

DOWN

EMU01297

TRIM ANGLE ADJUSTING RODThe position of the trim angle adjustingrod determines the minimum trim angleof the outboard motor in relation to thetransom.

000969

62Y-9-18-2 5/16/01 10:23 AM Page 9

-

E

2-9

q

t

w

r001081

e

y u

001085

EMU01617

DIGITAL TACHOMETERThis gauge contains the tachometer, trimmeter, hour meter, low oil pressure warn-ing indicator, and the overheat warningindicator.

1 Tachometer2 Trim meter3 Hour meter4 Low oil pressure warning indicator5 Overheat warning indicator6 Set button7 Mode button

NOTE:

All segments of the display will lightmomentarily after the main switch isturned on and will return to normal there-after.

001058

EMU00136

TachometerThis meter shows the engine speed.

62Y-9-18-2 5/16/01 10:23 AM Page 10

-

2-10

E

001059

EMU01109

Trim MeterThis meter shows the trim angle of youroutboard motor.NOTE:

8 Memorize the trim angles that workbest for your boat under different condi-tions. Adjust the trim angle to thedesired setting by operating the powertrim and tilt switch.8 If the trim angle of your motor exceeds

the trim operating range, the top seg-ment on the trim meter display will startto blink.

001088

EMU01620

Hour MeterThis meter shows the number of hoursthe engine has been run. It can be set toshow the total number of hours or thenumber of hours for the current trip. Thedisplay can also be turned on and off.8 Changing the display format

Pressing the MODE button changes thedisplay format in the following circularpattern:Total hours - Trip hours - Display off8 Resetting the trip hours

Simultaneously pressing the SET andMODE buttons for more than 1 secondwhile the trip hours are displayed resetsthe trip counter to 0 (zero).

NOTE:

The total number of hours the engine hasbeen run cannot be reset.

62Y-9-18-2 5/16/01 10:23 AM Page 11

-

2-11

E

001060q

EMU01110

Low Oil Pressure Warning IndicatorIf oil pressure drops too low, the warningindicator will start to blink. Refer to thesection LOW OIL PRESSURE WARNINGfor details.

1 Low oil pressure warning indicator

cC8 Do not operate the engine without oil.

Serious engine damage will occur.8 The low oil pressure warning indicator

does not indicate the oil level in theengine. Use the Oil Level Gauge tocheck the remaining oil quantity. (Referto the section CHECKING THE ENGINEOIL LEVEL for details.)

001061

q

EMU01553

Overheat Warning IndicatorIf the engine temperature rises too high,the warning indicator will start to blink.Refer to OVERHEAT WARNING fordetails.

1 Overheat warning indicator

cCDo not continue to operate the engine if awarning device has activated. If neces-sary, refer to the TROUBLESHOOTINGsection in this manual. Consult your deal-er if the problem cannot be located andcorrected.

62Y-9-18-2 5/16/01 10:23 AM Page 12

-

2-12

E

301011

EMD62110

TOP COWLING LOCK LEVERTo remove the engine top cowling, pullup the lock lever. Then lift off the cowling.When replacing the cowling, check to besure it fits properly in the rubber seal.Then lock the cowling again by movingthe lever downward.

000971

EMD60010

TILT SUPPORT LEVERTo keep the outboard motor in the tilted-up position, lock the tilt support lever tothe clamp bracket.

EMU01146

FLUSHING DEVICEThis device 1 is used to clean the coolingwater passages of the motor using a gar-den hose and tap water.NOTE:

Refer to Cleaning Cooling-water Pas-sages in Chapter 4 for instructions onusage.000280

q

62Y-9-18-2 5/16/01 10:23 AM Page 13

-

E

2-13

001062

EMD80010

WARNING SYSTEM

cCDo not continue to operate the engine ifthe warning device has activated. Consultyour Yamaha dealer if the problem can-not be located and corrected.

EMU00170

OVERHEAT WARNINGThis engine has an overheat warningdevice. If the engine temperature rises toohigh, the warning device will activate.

(1); Included (); N/A

If the warning system has been activated,stop the engine and check the water inletfor clogging.

605015

Activation of Tiller Remote warning device control control

model model

The engine speed will automatically

1decrease to about 2,000 r/min.

The overheat warning indicator 1will come on.

The buzzer will sound. 1

62Y-9-18-2 5/16/01 10:23 AM Page 14

-

E

2-14

EMU00173

LOW OIL PRESSURE WARNINGIf oil pressure drops too low, the warningdevice will activate.

(1):Included ():N/A

If the warning system has been activated,stop the engine as soon as it is safe to doso. Check oil level and add oil as needed.If the oil level is correct, consult yourYamaha dealer.

cCDo not continue to run the engine if thelow oil pressure lamp is ON. Seriousengine damage may occur.

001086

Activation of Tiller Remote warning device control control

model model

Engine speed will automatically

1decrease to about 2,000 r/min.

The low oil pressure warning indicator 1will come on.

The buzzer will sound. 1

62Y-9-18-2 5/16/01 10:23 AM Page 15

-

E

-MEMO-

62Y-9-18-2 5/16/01 10:23 AM Page 16

-

EMF00010

Chapter 3

OPERATION

INSTALLATION ........................................3-1Mounting the outboard motor............3-2

FILLING FUEL ...........................................3-4

PRE-OPERATION CHECKS ......................3-5Checking the engine oil level ..............3-6

BREAKING IN (RUNNING IN) ENGINE ..3-7

STARTING ENGINE .................................3-8

WARMING UP ENGINE .........................3-11

SHIFTING ................................................3-12Forward ...............................................3-12Reverse................................................3-12

STOPPING ENGINE ...............................3-13

TRIMMING OUTBOARD MOTOR.........3-14Adjusting trim angle ..........................3-15

TILTING UP/DOWN ...............................3-17

CRUISING IN OTHER CONDITIONS.....3-19Cruising in salt water.............................3-19

Cruising in turbid water.....................3-19

1

2

3

4

5

6

E

62Y-9-18-3 5/16/01 10:31 AM Page 1

-

E

3-1

EMF10010

INSTALLATION

cCIncorrect engine height or obstructions tosmooth water flow (such as the design orcondition of the boat or accessories suchas transom ladders/depth finder trans-ducers) can create airborne water spraywhile the boat is cruising. Severe enginedamage may result if the motor is operat-ed continuously in the presence of air-borne water spray.

NOTE:

During water testing check the buoyancyof the boat, at rest, with its maximumload. Check that the static water level onthe exhaust housing is low enough to pre-vent water entry into the powerhead,when water rises due to waves when theoutboard is not running.

000940

62Y-9-18-3 5/16/01 10:31 AM Page 2

-

E

3-2

EMF12012

MOUNTING THE OUTBOARDMOTOR

wImproper mounting of the outboardmotor could result in hazardous condi-tions such as poor handling, loss of con-trol, or fire hazards. Observe the follow-ing:8 The information presented in this sec-

tion is intended as reference only. It isnot possible to provide completeinstructions for every possibleboat/motor combination. Propermounting depends in part on experi-ence and the specific boat/motor com-bination.8 Your dealer or other person experi-

enced in proper rigging should mountthe motor. If you are mounting themotor yourself, you should be trainedby an experienced person. [permanentmounted type]8 Your dealer or other person experi-

enced in proper outboard motormounting should show you how tomount your motor. [portable type]

Mount the outboard motor on the centerline (keel line) of the boat, and ensure thatthe boat itself is well balanced. Otherwise,the boat will be hard to steer. For boatswithout a keel or which are asymmetrical,consult your dealer.

1 Center line (keel line)

104011*q

62Y-9-18-3 5/16/01 10:31 AM Page 3

-

E

3-3

EMU01299

Mounting HeightTo run your boat at optimum efficiency,the water-resistance (drag) of the boatand outboard motor must be made as lit-tle as possible. The mounting-height ofthe outboard motor greatly affects thewater-resistance. If the mounting-heightis too high, cavitation tends to occur, thusreducing the propulsion; and if the pro-peller tips cut the air, the engine speedwill rise abnormally and cause the engineto overheat. If the mounting-height is toolow, the water-resistance will increaseand thereby reduce engine efficiency.Mount the engine so that the anti-cavita-tion plate is in alignment with the bottomof the boat .NOTE:

8 The optimum mounting height of theoutboard motor is affected by theboat/motor combination. Test runs atdifferent heights can help determine theoptimum mounting height.8 Refer to the section TRIMMING OUT-

BOARD MOTOR for instructions onsetting the trim angle of the outboard.

104014

wOverpowering a boat may cause severeinstability. Do not install an outboardmotor with more horsepower than themaximum rating on the capacity plate ofthe boat. If the boat does not have acapacity plate, consult the boat manufac-turer.

62Y-9-18-3 5/16/01 10:31 AM Page 4

-

3-4

EMF30211*

FILLING FUEL

1) Remove the fuel tank cap.2) Fill the fuel tank carefully.3) Close the cap securely after refueling.

Wipe up any spilled fuel.

E

902055EMF21110

Ring Free Fuel AdditiveGasoline is a precise blend of many differ-ent substances, each chosen to give cer-tain characteristics. Gasoline blends havebeen changing in recent years inresponse to concerns about pollution andresulting emissions regulations. One ofthe most obvious changes has been theelimination of lead from most fuels.

As gasoline has changed, the amount ofadditives such as aromatics and oxy-genates has increased. These additivesare important for the engines in passen-ger cars, but they can have detrimentaleffects in marine engines, because ofincreased deposits in the combustionchamber. When enough deposits collect,piston rings begin sticking. Performancedrops and engine wear increases dramati-cally.

While many additives available mayreduce deposits, Yamaha recommendsthe use of Ring Free Fuel Additive, avail-able from your Yamaha dealer. Ring Freehas repeatedly proven its ability to cleancombustion deposits from inside theengine, notably the critical piston-ring-land area, and fuel system components.Follow product labeling for use instruc-tions.

62Y-9-18-3 5/16/01 10:31 AM Page 5

-

E

3-5

EMF40012

PRE-OPERATION CHECKS

wIf any item in the pre-operation check isnot working properly, have it inspectedand repaired before operating the out-board motor. Otherwise, an accidentcould occur.

EMF41110

Fuel8 Check to be sure you have plenty of fuel

for your trip. 8 Make sure there are no fuel leaks or

gasoline fumes. 8 Check fuel line connections to be sure

they are tight. 8 Be sure the fuel tank is positioned on a

secure, flat surface, and that the fuelhose is not twisted or flattened, or likelyto contact sharp objects.

EMF42210

Oil8 Check the level of the oil in the sump

with the dipstick. If necessary, add oil tobring the level up to the upper mark.

EMF43010

Controls8 Check throttle, shift, and steering for

proper operation before starting theengine.8 The controls should work smoothly,

without binding or unusual free play. 8 Look for loose or damaged connec-

tions.8 Check operation of the starter and stop

switches when the outboard motor is inthe water.

62Y-9-18-3 5/16/01 10:31 AM Page 6

-

E

3-6

EMF43510

Engine8 Check the engine and engine mounting. 8 Look for loose or damaged fasteners. 8 Check the propeller for damage.

cCDo not start the engine out of water.Overheating and serious engine damagecan occur.

EMU01436

CHECKING THE ENGINE OIL LEVEL1) Put the outboard motor in an upright

position (not tilted).2) Pull out the oil dipstick and wipe it

clean.3) Completely re-insert the dipstick and

pull out it again.4) Check the oil level using the dipstick

to be sure the level falls between theupper and lower marks. Fill with oil ifit is below the lower mark, or drain tothe specified level if it is above theupper mark.

1 Oil dipstick2 Lower level mark3 Upper level mark

201011*

q

201012*

we

q

62Y-9-18-3 5/16/01 10:31 AM Page 7

-

E

3-7

EMF50312

BREAKING IN (RUNNING IN)ENGINE

Your new engine requires a period ofbreak-in (running-in) to allow mating sur-faces of moving parts to wear-in evenly.Correct break-in (running-in) will helpensure proper performance and longerengine life.

cCFailure to follow the break-in (running-in)procedure may result in reduced enginelife or even severe engine damage.

EMU00233

Run the engine under load (in gear with apropeller installed) as follows.1) For the first hour of operation:

Run the engine at 2,000 r/min or atapproximately half throttle.

2) For the second hour of operation:Run the engine at 3,000 r/min or atapproximately three-quarter throttle,and during this period run it at fullthrottle for approximately one minuteevery ten minutes.

3) For the next eight hours of operation:Avoid continuous operation at fullthrottle for more than five minutes ata time.

4) After these first 10 hours:Operate the engine normally.

Break-in (running-in) time: 10 hours

62Y-9-18-3 5/16/01 10:31 AM Page 8

-

E

3-8

EMU01147

STARTING ENGINE

w8 Before starting the engine, make sure

that the boat is tightly moored and thatyou can steer clear of any obstructions.Be sure there are no swimmers in thewater near you.8When the air vent screw is loosened,

gasoline (petrol) vapor will be released.Gasoline (petrol) is highly flammable,and its vapors are flammable andexplosive. Refrain from smoking, andkeep away from open flames andsparks while loosening the air ventscrew.8 This product emits exhaust gases

which contain carbon monoxide, a col-orless, odorless gas which may causebrain damage or death when inhaled.Symptoms include nausea, dizziness,and drowsiness. Keep cockpit andcabin areas well ventilated. Avoidblocking exhaust outlets.

1) If there is an air vent screw on the fueltank cap, loosen it 2 or 3 turns.

2) If there is a fuel joint on the motor,firmly connect the fuel line to thejoint. Then firmly connect the otherend of the fuel line to the joint on thefuel tank.

NOTE:

During engine operation place the tankhorizontally, or fuel cannot be drawn intothe engine.

3) Squeeze the primer bulb with the out-let end up until you feel it becomefirm.

902053

304011*

902061

902025

62Y-9-18-3 5/16/01 10:31 AM Page 9

-

E

3-9

N

701014

OFF

000977

ON

EMU01000

PROCEDURE FOR REMOTECONTROL MODEL4) Place the remote control lever in the

Neutral position.When the engine is warm, open thethrottle slightly using the neutralthrottle lever or the free accelerator.After the engine starts, return thethrottle to the fully closed position.

NOTE:

The start-in-gear protection device pre-vents the engine from starting exceptwhen in Neutral.

5) Attach the engine stop switch lanyardto a secure place on your clothing, oryour arm or leg. Then, install the lockplate on the other end of the lanyardin the engine stop switch.

w8 Attach the engine stop switch lanyard

to a secure place on your clothing, yourarm or leg while operating.8 Do not attach the lanyard to clothing

that could tear loose. Do not route thelanyard where it could become entan-gled, preventing from functioning.8 Avoid accidentally pulling the lanyard

during normal operation. Loss ofengine power means the loss of moststeering control. Also, without enginepower, the boat could slow rapidly.This could cause people and objects inthe boat to be thrown forward.

6) Turn the main switch to ON.

000293

62Y-9-18-3 5/16/01 10:31 AM Page 10

-

E

3-10

EMU00949

Electric Start Model7) Turn the main switch to START,

and hold it for a maximum of 5 sec-onds.

8) Immediately after the engine starts,release the main switch to return it toON.

cC8 Do not turn the main switch to

START when the engine is running.8 Do not keep the starter-motor turning

for more than 5 seconds. The batterywill rapidly become exhausted and itwill be impossible for it to start theengine. If the engine does not startwithin 5 seconds, return the mainswitch to ON, wait 10 seconds, andthen crank the engine again.

ON

000978

START

62Y-9-18-3 5/16/01 10:31 AM Page 11

-

E

3-11

EMG00410

WARMING UP ENGINE

1) Before beginning operation, allow theengine to warm up at idling speed for3 minutes. (Failure to do this willshorten engine life.)

2) Be sure the low oil pressure warninglamp goes off after starting theengine.

3) Check for a steady flow of water fromthe cooling-water pilot hole.

cC8 If the low oil pressure lamp does not go

off after the engine starts, stop theengine. Otherwise, serious engine dam-age could occur. Check the oil level andadd oil if necessary. If the cause for thelow oil pressure warning lamp cannotbe found, consult your Yamaha dealer.8 A continuous flow of water from the

pilot hole shows that the water pumpis pumping water through the coolingpassages. If water is not flowing out ofthe pilot hole at all times while theengine is running, do not continue torun the engine. Overheating and seri-ous damage could occur. Stop theengine and check to see if the waterinlet on the lower casing is blocked. Ifthe problem cannot be found and cor-rected, consult your Yamaha dealer.

309011

62Y-9-18-3 5/16/01 10:31 AM Page 12

-

E

3-12

EMG20111

SHIFTING

wBefore shifting, make sure there are noswimmers or obstacles in the water nearyou.

cCTo change the shifting position from for-ward to reverse or vice-versa, close thethrottle first so that the engine idles (orruns at low speeds).

EMU00264

FORWARDPull up the neutral interlock trigger (Ifequipped) and move the remote controllever quickly and firmly from Neutral toForward.EMU00269

REVERSE

wWhen operating in Reverse, go slowly. Donot open the throttle more than half. Oth-erwise, the boat may become unstable,which could result in loss of control andan accident.

Pull up the neutral interlock trigger (Ifequipped) and move the remote controllever quickly and firmly from Neutral toReverse.

000323

UP

DN

701043

NF

N R

701044

000323

UP

DN

62Y-9-18-3 5/16/01 10:31 AM Page 13

-

E

3-13

EMG38010

STOPPING ENGINE

Let it cool off for a few minutes at idle orlow speed first. Stopping the engineimmediately after operating at high speedis not recommended.

EMU00276

PROCEDUREMain switch equipped model

1) Turn the main switch to OFF.

2) If the fuel joints are provided, discon-nect the fuel line from the motor afterstopping the engine.

3) Tighten the air vent screw on the fueltank cap after stopping the engine, ifit is equipped.

4) Remove the key if the boat will be leftunattended.

NOTE:

The engine can also be stopped bypulling the lanyard and removing the lockplate from the engine stop lanyard switch(then turning the main switch to OFF).

304011*

902052

ONSTARTOFF

701023

62Y-9-18-3 5/16/01 10:31 AM Page 14

-

E

3-14

EMU01412

TRIMMING OUTBOARDMOTOR

The trim angle of the outboard motorhelps determine the position of the bowof the boat in the water. The correct trimangle will help improve performance andfuel economy while reducing strain on theengine. The correct trim angle dependsupon the combination of boat, engine,and propeller. Correct trim is also affectedby variables such as the load in the boat,sea conditions, and running speed.

wExcessive trim for the operating condi-tions (either trim up or trim down) cancause boat instability and can makesteering the boat more difficult. Thisincreases the possibility of an accident. Ifthe boat begins to feel unstable or is hardto steer, slow down and/or readjust thetrim angle.

NOTE:

Refer to the section ADJUSTING TRIMANGLE for instructions on usage.

1 Trim operating angle

q

000946

62Y-9-18-3 5/16/01 10:31 AM Page 15

-

E

3-15

ADJUSTING TRIM ANGLEEMU01401

Power Trim/Tilt Model

w8 Be sure all people are clear of the out-

board motor when adjusting thetrim/tilt angle, also be careful not topinch any body parts between the driveunit and clamp bracket.8 Use caution when trying a trim position

for the first time. Increase speed gradu-ally and watch for any signs of instabili-ty or control problems.8 Use the power trim/tilt switch located

on the bottom engine cowling (ifequipped) only when the boat is at acomplete stop with the engine off.

The outboard motor trim angle can beadjusted operating the power trim/tiltswitch 1.

To raise the bow (trim-out), push theswitch UP.

To lower the bow (trim-in), push theswitch DN.

Make test runs with the trim set to differ-ent angles to find the position that worksbest for your boat and operating condi-tions.NOTE:

To adjust the trim angle while the boat ismoving, use the power trim and tiltswitch located on the remote controldevice or tiller handle, if so equipped.

UPDN

701034*

UP

DN

q

62Y-9-18-3 5/16/01 10:31 AM Page 16

-

E

3-16

EMG62010

Bow upWhen the boat is on plane, a bow-up atti-tude result in less drag, greater stabilityand efficiency. This is generally when thekeel line of the boat is up about 3 to 5degrees. When trimmed out, the boatmay have more tendency to steer to oneside or the other. Compensate for this asyou steer. The trim tab can also be adjust-ed to help offset this effect.

Too much trim-out puts the bow of theboat too high in the water. Performanceand economy are decreased because thehull of the boat is pushing the water andthere is more air drag.Excessive trim-up can cause the propellerto ventilate, which reduces performancefurther. When trimmed-out too much, aboat may porpoise (hop in the water),which could throw the operator and pas-sengers overboard.EMG62110

Bow downWhen the bow of the boat is down, it iseasier to accelerate from a standing startonto plane.

Too much trim-in causes the boat toplow through the water, decreasingfuel economy and making in hard toincrease speed.Operating with excessive trim-in at higherspeeds also makes the boat unstable.Resistance at the bow is greatlyincreased, heightening the danger ofbow steering and making operation dif-ficult and dangerous.

1 Bow up2 Bow down3 Optimum angle

105011

q

105013

w

105015

e

62Y-9-18-3 5/16/01 10:31 AM Page 17

-

E

3-17

EMU01200

TILTING UP/DOWN

If the engine will be stopped for sometime, or if the boat is moored in shallows,the engine should be tilted up to protectthe propeller and casing from damage bycollision with obstructions, and also toreduce salt corrosion.

cCBefore tilting the motor, follow the proce-dures under STOPPING ENGINE. Nevertilt the motor while the engine is running.Severe damage from overheating canresult.

wBe sure all people are clear of the out-board motor when adjusting the tiltangle, also be careful not to pinch anybody parts between the drive unit andengine bracket.

wLeaking fuel is a fire hazard. Disconnectthe fuel line or close the fuel cock if theengine will be tilted for more than a fewminutes. Otherwise, fuel may leak. (If thefuel connector is provided on the motor.)

000817

62Y-9-18-3 5/16/01 10:31 AM Page 18

-

E

3-18

EMU01029

PROCEDURE FOR TILTING UPPower trim/tilt model

1) Remove the fuel-line connection fromthe motor. (If the fuel connector isprovided on the motor.)

000971

304011*

UPDN

701034*

UP

DN

302011

UP

DN

2) Push the power trim/tilt switch UPuntil the outboard has tilted up com-pletely.

3) Turn the tilt-support lever towardengine bracket and support theengine.

w8 After tilting the engine, be sure to sup-

port it with the tilt-support lever. Oth-erwise, the engine could fall back downsuddenly if oil in the power trim/tiltunit should lose pressure.8 Never operate the engine while it is

supported by the tilt-support lever.

62Y-9-18-3 5/16/01 10:31 AM Page 19

-

E

3-19

EMH60010

CRUISING IN OTHER CONDITIONS

CRUISING IN SALT WATERAfter operating in salt water, wash out thecooling-water passages with fresh waterto prevent them from becoming clogged-up with salt deposits.NOTE:

Refer to cooling system flushing instruc-tions in TRANSPORTING AND STORINGOUTBOARD MOTOR.

CRUISING IN TURBID WATERIt is strongly recommended that theoptional chromium-plated water-pump kitbe installed if the outboard is to be usedin turbid (muddy) water conditions.

EMU00303

PROCEDURE FOR TILTING DOWNPower trim/tilt model

1) Push the power trim/tilt switch UPuntil the engine is supported by thetilt rod.

2) Release the tilt-support lever.3) Push the power trim/tilt switch DN

(Down) to lower the engine to thedesired position.

000979

62Y-9-18-3 5/16/01 10:31 AM Page 20

-

EMK00010

Chapter 4

MAINTENANCE

SPECIFICATION DATA.............................4-1

TRANSPORTING AND STORINGOUTBOARD MOTOR ...............................4-3

Trailering outboard motor...................4-3Storing outboard motor ......................4-4

PERIODIC MAINTENANCE......................4-8Replacement parts ...............................4-8Maintenance chart................................4-9Greasing ..............................................4-10Cleaning and adjusting spark plug...4-11Checking fuel system.........................4-13Inspecting fuel filter ...........................4-14Adjusting idling speed.......................4-16Changing engine oil ...........................4-17Checking timing belt ..........................4-19Replacing fuse ....................................4-20Checking wiring and connectors ......4-20Exhaust leakage..................................4-20Water leakage .....................................4-20Checking power trim and tilt system .4-21Checking propeller .............................4-22Changing gear oil ...............................4-24Cleaning fuel tank...............................4-25Inspecting and replacing anode(s) ...4-27Checking battery.................................4-28Checking bolts and nuts ....................4-31Motor exterior.....................................4-31Cleaning cooling-water passages....4-31Coating the boat bottom ...................4-32

1

2

3

4

5

6

E

62Y-9-18-4 5/2/01 3:12 PM Page 1

-

4-1

E

EMK10111*

SPECIFICATION DATA

ModelUnit F50TRA

Item

18 (1.8, 13)35 (3.5, 25)18 (1.8, 13)18 (1.8, 13)

8Spark plug Nm (kgfm,lbft)8Propeller nut Nm (kgfm,lbft)8Engine oil drain bolt Nm (kgfm,lbft)8Engine oil filter Nm (kgfm,lbft)

DIMENSIONS

PERFORMANCE

8Overall Length mm (in.)8Overall Width mm (in.)8Overall Height L mm (in.)8Transom height L mm (in.)8Weight L kg (lb.)

718 (28.3)361 (14.2)1,397 (55.0)533 (21.0)108 (238)

8Full throttle operating range r/min8Maximum output kW (HP)8Idling speed (in Neutral) r/min

5,000~6,00036.8 (50.0) at 5,500 r/min700~800

ENGINE

8TypeDisplacement cm3 (cu.in.)Bore stroke mm (in.)8Valve clearance (cold engine) IN mm (in)

EX mm (in)8Ignition system8Spark plug NGK

Spark plug gap mm (in.)8Control system8Starting system8Battery capacity V-AH

Minimum cold crank performance Amps at -17.8C (0F)Minimum reserve capacity minutes at 26.7C (80F)8Alternator output V-A (W)8Starting carburetion system

4-stroke, L4935 (57.1)63.0 75.0 (2.48 2.95)0.15~0.25 (0.006~0.010)0.25~0.35 (0.010~0.014)C.D.I systemDPR6EA-90.8 ~ 0.9 (0.031~0.035)Remote controlElectric start12-70 ~ 100 38012412-10Prime start system

DRIVE UNIT

8Gear positionsGear ratio8Trim/tilt system8Propeller mark

Forward-Neutral-Reverse1.85 (13:24)Power trim & tiltG

FUEL AND OIL

TIGHTENING TORQUE

8Fuel

Fuel tank capacity L (US gal, Imp gal)8Recommended engine oil

APISAE

Engine oil capacity (without oil filter) L (US qt, Imp qt)Engine oil capacity (with oil filter) L (US qt, Imp qt)8Recommended gear oil

Gear oil capacity cm3 (US oz, Imp oz)

Regular-unleaded gasoline (P.O.N.: minimum 86)4-stroke motor oilSE, SF, SG, SH10W-30, 10W-40, 20W-402.0 (2.1, 1.8)2.2 (2.3, 1.9)Hypoid gear oil (SAE90)430 (14.5, 15.1)

62Y-9-18-4 5/2/01 3:12 PM Page 2

-

T50TRA

4-stroke, L4935 (57.1)63.0 75.0 (2.48 2.95)0.15~0.25 (0.006~0.010)0.25~0.35 (0.010~0.014)C.D.I systemDPR6EA-90.8 ~ 0.9 (0.031~0.035)Remote controlElectric start12-70 ~ 100 38012412-10Prime start system

4-2

E

718 (28.3)361 (14.2)1,436 (56.5)533 (21.0)112 (247)

5,000~6,00036.8 (50.0) at 5,500 r/min900~1,000

Forward-Neutral-Reverse2.30 (13:30)Power trim & tiltK

Regular-unleaded gasoline (P.O.N.: minimum 86)4-stroke motor oilSE, SF, SG, SH10W-30, 10W-40, 20W-402.0 (2.1, 1.8)2.2 (2.3, 1.9)Hypoid gear oil (SAE90)610 (20.6, 21.5)

18 (1.8, 13)35 (3.5, 25)18 (1.8, 13)18 (1.8, 13)

62Y-9-18-4 5/2/01 3:12 PM Page 3

-

4-3

EMU00326

TRAILERING OUTBOARD MOTORThe motor should be trailered and storedin the normal running position. If there isinsufficient road clearance in this position,then trailer the motor in the tilt positionusing a motor support device such as atransom saver bar.For further details, consult your Yamahadealer.

w8 Never get under the lower unit while it

is tilted, even if a motor support bar isused. Severe injury could occur if theoutboard accidentally falls.8 USE CARE when transporting fuel tank,

whether in a boat or car.8 DO NOT fill fuel container to maximum

capacity. Gasoline will expand consid-erably as it warms up and can build uppressure in the fuel container. This cancause fuel leakage and a potential firehazard.

cCDo not use the tilt support lever/knobwhen trailering the boat. The outboardmotor could shake loose from the tiltsupport and fall. If the motor can not betrailered in the down position, use anadditional support device to secure it inthe up position.

E

EMU01369

TRANSPORTING AND STORING

OUTBOARD MOTORwLeaking fuel is a fire hazard. When trans-porting and storing the outboard motor,close the air vent screw and fuel cock toprevent fuel from leaking.

62Y-9-18-4 5/2/01 3:12 PM Page 4

-

4-4

E

EMK16210

STORING OUTBOARD MOTORWhen storing your Yamaha outboard forprolonged periods of time, (2 months orlonger), several important proceduresmust be performed to prevent expensivedamage. It is advisable to have your outboard ser-viced by an authorized Yamaha dealerprior to storage. However, the followingprocedures can be performed by you, theowner, with a minimum of tools.

cC8 To prevent problems which can be

caused by oil entering the cylinder fromthe sump, keep the engine in the atti-tude shown when transporting andstoring it.8 Do not place the engine on its side

before the cooling water has drainedfrom it completely, or water may enterthe cylinder through the exhaust portand cause problems.8 Store the engine in a dry, well-ventilat-

ed place, not in direct sunlight.

1 Vertical position2 Horizontal position

000940

102012

1

2

EMK21010

Filling Fuel TankFill the fuel tank with fresh fuel and addone ounce of Yamaha Fuel Conditionerand Stabilizer (Part No. LUB-FUELC-12-00) to each gallon of fuel.NOTE:

The use of Yamaha Fuel Conditioner andStabilizer eliminates the need to drainthe fuel system. Consult your Yamahadealer or other qualified mechanic if thefuel system is to be drained instead.

62Y-9-18-4 5/2/01 3:12 PM Page 5

-

4-5

E

605014

EMK22611

Flushing Cooling System and FoggingEngineCooling system flushing is essential toprevent the cooling system from cloggingup with salt, sand, or dirt. In addition, fog-ging of the engine is mandatory to pre-vent expensive engine damage due torust. Perform the flushing and fogging atthe same time.1) Remove the top cowling and the pro-

peller.2) Install a flushing attachment to the

lower unit.(Flushing attachment avail-able from your Yamaha dealer).

cCAvoid running the outboard at highspeed while on the flushing attachment,or overheating could occur.

w8 Do not touch or remove electrical parts

when starting or during operation.8 Keep hands, hair and clothes away

from flywheel and other rotating partswhile engine is running.

3) Run the engine at a fast idle for 10~15minutes.

4) Just prior to turning off the engine,quickly spray Yamaha Stor-RiteEngine Fogging Oil (Part No. LUB-STRRT-12-00) alternately into thesilencer cover. When properly done,the engine will smoke excessivelyand almost stall.

5) Remove the flushing attachment andwipe off any excess water.

6) Install the top cowling and the pro-peller.

62Y-9-18-4 5/2/01 3:12 PM Page 6

-

4-6

E

EMK26011

Lubrication1) Remove the spark plugs, and spray a

10 second spray of Yamaha Stor-Rite Engine Fogging Oil into eachcylinder. Grease the spark plugthreads and reinstall the spark plugsand torque to proper specification.(Refer to the CLEANING ANDADJUSTING SPARK PLUG).

2) Turn the engine over with the stoplanyard disconnected to work the fog-ging oil into the piston rings.

3) Change the lower unit oil. (Refer toCHANGING GEAR OIL). Inspect theoil for the presence of water whichindicates a leaky seal. Seal replace-ment should be performed by anauthorized Yamaha dealership priorto use.

4) Grease all grease fittings. (Refer tothe GREASING)

EMK27011

Cleaning and Anti-corrosion Measure1) Wash down the exterior of the out-

board with fresh water and dry offcompletely.

2) Spray the engines exterior withYamaha Silicone Protectant (PartNo. LUB-SILCNE-13-00).

3) Wax the cowling with a non-abrasivewax such as Yamaha Silicone Wax(Part No. ACC-11000-15-02).

62Y-9-18-4 5/2/01 3:12 PM Page 7

-

4-7

E

EMK29010

Battery Care

wBattery electrolyte is poisonous and dan-gerous, causing severe burns, etc. It con-tains sulfuric acid. Avoid contact withskin, eyes, or clothing.Antidote:EXTERNAL; Flush with water.INTERNAL; Drink large quantities ofwater or milk. Follow with milk of mag-nesia, beaten egg, or vegetable oil. Callphysician immediately.EYES; Flush with water for 15 minutesand get prompt medical attention.Batteries produce explosive gases: Keepsparks, flame, cigarettes, etc. away. Ven-tilate when charging or using in a closedspace. Always wear eye protection whenworking near batteries.KEEP OUT OF REACH OF CHILDREN.

NOTE:

Batteries vary among manufacturers.Therefore the following procedures maynot always apply. Consult your batterymanufacturers instructions.

1) Disconnect and remove the batteryfrom the boat. Always disconnect theblack negative lead first to prevent therisk of shorting.

2) Clean the battery casing and termi-nals. Fill each cell to the upper levelwith distilled water.

3) Store the battery on a level surface ina cool, dry, well-ventilated place outof direct sunlight.

4) Once a month, check the specificgravity of the electrolyte and rechargeas required to prolong battery life.

62Y-9-18-4 5/2/01 3:12 PM Page 8

-

4-8

E

EMU00913

PERIODIC MAINTENANCE

wBe sure to turn off the engine when youperform maintenance unless otherwisespecified. If the owner is not familiar withmachine servicing, this work should bedone by a Yamaha dealer or other quali-fied mechanic.

Maintenance, replacement, or repair ofthe emission control devices and systemsmay be performed by any marine enginerepair establishment or individual. Allwarranty repairs, however, includingthose to the emission control system,must be performed by an authorizedYamaha marine dealership.A service manual is available for purchasethrough a Yamaha dealer for owners whohave the mechanical skills, tools, andother equipment necessary to performmaintenance not covered by this ownersmanual.EMK33011

REPLACEMENT PARTSIf replacement parts are necessary, useonly genuine Yamaha parts or equiva-lents of the same type and of equivalentstrength and materials. Any part of inferi-or quality may malfunction, and theresulting loss of control could endangerthe operator and passengers.Yamaha genuine parts and accessoriesare available from a Yamaha dealer.

62Y-9-18-4 5/2/01 3:12 PM Page 9

-

4-9

E

Spark plug Cleaning/Adjustment/ 4-11ReplacementGreasing points Greasing 4-10Gear oil Change 4-24Fuel system Inspection 4-13Fuel filter Inspection/Replacement 4-14Fuel tank Cleaning 4-25Idling speed Adjustment 4-16Anode Inspection/Replacement 1 1 4-27Outboard motor exterior Inspection 4-31Cooling water passages Cleaning 4-5Propeller Inspection 4-22Timing belt Inspection 1 4-19

Battery Inspection (every 4-28month)Power trim and tilt Inspection 4-21Ignition timing Inspection/Adjustment 1 1 Bolts and nuts Retightening 1 1 4-31Engine oil Change 4-17Oil filter Change 1 Valve clearance Inspection/Adjustment 1 1 Thermostat Inspection 1

Interval

Item

Initial EveryRefer page10 hours

50 hours(3 months)

100 hours(6 months)

200 hours(1 year)

EMK30510*

MAINTENANCE CHARTFrequency of maintenance operations may be adjusted according to the operating con-ditions, but the following table gives general guidelines.

The mark () indicates the check-ups which you may carry out yourself.The mark (1) indicates work to be carried out by your Yamaha dealer.

NOTE:

8When operating in salt water, turbid or muddy water, the engine should be flushedwith clean water after each use.8 If leaded gasoline is usually used, engine valves and related parts should be inspect-

ed after every 300 hours of operation in addition to the items on the maintenancechart above.

62Y-9-18-4 5/2/01 3:12 PM Page 10

-

4-10

E

EMU00366

GREASINGYamaha marine grease(Water resistant grease)

000567

62Y-9-18-4 5/2/01 3:12 PM Page 11

-

4-11

EMU01202

CLEANING AND ADJUSTING SPARKPLUG

wWhen removing or installing a spark plug,be careful not to damage the insulator. Adamaged insulator could allow externalsparks, which could lead to explosion orfire.

The spark plug is an important enginecomponent and is easy to inspect. Thecondition of the spark plug can indicatesomething about the condition of theengine. For example, if the center elec-trode porcelain is very white, this couldindicate an intake air leak or carburetionproblem in that cylinder. Do not attemptto diagnose any problems yourself.Instead, take the outboard motor to aYamaha dealer. You should periodicallyremove and inspect the spark plugbecause heat and deposits will cause thespark plug to slowly break down anderode. If electrode erosion becomesexcessive, or if carbon and other depositsare excessive, you should replace thespark plug with another of the correcttype.

Before fitting the spark plug, measure theelectrode gap with a wire thicknessgauge; adjust the gap to specification ifnecessary.

E

Standard spark plug:Refer to SPECIFICATIONS, page 4-1.

Spark plug gap:Refer to SPECIFICATIONS, page 4-1.

62Y-9-18-4 5/2/01 3:12 PM Page 12

-

4-12

When fitting the plug, always clean thegasket surface and use a new gasket.Wipe off any dirt from the threads andscrew in the spark plug to the correcttorque.

NOTE:

If a torque-wrench is not available whenyou are fitting a spark plug, a good esti-mate of the correct torque is 1/4 to 1/2 aturn past finger-tight. Have the spark plugadjusted to the correct torque as soon aspossible with a torque-wrench.

1 Spark plug gap2 Spark plug I.D. mark (NGK)

E

Spark plug torque:Refer to SPECIFICATIONS, page 4-1.

Initial of spark Plug wrench sizeplug I.D. mark

B 21 mm (13/16 in.)

C/BK 16 mm (5/8 in.)

D 18.3 mm (23/32 in.)

903022

qw

62Y-9-18-4 5/2/01 3:12 PM Page 13

-

4-13

EMK38010

CHECKING FUEL SYSTEM

wGasoline (petrol) and its vapors are highlyflammable and explosive. Keep awayfrom sparks, cigarettes, flames or othersources of ignition.

Check the fuel line for leaks, cracks, ormalfunctions. If any problem is found, itshould be repaired immediately by Yama-ha dealer or other qualified mechanic.

Checking points8 Fuel system parts leakage.8 Fuel hose joint leakage.8 Fuel hose cracks or other damage.8 Fuel connector leakage.

wLeaking fuel can result in fire or explo-sion.8 Check for fuel leakage regularly.8 If any fuel leakage is found, the fuel

system must be repaired by a qualifiedmechanic. Improper repairs can makethe outboard unsafe to operate.

E

000972

62Y-9-18-4 5/2/01 3:12 PM Page 14

-

4-14

E

EMU00370

INSPECTING FUEL FILTER

wGasoline (petrol) is highly flammable, andits vapors are flammable and explosive.8 If you have any question about properly

doing this procedure, consult yourYamaha dealer.8 Do not perform this procedure on a hot

or running engine. Allow the engine tocool.8 There will be fuel in the fuel filter. Keep

away from sparks, cigarettes, flames orother sources of ignition.8 This procedure will allow some fuel to

spill. Catch fuel in a rag. Wipe up anyspilled fuel immediately.8 The fuel filter must be reassembled

carefully with O-ring, filter cup, andhoses in place. Improper assembly orreplacement can result in a fuel leak,which could result in a fire or explosionhazard.

207011

000983

q

w

er

EMU00978

F50

1) Remove the nut holding the fuel filterassembly if equipped.

2) Unscrew the filter cup 1, catchingany spilled fuel in a rag.

3) Remove the filter element 2, andwash it in solvent.Allow it to dry. Inspect the filter ele-ment and O-ring 3 to make sure theyare in good condition. Replace them ifnecessary.

4) Reinstall the filter element in the cup.Make sure the O-ring in position inthe cup. Firmly screw the cup ontothe filter housing 4.

62Y-9-18-4 5/2/01 3:12 PM Page 15

-

4-15

E

000960

000309

q

e

w

r

t

EMU01282

T50

NOTE:

If any water is in the fuel, the float willrise. If so, remove the cup and drain thewater.

1) Remove the nut holding the fuel filterassembly if so equipped.

2) Unscrew the filter cup 1, catchingany spilled fuel in a rag.

3) Remove the filter element 2, andwash it in solvent.Allow it to dry. Inspect the filter ele-ment and O-ring 3 to make sure theyare in good condition. Replace them ifnecessary.

4) Reinstall the filter element in the cup.Make sure the O-ring is in properposition in the cup. Firmly screw thecup onto the filter housing 4.

5) Attach the filter assembly to thebracket.

6) Run the engine and check the filterand lines for leaks.

5) Attach the filter assembly to thebracket with that the fuel hoses areattached to the filter assembly.

6) Run the engine and check the filterand lines for leaks.

62Y-9-18-4 5/2/01 3:12 PM Page 16

-

4-16

E

EMU00376

ADJUSTING IDLING SPEED

w8 Do not touch or remove electrical parts

when starting or during operation.8 Keep hands, hair and clothes away

from flywheel and other rotating partswhile engine is running.

cCThis procedure must be performed whilethe outboard motor is in the water. Aflushing attachment or test tank can beused.

A diagnostic tachometer should be usedfor this procedure.1) Start the engine and allow it to warm

up fully in Neutral until it is runningsmoothly. If the outboard is mountedon a boat, be sure the boat is tightlymoored.