OPW AST Catalog.sflb

-

Upload

gabriel-polanco-fossatti -

Category

Documents

-

view

232 -

download

0

Transcript of OPW AST Catalog.sflb

-

7/28/2019 OPW AST Catalog.sflb

1/52

U N I T E D S T A T E S | B R A Z I L | E U R O P E | C H I N A | A N D E V E R Y W H E R E I N B E T W E E N

O P W A S T P R O D U C T S C A T A L O G | 2011

www.opwglobal.com

Couplers, Adaptors and Caps

Tank Venting

Tank Valves

Leading the Wayin Above Ground Storage Tank Innovation Worldwide

Overfll Prevention Spill Containment

Tank Alarms and Gauges Protective Curb

Piping & Containment Systems

Fuel Control SystemsDispensing Products

-

7/28/2019 OPW AST Catalog.sflb

2/52

-

7/28/2019 OPW AST Catalog.sflb

3/52

2Leading The Wayin Fueling Innovation Worldwide

Above Ground Storage Tank Equipment

2

Above Ground Tank Diagrams

- Non-EVR Direct Fill AST Application ........................................................................................... 3 - 4

- Non-EVR Remote Fill / Remote Dispensing AST Application.................................... 5 - 6

- Non-EVR Remote Fill / Remote Dispensing AST Fleet Application ....................... 7 - 8

- Non-EVR Remote Fill Diesel/Fuel Oil/Generator Application.................................. 9 - 10

- Phase 1 CARB Certied AST EVR Direct Fill AST Application ................................ 11 - 12

- Phase 1 CARB Certied AST EVR Remote Fill / Remote DispensingAST Application .................................................................................................................................... 13 - 14

Emergency Venting Size Selection Guide .................................................................................. 15 - 16

Spill Containment........................................................................................................................................ 17 - 18

Overll Prevention ..................................................................................................................................... 19 - 20

Fuel Delivery Coupler/Accessories .................................................................................................. 21 - 22

Stage 1 Vapor Recovery Adaptors, Caps and Bushings .................................................... 23 - 25

Tank Venting.................................................................................................................................................... 26 - 31

Electronic Fuel Management Systems ................................................................................................... 32

Mechanical Tank Gauges.................................................................................................................................. 33

Tank Alarms ............................................................................................................................................................... 34

OPW 62M Monitor Probe Cap & Adaptor.............................................................................................

35

Face Seal Adaptor and Dedicated Gauging Port ............................................................................ 36

Anti-Siphon Valves................................................................................................................................................ 37

Solenoid Valves ....................................................................................................................................................... 38

Two-Way Ball Valve ............................................................................................................................................... 39

Emergency Shut-Of Valves ............................................................................................................................ 40

Swing Check Valves.............................................................................................................................................. 41

Dispensing Products ........................................................................................................................................... 42

Hose Retractors.............................................................................................................................................. 43- 45

Dispenser Pedestals ............................................................................................................................................. 46

Piping & Containment........................................................................................................................................

47

Island Forms & Protective Curbing............................................................................................................ 48

Fuel Compatibility Matrix ................................................................................................................................ 49

OPW Standard Product Warranties ........................................................................................................... 50

-

7/28/2019 OPW AST Catalog.sflb

4/52

D

C

3

Above

Ground

Storage

Tank-DirectFill

TypicalNo

n-EVR

DirectFillASTA

pplication

S

uction

Pump

A

B

1

20

2

21

ToPressureVacuumVent

-

7/28/2019 OPW AST Catalog.sflb

5/52

4

TOP OF AST(not supplied)

1DK-2100EVRDrain Valve

16

17

18

10

9

11

12

14

14

15

13with 1DK-2100EVR

Drain Valve

Direct ll drop tubes shall be cut

at 45 angle, with top o cut no

greater than 6" rom the bottom

o the tank (Or i outside the

State o Caliornia, per local

requirements)

C D

2" Nipple(not supplied)

2" Pipe

(not supplied)

TOP OF AST(not supplied)

19

4" Nipple (not supplied)

2" Nipple (supplied)

B3

A

4

NOTE: The

compliance

then these t

tank gauge

6"

1 2(

2 6

33

(

43

(

5 1

6 1

7 1

8 6

9 1

10 6

11

A

B

126

T

13 3

14 6

15 6

16 6

17 2

18 6

19 5

20 6

21 F

TOP OF AST

(not supplied)

TOP OF AST(not supplied)

5

6 8

7

TOP OF AST(not supplied)

OR

B

PR

-

7/28/2019 OPW AST Catalog.sflb

6/52

1

2 3

5Above Ground Storage Tank - Remote Fill - Re

Typical Non-EVR Remote Fill / Remote Dispensing

1

2

5

3 427

28

A D

B

ToPressureVacuum

Vent

Vapor Return

Fill Pipe

-

7/28/2019 OPW AST Catalog.sflb

7/52

TOP OF AST(not supplied)

2" Nipple(not supplied)

Fill Pipe

6

KEY

1 178S

2 821 S

3 21BV

4 199AS

5 82RV

6 53-00X

7 634B-

8 20424

9 633AS

10301 S

(See V

11301 S

(See V

12 61ST

13 61FT

14

200TG

(optio

15 61T S

16 TGTA

17 44TA-

18 175 S

19 6211R

201611A1611AKamv

21

A) 634

B) 634633

C) 634or

D) 634

16

22 1711D

23 1711T

24 144TA(optio

25 1611A

26 61VS

27 62M S

28 FSA-4

7

8

9

A C

2" Nipple(not supplied)

2" Pipe(not supplied)

TOP OF AST

(not supplied)

6

16

17

24

20 21

22

1923

15

14

13

12

B

Direct ll drop tubes shall be cut at 45 angle, withtop o cut no greater than 12" rom the bottom o

the tank (Or i outside the State o Caliornia, perlocal requirements)

D

TOP OF AST(not supplied)

TOP OF AST(not supplied)

10

11

12"

25 or 26

NOTE: The OPW 200TG and 144TA/444TA are not required or EVR compliance, but i a tank gauge or tank alarm

is used on your tank then these two OPW products are the only CARB AST EVR certied tank gauge and alarm.

-

7/28/2019 OPW AST Catalog.sflb

8/52

7

ToPressureVacuumV

ent

77

A

26

27

28

1 430

B

29

29

3 7

8

28

2

Vap

Fill

Above Ground Storage Tank - Remote Fill - ReTypical Non-EVR Remote Fill / Remote Dispensing AS

24

34

33

32

OPTIO29

35

26

-

7/28/2019 OPW AST Catalog.sflb

9/52

8

O

1 821 Series Solenoid V

2 82RV Series Pressure

3 21BV Series Ball Valv

4 199ASV Series Anti-S

5301 Series Emergency

(See Vent Size Congu

6301 Series Emergency

(See Vent Size Congu

7 62M Series Monitoring

8 FSA-400 Face Seal Ad

9 200TG-ENG Series Ta

10 TGTA-0400 4" Gauge/A

11 44TA-LLFS Liquid Lev

12 61STOP-XXXX Serie

13 61T Series Drop Tube

14 61FT Series Drop Tub

15 175 Series Swing Che

16 6211R Series Remote

17 144TA/444TA Series T

181611AN-0200 or 16121611AN-0300 or 1612A

19

A) 634B-0140 Dust Cap

B) 634B-0150 Dust Cap

C) 634B-0160 Dust Cap 1611AN-2040 or 161

D) 634B-0170 Dust Cap

20 1711D & 1712D Series

21 1711T-7085-EVR Cap or

22 1611AV Vapor Recove23 61VSA Series Vapor R

24 S100 & 102 Series Hos

25 OPW Dispenser Pede

26* Flexible Piping System

27* Commando Flexible C

28* Underground Containm

29* Probes & Sensors or Liq

30* Automated Fuel Contr

31* Automatic Tank Monitor

PRODUCT K

C

B

Direct ll drop tubes shall be cut at 45 angle, with top o cut nogreater than 12" rom the bottom o the tank (Or i outside theState o Caliornia, per local requirements)

9

10

11

13

12

14

2116

17

18 19 20

A

TOP OF AST(not supplied)

5

6

TOP OF AST(not supplied)

Fill Pipe

TOP OF AST(not supplied)

12"

2" Nipple(not supplied)

ConduitTo Remote

Alarm

22 or 23

34* OPW Breakaways

35* OPW Island Forms and Bumper Guards

32* OPW Fueling Nozzles

33* OPW Swivels

NOTE: The OPW 200TG and 144TA/444TA are not required or EVR compliance, but i a tank gauge or tank alarm is used on your tank then these two OPW products

are the only CARB AST EVR certied tank gauge and alarm.

*See OPW 2011 Catalog or visit: www.opwglobal.com

-

7/28/2019 OPW AST Catalog.sflb

10/52

9Above Ground Storage Tank - Remote FillTypical Diesel/Fuel Oil/Generator Application

3

29

A*

B

ToPressureVacuumV

ent

1

2

11

123

Vap

C

31

31 2829

27

Entry Boot

(Not Supplied)

29

27

29

-

7/28/2019 OPW AST Catalog.sflb

11/52

Direct ll drop tubes shall be cut at 45 angle, with top

o cut no greater than 12" rom the bottom o the tank(Or i outside the State o Caliornia, per local requirements)

10

4

5

6

A*

2" Nipple(not supplied)

2" Pipe(not supplied)

TOP OF AST(not supplied)

7

PROB

TOP OF AST(not supplied)

D

2" Nipple

(not supplied)

Fill Pipe

ConduitTo Remote

Alarm

TOP OF AST(not supplied)

C

15

16

17

8

13

14

9

25 or 26

2419

20

21 22

23

NOTE: The OPW 200TG and 144TA/444TA are not

required or EVR compliance, but i a tank gauge

or tank alarm is used on your tank then these two

OPW products are the only CARB AST EVR

certied tank gauge and alarm.

10

TOP OF AST(not supplied)

12"

1 21

2 82

3 PD

4 63

5 206 63

7 53

8 61

930

(Se

1030

(Se

11 62

12 FS

13 61

14 61

15 20(op

16 TG

17 44

18 17

19 62

20 14(op

211616Ka

22

A)

B)

C)

D)

23 17

24 17

25 16

26 61

27Fle

Ge

28 Un

29 En

30 Automatic Tank Monitoring & Leak Detection Equipment

31 Probes & Sensors or Liquid & Vapors

*See OPW 2011 Catalog or visit: www.opwglobal.com

*NOTE: Per local & state jurisdictionrequirements.

-

7/28/2019 OPW AST Catalog.sflb

12/52

11

C

11Above Ground Storage Tank - Dire

Typical OPW Phase I System or A

3

1

2

4

Suction

Pump

A B

ToPressureVacuumV

ent

CARB REQUIRED PRODUCTS

The only Above GroundStorage Tank (AST)products in the industryto be certifed by CARB

NOTE: The 61T Series DropTube must be ordered whenusing a 200TG Tank Guage

-

7/28/2019 OPW AST Catalog.sflb

13/52

1212

TOP OF AST

(not supplied)

1DK-2100EVRDrain Valve

17

18

19

11

12

13

15

16

14with 1DK-2100EVR

Drain Valve

Direct ll drop tubes shall be cutat 45 angle, with top o cut nogreater than 6" rom the bottom othe tank (Or i outside the State oCaliornia, per local requirements)

C D

2" Nipple(not supplied)

2" Pipe

(not supplied)

TOP OF AST(not supplied)

20

4" Nipple (not supplied)

2" Nipple (supplied)

1 62

2 FS

3 200(op

4 61

530

(Se

630

(Se

7 17

8 16

9 17

10 61

11 17

12

A)

B)

C)

D)

1316

16

Ka

14 33

15 61

16 61

17 63

18 20

19 63

20 53

A

6

TOP OF AST(not supplied)

NOTE: The OPW 200TG and 144TA/444TA are not required or EVR compliance, but i a tank gauge or tank alarm

is used on your tank then these two OPW products are the only CARB AST EVR certied tank gauge and alarm.

5

TOP OF AST

(not supplied)

6"

7

8 10

9

TOP OF AST(not supplied)

B

OR

Any Combination

-

7/28/2019 OPW AST Catalog.sflb

14/52

13Above Ground Storage Tank - Remote Fill - Re

Typical OPW Phase I System or A

ToPressureVacuumV

ent

AB

D

OPW RECOMMENDED PRODUCTS

CARB REQUIRED PRODUCTS

The only Above GroundStorage Tank (AST)products in the industryto be certifed by CARB

5

3 42

1

Fill Pipe

Vapor Return

28

27

-

7/28/2019 OPW AST Catalog.sflb

15/52

27 62M Series Monitoring Probe Cap & Adaptor 35

28 FSA-400 Face Seal Adaptor 36

14

7

8

9

A C

2" Nipple(not supplied)

2" Pipe(not supplied)

TOP OF AST(not supplied)

6

1626

20 21

22

1925

14

15

13

12

6

B

D

Direct ll drop tubes shall be cut at 45angle, with top o cut no greater than 12"rom the bottom o the tank (Or i outside the

State o Caliornia, per local requirements)

KEY

1 178S Se

2 821 Ser

3 21BV Se

4 199ASV

5 82RV S

6 53-00XX

7 634B-01

8 204247

9 633AST

10301 Ser

(See Ve

11301 Ser

(See Ve

12 61STOP

13 61FT Se

14 61T Ser

15200TG-E

(optiona

16 TGTA-0

17 44TA-LL

18 175 Ser

19 6211R S

201611AN1611ANKamvalo

21

A) 634BB) 634B

633AS

C) 634Bor 16

D) 634B1612A

22 1711D &

23 1611AV

24 61VSA S

25 1711T-70

26 144TA/4

NOTE: The OPW 200TG and 144TA/444TA are not required or EVR compliance, but i a tank gauge or tank alarm

is used on your tank then these two OPW products are the only CARB AST EVR certied tank gauge and alarm.

REQUIRED P

TOP OF AST(not supplied)

10

TOP OF AST(not supplied)

11

TOP OF AST(not supplied)

17

Fill Pipe

12"

2" Nipple

(not supplied)Conduit

To Remote

Alarm

23 or 24

-

7/28/2019 OPW AST Catalog.sflb

16/52

15

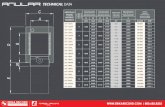

EMERGENCYVENTGUIDE

Table 1

15

Emergency Venting Size Selection GuideFor Horizontal Above Ground Storage Tanks

The OPW AST Venting Guide is supplied to assist emergency venting selection for above ground storage tanks (AST).

The table below contains common tank sizes and based on the Wetted Area of a horizontal cylindrical storage tank, the correct

size OPW Emergency Vent . The following chart, was taken directly from NPFA 30 and UL 142.

Horizontal AST Emergency Venting Size Guide

Tank Specications

Capacity Diameter Length Wetted Area Required Vent Capacity OPW 301Vent Size

Gallons Liters ft. or in. Meters ft. or in. Meters sq. ft. sq. m. CFH CMH

280 1,060 3' 0.914 5'-2" 1.574 47 4.366 49,520 1,402 4"

300 1,136 38" 0.965 5' 1.524 49 4.552 51,640 1,462 4"

500 1,893 4' 1.219 5'-5" 1.651 69 6.410 72,650 2,057 4"

530 2,006 4' 1.219 6' 1.828 71 6.596 74,750 2,117 4"

550 2,082 64" 1.626 6' 1.828 75 6.967 78,950 2,236 4"

1,000 3,785 64" 1.626 10'-8" 3.251 119 11.055 124,950 3,538 6"

1,000 3,785 64" 1.626 6' 1.828 109 10.126 114,450 3,241 6"

1,500 5,678 64" 1.626 9' 2.743 147 13.657 154,350 4,371 6"

2,000 7,571 64" 1.626 12' 3.657 184 17.094 193,200 5,471 6"

2,500 9,464 64" 1.626 15' 4.572 222 20.624 223,320 6,324 6"

3,000 11,356 64" 1.626 18' 5.486 259 24.062 243,680 6,900 6"

3,000 11,356 6' 1.828 14' 4.267 240 22.297 233,400 6,609 6"

4,000 15,142 64" 1.626 24' 7.315 335 31.123 281,100 7,960 8"

4,000 15,142 6' 1.828 19' 5.791 311 28.893 270,060 7,647 8"

5,000 18,927 8' 2.438 13'-4" 4.064 326 30.286 276,960 7,843 8"

6,000 22,712 8' 2.438 16' 4.876 376 34.932 300,480 2,364 8"

8,000 30,283 8' 2.438 21'-4" 6.502 477 44.315 344,340 9,751 8"

10,000 37,854 8' 2.438 27' 8.229 584 54.255 385,920 8"

10,000 37,854 9' 2.743 21' 6.400 540 50.168 369,200 10,455 8"

10,000 37,854 10' 3.048 17' 5.181 518 48.124 360,840 10,218 8"

10,000 37,854 10'-6" 3.200 15'-7" 4.749 515 47.845 359,700 10,186 8"

12,000 45,425 8' 2.438 32' 9.753 678 62.988 420,080 11,895 8"

12,000 45,425 9' 2.743 25' 7.620 625 58.064 401,000 11,355 8"

12,000 45,425 10' 3. 048 20'-6" 6.248 600 55.742 392,000 11,100 8"

12,000 45,425 11' 3.352 17' 5.181 583 54.162 385,540 10,917 8"

15,000 56,781 8' 2.438 40' 13.192 829 77.017 470,990 13,336 10"

15,000 56,781 8' 2.438 23'-5" 7.137 703 65.311 429,020 12,148 10"

20,000 75,708 10' 3.048 34'-2" 10.414 922 85.657 499,820 14,153 10"

20,000 75,708 10'-6" 3.200 31' 9.448 896 83.241 491,760 13,925 10"

20,000 75,708 11' 3.352 28' 8.534 868 80.640 483,080 13,679 10"

25,000 94,635 10'-6" 3.200 38'-6" 11.734 1,082 100.52 537,530 15,221 10"

30,000 113,562 10'-6" 3.200 46'-3" 14.097 1,274 118.36 568,100 16,087 10"

Table 1

-

7/28/2019 OPW AST Catalog.sflb

17/52

1616

Horizontal AST Emergency Vent SelectionFor Horizontal Above Ground Storage Tanks

TABLE 1 is a pre-calculated chart that may have all the information needed to choose the proper emergency vent. If the tank size is notin the pre-calculated chart, use the example below as a guide to gure out the wetted area, cubic feet per hour (CFH), and proper ventselection for the particular tank.

**EXAMPLE:

Given: Tank capacity is 10,000 gallons; 10 feet in diameter x 17 feet long.Table 2From TABLE 1: WA = 518 sq. ft.

If not in the table, do the following to calculate the wetted area:

Formula: WA=.75 2 + pdl =.75 + pdl

WA = wetted area in square feet75% = horizontal tank factorp = 3.14d = diameter of tank end in feetl = length of tank in feet

WA=.75 + (3.14 x 10 x 17)WA=.75 (157.0 + 533.8) = 518 square feet rounded

Step 2

If the tank size is in the chart, use the supplied CFH values todetermine the emergency vent size needed in TABLE 1.

If not in the charts, continue the following example:

Using 518 square feet, the cubic feet per hour (CFH) can be found using TABLE 1.Since 518 falls between the values of 500 and 600, interpolation is necessary as follows:

600 sq. ft. 392,000 CFH-500 sq. ft. -354,000 CFH

Difference: 100 sq. ft. 38,000 CFH

38,000 x

100 518-500Total CFH required = 354,000 CFH + 6,840 CFH = 360,840 CFH

Step 3

Vent selection: using TABLE 1, nd the range in which 360,840 CFH falls.The tables show that an 8" emergency vent is needed.

**PEI Recommended Practices 200-96

3.14 x102

2

pd 2

4

pd 2

2

Wetted Area vesus

Cubic Feet of Free Air Per Hour(14.7 PSIA and 60)

sq. ft. sq. m. CFH CMH

20 1.858 21,100 597.48

30 2.787 31,600 894.81

40 3.716 42,100 1,192.13

50 4.645 52,700 1,492.29

60 5.574 63,200 1,789.62

70 6.503 73,700 2,086.95

80 7.432 84,200 2,384.2790 8.361 94,800 2,684.43

100 9.290 105,000 2,973.26

120 11.148 126,000 3,567.92

140 13.006 147,000 4,162.57

160 14.864 168,000 4,757.23

180 16.723 190,000 5,380.20

200 18.581 211,000 5,974.85

250 23.226 239,000 6,767.72

300 27.871 265,000 7,503.96

350 32.516 288,000 8,155.25

400 37.161 312,000 8,834.85

500 46.452 354,000 10,024.16

600 55.742 392,000 11,100.20

700 65.032 428,000 12,119.61

800 74.322 462,000 13,082.38

900 83.613 493,000 13,960.20

1,000 92.903 524,000 14,838.02

1,200 111.48 557,000 16,338.82

1,400 130.06 587,000 16,621.98

1,600 148.64 614,000 17,386.54

1,800 167.23 639,000 18,094.46

2,000 185.81 662,000 18,745.75

2,400 222.97 704,000 19,935.06

>2,800 > 260.13 742,000 21,011.10

SOURCE:Flamable and Combustible Liquids Code 30, NFPA.

Interpolate for immediate values.

Table 2

; x =6,840 CFH

See TABLE 2 foradditional CFH values.

-

7/28/2019 OPW AST Catalog.sflb

18/52

17

ABOVEGROUNDSTORAGETANKSPILLCONTAINERS

Dimensions

Capacity A B

Model # gal. liter in. cm in. cm

331 7 26.5 15 38 17 43

332 7 26.5 14 35 17 43

uEasy Installation 4" and 6" NPT

threaded base screws directly to the

tank riser pipe. No urther adjustments

are needed.

uIntegral Drain Valve allows high-

speed drainage o spilled product back

into the tank.

uCapacity available in 7-gallon (26.5

liter) container capacity. Larger 7-gallon

capacity spill containers provide

additional clearance or 61STOP

Overll Prevention Valves

(3.5 gallon-221 only).

uRain-Shedding Cover Design

hooded cover design helps prevent

water or snow entry by extending the

lip o the cover over the body o the

spill container.

uWelded-Hinge, Lockable Hatch the

cover includes a provision or a padlock

and a welded-hinge assembly or

added security.

u12 Gauge Epoxy-Powder Coated

Construction heavy-duty materials,

compatible with hydrocarbons, or long

service lie and added security.

u331AST Heavyweight, Welded Base

Design all versions have cast-iron

base and 12-gauge steel walls

(model 331) and 14-gauge steel

wall (model 332) provide solid

strength or heavy-duty applications.

u332AST Spun Steel Design spunsteel construction provides a lightweight,

one-piece design or easy installation

and a clean, sleek appearance on

aboveground tanks.

uAll Models Are ULC Listed clearly

labeled to identiy the listing.

uCARB EVR Certied

POMECO/OPW 331AST& 332AST Direct-FillAbove Ground StorageTank Spill Containers

POMECO/OPW Direct-Fill AST Spill

Containers are designed to preventspilled product rom entering soil near

the ll and vapor return riser connections

on an above ground storage tank during

normal tank lling operation. The spill

containers catch spillage to help prevent

soil contamination and groundwater

pollution. POMECO/OPW Direct-Fill AST

Spill Containers thread on the top o an

above ground tank and allow or drainage

o spilled product back into the tank.

Features

331AST

331AST and 332AST Spill Containers

Instruction Sheet Order Number: 203168

CARB APPROVED AST EQUIPMENT

Product No. Description Liters

331-ASTW74 Welded, 7 gallon, 4" NPT Welded, 26.4 liter, 4" NPT

331-ASTW76 Welded, 7 gallon, 6" NPT Welded, 26.4 liter, 6" NPT

332-ASTW74 Spun, 7 gallon, 4" NPT Spun, 26.4 liter, 4" NPT

332-ASTW76 Spun, 7 gallon, 6" NPT Spun, 26.4 liter, 6" NPT

Ordering Specifcations:

Listings and

Certifcations

CARB Certifed

AST Phase 1 Enhanced Vapor Recovery (EVR) System

EO-VR 401-B

B

A

331-AST

B

A

332-AST

Replacement Parts:Part # Description

1DK-2100-EVR Drain Valve

-

7/28/2019 OPW AST Catalog.sflb

19/52

18

L Adjustable legs andNo base drain valve

LD Adjustable legs withbase drain valve

N No legs and Nobase drain valve

ND No legs with basedrain valve

6 R

211 15 0 B2 L

211SS 20 1 B3 LD

30 2 B4 NN ND

0 No entry holes1 1, 4" entry hole2 2, 4" entry holes

(30 Gallon Only)

211 12 Gauge Powder-

Coated SteelConstruction

211SS Stainless SteelConstruction

POMECO/OPW211-RMOT Remote-FillAbove Ground StorageTank Spill Containers

POMECO/OPW Remote-Fill AST Spill

Containers are designed to prevent spilledproduct rom entering soil near the remote,

horizontal-ll and vapor return connections

on an above ground storage tank during

normal tank lling operation. The spill

containers catch spillage to help prevent

soil contamination and groundwater

pollution. POMECO/OPW Remote-Fill

AST Spill Containers slip on the remote-

ll and vapor return piping connected to

an above ground tank. Compatible with

methanol, ethanol, jet and AV-Gas uels.

D

C

B

A

2" FNPTFitting

F

E

G

Featuresu Easy Installation a 4" fexible boot

on the back panel allows or a quick,simple connection to the remote ll orvapor lines. Optional reducer insertsare available to accommodate 3" and 2"piping connections.

u Models to Accommodate VariousFill Pipe Congurations availablein 15, 20 and 30-gallon containercapacity. Smaller 15-gallon models aredesigned or a single-ll or vapor returnconnection. Larger 20 and 30-gallonmodels accept both ll and vapor returnpiping in a dual-port conguration. The30-gallon model will accommodate bothll and vapor return piping in a single-port conguration and allow the use o3" Dry Disconnects (OPW 1611AN and1711D) in a dual-port conguration.

u Rain-Shedding Cover Design hooded cover design helps prevent

water or snow entry by extending the lipo the cover over the body o the spillcontainer.

u 12-Gauge Epoxy-Powder CoatedSteel or Stainless Steel Constructionheavy-duty materials, compatible withhydrocarbons, or long service lie andadded security.

u Welded-Hinge, Lockable Hatch cover includes a provision or a padlockand a welded-hinge assembly or addedsecurity.

u Easy Product Drainage lockable ballvalve drain provides or quick and easyproduct removal.

u Height Adjustable adjustable legsenable the spill container to be set ata variety o heights, rom 161/2" to 30".Each leg is independently adjustable toaccount or uneven ground conditions.

uCARB Certied

u Custom Sizes Available UponRequest.

Dimensions15 Gallon 20 Gallon 30 Gallon

in. cm in. cm in. cm

A 181/4 46 24 61 21 53B 738 19 71/2 19 101/2 27

C 1358 35 161/2 42 161/2 42

D 161/2 to 30 42 to 76 161/2 to 30 42 to 76 161/2 to 30 42 to 76

E 181/4 46 24 61 34 86

F 91/8 23 12 301/2 91/2 24

G 47 to 601/2 119 to 154 561/2 to 80 144 to 203 561/2 to 80 144 to 203

Replacement Parts

Part # Description

201758 4 x 2 Reducer Insert

201759 4 x 3 Reducer Insert

PBOOT Nitrile (Fuel-Resistant) Boot

202312 Aluminum Flange

21BV-0075 Fullport 3/4"

PRMOT-LEGKIT Leg Kit

Ordering Chart:

6211-R

15 15 Gallon Capacity20 20 Gallon Capacity30 30 Gallon Capacity

2 2" Fitting3 3" Fitting4 4" Fitting

B Booted entryttings in holes

N No ttings in holes

Note: an item must be selected for each column.

See PomecoProductCongurator

211R Instruction Sheet Order Number: H15857PA

-

7/28/2019 OPW AST Catalog.sflb

20/52

19

OVE

RFILLPREVENTIONVALVES OPW 61STOP

THE STOPPEROverfll PreventionValves

The OPW 61STOP Overll Prevention

Valve (The Stopper) is designed to prevent

overlling o above ground storage tanksby providing a positive shut-o during a

pressurized-ill (pump-on ill) delivery.

The Stopper threads into the ll opening

and is an integral part o the ill tube.

The OPW61STOP is ully adjustable to

allow or easy installation in new or existing

above ground tanks o various heights and

storage capacities.

The Stopper is a single-action, complete

shut-o valve. When the liquid level rises to

your specic, pre-determined tank capacity,

the valve mechanism is released and

automatically closes with the low o the

product. Any excess product let between

the valve and the uel delivery coupler is

drained into the tank through internal drain

vents. The drain vents on the 61STOP act as

an anti-siphon, by introducing air/vapor into the

ll line, to help isolate the tank rom a potential

siphon due to a broken or leaking ll pipe.

The 61STOP, available in either 2" or 3"

ull-fow models, maximizes fow rates and

minimizes delivery times. The 2" 61STOP

requires a 4" tank opening and minimum tank

ullage (space rom the top o the stored product

to the inside top o the tank) o 8" on the

61STOP-1000 Cylindrical Float model and

a minimum ullage o 4" on the 61STOP-

2000 Float Arm model. The 61STOP-1000,

with the cylindrical foat, eliminates the need

to position the valve to avoid tank walls or

cross-bracing. The 61STOP-2000 with the

foat arm allows or increased usable storage

capacity in the tank, and is well-suited or

small capacity rectangular ASTs. The 3"

61STOP requires a 6" tank opening and

incorporates a cylindrical foat requiring 8"

o tank ullage space.

61Stop-1000 61Stop-3050

u A Special Crossbar Tank-Inlet Adaptor

is provided with each Stopper to provide

or tight-lls and help prohibit open-

lls. Mounting hardware, upper drop

tube and 14" lower drop tube provided

(longer-length drop tubes can be

purchased or added).

u Completely Automatic Operation no pre-checks to perorm, no resets, and

no overrides to be broken or abused.

u Direct or Remote-Fill Compatible

uel delivery couplers can be connected

directly to the 61STOP, or steel pipe

can be threaded into the top o the valve

and piped to a remote location where

the couplers are contained in a

211-RMOT Spill Container.

u Integral Anti-Siphon Valve drain vents

on the 61STOP act as an anti-siphon,

by introducing air/vapor into the ll line

ater the valve actuates, to help isolate

the tank rom a potential siphon due to

a broken or leaking remote-ll pipe.

u 150 psi (10 bar) Pressure Rated* with

Low Pressure Drop to enable quick,sae delivery o uel into the tank.

u 25 GPM (95 lpm) Minimum Flow Rate

Required.

u UL and ULC Listed to satisy

Third Party accreditation

requirements o many jurisdictions.

u CARB Approved VR-401-A; VR-401-B

Features

Valve Body, Adaptor and Collar:Cast aluminum

Poppet: Cast aluminum,hard-coated

Cam: Stainless steel

Follower: BrassShat: CRS zinc-plated

Bearing: Sintered bronze

Float: Closed-cell Nitrile

Nipple: 2" - 3" schedule40 steel pipe

Lower Nipple: 2" - 3" schedule40 steel pipe with Duragardcoating

Materials

*OPW does not recommend pumping pressures above 100 psi or Class 1B uels or remoteapplications and we make no warranties or products used in conjunction with the 61STOP.

NOTE: OPW recommends the use o the 61STOP with clean product only. Debris and otherproducts such as contaminated waste oil may cause improper operation o the valve.

NOTE: The 61Stop can be used in gravity drop provided the minimum fow rate is maintained.A tight shut-o is not achieved in the closed position. However with a minimum tank size o 1,000gallons, the leak rate will provide a 30-minute warning beore the tank is ull.

CARB EVR Certifed

VR-401-A; VR-401-B

Approvals

and Listings

61Stop-2000T 61Stop-3050T61Stop-1000T

61Stop-2000

-

7/28/2019 OPW AST Catalog.sflb

21/52

20

Ordering Specifcations and DimensionsA B C D E F

Product # Description in. cm in. cm in. cm in. cm in. cm in. cm

61STOP-1000 2" Cyl. Float 3 7.6 10 25.4 2 5.1 9 22.4 31516 10 n/a n/a

61STOP-2000 2" Float Arm 3 7.6 10 25.4 1/2 3.8 5-18 22.4 13132 5 6 15.2

61STOP-3050 3" Cyl. Float 3 7.6 105/8 27 2 5.1 8 20.3 51/8 13 n/a n/a

Replacement Parts 3"

Product # Description

D02037M 6" Retaining Collar

C04474RS 14" Nipple

Replacement Parts 2"

Product # Description

C04093M 4" Retaining Collar

C04114RS 14" Nipple

61Stop-1000

2" Schedule40 Pipe Nipple

4" NPTInternal

2" Schedule40 PipeNipple

E

D

B

A

C

61Stop-1000T

2" Schedule40 PipeNipple

D

B

A

C

A

BF

C D

E

61Stop-2000

A

B

E

C

D

61Stop-2000T

B

C

3" Schedule 40Pipe Nipple

6" NPT InternalThreads

E

3" Schedule 40Pipe Nipple

D

271/2"

A

61Stop-3050

B

C

3" Schedule40 Pipe Nipple

D

271/2"

A

61Stop-3050T

61Stop-2"

PRESSUREDROP-PSI

FLOW RATE - GPM

61Stop-3"

PRESSUREDROP-PSI

FLOW RATE - GPM

Replacement Parts 3"

Product # Description

C04438M Float (4 pieces required or 3050)

OPW 61FT Drop TubeThe OPW 61FT Drop Tube is designed toinstall on the bottom o the 61STOP AST

Overll Prevention Valves when a lightweight,

longer, lower drop tube is required.

Constructed o extruded aluminum, the

OPW 61FT is connected to the bottom o the

61STOP by a clevis and cotter pin assembly

and allows or submerged lling o ASTs.

Replacement Parts 2"

Product # Description

H12617M Float or 1000 (4 pieces required)

61ARM-2000 Floating Arm Retrot Kit For 2000

CARB APPROVED AST EQUIPMENT

Product # Description

61FT-0206 2" x 6' Drop Tube Kit

61FT-0312 3" x 12' Drop Tube Kit

61FT Drop Tube Instruction Sheet Order Number:

H14428PA

61FSTOP-1000, 100M, 200M Instruction Sheet Order Number: H12676M

61FSTOP-2000 Instruction Sheet Order Number: H13337M

61FSTOP-3000, 3050, 305A Instruction Sheet Order Number: H13315M

61FT-0312, 0206 Instruction Sheet Order Number: H14428PA

61FSTOP-1000T, 2000T, 3050T Instruction Sheet Order Number: 203163

CARB APPROVED AST EQUIPMENT

A B C D E

Product # Description in. cm in. cm in. cm in. cm in. cm

61STOP-1000T2" NPT withcylindrical foat

10 25.4 2 5.1 9 22.4 31516 10 n/a n/a

61STOP-2000T 2" NPT with foat arm 10 25.4 1/2 3.8 5-18 22.4 13132 5 6 15.2

61STOP-3050T3" NPT withcylindrical foat

105/8 27 2 5.1 8 20.3 51/8 13 n/a n/a

*Recommended or E85

NOTE: When ordering a CARB EVR CertiedOPW 61 STOP, the Kamvalok Adaptor must

be ordered separately. Reer to page 22.

61FT

45

6 inches above the bottomo tank or Local Code

-

7/28/2019 OPW AST Catalog.sflb

22/52

21

ANDACCESSORIES

Typical AST Filling Application

Fuel Delivery CouplersAnd Accessories

Fuel Delivery Couplers and Accessories

are designed to connect uel delivery

transport truck hoses or nozzles to the

ll pipe o an aboveground storage tank.

633B Coupler

Kamlok Couplers

The 633BD has a Kamlok Coupler on one end and external threads on the other end.

This coupler should be threaded into an OPW 190 Nozzle and then coupled to the

61STOP or lling ASTs.

Ordering Specifcations

Elbow/Thread

Product # in. mm

633BD-1261 2 x 11/2 51 x 38

633B-0150 2 x 2 51 x 51

633AST Spout Adaptor

Ordering Specifcations

Elbow/Thread

Product # in. mm

633AST-2061 2 x 2 51 x 51633AST-3061 3 x 3 77 x 77

Tank Inlet Spout Adaptors With Crossbar

The 633AST Series Adaptors, with a boss installed across the inlet, are designed to prohibit

open-lls. Adaptors are supplied with the 61STOP to provide or tight-lls.

633AST Spout Adaptor

Tank Inlet Spout Adaptors

The 633AST is an adaptor that can be threaded onto a 297 Spout. The spout and adaptor

assembly may then be attached to a 190 Nozzle equipped with a 633BD Kamlok coupler

or open lling o ASTs when a 61STOP is not installed.

Dust Caps

The 634B Dust Caps are installed on 633AST Adaptors when not in use. The 634B is

designed to deter dust, debris and water rom entering the tank.

Ordering SpecifcationsCARB APPROVED AST EQUIPMENT

Product # Description in. mm

634B-0140 For 633AST-0150 1-1/2 38

634B-0150 Caps 633AST-2061 or 633AST-0200 Adaptor 2 51

634B-0160Caps 1611AN-0200 or 633AST-0250 or

1611AN-2040 or 1612AN-2040 Adaptors2-1/2 64

634B-0170Caps 61STOP (633AST-3061) or366AST-0300 or 1611AN-3060 or

1612AN-3060 Adaptors3 77

634B-01801611AN-0300 Kamvalok Adaptor or

633AST-0400 Adaptor4 103

OPW 190High-Flow

Nozzle

OPW 633BDKamlok Coupler

OPW 633ASTSpout Adaptor

Pomeco211AST

AST SpillContainer

OPW 634BDust Cap

(covers inletwhen not lling)

OPW 61STOPOverll

PreventionValve

Typical AST Filling Application

OPW 190High-Flow

Nozzle

OPW 633BDKamlok Coupler

Pomeco 211ASTAST Spill Container

OPW 633ASTSpout Adaptor

OPW 297Aluminum Spout

For more inormation contact OPW Customer Service at

1-800-422-2525; International call 1-513-870-3315.

Ordering SpecifcationsCARB APPROVED AST EQUIPMENT

Elbow/Thread

Product # in. mm

633AST-0150 1.5 x 1.5 38 x 38

633AST-0200 2 x 2 51 x 51

633AST-0250 2.5 x 2.5 64 x 64

633AST-0300 3 x 3 76 x 76

633AST-0400 4 x 4 102 x 102

633FAST-XXXX, Male Thread Equivelent o Adaptors Above

Dust Cap

-

7/28/2019 OPW AST Catalog.sflb

23/52

22

Dust Plug

Lockable Dust Plug

Lockable Dust Caps

The 634BK-0090 is a 2" lockable dust cap or

the 61STOP. It will cap o any 2" 633AST

Tank Inlet Spout Adaptor and oers theadded eature o being lockable.

Ordering Specifcations

CARB APPROVED AST EQUIPMENT

Product # Description in. mm

634BK-0090 Caps 633AST Adaptor 2 51

634BK-0100 Caps 633AST Adaptor 3 77

634BK-0200 Caps 633AST Adaptor 4 103

Spout Kits AndDelivery CouplersAnd Accessories

Fuel Delivery Couplers and Accessories

are designed to connect uel delivery

transport truck hoses or nozzles to the ll

pipe o an aboveground storage tank.

Poppeted Kamvalok Fill Adaptors

The 1611AN Series Kamvalok Adaptor is installed at the ll pipe and replaces the 633AST.

The 1611AN contains an internal spring-loaded valve assembly that automatically closes tohelp prevent uel spillage. The 1611AN mates with the 1711D Coupler to open the

spring-loaded valve and proceed with a delivery.

1611 & 1612 Series Kamvalok Fill Adaptors

Installed onto the 61STOP overfll prevention valve. Contains an internal spring- loaded valveassembly that automatically closes to help prevent uel spillage.

Ordering Specifcations

CARB APPROVED AST EQUIPMENTProduct # Seal in. mm

1611AN-0200 Remote Fill with Buna Seal 2 51

1611AN-0300 Remote Fill with Buna Seal 3 77

1612AN-0150 Remote Fill with Viton Seal 11/2 38

1612AN-0200 Remote Fill with Viton Seal 2 51

1612AN-0300 Remote Fill with Viton Seal 3 77

* Thread and Kamvalok same size

Poppeted Kamvalok Couplers

The 1711D Series Kamvalok Couplers are installed on the uel delivery transport truck hose

and mate with the 1611AN Adaptors. The combination o the 1711D and 1611AN enable dry

connection and dry disconnection o delivery ttings to help prevent accidental spillage o product.

Ordering SpecifcationsCARB APPROVED AST EQUIPMENT

Product # Seal in. mm

1711D-1075 Buna 2 51

1711D-1080 Buna 3 77

1712D-1085 Viton 11/2 38

1712D-1090 Viton 2 51

1712D-1095 Viton 3 77

* Thread and Kamvalok

same size

Dust Plugs

The 634A Dust Plug is installed in the end o the 1711D,

when not in use. The 634A is designed to help prevent

dust, dirt and debris rom damaging the internalcomponents o the 1711D Kamvalok Coupler.

Ordering SpecifcationsProduct # Description in. mm

634A-0160 Plugs 1711D or 1712D - 2" Kamvalok Coupler 2 1/2 64

634A-0180 Plugs 1711D or 1712D - 3" Kamvalok Coupler 4 103

Poppeted Kamvalok Couplers

Poppeted Kamvalok CouplersorRemote Fill

Kamvalok AdaptororDirect Fill

Typical AST Filling Application

OPW 1611AN or 1612ANKamvalok Adaptor

OPW 1711D or 1712DKamvalok Coupler

OPW 211-RMOTRemote Fill

Spill Container

CARB APPROVED AST EQUIPMENT

Product # Seal in. mm

1611AN-2040 Direct Fill with Buna seal 2 51

1612AN-2040 Direct Fill with Viton seal 2 51

1611AN-3060 Direct Fill with Buna seal 3 77

1612AN-3060 Direct Fill with Viton seal 3 77

Ordering Specifcations

1611AN Adaptor Instruction Sheet Order Number: 204016

1611AN Adaptor Instruction Sheet Order Number: 204016

H32116PA Coupler Instruction Sheet Order Number: 204016

-

7/28/2019 OPW AST Catalog.sflb

24/52

23

ANDCAPS OPW Stage I Vapor

Recovery Adaptors

Stage I Vapor Recovery Adaptors are

installed in spill containment manholes

on the vapor recovery riser pipe rom

an underground gasoline storage tank.

They mate with the vapor recovery elbowon the delivery transport truck when

recovery o gasoline vapors is required.

OPW 61VSA VaporSwivel Adaptor

The OPW 61VSA Vapor Swivel Adaptor

is a poppeted adaptor, designed to mate

with a vapor recovery elbow, eaturing

a top section that rotates with hose

movement while the bottom section

remains securely sealed to the 4-inch

tank riser.

OPW 61SA-TOOL

The 61SA-TOOL is a wrench designed

to thread on the 61SA Fill and 61VSA

Vapor Adaptors. The OPW 61SA-TOOL

Adaptor installation tool is required

to ensure proper installation o OPW

rotatable swivel adaptors, thread-on spill

containers, ll and vapor adaptors,TC-400

torque cap or pipe nipples and threaded

riser adaptors as per EVR requirements.The 61SA-TOOL includes provisions or

the use o a torque wrench to acilitate

accurate installation and testing.

57/8"149mm

51/2" Across Lugs139.7mm

445/64"120mm

Adaptor: Bronze

Base: Bronze

Retaining ring:Conductive nylon

Set screws:

Stainless steelSeals: Nitrile

Materials

uDual Seals ensure a vapor and

liquid-tight seal.

uConductive, Sel-Lubricating Retaining

Rod ensures maintenance-ree, reliable

service lie.

uSame Internal Dimension as Standard

633T Adaptors to minimize pressure

drop and maximize fow rates or quick

product delivery.

uSel Guiding Poppet or consistenttight seal.

Features

61SA-TOOL

61VSA-1020-EVRUSA Patent No. 5,664,951

-

7/28/2019 OPW AST Catalog.sflb

25/52

24

Product # Description

PDT-411 4" x 1" x 1" Double Tap Bushing

Ordering Specifcations

5 7/16"138mm

5 1/8"128mm

Replacement Parts

Key Part # Description

1 C02642M Bridge Guide

Not Shown H15294M Screw (3") (76mm)

2H04145MH04150M

Gasket (3") (76mm)Gasket (3"x 4")(76 x 102mm)

3 H08989M Spring

61VSA-KIT Complete Replacement Kit

Product # ElbowSize

RiserThread Body Material

in. mm in. mm lbs. kg

1611AV-1605 3 76 3 76 2.91 1.32 Clear Anodized Aluminum

1611AV-1620 3 76 4 102 3.25 1.48 Clear Anodized Aluminum

1611AVB-1625 3 76 4 102 7.97 3.62 Cast Bronze

Ordering Specifcations

OPW 1611 Series VaporRecovery Adaptor

The OPW 1611AV and 1611AVB are

poppeted adaptors, designed to mate

with a vapor recovery elbow, or returning

gasoline vapor to the tank truck during

a uel delivery to an underground tank.

FlexWorks PDT-411Double Tapped TankBung Fitting

FlexWorks Double-Tapped Tank Bung

Fitting, 4" (10 cm) MNPT w/Dual 1" (3 cm)

FNPT Taps - Used in 4" (10 cm) Tank

Bung to accommodate FOP Supply

and Return Lines

Materials

Body: Clear anodized aluminumor cast bronze

Stem: Chrome-plated steel

Stem Guide:Acetal resin

Spring: Stainless steel

Gasket: Nitrile

1611AV 3" x 4"(76 x 102mm)

PDT-411

-

7/28/2019 OPW AST Catalog.sflb

26/52

25

OPWSTAGE

1VAPORRECOVERYCAPS

Look or this label orauthentic OPW EVRApproved products.

Replacement Parts

Part # Description

H15005M Nitrile Gasket

Ordering Specifcations

Product # in. mm lbs. kg

1711LPC-0300 3 76 3.5 1.59

63/4" REF.

3 5/16"REF.

7"178mm.

Eective height above adaptor 11932"

Eective height above adaptor12"

2 9/16"65mm.

8 7/16"

7/8"23mm

6.873"174.5mm

Product # in. mm lbs. kg

1711T-7085-EVR 3 76 1.1 .50

Replacement Parts

Part # Description

H10886M Nitrile Gasket

OPW Stage 1 VaporRecovery Caps

OPW 1711T

The OPW 1711T Vapor Recovery Cap

is or use with the OPW 1611AV, 61VSA,

1611AVB and 1611VR Adaptors. The

1711T is installed on the vapor recovery

adaptor, when not in use, to prevent

vapors rom escaping and to prevent

water, dust and debris rom entering the

tank. Constructed o Duratu to help

prevent corrosion, the OPW 1711T will

couple to Civacon/OPW 4" Kamloks,

and eatures a center post that allows

an even distribution o orce when

coupling to the adaptor. The 1711T

can be locked with a padlock.

OPW 1711LPC LowProfle Vapor Cap

The OPW 1711LPC Low Prole Top-

Seal Vapor Cap is designed or tight

installations where the clearance

between the top o the vapor adaptor

and the underside o the spill container

or manhole cover is limited. The

rugged iron lever provides a positive

cam-action that seats the cap rmly

in the adaptor groove or a water and

vapor-tight seal. When engaged, the

lockable cap adds only 1/2" to the

nal height o the adaptor. The cap is

powder-coated API Orange to signiy

vapor recovery. The 1711LPC can

be used with the OPW 3" 1611AV,

1611AVB and 61VSA series vapor

adaptors.

Body: Duratu

Pins: Stainless steel

Links: Duratu

Gasket:Nitrile

Color: Orange

Materials

Cap: Cast zinc alloy(powder-coated

orange)

Lever: Ductile iron

Gasket:Nitrile

Materials

Ordering Specifcations

1711T Cap

1711LPC Cap

Listings and

Certifcations

-

7/28/2019 OPW AST Catalog.sflb

27/52

26

Materials

Approvals

and Listings

OPW 301Emergency Vents

The OPW 301 Emergency Vent is

designed to prevent an above ground

storage tank rom becoming over-

pressurized by providing high-capacity

venting in the event o a re or blockage.

The 301 is a weighted, mushroom-style

emergency vent. When the AST builds

pressure, the weighted cast iron lid

is orced up o its seat to relieve the

pressure. When pressure is relieved, the

lid lowers and is automatically reset. The

appropriate 301 Series vent is determined

by the emergency venting capacity

requirements o the AST and the type

o connection at the tanks emergency

vent opening. The OPW 301 Emergency

Vent is available in 4", 6", 8" and 10"

openings with emale NPT, male NPT

or fanged connections (8"-10") to allow

or easy installation in new or existing

above ground tanks. Various lid pressure

settings determine the initial venting o

the valve.

Lid: Cast iron withpowder-coated nish

Body: Aluminum

Shat: Zinc-plated steel

O-Ring: Buna-N

301 SCFH @ 21/2 PSI(0.17 bar)

4"- 101,0006"- 250,0008"- 471,000

Ordering SpecifcationsCARB APPROVED AST EQUIPMENT

Pressure Mounting A B Weight

Model # in. mm Setting Connection in. mm in. mm lbs. kg

301-3080 3 76 8 oz. Female NPT 4.7 119.4 5.1 129.5 6.7 3

301M-3081 3 76 8 oz. Male NPT 4.7 119.4 5.1 129.5 6.7 3

301-3160 3 76 16 oz. Female NPT 5.7 144.8 5.1 129.5 11.4 5.2

301M-3161 3 76 16 oz. Male NPT 5.7 144.8 5.1 129.5 11.4 5.2

301-4080 4 101.5 8 oz. Female NPT 4.9 124.5 6.1 154.9 10.6 4.8

301M-4081 4 101.5 8 oz. Male NPT 4.9 124.5 6.1 154.9 10.6 4.8

301-4160 4 101.5 16 oz. Female NPT 6.1 154.9 6 152.4 18.1 8.2

301M-4161 4 101.5 16 oz. Male NPT 6.1 154.9 6 152.4 18.1 8.2

301-6080 6 152 8 oz. Female NPT 5.9 149.9 8.1 205.7 20.9 9.5

301M-6081 6 152 8 oz. Male NPT 5.9 149.9 8.1 205.7 20.9 9.5

301-6160 6 152 16 oz. Female NPT 7.4 188 8.1 205.7 37.5 17

301M-6161 6 152 16 oz. Male NPT 7.4 188 8.1 205.7 37.5 17

301-8080 8 203 8 oz. Female NPT 6.2 157.5 10.1 256.5 33.9 15.4

301M-8081 8 203 8 oz. Male NPT 6.2 157.5 10.1 256.5 33.9 15.4

301-8160 8 203 16 oz. Female NPT 7.8 198.1 10.1 256.5 61.9 28

301M-8161 8 203 16 oz. Male NPT 7.8 198.1 10.1 256.5 61.9 28

301F-8085 8 203 8 oz. Flange 6.2 157.5 10.1 256.5 41.8 19

301F-8165 8 203 16 oz. Flange 7.8 198.1 10.1 256.5 70 31.8

301F-1085 10 254 8 oz. Flange 6.5 165.1 13 330.2 65.2 29.6

Features

u Automatically Resets weighted cast

iron cover reseats once the pressure in

the tank is relieved.

u Aluminum Body and Cast Iron Lid

u Epoxy Powder-Coated Cover

prevents rusting o the cover to protect

expensive nishes on ASTs.

u UL Listedto satisy third party

accreditation requirements

o many jurisdictions.

u CARB CertiedAST Phase 1

Enhanced Vapor Recovery (EVR)

System

301 Series Instruction Sheet Order Number: 203568

CARB Certifed

AST Phase 1 Enhanced Vapor Recovery (EVR) System

A

B

Replacement Parts

Part # Description201877 4" Seal

202721 6" Seal

203325 8" Seal

-

7/28/2019 OPW AST Catalog.sflb

28/52

27

O

PW202EMERGENCYVENTS OPW 202

EMERGENCY VENTS

The OPW 202 Emergency Vent is

designed to prevent an aboveground

storage tank rom becoming over-

pressurized by providing ull-bore, high-

capacity venting in the event o a re orblockage o the OPW 23, 113, 523V, or

623V. The 202 is a vapor-tight, spring-

loaded emergency vent. When the AST

builds pressure to 2.5 psi, the spring-

loaded lid opens ull-bore and discharges

vapors upward to relieve the pressure. The

lid remains open or inspection to indicate

a problem with the normal tank venting,

or i a re has taken place, until manually

reset. The appropriate 202 Series vent

is determined by the emergency ventingcapacity requirements o the AST and the

type o connection at the tanks emergency

vent opening. The OPW 202 Emergency

Vent is available in 4", 6", and 8" openings

with emale NPT connections.

uLightweight Construction allows

or sae, easy installation on large

aboveground tanks.

uSpring-Loaded, O-Ring Sealed

Cover with Tefon-Coated Seat

ensures smooth, vapor-tight sealing

surace and reliable service lie.

uFull-Bore, High-Capacity Upward

Venting enables smaller diameter

vents, with higher venting capacity, to

be used on ASTs when compared to

weighted, mushroom-style vents.

uAluminum Cover and Body with

Stainless Steel Components

corrosion-resistant construction to protect

expensive nish or epoxy coatings on

ASTs.

uMounts Vertical or Horizontal.

uAlerts Tank Operators o Possible

Venting Problems when the

emergency vent is actuated, the lid

remains open or inspection until

manually reset. The actuation o the

emergency vent indicates abnormal

excessive pressure build-up in the tank

due to either a blockage in the normal

tank vent or in the event o a rapid

expansion o vapors possibly rom a re.

uEasy Vent Reset no extra parts

required. Simply push the vent lid closed

until an audible click is heard, indicating

the vent is back in operation.

uUL Listed to satisy Third Partyaccreditation requirements

o many jurisdictions.

B

A

C

Ordering Specifcations

Model # in. mm lbs. kg

202-0640 4 102 2.05 .95

202-0660 6 152 3.55 1.6

202-0680 8 203 5.1 2.3

Dimensions 202

4" (102mm) 6" (152mm) 8" (203mm)

in. mm in. mm in. mm

A 23/8 60 23/8 60 25/8 67

B 4 102 5 127 57/8 149

C 61/2 165 89/16 218 103/4 273

Features

Materials

Cover and body: Aluminum

Link: Duratu

Spring: Stainless steel

Sealing surace: Tefon-coatedaluminum

202 SCFH @ 21/2 PSI(0.17 bar)

4 150,000 6 335,000 8 555,000

Ordering Specifcations

Flange Mount

Model # in. mm lbs. kg

202F-0600(Flange Mount)

8 203 5.2 2.4

202 Series Instruction Sheet Order

Number: H11792M

Listings and

Certifcations

-

7/28/2019 OPW AST Catalog.sflb

29/52

28

ATEX Approved

Patent No.

WO2004/036096AZ

OPW 623V PressureVacuum Vent

Pressure Vacuum Vents are installed on

the top o vent pipes rom underground

or above ground uel storage tanks.

The vent cap and internal wire screen

are designed to protect the tank vent

lines against intrusion and blockage

rom water, debris or insects. A normally

closed poppet in the valve opens at

a predetermined pressure or vacuum

setting to allow the tank to vent.

Listings and

CertifcationsOPW 623V &

523V

Replacement Parts

Part Number Description

C05086M Lower Screen

H14895M Upper Screen

C05089 2" Threaded Base Adaptor

C05122 3" Threaded Base Adaptor

Materials

Top/Body: Polypropylene

Base: Anodized aluminum

Poppet: Anodized aluminum

Screen: Stainless steel mesh

Gasket: Closed cell oam

Features

623VVent Must Be Mounted

Vertically

623V Instruction Sheet Order

Number: H14898PA

Ordering Specifcations

Product # DescriptionIdenticationLabel Color lb. kg

623V-2203 2.5" to 6" WC Pres., -6" to -10" WC Vac. Thread-On Yellow 1.55 .70

623V-3203 2.5" to 6" WC Pres., -6" to -10" WC Vac. Thread-On Yellow 2.20 1.00

Conversion Table

MeasurementUnits

In H2O In Hg

= Oz. PSI (WC) (Merc) Bar

Bar x 236.0 14.5 401.4 29.53

In. Hg (Mercury) x 7.843 0.49 13.6 0.034

In H2O (WC) x 0.578 0.04 0.074 0.002

PSI x 16.00 27.68 2.04 0.069

Oz. x 0.063 1.73 0.128 0.004

uPressure/Vacuum Setting 2.5" to 6" water column pressuresettings and -6" to -10" water columnvacuum settings are actory presetand tested.

uReliable Service cycle tested to theequivalent o 80 years o service in themost severe environment withoutleakage problems.

uCorrosion-Resistant Construction aDuratu composite body ensures along service lie.

uEasy Installation the 623V isavailable in 2" and 3" threaded versions.

uComplies with NFPA 30 Requirementsor venting gasoline vapors upward.

uManiold Vent Pipes vent pipesmay be maniolded to produce a singlePressure Vacuum Vent line. The 623Vexceeds Caliornias requirements o amaximum vapor leak rate o 0.17 SCFH

at 2.00 inches H2O.

uHigh Maximum Flow Rate 6450SCFH at 2 psi (0.1 bar) pressure drop.

uLeak Rate multiple pressure vacuumvents may be installed on a single site.The 623V exceeds Caliornia standardswith a leak rate o 0.05 SCFH or less at2.00 inches H

2O.

uMaintenance no tools required. Aremovable snap t top allows or easymaintenance (recommended yearly).

u100-Mesh Stainless Steel WireScreens helps prevent debris andinsects rom entering the tank vent lines.

An added screen installed at the baseprevents debris rom intruding rom thevent stack.

uAdaptor Bushing removable hexthreaded bushing designed or easyinstallation on NPT threaded risers.

Allows easy access to lower screen.

uATEX Approved or fame arrestorapplications

-

7/28/2019 OPW AST Catalog.sflb

30/52

29

OPW523VPRESSUREVACUUMVENT

OPW 523V SeriesAdaptor Bushings

The 523V Series Adaptor Bushings are

designed to thread into the base o 2"

threaded 523V vents. The adaptor bushings

convert a 2" 523V to 3" threaded, 2" slip-on

or 3" slip-on connection.

Replacement Parts

Part Number Description

H11432M O-Ring or 2" Thread

H11456M O-Ring or 3" Thread

523V Instruction Sheet Order

Number: H11972M

Features

523V

Ordering Specifcations

Identication

Product # Description Label Color lb. kg

523V-1100 2" 8 oz pres., 1/2 oz. Vac. Thread-On Red 1.65 .75

523V-1150 2" 8 oz pres., 1/2 oz. Vac. Slip-On Red 1.65 .75

523V-3100 3" 8 oz pres., 1/2 oz. Vac. Thread-On Red 3.2 1.45

523V-3150 3" 8 oz pres., 1/2 oz. Vac. Slip-On Red 3.2 1.45

523V-2300 2" 12 oz pres., 1/2 oz. Vac. Thread-On Blue 1.65 .75

523V-2350 2" 12 oz pres., 1/2 oz. Vac. Slip-On Blue 1.65 .75

523V-2200 2" 1 oz pres., 1/2 oz. Vac. Thread-On Silver 1.65 .75

523V-2250 2" 1 oz pres., 1/2 oz. Vac. Slip-On Silver 1.65 .75

523V-3200 3" 1 oz pres., 1/2 oz. Vac. Thread-On Silver 3.2 1.45

523V-2203 2" 3" WC pres., 8" WC Vac. Thread-On Yellow 1.65 .75

523V-2253 2" 3" WC pres., 8" WC Vac. Slip-On Yellow 1.65 .75

523V-3203 3" 3" WC pres., 8" WC Vac. Thread-On Yellow 3.2 1.45

523V-3253 3" 3" WC pres., 8" WC Vac. Slip-On Yellow 3.2 1.45

uComplies with NFPA 30 Requirements or venting gasoline vapors upward.

uHigh Maximum Flow Rate 7000 SCFHat 2 psi pressure drop.

u40-Mesh Stainless Steel Wire Screen helps prevent debris and insects romentering the tank vent lines.

uA Variety o Pressure/Vacuum Settings 3" water column, 1 oz., 8 oz., 12 oz.pressure settings and 8" water columnor1/2 oz. vacuum settings are actorypreset and tested.

uReliable Service sel-guided poppet

assembly ensures consistent seating othe pressure/vacuum valve.

uCorrosion-Resistant ConstructionDuratu composite body assures along service lie.

uEasy Installation 523V is available in2" and 3" threaded versions or slip-onmodels that provide or attachment tothe vent line with allen head screwsand radial sealing O-ring.

Materials

Body: Aluminum

O-Ring: Nitrile

523SA(Bottom View)

523SA(Top View)

Ordering SpecifcationsProduct # Description in. mm lb. kg

523A-1003 3" Thread-On Adaptor or use with 523V Pressure / Vacuum Vents 2 x 3 51 x 76 .47 .213

523SA-1003 3" Slip-On Adaptor or use with 523V Pressure / Vacuum Vents 2 x 3 51 x 76 .63 .286

523SA-1002 2" Slip-On Adaptor or use with 523V Pressure / Vacuum Vents 2 x 2 51 x 51 .31 .141

OPW 523V PressureVacuum Vent

Pressure Vacuum Vents are installed on

the top o vent pipes rom underground or

above ground uel storage tanks. The vent

cap and internal wire screen are designed

to protect the tank vent lines against

intrusion and blockage rom water, debris

or insects. A normally closed poppet

in the valve opens at a predetermined

pressure or vacuum setting to allow the

tank to vent.

Conversion Table

MeasurementUnits

In H2O In Hg

= Oz. PSI (WC) (Merc) Bar

Bar x 236.0 14.5 401.4 29.53

In. Hg (Mercury) x 7.843 0.49 13.6 0.034

In H2O (WC) x 0.578 0.04 0.074 0.002

PSI x 16.00 27.68 2.04 0.069

Oz. x 0.063 1.73 0.128 0.004

-

7/28/2019 OPW AST Catalog.sflb

31/52

30

OPW 514 & 515 UtilityTank Vents

OPW Utility Tank Vents are installed

directly on the top o above ground storage

tank or utility tank vent pipes. The vent

cap is designed to protect the tank against

intrusion o water, debris or insects. The

515ML incorporates a lame arrester

screen or jurisdictions that require these

on tanks. A normally closed poppet in the

valve opens at a predetermined pressure

or vacuum setting to allow the tank to vent.

515ML

1

2

3

4

5B

11

10

9

8

DC

6

7B

7A

514F

A

B

1

2

3

C

D

E

4

65

78

F

Dimensions (514F)in. mm

A 25/16 59

B 25/16 75

C 15/16 24

D 2 21/32 67

E 115/16 49

F 7/16 11

Dimensions (515ML)in. mm

A 25/16 59

B 51/4 133

C 31/8 79

D 115/16 49

Features

Materials

Features

Materials

u3-Pound Pressure and 1 oz. VacuumSettings actory preset and tested toprotect against product vapor loss andallow or rapid withdrawal o productrom the tank.

uReliable Service precision-machined,lapped bronze pressure and vacuumseats ensure consistent seating o thepressure/vacuum valve.

uCorrosion-Resistant Construction zinc/aluminum alloy body and zinc-plated

steel dome assure a long service lie.

u Easy Installation 514F is available in2" (111/2" NPSH) emale straight threadswith a Buna-N gasket.

uHigh Maximum Flow Rate 3500 SCFHat 4.5 psi (0.31 bar) pressure drop.

uLockable Base - a provision orpadlocking the vent to the tank isintegrated into the base.

Ordering Specifcations

Product # in. mm lbs. kg

514F-3050 2 51 .46 .21

Replacement Parts

Key Part # Description

1 H01967M Nut

2 H10096M Pressure Spring

3 H07355M Screen

4 H11432M Seal

5 C03991M Dome

6 H07356B Vacuum Disc

7 H08380AH Pressure Disc

8 H07353M Vacuum Spring

Ordering SpecifcationsProduct # in. mm lbs. kg

515ML-1030 2 51 1.80 .82

Key Part # Description

7A H11211M O-Ring

7B H03636M Cap Gasket

8 C03991M Dome

9 H07356B Vacuum Disc

10 H08380AH Pressure Disc

11 H07353M Vacuum Spring

Cap Body: High-tensile aluminum alloyconstruction. Has straight pipe threads with

Nitrile gasket or tight seal to tank.

Dome: Plated steel

Screen: 40 mesh brass 515ML

514F

uFlame Arrestor Screen or jurisdictionsthat require fame arrestors on tank vents.

u5 PSI (0.34 bar) Pressure and 1 oz.Vacuum Settings actory preset andtested to protect against product vaporloss and allow or rapid withdrawal o

product rom the tank.

uReliable Service precision-machined,lapped bronze pressure and vacuumseats ensure consistent seating o thepressure/vacuum valve.

uCorrosion-Resistant Construction zinc/aluminum alloy body and zinc-platedsteel dome assure a long service lie.

uEasy Installation 515ML is available in2" (111/2" NPSH) male straight threads.

uHigh-Maximum Flow Rate 3500 SCFHat 7.5 psi (0.52 bar) pressure drop.

Cap body: High-tensile aluminum alloyconstruction. Has straight pipe threads

with Nitrile or tight seal to tank. 2" - 11 1/2"NPSH threads.

Dome: Plated steel

Screen: 40-mesh brass

-

7/28/2019 OPW AST Catalog.sflb

32/52

31

OPW23SERIESOPENATMOSPHERICVENTS

35/8"92mm

37/8"99mm

B

C

A

OPW 23 Series OpenAtmospheric Vents

Open Atmospheric Vents are installed on

the top o vent pipes rom underground or

above ground uel storage tanks. The vent

cap and internal wire screen are designed

to protect the tank vent lines againstintrusion and blockage rom water, debris

or insects. These vents are always open

to atmosphere and allow any pressure or

vacuum into the tank to vent.

OPW 113 SeriesOpen AtmosphericUtility Vents

OPW 113 Open Atmospheric Utility

Vents are installed on the top o above

ground uel storage tanks. The vent cap

and internal wire screen are designedto protect the tank vent lines against

intrusion and blockage rom water, debris

or insects. These vents are always open

to atmosphere and allow any pressure

or vacuum into the tank to vent. The

113 vents vapors downward and is used

primarily on diesel, uel oil, waste-oil and

motor-oil tanks, but can also be used on a

wide variety o above ground storage tank

venting applications.

Materials

Features

Materials

23

Body: Aluminum

Screen: 40-mesh brass

Set Screws: Brass

uReliable Service vent cap drain spouts

extend outward to deter rainwater entry.

uCorrosion-Resistant Construction

aluminum body and cap assure a long

service lie.

uEasy Installation 23 series is available

in 2" and 3" slip-on models that provide

or attachment to the vent line with

set screws.

uComplies with NFPA 30 Requirements

or venting gasoline vapors upward.

uHigh-Maximum Flow Rate 7000

SCFH at 2 psi (0.14 bar) pressure drop.

u40-Mesh Brass Wire Screen helps

prevent debris and insects rom entering

the tank vent lines.

Ordering Specifcations

Product # in. mm oz. kg Description

23-0044 11/2 38 3.8 .11 Open Vent

23-0033 2 51 4.3 .12 Open Vent

23-0055 3 76 5.0 .14 Open Vent

Replacement Parts

Part # Description

H00122M Screw

H01967M Nut

H01969M Screen

Ordering Specifcations

Product # in. mm lbs. kg

113-0066 2 51 .88 .40

113-0099 4 102 7.50 3.41

Dimensions

2" (51mm) 4" (102mm)

in. mm in. mm

A 11/2 38 23/4 70

B 33/4 95 77/16 189

C 23/4 70 415/16 125

Body: Zinc/aluminum

Screen: Brass

Cap: 2" - Steel 4" - cast iron

Screen: 40-mesh stainless steel 113

For more inormation contact OPW Customer Service at1-800-422-2525; International call 1-513-870-3315.

-

7/28/2019 OPW AST Catalog.sflb

33/52

32

Part of the

family of products

924B

MAGNETOSTRICTIVEPROBE

SITESENTINEL iSITEOR iTOUCH CONSOLE

DENSITY

MEASUREMENT

VSMARTMODULE

INTELLISENSESMART SENSORS

MAG SUMPSENSORS

Leading The Wayin Fueling Innovation Worldwide

Setting the indu

standard in reta

commercial uel

solutions worldw

since 1892.

3

Electronic FuelManagement Systems

From the most innovative tank gauging

systems in the world to the most reliable

and accurate uel control systems, there

is no better or more comprehensive

solution on the market today to ensure

that you know exactly how much uel

you have and where it is going. When it

comes to complete uel accountability,

unparalleled protection against thet

and total reconciliation, OPW Fuel

Management Systems is Leading the

Way in keeping you and your assets

covered both coming and going!

AST

FLEXIBLE PROBE

See Pages 314-345

in the 2011 OPWProduct Catalog

-

7/28/2019 OPW AST Catalog.sflb

34/52

33

TANKGAUGE

C

Listings and

Certifcations

OPW 200TG ASTMechanical Tank Gauge

The OPW 200TG Tank Gauge is designed

or reading liquid levels in horizontal or

vertical above ground storage tanks. The

200TG Tank Gauge provides an accurate

numerical counter readout, eliminating theneed or any on-site manual gauging.

u Vapor-Tight allows or standard tank

pressure testing and sealing up to

25-psig (1.72 bar).

u Angled Face improves visibility rom

ground on large diameter tanks. May

be read easily up to 30 eet away

(9.14 m).

u Swivel Adaptor Base allows or

360 o rotation o gauge ace or easy

viewing wherever needed.

u Easy Installation 2" NPT-threaded base

reduces labor time, and comes standard

with emale thread. A H11421RS

may be purchased or male threaded

applications.

u Corrosion-Resistant Construction

powder-coated die cast-aluminum body

assures or long service lie in manyfuids.

u Drop Tube prevents foat entanglement

in the tank, and gives the gauge a more

accurate reading when turbulence is

present (Drop Tubes sold separately.

They are recommended or use in tanks

with high turbulence, and where other

piping and structures inside the tank

may cause entanglement).

u Float Buoyancy designed to foat in

all approved uels with a specic gravity

o 0.65 and greater.

u Tank Height unit designed or use

on any horizontal or vertical aboveground

tank up to 18 eet (5.5 m) in depth.

Specials available upon request.

u Numbering black letters on white

background or ultimate contrast and

better visibility. Characters stand over

1" (25 mm) tall.

u Unit Measurement can be purchased

in metric units to read in meters, 1/10,

1/100, or in English units to read in eet

and inches.

u Maintenance no annual maintenance

required.

u U.S. Patent No.: 6,523,404 - Other

patents pending.

u Compatible Fuels see chart on

page 40.

uTemperature Rating 120F to -40F

(49C to -40C)

Underwriters Laboratory Listed UL Listing MH29367.

Liquid level gauges which are intended to be used on

above ground storage tanks and monitor the level o

petroleum-based fammable or combustible fuids.

A

B

E

D

Features

Materials

Enclosure: Powder-coated aluminum

Swivel Base: Hard-coat aluminum

Float: 304 stainless steel

Lenses: Tempered borosilicate

Gears: Acetal

Gaskets & O-Rings: Nitrile

All Hardware: Stainless steel

Accuracy: + or - 2"

Dimensions:in. cm

A 81/4 21

B 101/4 26

C 9 22.75

D 63/4 17.25

E 11/2 3.75

Replacement Parts:

Part # Description

C05165M Float

H14358M Lens

H14909M Lid Gasket

Ordering Specifcations:Product # Description lb. kg

200TG-ENG English Unit Tank Gauge up to 18 ft. 7.75 3.52

200TG-ENG40 English Unit Tank Gauge - 40 ft. 7.75 3.52

200TG-MET Metric Unit Tank Gauge up to 6 m 7.75 3.52

200TG-MET40 Metric Unit Tank Gauge - 10 m 7.75 3.52

(Ancillary Equipment)

Product # Description lb. kg

H11421RS 2" NPT Male x Male Nipple 1.5 0.68

CARB CERTIFIED AST EQUIPMENT

61T-0208 2" Dia. x 8' Long Drop Tube 2.67 1.21

61T-0212 2" Dia. x 12' Long Drop Tube 4.00 1.81

61T-0216 2" Dia. x 16' Long Drop Tube 5.33 2.42

200TG

200TG Tank Gauge Instruction

Sheet Order Number: H14912PA

-

7/28/2019 OPW AST Catalog.sflb

35/52

34

Ordering Specifcations:Product # Description lb. kg

444TA-0100* Four Signal Tank Alarm, does not include Float Switch 4 1.8

44TA-LLFS* 36" Liquid-Level Float Switch Sub-Assembly 0 0.0

144TA-0100Single Channel Liquid Level Tank Alarm,does not include Float Switch

4 1.8

TGTA-04004" Tank Bung Gauge and Alarm Combo Fitting(OPW 61T required or use)

10 4.5

The OPW 144TA Requires the OPW 44TA-LLFS, the OPW44TA-LLFS must be purchased as a separate item.

uUp to our alarm signals (444TA) can be used or high or low liquid levelsensing, interstitial monitoring, and/orother signals in one to 4 separate tanks.

uSel-Powered lithium battery with a10-year shel lie or long service lie.

uAudible Alarm sounds a 90-decibelalarm at 4 eet away.

uVisual Notications red alarm lightwill fash during use or notication tothe user. Low battery light indicates

when battery needs replaced.

uCorrosion-Resistant Construction petroleum and environmental resistanthousing and all stainless steel pipe

tting ensure a long product lie.

uProduct /Alarm Identication Label located on top o the alarm or quick andeasy identication, allowing youto correspond alarms to signals. Labelhas a protective covering.

uIntrinsically Sae complies with ANSI/UL 913 or Class 1, Division 1 & 2 orGroups C & D hazardous locations.

uCold Weather Resistant all componentsare sae or temperatures down to -40Foperation (and up to 120 F).

uLong Lie Lithium Battery sel-powered by a lithium battery which

includes a 10-year shel lie to ensure

peace o mind or the owner.

uEasy Installation requires nocalibration and installs easily into

a 1" tank bung. May be assembledremotely or directly on top o tank.

Features

Materials

Enclosure: Polybutylene terephthalate

Wire Grommet: Nylon w/ buna seal

Float Switch: Closed cell buna foat

& stainless steel rod

Pipe: Stainless steel

Tank Adaptor:Aluminum hardcoat anodized

Conorms to ANSI / UL STD 913

Certied to CAN / CSA STD C22.2 No. 157-92

Florida EQ-610

CARB Certied

Replacement Parts:Part # Description

44TA-LLFS Liquid-Level Float Switch ASSY

H15412M Wire FittingH15411M Float Switch

Items to Convert to a Low Level Alarm:

202430 1/8" SST Nipple

C05295M SST Tube

Battery Module

H15937M 444TA-0100

See Note 144TA-0100*

444TA

Approvals

and Listings

TGTA-0400 4" TankBung Combo FittingNote: Drop Tube must beused with TGTA-0400.

3069027

444TA and 144TA Instruction Sheet Order Number: 200655

144TA Dimensions:in. cm

A 5 132 12.8

B 5132 12.8

C 3 7.6

D 4316 10.6

E 11516 4.9

F 35 88.9

G 11516 4.9

H 1 2.5

444TA Dimensions:in. cm

A 5 1/32 12.8

B 51

/32 12.8C 43/16 10.6

*NOTE: When replacing the battery or the 144TA-0100,open the alarm box and locate the OPW number on theblack battery module. I the number reads C05346 thenuse the replacement part 15615M. I the number reads144TA-0100 then use the replacement part 202891.

OPW 444TA ASTFour Signal Tank Alarmand OPW 144TA ASTLiquid Level Tank AlarmThe OPW AST remote Four Signal Tank

Alarm is designed to sense up to our

dierent liquid levels or other signals

using just one device.

The OPW 144TA Tank Alarm is designed

or liquid level sensing.

Alarm Technical Inormation:

Hazardous Location Approval: Class I, Groups C & D

Maximum Voltage: 7.2 Volts

Maximum Current: 8 ma. per input (32 ma. total)

Maximum Internal Capacitance: 23 uF

Maximum Internal Inductance: 33 mH

Maximum Ambient Temperature Rating: 60 C

Maximum Surace Temperature Classication:

T4 Surace Code

Wiring limitations: 1000 oot maximum between the144TA/444TA unit and any remote switch or eachchannel o the alarm. This assumes that maximumcapacitance or any input is 60 nanoFarads and thatthe maximum inductance is 0.2 milliHenry per input(UL-913 A7.3)

Note: This device is designed to work independentlyand should not be wired in parallel with another device,except as dened in the ollowing instructions.

Requirements or devices wired to the 144TA/444TA:

Attached wiring and devices must be classedIntrinsically Sae

No voltage or current source

Maximum capacitance: 60 nanoFarads (.06 uF)per input

Maximum inductance: 200 microHenrys (.2 mH)