GRAFICACION DRA. MARVA ANGELICA MORA LUMBRERAS Introducción 19/01/2011

Offshore Systems - CEDIPcedip.edu.mx/graficacion/petroleros/Geomecanica... · Offshore Systems In...

Transcript of Offshore Systems - CEDIPcedip.edu.mx/graficacion/petroleros/Geomecanica... · Offshore Systems In...

18

© CAMERON, P.O. BOX 1212, HOUSTON TX, 77251-1212, TEL: 713.939.2211, FAX: 713.939.2620, WWW.CAMERONDIV.COM

Offshore Systems

In today’s fast-paced, cost-conscious subsea production industry, Cameronhas successfully met the challenge to deliver safe, reliable systemsolutions. This experience allows Cameron to provide what no othersupplier can: Cameron quality from project concept through projectcompletion.

Whether the project requires components, modules or total fielddevelopment; existing technology or something innovative; EPC servicesor EPIC services; Cameron’s flexible organization allows us to establishteams strategically positioned to effectively handle the job.

Cameron Systems ExperienceCameron has worldwide experience in EPC and EPIC projects as well assystems experience in a variety of offshore development concepts such asplatforms, TLPs, and a variety of subsea scenarios including satellite,cluster, template and daisy chain.

However, Cameron’s experience goes far beyond providing theindustry’s best equipment; we also have a wide range of experience insystems engineering and project management including:• Interface engineering and management• Risk management and planning• Transportation, base and offshore logistics• Health Safety Environmental • Engineered phased development and expandability• Procurement• Managing multiple site locations• Equipment and materials selection• Field layout• Flow assurance• Reliability, availability and maintainability

Systems Integration Testing for Subsea Development

Cameron’s Subsea Production PhilosophyCameron works closely with our customersto provide a “big picture perspective” andto develop total system solutions that:• Reduce operational costs• Minimize capital expenditures• Proivide maximum quality and reliability• Meet or exceed all safety and

environmental standards• Provide life of field service

CAMTROL System Factory Integration System

© CAMERON, P.O. BOX 1212, HOUSTON TX, 77251-1212, TEL: 713.939.2211, FAX: 713.939.2620, WWW.CAMERONDIV.COM

19

Offshore Systems

Cameron ResourcesCameron maintains worldwide resources including:• Multi-disciplined engineering staff• Experienced project managers• Modern, well equipped manufacturing and assembly facilities• Ongoing research and development• CAMSERV Aftermarket Services Program

Cameron ProductsCameron has the industry’s most comprehensive, highly respected productline. Cameron products have proven themselves time and time again in

demanding service applications.Cameron SpoolTree ChristmasTrees have set an industrystandard and the CAMTROLProduction Control Systemsoffers the most advanced, highlyfunctional control of subseasystems on the market today.Other MOSAIC products such aschokes, valves and connectionsystems are equally renownedfor quality and reliability.

For more than 30 years,Cameron subsea systems haveset the industry standard. Only

Cameron can provide this level of experience and the coordination ofresources required to handle today’s demanding subsea projects. OnlyCameron can provide Cameron quality from project concept anddevelopment through the entire field life of the equipment.

CAMTROL System Integration Testing

Systems Development Team

Project Management Team

Executive Management Team

Systems Integration Testing

Field Installation

Life of Field Support

HSE / QA

Planning

Interface

Document Control

Procurement

Wellheads,Trees,

Gate Valves

Chokes Controls Manifold Jumpers,Connectors

UmbilicalRisers

A Cameron project team takes many talents and many specializedindividuals. Here is an example of a typical Cameron project team:

Executive Management TeamCameron Management RepresentativeOperator Management Representative

Project Management TeamCameron RepresentativesOperator Representatives

System Development TeamSystem Design Team

External Interface EngineerSystem Engineers

Wellhead, Trees and Gate ValvesChokesControlsManifoldIntervention SystemsJumpers and ConnectorsUmbilicals and RisersROV Tooling

Lead Installation EngineerLead Operations, Commissioning, Training Engineer SpecialistsFlow Assurance, RAM, Field Layout, IMR, Soil Analysis

System Engineering TeamTechnical ManagerPackage Lead Engineers

Wellhead, Trees and ChokesControlsManifoldJumpers and ConnectorsUmbilicals and RisersROV Tooling

Quality and HSE TeamHSE ManagersQuality Managers

Project Execution TeamProject Services

Project Services ManagerAccountingSchedulingLogisticsSubcontract AdministrationDocument Control

Systems Integration Testing TeamField Installation Team

Lead Installation EngineerPackage Lead EngineersLead Operations, Commissioning and Training Engineers

Life of Field Support TeamCAMSERV Aftermarket SpecialistsCAMSERV Field Service Technicians

MOSAIC™ Subsea Systems

20

Cameron’s MOSAIC Subsea Components

The Cameron MOSAIC product line incorporates field-proven components including: Cameron SpoolTree Subsea Trees — proven over and over in field applications around the world.Subsea Retrievable Insert Chokes — with a selection of actuator assemblies and trim cartridges.CAMTROL Production Control System — standard components which adapt to a variety of fieldconfigurations. And other field-proven MOSAIC components.

MOSAIC provides flexible modularity to create nearly endless system combinations with reliable andeconomical subsea equipment. MOSAIC systems are all based upon a combination of standardcomponents. This modular, or building block approach, allows producers to specify pre-engineeredcomponents with application specific features.

The Cameron MOSAIC solution for this field development is one of the myriad of combinationsavailable. Contact us and we will design one for you.

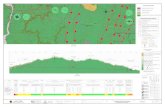

Cameron systems solution used field-proven components from theCameron MOSAIC product line. MOSAIC provides flexible modularity tocreate nearly endless system combinations with reliable and economicalsubsea equipment. Typical Cameron MOSAIC Systems and Subsystemsinclude:

Wellhead Systems Subsea Wellhead Systems

STC WellheadSTM Wellhead

Christmas TreesDual Bore and SpoolTree Christmas Trees

Guideline, GuidelinelessProduction, Gas Lift, Water Injection

Tree ConnectorsDog and Window (DHW)Deepwater High Capacity (DWHC)

Block ValvesUp to 40 Wing ArrangementsSingle or Double Master Valves

Gate ValvesFL, FLS or FLS-RThreaded, Flanged, Block

Gate Valve ActuatorsSurface or SubseaPneumatic, Hydraulic, Wireline Cutting

Chokes Non-retrievable, Retrievable

Choke ActuatorsSurface or SubseaPneumatic or Hydraulic

Flowline Connection SystemsCameron Vertical Connection (CVC™) SystemsMcPac™ Flowline Connection SystemsStab and Hinge

Riser SystemsProduction Riser SystemsWorkover Riser SystemsFree-Standing Riser Systems

Manifolds and TemplatesFlowbasesValve BlocksConnectorsStructurePorch Extensions

Control Systems and DistributionCAMTROL Production Control Systems

Typical Surface ComponentsMaster Control Station (MCS)Electrical Power Unit (EPU)Hydraulic Power Unit (HPU)

Typical Subsea ComponentsSubsea Control Modules (SCMs) Subsea Accumulator Modules (SAMs)Electrical Distribution Units (EDUs) Umbilicals and Jumpers

Workover Control SystemsSurface PanelsHose Reels

Tie-In and Intervention Equipment

UmbilicalsROV Tooling

21

™

22

© CAMERON, P.O. BOX 1212, HOUSTON TX, 77251-1212, TEL: 713.939.2211, FAX: 713.939.2620, WWW.CAMERONDIV.COM

SpoolTree™ Production Systems

SpoolTree System Valve Assembly ConfigurationsIn the Cameron SpoolTree design, the spool body provides outlets to attachproduction, annulus and isolation valves for downhole functions and theelectrical penetrator bonnet assembly. The tubing hanger landing shoulder is specially ported to accept control stabs and provides hydraulic continuitybetween the production control system and downhole hydraulics.

The valves are contained both as an integral part of the spool body, and in mini-blocks external to the vertical bore of the tree. A typical valve clusterincludes production and annulus master valve, production and annulus wingvalve, crossover valve, workover valve and isolation valves for SCSSV, CIV andother requirements. Assemblies are available for 3" through 7" completions.

Basic Chemical Injection Annulus Crossover

Gas Lift ChokeProduction Choke

The Cameron SpoolTree Production System is one of the most widely usedtrees in the world and offers many time and cost saving advantages overconventional tree systems.

Instead of the typical wellhead-hanger-tree stackup, the SpoolTreedesign has a wellhead-tree-hanger stackup. In this configuration, theChristmas tree consists of a concentric bore spool with a wellheadconnector below and a wellhead connector profile on top. The tubinghanger is hung off inside the spool on a dedicated load shoulder, and the

valves are situated on the side of the spool. No valves are in the verticalbore of the wellhead/tree system. The completion is run after the tree isinstalled and the completion can be pulled with the tree in place andflowline connections undisturbed.

MOSAIC SpoolTree Production Systems can be configured with a widearray of component choices. The possible combinations of components,available pressure ratings and sizes are virtually endless. The result is acost-effective system that can be adapted to virtually any subsea job.

SpoolTree Subsea Production System

GuidebaseFor template or satellite installation. Guideline orguidelineless. Variety of connection types available.

Valve Actuator25 Compact Modular (CM) modules available. Sizes from 2" to 7". To 15,000 psi WP.

Internal Tree CapWIth or without wireline plugs.

Tree ConnectorMechanical or hydraulic. Deepwater high capacity(DWHC) model available.

WellheadSTM or STC wellhead. Metal-to-metal or metal end-cap seals. Five or six string configuration. Variety ofcasing programs.

Spool Body and Modular Gate Valve AssemblyConfigured for various production applications.Cameron FL, FLS or FLS-R gate valves. Workingpressures up to 15,000 psi.

Flowline and Pipeline ConnectionVertical, horizontal, diver assist or ROV. Commoninterfaces used throughout.

Tubing HangerUp to six hydraulic and two electrical penetrations. 3" through 7" completions.

Subsea ChokeDiver-assist or diverless. Inserts are retrievable or non-retrievable (fixed). Crown or clamp connectors.

Control ModuleUp to 32 hydraulic control points. Variety ofintervention methods.

Debris Cap (not shown)Weight set or hydraulic

1

2

3

4

5

6

7

89

10

SpoolTree Production System

1

2

3

4

5

6

7

8

9

10

11

23

Dual Bore Production Systems

Dual Bore Subsea Production System

GuidebaseFor template or satellite installation. Guideline orguidelineless. Variety of connection types available.

Valve Actuator25 Compact Modular (CM) modules available. Sizesfrom 2" to 7". To 15,000 psi WP.

External Tree Cap (not shown)WIth or without wireline plugs.

Tree ConnectorMechanical or hydraulic. Deepwater high capacity(DWHC) model available.

WellheadSTM or STC wellhead. Metal-to-metal or metal end-cap seals. Five or six string configuration. Variety ofcasing programs.

Modular Valve AssemblyTotal of 320 configurations available. Cameron FLSgate valves. Working pressures up to 15,000 psi.

Flowline and Pipeline ConnectionVertical, horizontal, diver assist or ROV. Commoninterfaces used throughout.

Tubing HangerChoice of tubing sizes, threads and wireline preps.Metal seals with resilient backup available. One tofour SCSSC ports. With or without electricalpenetrator.

Subsea ChokeDiver-assist or diverless. Inserts are retrievable ornon-retrievable (fixed). Crown or clamp connectors.

Control ModuleUp to 32 hydraulic control points. Variety ofintervention methods.

The Cameron Dual Bore Production System has been the number onechoice of operators for many years. More than 300 have been deliveredworldwide since it was introduced in 1985. Today’s version has beenreengineered for modularity and standard interfaces have been added to ensure compatibility with a range of systems.

The dedicated annulus bore and vertical full-bore access to both theproduction tubing and annulus provide several advantages. The tubingcasing annulus can be circulated and pressure bled off. This simplifies

2

4

5

6

7 8

9

10

Dual Bore Production System

1

troubleshooting by enabling annulus monitoring for downhole pressureand temperature, sand production and tubing and packer leaks. In addi-tion, one or more electrical penetrators can be provided for downholepressure and temperature gauges and for electrical submersible pumps.

Versions of the dual bore tree are offered for 5000, 10,000 and 15,000psi WP and water depths to 10,000 feet. They are used for oil and gasproduction, gas and water injection service on satellite wells, clusters ortemplates.

1

2

3

4

5

6

7

8

9

10

Production

Production withInternal Crossover

Production with InternalCrossover and Choke

Production with Choke andAnnulus Connection

Production with Choke

Gas Lifted Productionwith Two Chokes

Dual Bore Valve Assembly ConfigurationsThe Modular Dual Bore Tree has a total of 320 pre-determined master valveblock assemblies. Valve assemblies are available in 4", 5", or 6-3/8" nominalbore sizes with 5000, 10,000 or 15,000 psi WP ratings. Valve assemblies featureCameron FLS gate valves with one-piece gate, spring-loaded seats and corrosion-resistant, metal-to-metal seals for maximum sealing integrity.

A choice of 40 valve module arrangements is available for each wing valveblock, covering requirements for production, water injection and gas lift. Themodules offer flexibility in location of crossover valve, chemical injection valve,etc. Master and swab valves are located in the well bore. Either commercialcartridge-type isolation needle valves or Cameron heavy-duty isolation needlevalves can be used for chemical injection and control line isolation.

© CAMERON, P.O. BOX 1212, HOUSTON TX, 77251-1212, TEL: 713.939.2211, FAX: 713.939.2620, WWW.CAMERONDIV.COM

24

© CAMERON, P.O. BOX 1212, HOUSTON TX, 77251-1212, TEL: 713.939.2211, FAX: 713.939.2620, WWW.CAMERONDIV.COM

TLP Systems

Drilling or production, surface or subsea,Cameron offers a range of products tomeet the requirements of TLP applications.The Cameron product line covers everythingfrom the subsea wellhead to the drilling/production system on the platform. In ad-dition, Cameron offers a complete line ofdrilling, production and workover controlsystems as well as the industry’s most com-prehensive suite of aftermarket services tomeet the needs of any TLP application.

TLP System Components

Drilling SystemsRam-Type BOPsAnnular BOPsDrilling ConnectorsDrilling ControlsSubsea WellheadsAdjustable Drilling Riser Hanger SystemsRiser Joints/CouplingsInternal Riser TiebacksRiser Tieback ConnectorsTensioner SystemsStress Joints

Production SystemsSurface Christmas TreesSurface WellheadsWellhead ConnectorsProduction RisersInternal Production TiebacksProduction Tieback ConnectorsProduction Riser Tensioner SystemsStress Joints

Export SystemsExport Risers and Riser BasesManifolds/Tie-in Systems

Mooring SystemsTendon ConnectorTendon Installation/Handling Equipment

DrillingMode

BOPs

Tensioner System

Drilling RiserSystem

ProductionMode

Surface Wellheadand Tree

Tensioner System

Production RiserSystem

WellheadConnection

Subsea Wellhead

© CAMERON, P.O. BOX 1212, HOUSTON TX, 77251-1212, TEL: 713.939.2211, FAX: 713.939.2620, WWW.CAMERONDIV.COM

25

DDCV Systems

Deep Draft Caisson Vessel (DDCV)Systems are designed for economicaldrilling and production in deepwaterapplications. Cameron’s experience in deepwater drilling and productionsystems provides a vast amount ofexpertise and proven performance forthis demanding market. The Cameronproduct line covers systems from theocean floor to the platform. In addition,Cameron offers a complete line ofdrilling and production control systemsas well as complete aftermarket servicesto meet the needs of any DDCVapplication.

DDCV System ComponentsDrilling Systems

Ram-Type BOPsAnnular BOPsDrilling ConnectorsDrilling Controls

Drilling WellheadsAdjustable Drilling Riser Hanger SystemsRiser Joints/CouplingsRiser Tieback ConnectorsTensioner SystemsStress JointsKeel/Transition Joints

Production SystemsSurface Christmas TreesSurface WellheadsWellhead ConnectorsProduction RisersInternal Production TiebacksProduction Tieback ConnectorsStress JointsTension Land Monitoring SystemKeel/Transition JointsBuoyancy Unit Tensioner System

Drilling Mode

BOPs

Tensioner System

Drilling RiserSystem

ProductionMode

Surface Wellheadand Tree

Buoyancy Units

Production RiserSystem

WellheadConnection

Subsea Wellhead

CAMTROL Production Control Systems Application

26

© CAMERON, P.O. BOX 1212, HOUSTON TX, 77251-1212, TEL: 713.939.2211, FAX: 713.939.2620, WWW.CAMERONDIV.COM

CAMTROL™ Production Control System

The CAMTROL Advanced Electro-HydraulicMultiplexed Production Controls Systemfrom Cameron Controls has beenengineered and qualified as acompletely integrated system fromthe ground up—starting with 30 years of subsea experience,combined with the latest controltechnology and system analysis tools.With its integrated approach andcomponent-level modularity, theCAMTROL system offers unequaledadvantages in cost savings, flexibility andexpandability. It’s the first and only systemavailable that incorporates all the advancedfeatures the industry now demands:• Modular components

The reliability of pre-engineered components, the adaptability tohandle any field scenario, plus the flexibility to expand as developmentscenarios change.

• High-integrity materialsRobust, seawater-tolerant components, designed and qualified to10,000 ft. (3000 m).

• Segregated, redundant electronicsDelivers maximum reliability against single-mode failures.

• Smaller and lighterCompact Subsea Control Module weighs less than 2200 lb (1000 kg), allowing easy installation and intervention with standard work-class ROVs.

• The most functionality in the industryUp to 32 control functions in each standard subsea control module.

• RetrievabilityStandard tooling and modular design enable critical subseacomponents to be easily retrieved.

Systems Level Design ApproachBeyond field-proven reliability, the flexible, modular structure of theCAMTROL Production System allows Cameron Controls to look at yourfield development from a systems level. Rather than designing newcomponents, we can focus on analyzing the base case and optionsdevelopment scenarios, then reconfigure our standard, pre-engineeredequipment and components to meet the RAM analysis optimized solutionto your project.

This big-picture approach means we get an accurate look at capitaland operating expenses up front, saving you money now and through thelife of your field. And only Cameron Controls combines this approachwith the technical and project management resources of the Cameronorganization, offering you:

Subsea CAMTROL Components

SCM/SAM Transportation Cage

MMRT-SEM

Subsea Control Module (SCM)

Subsea Accumulator Module (SAM)

SCM Mounting Base

Controls Flying Leads

Manifold

Subsea Distribution Unit (SDU)

Umbilical Termination Assembly (UTA)

Main Controls Umbilical

Workover Umbilical

Emergency Disconnect Unit (EDU)

Workover Flying Lead

1

2

3

4

5

6

7

8

9

10

11

12

13

12

3

4

5

6

7

89

10

11

12

13

3

4

6

89

10

CAMTROLSubsea Control Module

Platform Production

Seabed Intervention

FPSO Produduction

MODU Workover

14

15

16

17

14

15

16

17

System Applications

10

© CAMERON, P.O. BOX 1212, HOUSTON TX, 77251-1212, TEL: 713.939.2211, FAX: 713.939.2620, WWW.CAMERONDIV.COM

27

CAMTROL™ Production Control System

The Cameron Project Planning TeamEvery function within the Cameron Offshore Systems Group is involved inthe proposal phase, and an appropriate project team is assigned to seeyou through the entire life of your program. This team includes systemsengineers, project managers, marketing and proposal specialists, pur-chasing and procurement specialists, operations personnel, QA/HSEexperts and aftermarket support services.

Worldwide SupportCameron Controls operates manufacturing facilities in Houston, Texas and Celle, Germany, and maintains a worldwide network of engineering,testing, aftermarket, customer service and sales centers to support everyphase of your program. Dedicated customer service facilities in Aberdeen,Scotland, and Macae, Brazil, are two examples.

Factory and Site Integration TestingOnce the manufacture of your production control systems is completed,Cameron Controls conducts comprehensive Factory and Site IntegrationTesting at our dedicated testing facilities. This ensures proper operationand reliability of your complete system before installation and commis-sioning. This also minimizes infant mortality failures.

CAMSERV Aftermarket ServicesStarting from the FEED stage, Cameron Controls provides ongoingtechnical support and customer services for the life of your project. The CAMSERV worldwide network of dedicated aftermarket locationsprovides an extensive inventory of spare parts, field service, customerproperty management and other services.

Surface CAMTROL Components

DCS Console

Control Room

Master Control Station (MCS)

Electrical Power Unit (EPU)

Uninterruptible Power Supply (UPS)

Battery Bank

Chemical Injection Unit (CIU)

Topside Umbilical Termination Unit(TUTU)

Hydraulic Power Unit (HPU)

ESD Radio Unit

1

2

3

4

5

6

7

8

9

10

1 2

3

4

56

7

8

9

10

CAMTROL Production Platform Detail

28

© CAMERON, P.O. BOX 1212, HOUSTON TX, 77251-1212, TEL: 713.939.2211, FAX: 713.939.2620, WWW.CAMERONDIV.COM

CAMTROL™ Production Control System

Master Control Station (MCS)The MCS provides control and monitoring of the complete system,including surface and subsea installed equipment. Two complete and

segregated MCSchannel networkssimultaneously monitordata functions to andfrom each other, sur-face and subsea. Inthe event of a channelnetwork failure, theother continues toseamlessly operate thecontrol system. Thisdual redundant archi-tecture eliminatessingle mode failurepoints and the require-ment for bumplesstransfer from the failedto the healthy channelnetwork.

The MCS featuresopen-architectureelectronics with dual

Fast Ethernet links to the host control system (or serial RS-485 and choiceof topside communication protocol including MODBUS and Profibus). It is OPC v.2 compliant for compatibility with all other OPC v.2 compliantequipment. The MCS standard modems are qualified to control up to 10Subsea Control Modules at 24.9 miles (40 km) offset, and the standardMCS can accommodate up to eight modems per channel. Ultra-longoffset capabilitiy is assured by lowering the number of SCMs.

Electrical PowerUnit (EPU)The EPU providesconditioned electricalpower to the topsideand subsea systemcomponents. The EPUsupplies dual, isolated,single-phase power forthe subsea systemthrough the compositeservice umbilical,together with powersupply modules for theMCS and HPU.

Hydraulic PowerUnit (HPU)The HPU providesredundant low- andhigh-pressure hydraulicsupplies to the subsea system. Self-contained and totally enclosed, theHPU includes duty and backup electrically driven hydraulic pumps, dualredundant filters, accumulators, and control and instrumentation for eachLP and HP hydraulic circuit. The unit operates autonomously under the

Master Control Station

control of its dedicatedprogrammable logiccontroller (PLC), whichprovides pump motorcontrol, interlocks andinterface with theMCS.

Topside UmbilicalTermination Unit(TUTU)The TUTU provides theinterface between the topside control equipment and the main umbilicalsystem. This fully enclosed unit incorporates electrical junction boxes forthe electrical power and communication cables, as well as tube work,gauges, and block and bleed valves for the appropriate hydraulic andchemical supplies.

Subsea ControlModule (SCM)Rated for waterdepths up to 10,000ft (3000 m), theCAMTROL SCM is theheart of the subseasystem. The SCMweighs less than 2200 lb (1000 kg)and measures only

29" x 29" x 34" high (736 mm x 736 mm x 860 mm high), making it thelightest, most compact control module in the industry. This allows easyinstallation and intervention by standard work-class ROVs with any of theCAMTROL suite of Multi-Mode Running Tools. Yet with up to 32 controlfunctions, 24 external (4-20 mA) electrical sensor inputs and availablemulti-dropped intelligent completion capability, the CAMTROL SCM leadsthe industry in functionality and future potential. This can reduce thenumber of SCMs needed for an entire project, thereby lowering capitalexpenses.

The SCM provides multiplexed electro-hydraulic control and monitoringof a wide variety of field functions including traditional tree functions,manifold valve control, choke adjustment, position indication, headerpressure/temperature monitoring, downholeintelligence monitoring, sand detection,corrosion monitoring and multiphase flowmeasurement. Other features include:• Oil-filled, pressure-compensated

construction designed for 14˚ to 122˚ F (–10 to+50˚C); controlled-environment electricalconnections; seawater-tolerant materialsavailable throughouthydraulic system

• Diverless or diver-assisted designs

Electrical Power Unit

Topside Umbilical Termination Unit

Hydraulic Power Unit

Subsea Control Module (HydraQuad Couplers not shown)

© CAMERON, P.O. BOX 1212, HOUSTON TX, 77251-1212, TEL: 713.939.2211, FAX: 713.939.2620, WWW.CAMERONDIV.COM

29

CAMTROL™ Production Control System

• 3000 or 5000 psi (207 or 345 bar) nominal supply pressures for treeand manifold valves; 5000 or 10,000 psi (345 or 690 bar) supplypressure for SCSSV and other HP needs

• Dual SEMs with dual valve electronics modules are standard • HydraQuad Couplers feature pressure-balanced shear seals which,

when combined with Cameron directional control valves, providevirtually leak-free operation for lower opex and less non-productivetime.

Subsea Distribution Unit (SDU)The modular CAMTROL design allows the SDU to be either separate orfully integrated. The SDU provides the hydraulic, chemical and electrical

distribution betweenthe subsea system and the main controlumbilical. The struc-ture is designed, testedand certified to accom-modate all handlingloads. For deepwaterapplications, the unitcan incorporate hinge-over lock capability.All components are

suitably earth bonded and corrosion protected to suit the installation.Additional features include:• ROV or diver make-up flying lead jumpers• ROV or diver-operated block and bleed valves• Electrical distribution system with optional

diver or ROV replaceable fuses• ROV interfaces compliant with API 17H• Available with integral SCM and SAM

Subsea AccumulatorModule (SAM)The Subsea Accumulator Module(SAM) provides a local source ofhydraulic fluid. Each standard SAM is fitted with four 5.3 gal (20 l) LP and two 0.7 gal (2.5 l) HP accumulators, providingsufficient capacity to operate100% of all the valves on aproduction tree. The SAM has theidentical footprint, lockdown andtooling interface as the SCM andcan be replaced using any Multi-Mode Running Tool. All com-ponents are suitably earth-bondedand corrosion-protected via adedicated electrical connector.

Subsea Distribution Unit

Intervention FlexibilityThe CAMTROL system usescommon intervention methods for the retrieval and re-installationof the SCM, as well as the SAM,compact multi-phase flow meterand Cameron Willis SubseaRetrievable Chokes. Methods may include diver-assist, diverless,guideline, guidelineless and ROV-assisted.

Multi-Mode Running Tool (MMRT)Cameron Controls offers a suite of MMRTs, which performinstallation and retrieval of thesystem elements detailed above.The MMRT design allows theseoperations to be performed using common intervention methods — diver-assisted, conventional guideline, guidelineless or with an ROV — in

water depths to 10,000 ft (3000 m).The MMRT is designed for efficient

operation with a work-class ROV and isinterface-compliant with API 17H usingweight transfer systems for neutralbuoyancy.

Deepwater Liftline Running Tool(DLRT) Designed with the identical functionalityand capability of the MMRT, the DLRT isintended for applications without highcurrents or other problematic conditions.The DLRT is suspended by a liftline andcan be guided by an ROV.

Diver Change-Out Tool (DCOT)The DCOT is designed for diver intervention applications for a variety of change-out functions. Like the MMRT, the DCOT locates onto an API 17H weightreceptacle interfaceand is run on aliftline with orwithout guide wires.

Subsea Accumulator Module

Deepwater Liftline Running Tool

Multi-Mode Running Tool for Seabed Exchange Mode

Diver Change-Out Tool