Nonferrous Metals: Industrial Applications and Properties Metallurgy for the Non-Metallurgist.

-

Upload

evan-august-warner -

Category

Documents

-

view

238 -

download

10

Transcript of Nonferrous Metals: Industrial Applications and Properties Metallurgy for the Non-Metallurgist.

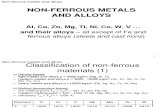

Nonferrous Metals: Nonferrous Metals: IndustrialIndustrial

Applications and Applications and PropertiesProperties

Metallurgy for the Non-Metallurgist

Learning ObjectivesLearning Objectives• After completing this lesson, students will be able

to:

o List the significant properties of aluminum, beryllium, magnesium, titanium, copper, lead, tin, and zinc

o Describe the primary applications for several nonferrous metals and alloys

o Identify the precious metals and outline some of their principal applications

Introduction: Nonferrous Introduction: Nonferrous

MetalsMetals

• Light metals: Mg, Be, Al, Ti; density less than steel• Sn, Zn, Mg largely used to protect steel• Low MP’s good for die casting: Mg, Zn, Al• Co alloys, Ti, and SS for implants• Copper for conductivity• Precious metals for catalysis, corrosion• Ni superalloys: fortuitous precipitation

AluminumAluminum• Recovered electrolytically from bauxite• Forms adherent protective thin oxide film• Alloying(Mg, Cu, Si, Mn+) enhances strength• Used cast(engine) or wrought(wheels)• Amenable to die casting• May be GMA, GTA, friction stir welded• Many architectural uses

Typical applications of aluminum alloys. (a) Bodies of beverage cans, the largest volume alloy combination in the industry. (b) Castings such as gearboxes or wheels for automotive applications. (c) Formed sheet for parts such as internal door stiffeners. (d) Forgings for aerospace applications. (e) Architectural applications such as roof structures for arenas and gymnasiums. Photos courtesy of the Aluminum Association

Melting processes for used beverage can (UBC) scrap. (a) Early can scrapmelter. (B) Swirl scrap charge melter using a continuous melting process

MagnesiumMagnesium

• Recovered from Great Salt Lake• Very light, very reactive, anodize• Used as anodes: hot water heater, pipeline, Gulf• Amenable to die casting, rheocasting• Readily formed, welded• Readily machined, chips dangerous

Various applications of magnesium alloys. (a) Machine plates for hulls, hull stiffeners, decking, and superstructures for yachts and ocean liners. (b) Welded constructions for offshore oil rigs in high humidity and water exposure. (c) Die castings for wheel frame assemblies such as for wheelchairs (photo courtesy of International Magnesium Association). (d) Die castings for automotive parts such as seat frames and steeringcolumns. (e) Girder systems for bridges. Photos courtesy of the Aluminum Association unless mentionedotherwise

TitaniumTitanium

• Forms a highly protective oxide; resists oxidizing acids

• Nontoxic, biocompatible• High strength, stiffness, toughness, low density,

good corrosion resistance• Now used in architecture• CP for corrosion applications• Burns at elevated temperature

Various applications of titanium alloys. (a) Aerospace structures. (b)Components for marine and chemical processing operations. (c) Cast kneeand hip implants. (d) Tubing for heat exchangers, refrigeration systems, andbicycle frames. Photo courtesy of Timet

Typical applications of copper and copper alloys. (a) Copper cables used in building construction. (b) Connectors. (c) Ship propellers. (d) Architectural/decorative uses such as the Statue of Liberty and this casting of theGreat Seal of the United States (located at the Federal Deposit InsuranceCorporation in Washington, D.C.)

Copper for specialty applicationsCopper for specialty applications

• Traveling wave tube amplifiers• Rocket nozzles• Coins• Non-sparking tools: BeCu• Bells and bearings: CuSn with hard

intermetallic phases• Welding rod: CuSi, good corrosion

resistance, Si acts to deoxidize• CuNi,NiCu marine exposures, heat

exchangers

Stainless steelsStainless steels• Corrosion resistance due to ~12% or more Cr,

self healing film• Martensitic(e.g., 410SS) limited to ~13%Cr so

austenite can form; if annealed forms Cr carbide, loses corrosion resistance

• Ferritic: Higher Cr, never austenitic• Austenitic: Ni stabilizes FCC, strengthened by

working; 304, 316• Precipitation hardening: 14-17Cr plus alloy

additions(Al, Cu, P) for heat treatment response. Processed soft, then aged. Better corrosion resistance than martensitic SS’s.

• Duplex and super SS, compete w/ Ni alloys

Two principal applications of tin. (a) Tinplate for products such as these standard liquid measures and containers. (b) Solders, in this case precision tinning of conductor paths on thick-film circuits. Courtesyof International Tin Research Institute

Refractory MetalsRefractory Metals

• Ta, Nb, Mo, W• High melting points; used as heating

elements• Resistant to many corrosive environments• Ta implants as plating on SS or CoCr alloys• BCC, show BDTT, but Nb and Ta formable• Oxidize, esp Mo and W

Applications of zinc. (a) Galvanized steel framing for residential andlight commercial construction, produced on hot dip continuous galvanizinglines that submerge sheet steel into anticorrosive baths of zinc or zinc alloys.(b) Thicker zinc coatings are applied by hot dip galvanizing after fabricationto deploy thicker zinc coatings on components such as these highway guardrails. (c) Zinc die casting, used to mass produce high-quality parts quicklyand efficiently. Courtesy of Zinc Institute

SuperalloysSuperalloys

• Based on the NiAl system with Cr, Ti, Ta, W, Mo, Co, Y, Hf, Zr, C, B additions

• May have 60vol % precipitate• Actually increase in strength from RT to

~1200F• Creep resistant even at 2000F, especially

in single crystal form• Essential for gas turbine engines• Other Ni alloys primarily for corrosion

resistance

Comparison of nickel-base superalloy turbine blade cast structures showingmacro- and microstructures of (from left) equiaxed, columnar grain, and single-crystal alloys

Summary: Nonferrous MetalsSummary: Nonferrous Metals

• Valued for different reasons: density, cost, conductivity, fabricability, corrosion resistance, wear resistance, melting point

• Example: copper for electrical and thermal conductivity, corrosion resistance

• Wide range in strength, e.g. Al alloys• Essential for aerospace: Al, Ti, Ni alloys