New Fabrication Strategies for Ordered Nanoporous Alumina...Ordered nanoporous alumina • First...

Transcript of New Fabrication Strategies for Ordered Nanoporous Alumina...Ordered nanoporous alumina • First...

-

New Fabrication Strategies for OrderedNanoporous Alumina

Kathrin SchwirnMPI of Microstructure Physics

Halle/Saale

-

Outline

• Alumina - Initial point for applications• Ordered nanoporous alumina

– applications– self-ordering

• Tasks• High-voltage anodization of H2SO4

– lattice parameters– mechanism of pore growth– ordering conditions

• Outlook

-

Alumina - Initial point for Applications

• 1898 first patent on porous Al2O3– Corrosion passivation and upgrading of Al-components

Disordered porous alumina

• Condenser, rectifier• Absorber• Catalyst• Carrier material

Applications:

-

Ordered nanoporous alumina

• First report in 1995• Electrochemical anodization• Hexagonally ordered pores• Polydomain degree of order• High aspect ratio

– up to 1:4000

Al2O3

AlH. Masuda et al., Science 268, 1466 (1995)

Self-ordered porous alumina

-

Applications

• Nanotubes and nanorods– Electrochemical deposition of metals– Template wetting with polymers

• Hybrid systems– Aligned 1D nanostructures inside matrix

(e.g., high storage media)

• Nanobiotechnology– Separation of molecules– Infiltration of peptides– Cell growth– 1D diffusion of single fluorescence molecules

J. Choi et al., Chem. Mater. 15 776 (2003)

M. Steinhart et al., Science 296 1997 (2002)courtesy of P.Göring

-

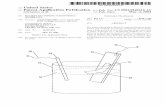

Self-ordering during electrochemical anodization

+-

O 2-/OH -Al3+

Electrode

Electrolyte

Al2O 3

Aluminium

+-

O 2-/OH -Al3+

Electrode

Electrolyte

Al2O 3

Aluminium

1.

EAl3+O2-

EAl3+O2-

+-

Electrode

+-

Electrode

4.

EE+-

Electrode

+-

Electrode

3.

EE

+-

Electrode

+-

Electrode

2.

O. Jessensky, J.Electrchem. Soc. 145, 3735 (1998)

1. Formation of barrier layer

2. Fluctuation in surfaceenhanced electric field

3. Pore nucleationenhancement of electric field

4. End of excess poresStable pore growth

0.00

0.02

0.04

0.06

0.08

0.10

0 25 50 75 100 125 150 175 2000

5

10

15

20

25

Icu

rren

t [A

]

volta

ge [V

]

time [s]

V

1.

2. 4.3.

-

Parameters that determine self-ordering

• Applied voltage– Interpore distance

(dint)=2,5nm/V*U

• Type and concentration ofelectrolyte– Threshold of pore formation– pH value determines pore

diameter

• Temperature– Removing local heat– Preventing formed alumina

from attack of acid

0 50 100 150 2000

75

150

225

300

375

450

525

inte

rpor

e di

stan

ce [n

m]

applied voltage [V]

sulfuric acid oxalic acid phosphoric acid d

int=2.5*U

K. Nielsch et al., Nano Letters 2, 677 (2002)

-

Tasks

• Extension of latticeparameters– close the gap

• Increase long-range order• Decrease of porosity

0 50 100 150 2000

75

150

225

300

375

450

525

inte

rpor

e di

stan

ce [n

m]

applied voltage [V]

sulfuric acid oxalic acid phosphoric acid d

int=2.5*U

K. Nielsch et al., Nano Letters 2, 677 (2002)

?

SZ.Chu et al. Adv. Mater 17, 2115 (2005)

Solution:

Anodization with high voltage under high current limitation

-

High-voltage anodization with H2SO4

• Extension of latticeparameters

• Interpore distance from70nm to 145nm

0 20 40 60 80 1000

50

100

150

200

250

inte

rpor

e di

stan

ce [n

m]

applied voltage [V]

sulfuric acid oxalic acid d

int=2.5*U

sulfuric acid (high voltage)

anodization with 80V

-

0 300 600 900 1200 1500 1800

25

30

35

40

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

curr

ent [

A]

volta

ge [V

]

time [s]

Mechanism of high-voltage anodizationwith H2SO4

-

30 40 50 60 70 80 900.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

coun

ts/#

of p

ores

distance [nm]

26V dint

=55nm 32V d

int=65nm

30 40 50 60 70 80 900.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

coun

ts/#

of p

ores

distance [nm]

26V dint

=55nm

30 40 50 60 70 80 900.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

coun

ts/#

of p

ores

distance [nm]

26V dint

=55nm 32V d

int=65nm

40V dint

=72nm

30 40 50 60 70 80 900.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

coun

ts/#

of p

ores

distance [nm]

26V dint=55nm 32V d

int=65nm

40V dint

=72nm 40V d

int=73nm

Evolution of the distribution of nearestneighbor distance

-

25

30

35

40

0 500 1000 15000.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

V

vo

ltage

[V]

curr

ent [

A]

time [s]

I

Mechanism of high-voltage anodization with H2SO4

• Periodicity of 120-150nm• Max/min ratio 1.5-1.7

• Pronounced die off ofpores

• Slight change of interporedistance with increasing voltage

• Sporadic ends of pores

-

40 50 60 70 80 900.0

0.1

0.2

0.3

0.4

coun

ts/#

of p

ores

pore distance [nm]

25V standard 40V

30 40 50 60 70 80 900.0

0.4

0.8

1.2

1.6

2.0

2.4

coun

ts/#

of p

ores

angle [°]

Local pair distribution functions

Local angular distribution functions

Distributions ofnearest neighbordistance

Distributions of anglebetween three nearestneighbors (expected forideal hexagonal lattice:sharp peak at 60°)

Comparison of lattice order

• High-voltage anodizationimproves the local order

Sample 25V HWHM 40V HWHMdint 62nm 3.5nm 66nm 3.0nmangle 60° 10.5° 60° 9.0°

-

Comparison of lattice order

0 200 400 600 800 10000.0

0.2

0.4

0.6

0.8

1.0

1.2 25V standard 40V

coun

ts/#

of p

ores

interpore distance [nm]

Pair distribution functions (long-range)

Distributions of following neighbor distances

• High-voltage anodizationleading to sooner loss of longrange order

• High-voltage process:correlation up to 850 nm

• Standard process: correlationup to more than 1000 nm

-

• Anodization under stress• Brittle membranes,

occurrence of cracks• Chemically more instable

Conclusions and Problems

• Extension of accessiblerange of lattice parameters

• Improved local order

-

Outlook

• Chemical composition of the oxide ?

• When/why takes high voltage anodization place ?

• Transition between standard and high voltageanodization ?

• How to produce mechanically stable membranes byhigh-voltage anodization ?

• Is it possible to reduce the porosity ?