Multronic Marine Stage V modular solution · Its flexible approach and custom solutions satisfy...

Transcript of Multronic Marine Stage V modular solution · Its flexible approach and custom solutions satisfy...

Multronic Marine Stage V modular solution

Antwerpen 16 November 2018

About Multronic

MAKING THE WORLD GREENER

• 35 years of experience in automotive industry

• Located in Belgium close to Brussels

• Design, manufacture and supply diesel engine emission aftertreatment systems

• Flexible approach and customized solutions,

• OEM and retrofit, in a wide range of market sectors

Multronic expands its business on production of retrofit systems for industrial engines

Delivery and installation of catalysts and closed loop systems

Main focus is brought to quickly expan-ding diesel engines market

DE-Tronic ECU system develop-ment started for in-house applications

An industrialization agreement for software development and hardware production was signed with Fuel System Solutions/BRC in Cherasco, Italy

OES agreement signed with Scania Benelux for all DPF SYSTEMS EURO III to EURO V for PM

Licensing agreement with TU Graz for their SCR dosing technology

OEM agreement signed with ZETOR Tractors for Stage IV and TIER 4F for turn key solution

Agreement signed with European Commission and TNO/TUV to develop OBD MARINE standard for marine Stage V

.KUS® exclusive distribution agreement for Europe.Dev, agreement signed with a major Indian OEM for TIER 4F and Bharat Stage 6.Dev. of specific urea level /temp sensor and suction system for marine applications; flow rates > 200 kg/h.Dev. of specific multi-purpose diesel level sensor and suction system for marine applications;flow rates > 250 kg/h

Supply to ZETOR Tractors of the Stage IV system& Supply to LIAZ, MAZ, URALAZ, KRAZ

2017

2016

2014

2010

20122007

2005

2001

1999

1996

1994

Developments over the Past 25 Years

► Since 1981, Multronic has developed an experience in the automotive industry. It designs, manufactures and supplies diesel engine emission aftertreatment systems.

► Its flexible approach and custom solutions satisfy both OEM and retrofit customers for a large variety of light, medium and heavy duty applications in the on/off road, marine, rail, stationary engine market sectors.

OEM agre-ement signed with YAMZ for Euro V turn key solution

2013

Further OEM development agreements in India negotiated TREM IV/CEV IV

20181994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 2013 2014 2015 2016 20172018

TORONTO, CANADA

Sales office

CHONGQING, CHINA

Sales and technical support office

UHERSKE HRADISTE, CZECH REPUBLIC

Engineering, Project management and technical

support office

LONDON, UK

Administration office handling the commercial activities of the company

TIENEN, BELGIUM

Facility for technology development, engineering,

system development, testing and validation

CARMAGNOLA, ITALY

Software development and production

ROTTERDAM, NL

Service and support marine operations

Bergen, Norway

Sales offices

Locations

Gurguan New Delhi ,India

Facility for componentproduction

5

Future Developments

► Focus on Electrical mobility: Management of satellites and accessories of electrical vehicles for power pack sensitive components and battery temperature management

► Stage 5 Marine engines OEM

► IMO TIER III dosing package homologation

EV management systemsGlobal

►Management systems for construction machines and non road

E V

Marine ocean goingGlobal

► Dosing systems IMO TIER III for engines from 5 to 50 megawatt

RETROFIT

▪ DE-Tronic

With the functionalities of DE-Tronic all diesel engines can be compliant with EURO IV/ V / VI, Stages III/IV/V, TIER 3/4i/4F

Products Compliance

►On-roadFor heavy duty vehicles in Europe & Russia our products are integrated on EEV, Euro V & EURO VI vehicles. For our Chinese customers we deliver China V and China VI packages. In India we are with BS IV & BS VI.► Off-roadMultronic Products comply with the highest emission standards of the world – Stage IV, V for Europe and TIER4F solutions for the US market►MarineMultronic has a separate division managing large after-treatment systems for marine and genset applications.The company has introduced the most innovative technologies and solutions for marine engine aftertreatment Stage V systems► StationaryAlso for stationary engine Multronic provides the perfect solution in respect of the environment. Our technology complies to Emission Standards Stage IV, Stage V and Tier 4 Final for the US market.

Product: Example of an Electronic Layout

Diesel E-gas system or CR

Urea heating

Ureapump Driver

Fuel dosing

∆P

RP

M

MA

F TI

Nρ

Vb

att

NO

X1

(Po

st)

TIN

Urea level

T1 T2 T3

Torq

ue

acco

rdin

g to

J1

93

9 s

tan

dar

d

Fuel

rat

e

Key

+

Ure

a Q

ual

ity

DASHBOARD

Analogue

CANBus 0 J1939PUBLIC CANbus

Power relay

Fuel Pump

EGR VALVE

T4

Engine pre heating – glow

plugs

MA

P

NO

X2

(Po

st)

Tem

p c

oo

lan

t

Mea

sure

d a

ctu

ato

r p

osi

ion

of

pu

mp

AC

T SE

NS

Transmission / Gear Box

Urea inject.

Urea temp

Urea Press

OBD connector

Ped

al P

osi

tio

n

CANBus 0 J1939Intra CANbus

NOX Table

Air intake

throttle valve

Legend

Markets

Heavy Duty

Agri culture

Marine

Rail

Light Duty

ROAD OFF-ROAD

Genset

Passenger car with JV

partner

Platform & Production

Marine market

Marine legislation

The scoped marine legislations are MARPOL

VI [TIER III] for coasters and sea going

vessels, and Stage V for inland shipping in

Europe and EPA TIER 4 for the inland

vessels in U.S.A..

To fulfill Stage V, NOX must be reduced

between 80 and 95 %.

This can be achieved by the Multronic SCR

and SCR + DPF systems.

0,000

0,050

0,100

0,150

0,200

0,250

0,300

0,350

0,400

0,450

0,500

0,0

1,0

2,0

3,0

4,0

5,0

6,0

7,0

8,0

9,0

PM

g/k

Wh

NOX g/kWh

Mechanical injection Electronic injection

Ultra modern common rail

D

P

F

SCR

Marine diesel engines

Name Low speed Medium Speed High Speed

Displacement (l/cyl) 200 - 2000 16-120 5 - 16 0,8 - 3 < 0,8

Power range (kW) 4000 – 100000 800 - 40000 kW Up to 10000 kW Up to 800 kW Up to 300 kW

Combustion type 2-stroke & 4 stroke 2-stroke & 4 stroke 2-stroke & 4 stroke 4 stroke 4 stroke

Rotation speed (rpm) 70-300 350 - 850 600 - 2200 600 - 3000 >3000

The marine market is characterized by an enormous variety of engines and power ranges. Each type, application

must fulfill different emission requirements.

Multronic scope

DPF systems for propulsion engines

Nevertheless Multronic equips all the DPF systems with

a back-up active regeneration system, Diesel Hydro

Carbon Post Injection (DHCPI). In case of long periods

of low engine load, the temperature of the exhaust gas

is raised by the injection of fuel over the catalyst.

The main advantages of the DHCPI system compared

to a burner are:

• very large operational window

• Independent from the engine load

• fuel efficient temperature raise

• stepless temperature regulation

• no air injection needed

Engin

e

DPF

Temp 1 Temp 3

DO

C/D

EC

Diesel

injecton

T

U

R

B

O

Temp 2Press 1

Driven by local rules, environmental

conscience, ship-owners or transport

companies equip the propulsion engines of

their vessels with DPF systems.

The soot is trapped in the filter and is

oxidised by means of a catalytic reaction

that takes place between 280 and 420°C.

Under normal operation this is the

temperature present after the turbocharger

in the exhaust stack.

0

20

40

60

80

100

CO HC PM NOX NO NO2

OE DPF

DPF systems for generators

The main driver to install DPF’s on ships is to

avoid deposits of soot on the water around the

ship, the hull and on the deck.

The engines responsible for these practical

problems are mainly the auxiliary engines used

for the generators.

Multronic has developed the E-DPF for a

durable solution on generators. The DPF

regenerates passively when the engine is

loaded above 50%.

Engin

e

DPF

Temp 3Press 1Temp 2

Heate

r

T

U

R

B

O

Generator

Temp 1

Under low load conditions the exhaust gas

temperature is artificially raised to oxidise the

trapped soot.

The electrical heater can be combined with a

diesel oxidation catalyst and diesel post injection

(DHCPI) to speed up the regeneration and

enlarge the operational window of the system.

The coating on both the DPF and DOC can be

chosen in function of the fuel quality.

Multronic recommend the use of fuel with a

maximum of 1000PPM sulphur.

Engin

e

DPF

DO

C/D

ECT

U

R

B

O

Generator

Temp 1 Temp 4

Hea

ter

Diesel

injecton

Temp 3Temp 2 Press 1

SCR systems for propulsion engines(IMO TIER III)

Engin

e

SCR

Temp 2

Urea

dosing

T

U

R

B

O

Temp 1Press 1

Emission legislation for IMO marine

engines focuses mainly on Nitrogen

oxide reduction.

One of the most effective methods to

reduce NOX is SCR, Selective

Catalytic Reduction.

Adblue / DEF, an aqueous urea

solution is injected in the exhaust gas

upstream of the SCR catalyst.

The urea is transformed into ammonia

and In the catalyst the ammonia reacts

with the NOX and is reduced to

nitrogen and water.

Standard SCR system

0

20

40

60

80

100

CO HC PM NOX NO NO2

OE SCR

Spark arrestor also used for

urea mixing and distributionExpansion chamber

(Piping not shown here)

Urea injection

area

Silencer(details not

shown here)

SCR(P)

element

POC or DOC

element2 SCR

elements

Room for

extra SCR

element

SCR systems for propulsion engines(IMO TIER III)

The patrol ship

The housing

DPF & SCR

HC dosing

Urea dosing

DOC

SCR+ systems for propulsion engines(Tier 4F PM by engine management)

Engin

e

AdBlue

injection

SCR

Temp

1

Temp

3

Press

1

NOX

DO

C/D

EC

Temp

2

Mixer

AS

C

To increase the efficiency of the SCR (SCR+ system) additional catalysts

can be added to the system. An ammonia slip catalyst can remove

excessive ammonia that can slip through the system when high

efficiencies are needed and an upstream diesel oxidation catalyst

balances the relation between NO and NO2 to improve the system

efficiency and urea consumption.

SCR + system

0 20 40 60 80 100

CO

HC

PM

NOX

NO

NO2

SCR+ OE

SCR+ systems for genset engines

To increase the efficiency of the SCR (SCR+ system) an additional heater can be installed before the SCR

system allowing the SCR to be fully operational and offering his complete efficiency even at extreme low power

demand.

0 20 40 60 80 100

CO

HC

PM

NOX

NO

NO2

SCR+ OE

Option

2

En

gin

e

AdBlu

e

inject

on

SCR

Temp

1

Temp

2

Temp

3

Press

1

NOX

Mixer

AS

C

Hea

ter

Combined DPF and SCR systems

Multronic Modular Stage V systemsE

ng

ine

DPFD

OC

/ D

EC

SCR

AS

C

AdBlue

injecton

Temp 1 Temp 3 Temp 4Temp 2Press 1 Press /

Ref 2

NOX

Diesel

injecton

Mixer Mixer

To achieve Stage V both NOX and PM must be

reduced between 60 and 90%. This can be achieved

with the Multronic modular solultions.

0

20

40

60

80

100

CO HC PM NOX NO NO2

Stage V

Emission systems

Inland vessels, coaster and luxury

yachts

Large cargo vessels

Medium and high speed diesel engines Low & medium speed diesel engines

4 stroke 2 and 4 stroke

Good quality fuels Heavy fuel oil , high sulphur levels,

phosphor and ash.

Good engine load profile Good engine load profile

High efficient aftertreatment technology

similar to on-road EURO VI heavy duty

emission systems

Requires specific EAT solution

Validation of DPF + SCR on ships(Build in 2012 and 12000 engine hours performed on 1/7/2017)

Barge

This is considered as a normal

application

Engine: Scania V8 16 liter 450 kW

Police Patrol ship

Considered as a worst case

scenario

Engine : 2 x MTU V2000-01 600 kW

1 x Caterpillar 3516

1590 kW

SCR and DPF

1 x Caterpillar 3512

1250 kW

SCR and DPF

Patrol ship: DPF & SCR

The housing

DPF & SCR

HC dosing

AUS dosing

DOC

The patrol ship

The silencer The DPF & SCR

Urea tanks on top of the rudder system

The control cabinet /monitor

The patrol ship

Tanker vessel: DPF & SCR

Spark arrestor also used

for urea mixing and

distribution

DPF elements (with SCR

coatings)

Urea injection

area

Flow

SCR and ASC

catalysts

DOC

element

Diesel

dosers

Tanker vessel: installation work

Stage V: DPF and SCR

Modular Stage V systems

To achieve Stage V both NOX and PM must be

reduced between 60 and 90%. This can be achieved

with the Multronic modular Stage V marine packages.0

20

40

60

80

100

CO HC PM NOX NO NO2

Stage V

Modular Stage V systems

Validation of the Multronic modular Stage V package

• Start of feasibility 01/01/2010

• First ships fitted with proof of concept 01/05/2012

• DPF modules: fitting and removal for maintenance validated

• Electronics, pumps, urea injectors, sensors fully tested

• Main validation for Stage V within EU consortium PROMINENT (2015 -

2018)

Modular Stage V systems

Easy installation

Stainless steel

housing

Airless AdBlue

injection

Compact setup

Fast eletrical

and hydraulical

fitting

Scalable

solution

for large

engine

range

Main advantages

Industrialization of the Modular Stage V systems

Cost improvement on catalyst substrates & DPF substrates

Substrates

• Available in high number of diameters

& lengths and materials and

specifications

• Options to reduce cost here is to limit

variety

DOC

• 6 models

• 1 coating type / washcoat and PGM

loading covering full range of ships

SCR and SCR/ASC

• 1 substrate model and type package

for 50 kW

DPF substrate

• Component with the highest constraint

• Largest cost driver over life time

(maintenance & service item)

• Drives design complexity (access to

substrates for service)

• High volume required to improve cost

• 1 DPF element and package type for 50 kW

DPF SCR

SCR + ASC

Modular Stage V systems

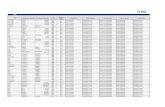

Standard shapes / volumes and module # in function of exhaust flow rate

Standard shape

Square box design

3 x 5DOC size

varies

Housing

size varies

Elements

are modular

Dosing is

modular

Modular Stage V systems

Stage V box design integrated mixing pipe / DOC delivered separately with

cones

LAYOUT

DPF & SCR LAYOUT

Flange

DIN

2573-

PN6

DOC SECTION DPF & SCR BOX SIZE

row column # Dia p Dia DOC DOC L P1 C P2 T Lenght width Height P3 P4

mm mantel mm mm mm mm mm mm mm mm mm mm

TWIN ROW

SYSTEMS

3 2 6 150 374 130 500 110 120 970 1100 900 650 300 200

4 2 8 200 404 130 520 100 120 970 1410 950 650 300 200

5 2 10 200 444 130 520 120 120 1010 1720 950 650 300 200

6 2 12 200 494 130 550 145 120 1090 2030 950 650 300 200

9 2 18 300 574 130 650 135 120 1170 3100 950 650 300 200

2 x 3

3 x 4

Modular Stage V systems

2 x 3

Standard shapes / volumes and module # in function of exhaust flow rate

DOC size

varies

Housing

size varies

Elements

are modular

Dosing is

modular Fixation &

gaskets

Mechanical details

Earlier stage design of housing for 3x5 modules

Mounting points are defined together with manufacturer and end-user

Oval pipe for larger systems

Round for smaller system

Current stage design of housing

for 2x3 modules

Modules are clamped to

Separation plate(better illustrated later)

Mechanical details

Mixing pipe with downward pointing outlet

ensures good evaporation and mixing

Outlet point can be placed on both

ends of the housing

Mounting points for all

sensors and injectors are

foreseen on the DOC housing

and on the DPF/SCR/ASC

housing

Extra mounting points on

exhaust are not required

Mechanical details

Elements size/weight is kept low to

allow 1 man to handle and mount them

DPF / SCR / ASC module can easily be

lifted out of the housing to allow

cleaning.

Mechanical details

Modules are held in place by

place holders sticking out

from the separation plate.

A clamp keeps the units

down.

Bolts/nuts which were

deformed by heat can be

welded off and replaced

during maintenance

Changing of filters

can be done by a

regular mechanic

or by technical

crew

Modular Stage V systems

CFD study of the different layoutsTargets:

• Standard injection configuration

• Guaranteed performance

• Back pressure estimation

Modular Stage V systems

Modular Stage V systems

Advantages

• Standardized modular package for marine

• Over 90% of all components are modular

• Flexible standard solutions for in and outlet position of the systems

• Compliance with marine lifetime expectations

• Long maintenance intervals

• Software incorporates all necessary OBD and diagnostic functions

• EPM (environmental performance monitor) integrated

• Low cost system calibration / SW package

• Ready for diesel electrical power trains & gensets

PROMINENT pilot case

PROMINENT field validation

AUS

tank

Conversion of

existing tank

DPF & SCR

systemDOC package

Engine

Engine

Control system

Motorization:

CAT 3508

750 kW

CCR 2

PROMINENT field validation

SCR at installation SCR after 15 months of use

Visual inspection of DPF performance

Marine Urea level sensors

52

CN9F :

sensor design and concept

Installation

Plastic head

Bajonet fitting

Large suction

tube 1

Large suction

tube 2

Strainer

Venting

Connection

Large port

connections 2x

Small port

connections 2x

Electronics /

output

Tube Clip for

sensor stability

Small port

connections 2x

Large port

connections 2x

Up to 2500 mm

>400 kg/ hour

for the large

suction

> 90 kg/ hour for

the small suction

CN9F Features

Stabilizer

• Length 100 mm ~3000mm

• Widely used on generators/gen set and marine

• Used in fule, water, kerosene and Chemical tanks

• Reed switch, steady output signal

• Anti-vibration, strong, Advanced corrosion resistance

• Resolution range 10 to 40mm

FUEL SENSOR S3 & S5

www.multronic.be

Leeuwerikweg 8

3300 Tienen

Belgium

Tel: + 32 (0)16 78 19 00

Contact details