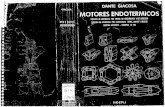

MOTORES DUALES

Transcript of MOTORES DUALES

This article was downloaded by: [Universidad Del Norte]On: 30 December 2011, At: 11:25Publisher: Taylor & FrancisInforma Ltd Registered in England and Wales Registered Number: 1072954 Registeredoffice: Mortimer House, 37-41 Mortimer Street, London W1T 3JH, UK

Combustion Science and TechnologyPublication details, including instructions for authors andsubscription information:http://www.tandfonline.com/loi/gcst20

Combustion of Syngas in InternalCombustion EnginesAndré L. Boehman a & Olivier Le Corre ba Department of Energy and Mineral Engineering, The PennsylvaniaState University, University Park, Pa 16802, USAb Department of Energetics and Environmental Engineering Ecole desMines de Nantes La F-44307, Nantes Cedex 3, France

Available online: 09 May 2008

To cite this article: André L. Boehman & Olivier Le Corre (2008): Combustion of Syngas in InternalCombustion Engines, Combustion Science and Technology, 180:6, 1193-1206

To link to this article: http://dx.doi.org/10.1080/00102200801963417

PLEASE SCROLL DOWN FOR ARTICLE

Full terms and conditions of use: http://www.tandfonline.com/page/terms-and-conditions

This article may be used for research, teaching, and private study purposes. Anysubstantial or systematic reproduction, redistribution, reselling, loan, sub-licensing,systematic supply, or distribution in any form to anyone is expressly forbidden.

The publisher does not give any warranty express or implied or make any representationthat the contents will be complete or accurate or up to date. The accuracy of anyinstructions, formulae, and drug doses should be independently verified with primarysources. The publisher shall not be liable for any loss, actions, claims, proceedings,demand, or costs or damages whatsoever or howsoever caused arising directly orindirectly in connection with or arising out of the use of this material.

COMBUSTION OF SYNGAS IN INTERNALCOMBUSTION ENGINES

Andre L. Boehman1 and Olivier Le Corre2

1Department of Energy and Mineral Engineering, The Pennsylvania StateUniversity, University Park, Pa 16802, USA2Department of Energetics and Environmental Engineering Ecole des Minesde Nantes La F-44307 Nantes Cedex 3 France

The combustion of synthesis gas will play an important role in advanced power systems

based on the gasification of fuel feedstocks and combined cycle power production. While

the most commonly discussed option is to burn syngas in gas turbine engines, another possi-

bility is to burn the syngas in stationary reciprocating engines. Whether spark ignited or

compression ignited, syngas could serve to power large bore stationary engines, such as

those presently operated on natural gas. To date, however, there has been little published

on the combustion of syngas in reciprocating engines. One area that has received attention

is dual-fueled diesel combustion, using a combination of diesel pilot injection and syngas

fumigation in the intake air. In this article, we survey some of the relevant published work

on the use of synthesis gas in IC engines, highlighting recent work on dual-fuel

(syngas 1 diesel) combustion.

Keywords: Diesel; Dual-fuel; Internal combustion engine; Syngas

INTRODUCTION

Advanced power systems that are projected to achieve high efficiency and lowemissions, such as those envisioned in the ‘‘Vision 21’’ (Rao et al., 2002) and‘‘FutureGen’’ (U.S. DOE, 2003) programs of the U.S. Department of Energy, relyon synthesis gas as a key intermediate energy carrier. In such systems, coal or otherfuels are converted to synthesis gas (composed mostly of hydrogen and carbonmonoxide) via gasification and=or partial oxidation. The targets outlined for Vision21 powerplants are 75% thermal efficiency for natural gas fueled plants on a LHVbasis and 60% for coal fueled plants on a HHV basis while producing electricity,without CO2 capture and sequestration or co-production of any transportation fuels.The goal for coal based plants producing H2 or transportation fuels only is a mini-mum fuel utilization efficiency of 75% on a LHV basis (Rao et al., 2002). Analysesof system configurations and efficiency limitations have suggested that the onlymeans to achieve such efficiency targets requires gas turbines integrated with solidoxide fuel cells (SOFC) in hybrid power systems.

Address correspondence to Andre L. Boehman, The Pennsylvania State University, 405 Academic

Activities Bldg., University Park, PA 16802, E-mail: [email protected]

1193

Combust. Sci. and Tech., 180: 1193–1206, 2008

Copyright # Taylor & Francis Group, LLC

ISSN: 0010-2202 print/1563-521X online

DOI: 10.1080/00102200801963417

Dow

nloa

ded

by [

Uni

vers

idad

Del

Nor

te]

at 1

1:25

30

Dec

embe

r 20

11

Because of their role in distributed energy (DE) production and their combi-nation of high efficiency and low cost, advanced reciprocating engines are anotherpotential means of converting synthesis gas into power. Mixtures of hydrogen andcarbon monoxide have high anti-knock behavior and therefore could serve as sparkignition (SI) fuels and as HCCI fuels (Shudo and Takahashi, 2004; Shudo, 2006).However, addition of hydrogen to carbon monoxide or to methane tends to increasecombustion temperatures and increases NO emissions under stoichiometric SIcombustion (Li and Karim, 2005). So, such mixtures may be more appropriate inlean burn applications where combustion temperatures are moderated by excessair. Such mixtures could also serve in ‘‘dual-fuel’’ engines that operate undercompression ignition using a pilot injection of diesel fuel.

Although there is little published work on the use of synthesis gas as a fuel forinternal combustion engines, there has been a substantial effort by Le Corre andco-workers on the use of various gaseous fuels, including synthesis gas, in dual-fuelcompression ignition engines. This work is one example of the large body ofactivity on pilot-ignited dual-fuel diesel engines that operate on a combination ofdiesel fuel and natural gas. Other engine studies related to synthesis gas includework by Karim and co-workers (Karim and Moore, 1990; Karim and Wierzba,1992) and McMillian and Lawson (2006), who examined the possibility of synthesisgas production via a natural-gas fueled ‘‘partial oxidation’’ engine.

In the work by McMillian and Lawson, a spark ignited engine was operated atequivalence ratios from 1.3 to 1.6 and was shown to yield H2 concentrations as highas 11 vol.% in a spark ignition mode. They estimated that hydrogen concentrationsas high as 20 vol.% could be achievable by operating in a homogeneous chargecompression ignition (HCCI) operating mode. Since there has been little reported workon the operation of internal combustion engines on synthesis gas, the rest of this paperwill focus on the dual-fuel application of synthesis gas as an IC engine fuel.

Dual-fuel engines have been employed in a wide range of applications to utilizegaseous fuels. They are most commonly modified diesel engines and can achieve verylow emission levels, particularly smoke and particulate. Benefits with the dual-fuelconversion include smoother and quieter operation, significantly longer engine lifebetween overhauls, fuel savings and enhanced safety. The gaseous fuel, which iscalled the primary fuel, provides most of the energy input. This is inducted alongwith air and compressed. At full load around 80% of the total energy could becontributed by the primary fuel. The pilot fuel is usually diesel, and in fact, is usedto ignite the gaseous fuel-air charge. The injection of the pilot fuel takes place nearTDC (Top Dead Center) like in the diesel engine. The pilot fuel self-ignites andforms multiple ignition centers from which primary fuel combustion is initiated(Poonia et al., 1998, Liu and Karim, 1997). Finally, the gaseous fuel and the pilotfuel burn together in the combustion chamber. The combustion process in a dual-fuel engine tends to display a combination of features of both diesel and sparkignition engines.

For compression ignition (CI) engines, the ignition of the primary fuel (i.e.,which is typically the gaseous fuel in dual-fuel CI combustion) is activated by thein-cylinder conditions. Some fuels do not have good enough ignition quality toenable ignition. Therefore, two fuels must be used as shown in Figure 1. First a pilotfuel, which could be for example diesel fuel, is injected, resulting in ignition and a rise

1194 A. L. BOEHMAN AND O. LECORRE

Dow

nloa

ded

by [

Uni

vers

idad

Del

Nor

te]

at 1

1:25

30

Dec

embe

r 20

11

of the temperature in the combustion chamber. Then, the second fuel, which couldbe for example syngas, is injected and ignites as the pilot fuel temperature increases.

In dual-fuel engines, the energy released by combustion comes about partlyfrom the combustion of gaseous alternative fuel, while the diesel fuel continues toprovide, through timed cylinder injection, the remaining part of the energy released.Ideally, in relation to the gaseous alternative supplied to the engine, there is a need todetermine the optimum diesel fuel quantity at a particular engine operatingcondition, so as to provide the best performance over the desired load range. The mainaim is to minimize the use of diesel fuel due to environmental considerations and max-imize its substitution by alternative fuels throughout the load and speed range. Thedual-fuel engine is an ideal multi-fuel engine that can operate effectively on a widerange of fuels with the flexibility of operating as a conventional diesel engine.

The typical combustion process in a dual-fuel engine consists of four stages, anignition delay period, premixed combustion of the pilot fuel, premixed combustionof the gaseous fuel and diffusion combustion of the gaseous fuel together with thecombustion of the remaining pilot fuel, as shown in Figure 2. Of interest is the deter-mination of the ignition delay, which is the time delay between injection of the pilotfuel and the initiation of chemical heat release, and correlation of the ignition delayfor various fuel combinations. During this ignition delay period, complex chemicalreactions take place. Ignition delay can be correlated by using an Arrhenius equation(see Hardenberg and Hase, 1979), which has been modified by Prakash et al. (1999)for biogas-diesel systems.

This relation takes into account several effects, such as oxygen concentrationand variations of polytropic coefficient. Bilcan et al. (2001) have proposed anexpression of the polytropic coefficient for different gaseous fuels and which has beenvalidated for a syngas-diesel engine by Garnier et al. (2005). The ignition delay for the

Figure 1 Conceptual diagram of dual fuel CI engine (from Garnier et al., 2005). Reprinted with permission

from SAE 2005-01-1731 # 2005 SAE International

COMBUSTION OF SYNGAS IN INTERNAL COMBUSTION ENGINES 1195

Dow

nloa

ded

by [

Uni

vers

idad

Del

Nor

te]

at 1

1:25

30

Dec

embe

r 20

11

pilot ignition of various gaseous fuels has also been measured by Kavtaradze et al.(2005) who compared ignition delays for diesel fuel, natural gas and mixtures referredto as ‘‘synthesis gas’’ (70%N2þ 30%CH4 and 60%H2þ 20%CH4þ20%N2). Whilethese ‘‘synthesis gas’’ mixtures are substantially different from the synthesis gasexpected within a Vision 21 power plant, the results are nonetheless instructive.Kavtaradze et al. found that for pilot ignition of various gaseous fuels, includingthe use of exhaust gas recirculation, the formula in Eq. (1) was effective for correlat-ing ignition delay.

si ¼ cKp�1:3 expE=R

T

� �ð1Þ

where c is an empirically determined constant with units of time (s), K is an empiri-cally determined parameter equal to 0:9z�0:09 where z is the percentage of exhaustrecirculation, p is the cylinder pressure at the time of fuel injection (bar), E is theactivation energy (J=mol) and R is the ideal gas constant (J=mol-K). In comparing theircorrelation of the ignition for different gaseous fuels and for various levels of exhaustgas recirculation, they observed that the impact of hydrogen on pilot-ignited dieselcombustion is to shorten both the ignition delay and the duration of combustion.

A review of the state of art in correlating ignition delay shows that two meth-ods exist. The first one is based on the Livengood and Wu (1955) integral. Thesecond one is based on an Arrhenius equation.

Livengood and Wu Integral Approach

Hountalas and Papagiannakis (2000) have studied the ignition delay with:

I ¼Z t

0

1

a p�k exp Ea

T

� � ds ð2Þ

Figure 2 Characteristic stages of the rate of heat release for combustion in a dual fuel engine (from

Garnier et al., 2005). Reprinted with permission from SAE 2005-01-1731 # 2005 SAE International

1196 A. L. BOEHMAN AND O. LECORRE

Dow

nloa

ded

by [

Uni

vers

idad

Del

Nor

te]

at 1

1:25

30

Dec

embe

r 20

11

The ignition delay s is obtained when the integral is equal to one. Depending uponthe fuels, the parameters are fitted to obtain good agreement with experiments.

Arrhenius Equation Approach

Ignition delay ID models dedicated to diesel or dual-fuel are based onArrhenius equation [c.f., Aligrot et al. (1997), Assanis et al. (1999), Heywood(1988), Liu and Karim (1995), or Ramos (1989)].

ID ¼ A p�k expEa

RT

� �ð3Þ

where ID is the ignition delay (ms), p and T the pressure (bar) and the temperature(K) averaged over ignition processes. Ea is the activation energy (J=mole), R theuniversal gas constant (J=mole=K), A and k are kinetic parameters.

Hiroyasu (1985) used the traditional Arrhenius equation to correlate ignitiondelay as follows:

ID ¼ A p�k GFAR�n expEa

RT

� �ð4Þ

where GFAR is the global fuel air ratio.Mansour et al. incorporated the engine speed N and the inlet temperature Tin:

ID ¼ A N�a T�bin p�k exp

Ea

RT

� �ð5Þ

The Prakash model (Prakash et al., 1999) was formulated to integrate theengine speed (by piston speed), an activation energy depending on cetane number,the oxygen concentration, and the thermodynamic conditions (pressure an tempera-ture) at TDC (top dead center). Garnier et al. (2005) found that the Prakash model,shown in the following formula and which is substantially more complex that thatused by Kavtaradze et al. (2005) in Eq. (1), provided an effective correlation:

ID ¼ ACf Okc exp EADþQ0:63

� �ð6Þ

Thus, effective correlation of the ignition delay in dual-fuel combustion can beachieved and the impact of using synthesis gas instead of, for instance natural gas, asthe gaseous fuel in a dual-fuel engine should serve to shorten the ignition delay andshorten the duration of combustion. In the rest of this paper, we survey some of theexperimental observations of Garnier et al. (2005) and others to provide an indi-cation of the unique impact of syngas on dual-fuel diesel combustion.

EXPERIMENTAL

A single cylinder, direct injection, air-cooled stationary diesel engine wasadapted to work in dual-fuel mode, using syngas as the primary fuel. The mainengine specifications are presented in Table 1. Atmospheric temperature during

COMBUSTION OF SYNGAS IN INTERNAL COMBUSTION ENGINES 1197

Dow

nloa

ded

by [

Uni

vers

idad

Del

Nor

te]

at 1

1:25

30

Dec

embe

r 20

11

the experiments varied from 20�C up to 27�C. Additionally, the atmospheric pressurechanged from 1002 mbar to 1023 mbar and the relative humidity from 47% to 69%.The engine is connected to an electrical dynamometer. To provide the gaseous fuel, amixing system was composed of nine pure gases provided by bottles (methane, ethane,propane, butane, nitrogen, carbon dioxide, oxygen, hydrogen and carbon monoxide).

The syngas used in this work is composed of H2 (10%), CH4 (4%), CO2 (12%),CO (25%) and N2 (49%). The thermodynamic conditions due to the autoignitionand combustion of the pilot fuel (diesel) allow this low energy content gas(LHV � 4.7 MJ=kg) to be ignited along the front flame. Consequently, the pilot fuelhas been kept above a minimum value of 5% to allow ignition.

The system for the acquisition of in-cylinder pressure was composed of:

. Piezo electric cylinder pressure sensor – AVL QH32D, gain 25.28pC=bar, range0–200 bar

. Charge amplifier – AVL 3066A0

. Shaft position encoder – AVL 364C

. Piezo resistive pressure sensor fixed inside the inlet manifold with its amplifier–range 0–2.5 bar

The ‘‘experimental’’ curves of the rate of heat release (ROHR), which are obtained frompressure versus crank angle data (with a resolution of 0.1 CA) averaged over 100 cycles,are derived from a thermodynamic model. The so-called ‘‘one zone model’’ [see Hey-wood (1988) or Thyagarajan and Babu (1985)] describes the behavior of a quasi-perfectgas, with a homogeneous temperature and pressure within the combustion chamber.These curves are used to determine the energy conversion rates during different phasesof the combustion process by application to the experimental data. Additionally, NOX

and CO2 emissions were measured using an infrared COSMA CRISTAL 500 analyzer.Averaged values were calculated on periods of 100 to 300 seconds.

The amount of gas injected at constant load is defined as the substitution rateof diesel fuel expressed by (Prakash et al., 1999):

ds ¼ddiesel � ddual�fuel

ddieselð7Þ

Table 1 Technical specifications of the dual fuel engine

Engine Lister-Petter diesel engine

Number of cylinder 1

Diesel nominal power [W] 2800

Engine speed [RPM] 1,500

Bore x Stroke [mm] 95.3� 88.9

Connecting rod length [mm] 165.3

Compression ratio 18

Injection timing Fixed, 20CA BTDC

Valve timing [CA] Inlet open: 36 BTDC

inlet close: 69 ABDC

exhaust open: 76 BBDC

exhaust close: 32 BTDC

1198 A. L. BOEHMAN AND O. LECORRE

Dow

nloa

ded

by [

Uni

vers

idad

Del

Nor

te]

at 1

1:25

30

Dec

embe

r 20

11

where ds is the defined diesel substitution, ddiesel is the quantity of diesel injected indiesel mode and ddual-fuel is the quantity of diesel injected in dual-fuel mode. Sincethis definition for the diesel substitution is based solely on the amounts of diesel fuelused with and without substitution, it represents both the mass and the energy frac-tion of the substitution on a percentage basis.

The mass flow rates of air, diesel and syngas were measured as well as theexhaust gas temperature. Substitutions between 10% and 70% were measured, butthe main interest of this engine remains for substitutions beyond 30% or 40%.Besides, diesel substitution has to be significant in order to bring out the severaladvantages of dual-fuel technology. Additional experimental details and descriptionof the analysis methodology are available elsewhere (Garnier et al., 2005).

RESULTS AND DISCUSSION

Ignition delay (ID) is an essential parameter to determine for all diesel fuelsand has a significant impact on combustion, energy conversion efficiency andpollutant formation. As mentioned in the introduction, the determination of ignitiondelay for a dual-fuel engine takes on the additional complication that the vaporizingpilot fuel spray is injected not solely into air but into an air-fuel mixture. Thus,correlation of the ignition delay for dual-fuel engines requires consideration of theimpact of the gaseous fuel on the stoichiometry in the cylinder.

As mentioned in the introduction, Garnier et al. (2005) found that the Prakashmodel, shown in Eq. (6), provided an effective correlation:

ID ¼ ACf Okc exp EADþQ0:63

� �ð6Þ

where A is as defined in Eq. (8) with units of (m=s) and Mps is the average pistonspeed (m=s),

A ¼ 0:36þ 0:22Mps ð8Þ

the activation energy (J=mol) is linked to the Cetane number of the diesel fuel,

EA ¼618840

CN þ 25ð9Þ

and Oc represents the oxygen concentration in the gas, whereby the air–fuel ratio isintroduced.

Oc ¼½O�charge

½O�air

ð10Þ

In-cylinder conditions are set by Eqs. (10) and (11).

D ¼ 1

RTinj� 1

17190ð11Þ

Q ¼ 21:2

Pinj � 12:4ð12Þ

COMBUSTION OF SYNGAS IN INTERNAL COMBUSTION ENGINES 1199

Dow

nloa

ded

by [

Uni

vers

idad

Del

Nor

te]

at 1

1:25

30

Dec

embe

r 20

11

In Eqs. (11) and (12), D has units of (mol=J), Q is dimensionless, and Tinj and Pinj arethe temperature (K) and pressure (bar) in the cylinder when diesel sprays is injected(introduced by Bilcan et al., 2001). In Eqn. (9) ndf and nair are the polytropic coeffi-cients of the compression phase, in dual-fuel mode and diesel mode, respectively. fp isthe gaseous concentration in the combustion chamber.

ndf ¼ nair þ afp ð13Þ

a ¼ dcdual fuel

dfpð14Þ

The unknown parameters needed to determine the ID are Cf, k and a. Thecoefficient a is obtained using experimental data of gaseous concentration fp, andtheoretical values of calorific capacities of air and gas. The slope of the curvendf ¼ f ðfpÞ at different loads leads to values of a. The average value gives a ¼ 0.26and is compared with other gaseous fuels defined by Bilcan et al. (1991) in Table 2.

The optimal pair of factors ðCf ¼ 1:784; k ¼ 0:542Þ is found by minimizingthe difference between experiment and theory, using the least square method forln(ID) curves. Experimental data of ID are then compared to predicted data(Figs. 3 and 4). The ignition delay is well predicted from diesel substitutions above30%: the uncertainty does not exceed 0.5�CA. Dual-fuel engines typically operate atdiesel substitutions above 50%.

The overall process of dual-fuel combustion can be described by a superpo-sition of multiple Wiebe’s functions, as shown by Liu and Karim (1997) who super-posed two functions to characterize the premixed and the diffusion combustionprocesses. Bilcan et al. (2001) have developed a procedure using 3 Wiebe’s laws,one for each combustion stage. These 3 laws describe the ROHR for biogas (fromlandfill)-diesel fuel engines (Fig. 2). In order to determine the onset of the diffusioncombustion phase, the predicted curve of the premixed pilot fuel combustion issubtracted from the experimental curve of ROHR. The end of the diffusion combus-tion is considered to occur when the burned fraction is 99.9%. Figure 5 illustrates aneffective decomposition of the phases of the combustion process.

As shown in Figure 6a, the peak value of the ROHR during the premixedcombustion of the pilot fuel is not significantly affected by the variation of the dieselsubstitution, until a certain limit is reached. This limit, at 45–50% substitution, isrepresented by the quantity of diesel that can be burned during the premixed phase.If the total quantity of diesel introduced inside the cylinder during the ignition delay

Table 2 Compared values of a for different fuels

Gaseous fuel a [-]

Biogas (63% CH4, 37% CO2) 0.19

NG (100% CH4) 0.18

LPG (30% C3H8, 70% C4H10) 0.31

1200 A. L. BOEHMAN AND O. LECORRE

Dow

nloa

ded

by [

Uni

vers

idad

Del

Nor

te]

at 1

1:25

30

Dec

embe

r 20

11

becomes smaller than this limit, the maximum value of ROHR for the premixedcombustion of the pilot fuel decreases.

As seen in Figure 6b, the ROHR during the second phase of the combustionprocess becomes significant only after the limit in diesel substitution, around45–50%. For lower levels of diesel substitution (below roughly 20%), since the fuelto air ratio in the gaseous mixture is quite small, the second premixed peak (forthe syngas) is almost imperceptible and as a consequence the energy released inthe second phase of the combustion process is modest.

Emissions of NOx show an expected trend of increasing with diesel substi-tution, since the increasing H2 content as a percentage of total fuel energy leads toan increase in adiabatic flame temperature, as shown in Figure 7. This is one reasonwhy the use of H2 fumigation in dual-fuel combustion may also require the use ofexhaust gas recirculation to prevent excessive NOx emissions. As mentioned already,there has been little consideration in the literature of the combustion of syngas inreciprocating engines, but there has been a significant amount of work on the fumi-gation of the intake air of diesel engines with hydrogen alone. At low concentrationsof hydrogen in the intake air (less than 20% diesel substitution), one might consider

Figure 3 Predicted and experimental ignition delay at 40% load.

Figure 4 Predicted and experimental ignition delay at 50% load.

COMBUSTION OF SYNGAS IN INTERNAL COMBUSTION ENGINES 1201

Dow

nloa

ded

by [

Uni

vers

idad

Del

Nor

te]

at 1

1:25

30

Dec

embe

r 20

11

this ‘‘hydrogen assisted’’ diesel combustion, while at higher levels of diesel substi-tution (greater than 20%), the process is the same dual-fuel combustion processconsidered here.

In the case of ‘‘hydrogen-assisted’’ combustion in CI engines, Varde and Frame(1983) reported some of the earliest work. They observed that at low levels of hydro-gen addition (e.g., 5–10% of the total energy injected as hydrogen in the intake air)there were reductions in smoke emissions at part load. At higher loads and higherlevels of hydrogen addition, NOx emissions increased. Senthil Kumar et al. (2003)examined hydrogen assisted combustion of a vegetable oil fuel from the jatrophaplant and showed mild efficiency improvements and reduced smoke at 5–7%hydrogen mass to diesel mass ratio.

They observed a NOx increase, however, when substituting hydrogen for thejatropha oil. Lu et al. (2004) examined the impact of hydrogen addition to DI diesel

Figure 5 Effective decomposition of the rate of heat release for the different phases of combustion.

1202 A. L. BOEHMAN AND O. LECORRE

Dow

nloa

ded

by [

Uni

vers

idad

Del

Nor

te]

at 1

1:25

30

Dec

embe

r 20

11

combustion through the use of a rapid compression machine with optical access.They observed increased OH radical intensity during the premixed ignition processand reduced soot intensity in the spray flame with hydrogen addition from 5–10%of the total energy. At higher levels of hydrogen addition, soot intensity increased.Tomita et al. (2001) showed that at fairly high diesel substitution levels, moderateload, and advanced diesel pilot injection timing, both smoke and NOx could be

Figure 6 Heat released for each part of the combustion process.

COMBUSTION OF SYNGAS IN INTERNAL COMBUSTION ENGINES 1203

Dow

nloa

ded

by [

Uni

vers

idad

Del

Nor

te]

at 1

1:25

30

Dec

embe

r 20

11

brought to very low levels with hydrogen addition (for pilot injections before40�BTDC). They suggest that a well mixed diesel fuel=hydrogen mixture providesa mild and distributed combustion throughout the cylinder, which represents apremixed charge compression ignition (PCCI) mode of combustion.

One would expect that these trends in performance of dual-fuel diesel combus-tion with hydrogen will be indicative of the performance with syngas, since hydrogenwill likely dominate the ignition characteristics of the gaseous fuel and carbonmonoxide will contribute to thermal energy release as combustion proceeds to com-pletion, just as it does in the late stages of combustion in premixed flames. Therefore,the observations by Garnier et al. (2005) for dual-fuel combustion with syngas andthose of various authors for dual-fuel combustion with hydrogen together providean indication of how IC engines could perform with the use of syngas for stationarypower generation.

CONCLUSIONS

The aim of this article is to survey the published work on the combustion ofsyngas in reciprocating engines, and focus on the dual-fuel combustion of syngasin compression ignition engines. From the experimental work and the literaturereviewed here, the following conclusions can be drawn.

. Syngas addition (i.e., substitution of syngas for diesel fuel) tends to shorten theignition delay and shorten the duration of combustion in dual-fuel operation

. Syngas addition tends to increase NOx emissions, presumably from the increase ofadiabatic flame temperature due to the hydrogen in the syngas

. Based upon observations of hydrogen assisted CI combustion, modest amounts ofsyngas addition in combination with advanced injection timing of the diesel pilotcan lead to effective low temperature ‘‘PCCI’’ combustion, yielding both reducedPM and reduced NOx.

Figure 7 Emissions of NOx as a function of load and diesel substitution.

1204 A. L. BOEHMAN AND O. LECORRE

Dow

nloa

ded

by [

Uni

vers

idad

Del

Nor

te]

at 1

1:25

30

Dec

embe

r 20

11

REFERENCES

Aligrot, C., Champoussin, J.C., Guerrassi, N., and Claus, G. (1997) A correlative model topredict autoignition delay of diesel fuels. Society of Automotive Engineers TechnicalPaper No. 970638.

Assanis, D.N., Filipi, Z.S., Fiveland, S.B., and Syrimis, M. (1999) A predictive ignition delaycorrelation under steady-state and transient operation of a direct injection diesel engine.Internal Combustion Engine Division of ASME, Fall Technical Conference, 33(2), 99-ICE-231, 95–104.

Bilcan, A., Tazerout, M., Le Corre, O., and Ramesh, A. (2001) Ignition delay in dual-fuelengines: an extended correlation for gaseous fuels. Internal Combustion EngineDivision of ASME, Spring Technical Conference April 29–May 2, 2001, Philadelphia,Pennsylvania, USA.

Garnier, C., Bilcan, A., Le Corre, O., and Rahmouni, C. (2005) Characterisation of a syngas-dieselfuelled CI engine, Society of Automotive Engineers Technical Paper No. 2005-01-1731.

Hardenberg, H.O. and Hase, F.W. (1979) An empirical formula for computing the pressurerise of a fuel from its cetane number and from relevant parameters of direct injectiondiesel engine, Society of Automotive Engineers Technical Paper No. 790493.

Heywood, J.B. (1988) Internal Combustion Engine Fundamentals, McGraw–Hill BookCompany, New York.

Hiroyasu, H. (1985) Diesel engine combustion and its modeling: Diagnostics and Modeling ofCombustion in Reciprocating Engines. Proc. of COMODIA Symposium, Tokyo, JSME,pp. 53–75.

Hountalas, D.T. and Papagiannakis, R.G. (2000) Development of a simulation model fordirect injection dual-fuel diesel-natural gas engines, Society of Automotive EngineersTechnical Paper No. 2000-01-0286.

Karim, G.A. and Moore, N.P.W. (1990) The production of hydrogen by the partial oxidationof methane in a dual-fuel engine. Society of Automotive Engineers Technical Paper No.901501.

Karim, G.A. and Wierzba, I. (1992) Safety measures associated with the operation of engineson various alternative fuels. Reliabil. Eng. System Safety, 37, 93–98.

Kavtaradze, R.Z., Zeilinger, K., and Zitzler, G. (2005) Ignition delay in a diesel engine utiliz-ing different fuels. High Temperature Apparatuses and Structures, 43(6), 951–960.

Li, H. and Karim, G.A. (2005) Exhaust emissions from an SI engine operating on gaseous fuelmixtures containing hydrogen. Inter. J. Hydrogen Energy, 30, 1491–1499.

Liu, Z. and Karim, G.A. (1995) The ignition delay period in dual-fuel engines. Society ofAutomotive Engineers Technical Paper No. 950466.

Liu, Z. and Karim, G.A. (1997) Simulation of combustion process in gas-fuelled diesel engine.Proceedings of the Institution of Mechanical Engineers, Part A: Journal of Power andEnergy, 211(2), 159–169.

Linvengood, J.C and Wu, P.C. (1955) Correlation of autoignition phenomenon in internalcombustion engines and rapid compression machines. Fifth Symposium (International)on Combustion, 347–356.

Lu, P.-H., Xie, X.-B., and Lai, M.-C. (2004) Spectral analysis and chemiluminescence imagingof hydrogen addition to HSDI diesel combustion under conventional and low-tempera-ture combustion. Society of Automotive Engineers Technical Paper No. 2004-01-2919.

McMillian, M.H. and Lawson, S.A. (2006) Experimental and modeling study of hydrogen=syngas production and particulate emissions from a natural gas-fueled partial oxidationengine. Inter. J. Hydrogen Energy, 31, 847–860.

COMBUSTION OF SYNGAS IN INTERNAL COMBUSTION ENGINES 1205

Dow

nloa

ded

by [

Uni

vers

idad

Del

Nor

te]

at 1

1:25

30

Dec

embe

r 20

11

Poonia, M.P., Ramesh, A., and Gaur, R.R. (1998) Effect of intake air temperature and Pilotfuel quantity on the combustion characteristics of a LPG – diesel dual-fuel engine, Societyof Automotive Engineers Technical Paper No. 982455.

Prakash, G., Ramesh, A., and Shaik, A.B. (1999) An approach for estimation of ignition delayin a dual-fuel engine, Society of Automotive Engineers Technical Paper No. 1999-01-0232.

Ramos, J.I. (1989) Internal Combustion Engine Modeling, Hemisphere Publishing Corpor-ation: New York.

Rao, A.D., Samuelsen, G.S., Robson, F.L., and Geisbrecht, R.A. (2002) Power plant systemconfigurations for the 21st century. American Society of Mechanical Engineers, Inter-national Gas Turbine Institute, Turbo Expo (Publication) IGTI, 1, 831–844.

Senthil Kumar, M., Ramesh, A., and Nagalingam, B. (2003) Use of hydrogen to enhance theperformance of a vegetable oil fuelled compression ignition engine. Inter. J. HydrogenEnergy, 28, 1143–1154.

Shudo, T. (2006) An HCCI combustion engine system using on-board reformed gases of meth-anol with waste heat recovery: ignition control by hydrogen. Inter. J. Vehicle Design, 41,206–226.

Shudo, T. and Takahashi, T. (2004) Influence of reformed gas composition on HCCI combus-tion engine system fueled with DME and H2-CO-CO2 which are onboard-reformed frommethanol utilizing engine exhaust heat. Trans. Japan Soc. Mech. Eng. Pt. B, 70(698),2663–2669.

Thyagarajan, V. and Babu, M.K.G. (1985) A combustion model for a dual-fuel direct injec-tion diesel engine, in proceedings of COMODIA Symposium on Diagnostics and Model-ling of Combustion in Reciprocating Engines, Tokyo, pp. 607–614.

Tomita, E., Kawahara, N., Piao, Z., Fujita, S., and Hamamoto, Y. (2001) Hydrogen combus-tion and exhaust emissions ignited with diesel oil in a dual-fuel engine. Society of Auto-motive Engineers Technical Paper No. 2001-01-3503.

US Department of Energy, Office of Fossil Energy 2003. FutureGen—A Sequestration andHydrogen Research Initiative, http://fossil.energy.gov/programs/powersystems/futuregen/futuregen_factsheet.pdf, (accessed Dec. 30, 2006).

Varde, K.S. and Frame, G.A. (1983) Hydrogen aspiration in a direct injection type dieselengine–its effects on smoke and other engine performance parameters. Inter. J. HydrogenEnergy, 8, 549–553.

1206 A. L. BOEHMAN AND O. LECORRE

Dow

nloa

ded

by [

Uni

vers

idad

Del

Nor

te]

at 1

1:25

30

Dec

embe

r 20

11