MOTOMAN MH-series - · PDF fileMOTOMAN MH-series Handling, Palletising & General Applications...

Transcript of MOTOMAN MH-series - · PDF fileMOTOMAN MH-series Handling, Palletising & General Applications...

MOTOMAN MH-series

Handling, Palletising & General Applicationswith the MH-series

•Strongerwrists

•Specificallydesigned

forhandling

•Longservicelife

MH165 MH200 MH215 MH250

MOTOMAN MH-series Handling, Palletising & General Applicationswith the MH-series

MOTOMAN MH165/MH200/MH215/MH250

The MOTOMAN MH-series are versatile, high-speed 6-axis robots offering superior performance in material handling, machine tending and press tending.

These robots feature a large work envelope and high moment of inertia ratings.

Fast axial speeds and acceleration reduce cycle times and increase production output.

Optimum cable management delivers higher uptime.

As a progressing of the MOTOMAN ES-robots, the compact and slim design allows these robots to access confined spaces, improving system productivity.

Key benefits

n Fast, flexible and powerful

n Compact design allows maximum performance using minimal floor space

n High payload – MH165: 165 kg – MH200: 200 kg – MH215: 215 kg – MH250: 250 kg

n Large working range – MH165: 2,651 mm – MH200: 2,651 mm – MH215: 2,912 mm – MH250: 2,710 mm

n Increased durability of media package thanks to routing through the robot’s upper arm

Handling, Palletising & General Appliations

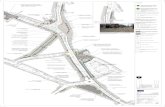

Specifications MH165

AxesMaximum

motion range[ º ]

Maximumspeed

[ º /sec.]

Allowablemoment

[ Nm]

Allowable momentof inertia[ kg · m2]

S

L

U

R

B

T

±180

+76/–60

+230/–142.5

±360

±130

±360

110

110

110

175

150

240

–

–

–

921

921

490

–

–

–

85

85

45

Controlled axes

Max. payload [kg]

Repeat. pos. accuracy [mm]

Max. working range [mm]

Temperature [º C]

Humidity [%]

Weight [kg]

Power supply, average [KVA]

6

165

±0.2

R = 2651

0 to +45

20 – 80

1100

5

MOTOMAN MH165 Technical Data

All dimensions in mm | Technical data may be subject to change without previous notice | Please request detailed drawings at [email protected] – YR-MH00165-A00, B-07-2012, A-No. 156806

Mounting option: Floor

2 x Ø 16 H7

893

640

735

640

540

8 x Ø 22

290±0.1 290±0.1

353±0.1

540

290±0.1 290±0.1

290±

0.129

0±0.1

350±

0.1

2 x Ø 20 H7

1307

0

687

126

2203

40

945 0

52

4

70

15

82

72

77

29

60°9.2°

1150

4 x M12,depth 24 mm

650

575

85137.5

50°

250

153

42° 25°

285

76°

9.2° 9.2°18°

82

1225 225

4612

1961 2651

16322

0

650

1024

348495

142.5°

3050

A

B

C

R

S

L

U B T

Working range Point P

P

Internal user wiring connectorMatching connector

2 x Air

R608

2 x M6, depth 12 mm

12.5

27.5

4 x M8, depth 15 mm

40255

R2651

344

73

R729 2 x M5, depth 10 mm4 x M8, depth 15 mm6016

92

120

133

45

410

491

2 x Ø 9, depth 8 mm

6 x M10, depth 12 mm

8

8

PCD 92

PCD 125

6 x M10,depth 12 mm

Ø 1

60 h

6

Ø 6

3 H

7

2 x Ø 10, depth 8 mm

491 294

View A

View B

View C

Allowable wrist load

130 kg

100 kg

165 kg

1000

800

600

400

200

200

400

600

800

1000

LB (mm)

LT (mm)

LT (mm)

B-axis center of rotation

T-, R-axiscenter of rotation

14001200

40 kg

60 kg

80 kg

1000400 600 800

P-Point

Specifications MH200

AxesMaximum

motion range[ º ]

Maximumspeed

[ º /sec.]

Allowablemoment

[ Nm]

Allowable momentof inertia[ kg · m2]

S

L

U

R

B

T

±180

+76/–60

+230/–142.5

±360

±125

±360

95

90

95

120

120

190

–

–

–

1344

1344

715

–

–

–

143

143

80

Controlled axes

Max. payload [kg]

Repeat. pos. accuracy [mm]

Max. working range [mm]

Temperature [º C]

Humidity [%]

Weight [kg]

Power supply, average [KVA]

6

200

±0.2

R = 2651

0 to +45

20 – 80

1130

5

MOTOMAN MH200 Technical Data

All dimensions in mm | Technical data may be subject to change without previous notice | Please request detailed drawings at [email protected] – YR-MH00200-A00, B-07-2012, A-No. 156806

0

1225

687

126

2203

40

76

6

53

25

82

78

97

75

1401

60°12,2

°

1150

58565

0

137,575

50°

250

153

42° 25°

285

76°

12,2° 12,2°18°

91

1225 250

46121961 2651

16

322

0

1089

650

348499142,5°

3050

1307 94

5 0

Working rangePoint P

P

4 x M12,depth 24 mm

A

B

C

R

S

L

U B

T

491 340

Mounting option: Floor

2 x Ø 16 H7

893

640

735

640

540

8 x Ø 22

290±0.1 290±0.1

353±0.1

540

290±0.1 290±0.1

290±

0.129

0±0.1

350±

0.1

2 x Ø 20 H7

Internal user wiring connectorMatching connector

2 x Air

2 x Ø 9, depth 8 mm

6 x M10, depth 12 mm

8

8

PCD 92

PCD 125

6 x M10,depth 12 mm

Ø 1

60 h

6

Ø 6

3 H

7

2 x Ø 10, depth 8 mm

R608

2 x M6, depth 12 mm

12.5

27.5

4 x M8, depth 15 mm

40255

R2651

344

73

R729 2 x M5, depth 10 mm4 x M8, depth 15 mm6016

92

120

133

45

410

491

View A

View B

View C

Allowable wrist load

130 kg

1200

1000

800

600

400

200

200

400

600

800

1000

1200

LB (mm)

80 kg

60 kg

LT (mm)

200 kg

165 kg

100 kg

LT (mm)

140012001000800600400

B-axis center of rotation

T-, R-axiscenter of rotation

P-Point

Specifications MH215

AxesMaximum

motion range[ º ]

Maximumspeed

[ º /sec.]

Allowablemoment

[ Nm]

Allowable momentof inertia[ kg · m2]

S

L

U

R

B

T

±180

+76/–60

+230/–142.5

±360

±125

±360

100

90

97

120

120

190

–

–

–

1176

1176

710

–

–

–

317

317

200

Controlled axes

Max. payload [kg]

Repeat. pos. accuracy [mm]

Max. working range [mm]

Temperature [º C]

Humidity [%]

Weight [kg]

Power supply, average [KVA]

6

215

±0.2

R = 2912

0 to +45

20 – 80

1140

6

MOTOMAN MH215 Technical Data

All dimensions in mm | Technical data may be subject to change without previous notice | Please request detailed drawings at [email protected] – YR-MH00215-A00, B-07-2012, A-No. 156806

Mounting option: Floor

491

280

375

2 x Ø 16 H7

893640

735

640

540

8 x Ø 22290±0.1 290±0.1

353±0.1

540

290±0.1 290±0.1

290±

0.129

0±0.1

350±

0.1

2 x Ø 20 H7

106

106

103

60°12.2

°50°

42° 25°

76°

12.2° 12.2°18°

2203

40

0

1150

855

650

137.575

250

153

285

91

250

0

1490

1008

3311

583

177

236

513329122222

650

77

509

1225

1477

1141 78

4

371

739

1401

899

844

4 x M12,depth 24 mm

Working rangePoint P

P

A

B

C

R

S

L

U B T

142,5°

R608

27.5

12.5

410

40255

R2912

73

R899

16

120

60

45

344 92

133

2 x M6, depth 12 mm4 x M8, depth 15 mm

2 x M5, depth 10 mm4 x M8, depth 15 mm

2 x Ø 9, depth 8 mm

6 x M10, depth 12 mm

8

8

PCD 92

PCD 125

6 x M10,depth 12 mm

Ø 1

80 h

6

Ø 6

3 H

7

2 x Ø 10, depth 8 mm

molexmolexmolex

A

Internal user wiring connectorMatching connector

2 x Air

View A

View B

View C

Allowable wrist load 1200

1000

800

600

400

200

200

400

600

800

1000

1200

200018001600

LT (mm)

1400 LB (mm)1200400 600 800 1000

LT (mm)

60 kg

80 kg

100 kg

215 kg

130 kg165 kg

B-axis center of rotation

TT-, R-axiscenter of rotation

P-Point

Specifications MH250

AxesMaximum

motion range[ º ]

Maximumspeed

[ º /sec.]

Allowablemoment

[ Nm]

Allowable momentof inertia[ kg · m2]

S

L

U

R

B

T

±180

+76/–60

+230/–142.5

±360

±125

±360

100

90

97

120

120

190

–

–

–

1385

1385

735

–

–

–

317

317

200

Controlled axes

Max. payload [kg]

Repeat. pos. accuracy [mm]

Max. working range [mm]

Temperature [º C]

Humidity [%]

Weight [kg]

Power supply, average [KVA]

6

250

±0.2

R = 2710

0 to +45

20 – 80

1130

6

MOTOMAN MH250 Technical Data

All dimensions in mm | Technical data may be subject to change without previous notice | Please request detailed drawings at [email protected] – YR-MH00250-A00, B-07-2012, A-No. 156806

142,5°

Working rangePoint P

P

4 x M12,depth 24 mm

1345

0

1225

647

80

2203

40

989 0

75

9

53

45

89

804

1401

60°12.2

°

1150

585

650

137.575

50°

250

153

42° 25°

285

76°

12.2°12.2°18°

91

1285 250

47302020 2710

52

381

0

1070

597440

3109

80

1

A

B

C

R

S

L

U B

T

491 375

R608

27.5

12.5

410

40255

R2710

73

R804

16

120

60

133

45

344 92

2 x M6, depth 12 mm4 x M8, depth 15 mm

2 x M5, depth 10 mm4 x M8, depth 15 mm

Mounting option: Floor

2 x Ø 16 H7

893

640

735

640

540

8 x Ø 22

290±0.1 290±0.1

353±0.1

540

290±0.1 290±0.1

290±

0.129

0±0.1

350±

0.1

2 x Ø 20 H7

Internal user wiring connectorMatching connector

2 x Air

2 x Ø 9, depth 8 mm

6 x M10, depth 12 mm

8

8

PCD 92

PCD 125

6 x M10,depth 12 mm

Ø 1

60 h

6

Ø 6

3 H

7

2 x Ø 10, depth 8 mm

View A

View B

View C

Allowable wrist load

P-Point

1200

1000

800

600

400

200

200

400

600

800

1000

1200

LB (mm)

LT (mm)

LT (mm)

B-axis center of rotation

T-, R-axiscenter of rotation

130 kg

60 kg

80 kg

100 kg

250 kg

165 kg

200 kg

2400220020001800160014001200400 600 800 1000

MOTOMAN MH-series

Technical data may be subject to change without previous notice.

YASKAWA contacts

YASKAWA Academy andsales offi ce Frankfurt

YASKAWA GroupA YASKAWA Austria

Schwechat/Wien +43(0)1-707-9324-15

CZ YASKAWA Czech s.r.o.Rudná u Prahy +420-257-941-718

E YASKAWA Ibérica, S.L.Gavà/Barcelona +34-93-6303478

F YASKAWA France SARL Saint-Aignan-de-Grand-Lieu +33-2-40131919

FIN YASKAWA Finland OyTurku +358-(0)-403000600

GB YASKAWA UK Ltd.Banbury +44-1295-272755

I YASKAWA Italia s.r.l.Torino +39-011-9005833

IL YASKAWA Europe Technology Ltd.Rosh Ha’ayin +972-3-9004114

NL YASKAWA Benelux B.V. EB Son +31-40-2895500

RUS YASKAWA Nordic ABMoskva +46-480-417-800

SE YASKAWA Nordic ABTorsås +46-480-417-800

SI YASKAWA SloveniaRibnica +386-1-8372-410

TR YASKAWA TürkiyeŞerifali Mah. Barbaros Cad. No: 24Ümraniye, İstanbul +90-216-5273450

ZA YASKAWA Southern Africa (PTY) LtdJohannesburg +27-11-6083182

DistributorsBG Kammarton Bulgaria Ltd.

Sofia +359-02-926-6060

CH Messer Eutectic Castolin Switzerland S.A.Dällikon +41-44-847-17-17

DK Robotcenter DanmarkLøsning +45 7022 2477

EE RKR Seadmed OÜ Tallinn/Estonia +372-68-35-235

GR Gizelis Robotics Nea Kifissia +30-2106251455

H Flexman Robotics KftBudapest +36-30-9510065

LT Profibus UABPanevezys +370-45-518575

N Optimove as Lierstranda +47-32240600

PL Integrator RHC Sp. z o.o.Torun +48-56-6519710

RO Sam Robotics srlTimisoara +40-720-279-866

YASKAWA Headquarters

YASKAWA Europe GmbHRobotics DivisionYaskawastraße 1D-85391 AllershausenTel. +49 (0) 8166/90-0Fax +49 (0) 8166/90-103

YASKAWA Europe GmbHRobotics DivisionHauptstraße 185D-65760 EschbornTel. +49 (0) 6196/77725-0Fax +49 (0) 6196/77725-39