Modification of Castor Oil by Isomerization, Halogenation ... · Oil as Plasticizer in Nitrile...

Transcript of Modification of Castor Oil by Isomerization, Halogenation ... · Oil as Plasticizer in Nitrile...

Journal of Scientific & Industrial Research Vol. 60, May 200 I, pp 383-395

Modification of Castor Oil by Isomerization, Halogenation and Application of Some Modified Products as Plasticizer in Nitrile Rubber Formulations

Elham A A Yousef, Ahmed E Hussain** and Zein E Shoeb*

*Fats and Oil s Department , National Research Centre, Cairo, Egypt

**Polymers and Pigments Dept., ational Research Center Cairo, Egypt

E-mai l Elh [email protected]

Rev ised received: 14 July 2000; accepted: 09 November 2000

The preparation of bromo-as well as chloro-derivati vcs of cas tor oil by addition and substitution reacti ons is reported. Bromine water and chlorine gas have been used to ha logenate the oi l by addition while N-bromosuccinimide and PCL have been used in the substitution reactions. The course of the reacti on has been fo llowed using 1H- MR and IR analyses."' Posi tional iso meri Lation and geometrical isomeri za tion of the double bond in castor oil have also been considered in this investigation . Conjugati on of the double bond in the bromo-castor oil has been checked by UV absorbance at 233 and 268 nm. Geometri cal isomerization whereby the cis-doubl e bond transforms into trans-isomer has been studied in case of castor oil as well as it s chloro-derivati ve using IR analys is. The results show that greater percentage of trans-acids can be achieved by isomerization of the chlorinated derivative. The percentage of the trans-acid of this derivative has been found as 75 per cent , compared to 8 per cent in the case of castor oil. In addition, castor oi l and its halogenated deri vati ves have been evaluated as plasticizer in NBR formulat ions instead of dibuty lphthalate. The evalu ation parameters used are the rheomet ri c characteristi cs and the physicomechanical properties of rubber such as tensile strength and elongation per cent at break . In addition, the effect of the prepared plast icizers on the rubber swelling in toluene as well as in motor oi l and their effect on the rubber properties after ag ing have also been studied . The results show that castor oi l and its derivatives are advantageous over dibutylphthalate in terms of their effect on the mechanical properties as well as the rubber resistance to swelling in motor o il. The best properties could be obtained using hexachloro-castor oil and the optimum concentration has been 3 phr.

Introduction

Castor oi l is derived from the bean of the castor plant (Ricinus communis) belonging to th e family Euphorbiaceae 1

• It is a mixture of trig lyceride fatty acids . The unique characteri stic of this oil is that most of its content, approximately 90 per cent , is ric ino le ic ac id . Ricinoleic acid has 18-carbon backbone with one hydroxyl group on the 12 carbon atom and cis-double bond between the ninth and tenth carbon atoms.

Several reviews covering agronomic, marketi ng, processing and applications aspects of thi s oil' ·(• have al

ready appeared . Castor oil is mostly used in the form of its modified derivati ves, such as dehydrated, hydrogenated, alkoxylated , su lphated and the halogenated derivatives '·(,. The po larity of castor oil is remarkab ly increased by halogenation. These polar derivati ves show such applications as plasticizers in some industries, including the rubber industry.

The polar synthetic types of rubber such as nitri l rubber are characterized by high degree of oi I resistance which increases the polarity of the rubber (ac rylonitrile

content) 7. The plasticization of the polar rubber is car

ried out by special types of plasticizers such as petroleum plastic izers, naphthenic oil, high molecul ar weight es ters. These plasticizers are characterized by the ir polarites . Therefore, the type of pl asticizer used in process ing the nitrile rubber should be carefu lly se lected so as to be quite compatible with the rubber. Such compatibility is essential to improve mixing and process ing and to decrease hardness and nerve of the rubber.

This paper reports the preparation of some isomers of castor o il as well as some halogenated derivatives and assesses their suitab ility as pl astic izers in the processing of nitrile rubber.

Materials and Methods The experimental work conducted in this paper com

pri sed two parts. The first concerned w ith halogenation and isomeri zation of castor oil and characte ri zation of the products, while the other concerned with the evaluation of the halogenated products of this oil as plasticizer in nitrile rubber process ing.

384 1 SCI IND RES VOL 60 MAY 2001

Materials

Castor oil used in the present work was purchasedfrom the Arabic Company for Chemicals, Egypt. Sol-vents and reagents used were all chemically pure, in-cluding petroleum ether (40-60 °C and 60-80 "C, respec-tively), diethylether, carbon tetrachloride, acetone, chlo-robenzene, chloroform, dioxane and dimethylsulphoxide. These were all dried over CaClz prior to use.Other reagents used were hexamethyl phosphoric acidtrimid (HMPT), and N-bromosuccinimide (NBS).

Nitrile butadiene rubber containing 33 per cent acry-lonitrile was used as the raw rubber. Its specific gravitywas 0.98, ash content was 0.5 per cent and its Mooneyviscosity was 45. Other rubber ingredients were all ofpure grades. They included N-cyclohexyl-2-benzothiazolsulphenamide (CBS) as an accelerator, phenyl ~-naph-thyl amine (P~N) as an antioxidant, carbon black as fillerin addition to dibutylphthalate (DBP) which was usedas plasticizer in the control formula.

Experimental Procedure

i-Preparation of the Halogenated Derivatives of Cas-tor Oil and Characterization of Derivatives and theStarting Material

Castor oil was analysed for its major chemical as wellas physical properties, according to the Official and Ten-tative methods of analysis". These properties includedspecific gravity, viscosity, acid value, iodine value, hy-droxy I value, saponification value and content ofunsaponifiable matters. The fatty acid composition ofthis oil was also determined by GLC analysis. Glass col-umn (1.5 m x 4 mm) packed with 15 per cent PEGAsupported on Chromosorb WGQ/80 was used in thisanalysis. The temperature was adjusted at 190 "C andthe flow rate of nitrogen gas used as a carrier was 30mL/min.

The bromo- as well as the chi oro-derivatives of cas-tor oil were prepared by addition as well as substitutionreactions. The addition of bromine and chlorine wasmade using liquid bromine and gaseous chlorinerespectively, whereas substituted derivatives wereprepared using NBS and PCI5• respectively,.,Preparation of Bromo-derivatives of Castor Oil

The procedures used to prepare the bromine additionas well as substitution derivatives of castor oil were thoseof Shani" with some modifications.

(ai-Preparation by Bromine Addition Derivatives

To a solution of 83.5 g (0.1 mole) castor oil in 350mL CCI4, a solution of 45.5 g Br, (0.28 mole) in 75 mLCCl4 was added dropwise over a period of half an hour.The reaction temperature was adjusted at 17-20 "C dur-ing the whole period of reaction. The quantity of bro-mine added was in excess of the calculated theoreticalamount. After the reaction was completed the amount ofbromine left unreacted in the reaction mixture was re-duced using excess sodium sulphite solution (5 per cent).The aqueous layer was then separated from the organiclayer which contained the desired product. Anhydroussodium sulphate was added and the solvent was distilled-off under vacuum.

(bt-Bromination with N-Bromosuccinimide (NBS) andPreparation of its Conjugated Product

A solution of 16.7 g of castor oil (0.02 mole) and 2I.3gNBS (0.12 mole) in 50 mL CCI4 was refluxed for fourhours. The product, crude allylic bromide dissolved inCCI4, was obtained from the refluxed mixture by filtra-tion. The solvent was then distilled under the reducedpressure.

The conjugation of the double bonds in the bromi-nated derivative obtained using NBS was then performedusing the procedure of Shani".

A mixture of 3.38 g (2.6 mmole) of bromo derivative,1.27 g (0.03 mol) of dry LiCI and 1.48 g of dry Li,COJ

(0.02 mole) in 10mL dry dioxane was stirred vigorouslyand refluxed for 24 h. The yield was purified by usingpreparative thick layer chromatography (PLC). The elut-ing solvent consisted of diethyl ether and petroleum ether(60-80 "C) at a volumetric ratio of 1:9. The brominatedsample of castor oil using NBS was then analysed for itscomposition before and after conjugation, using Uv, IRand NMR techniques. The absorbance of the samples inthe UV spectrum was measured at 233 and 268 nm, us-ing Unicam UV Shimadzu spectrophotometer. CCI4 wasused as a blank. IR spectra were recorded on a Mattson5000 FT-IR Spectrophotometer. 'H-NMR spectra weredetermined on a Joel Hz Spectrometer usingtetramethylsilane as the internal standard.

Preparation of Chloro-derivative of Castor Oil

(ai-Chlorination by Addition of Chlorine GasTo a solution of 1()()g castor oil in 500 mL CCI4, chlo-

rine gas was bubbled until the solution became yellow-ish green. The solution was then washed using 5 per cent

YOUSEF eta/. : MODIFICATION OF CASTOR OIL 3X5

sodium sulphite solution to remove excess chl orine. The organi c laye r was separated from the aqueous laye r of the reacti on mi xture and washed several times with wa

ter. The product disso lved in CC I~ was then dried over anhydrous sodiu m sulphate and the solvent evaporated .

(b)-Chlorination of Castor Oil hy Substitut ion using IJCI ,

A mixture of 32 g castor oil di ssolved in 300 mL petro le um e th e r (40-60C 0

) and 23 g phosphor us pentachl oride was refluxed for one hour. The mi xture was then wa ter-washed, dried in the presence of anhydrous sodi um sulphate and the solvent evaporated under

vacuum .

The modifi cati on in the structure of castor o i I achieved by the halogenation, bromination and chlorination , was studied by infra red and 1H-NMR analyses.

Isomerization of the cis-Double Bond in Cosror Oil ond Its Derivative to trans-Isom er

The transformat ion of the cis-doub le bond in cas tor oil to its trans- isomer was studied via two methods ; using castor oil and using its hexachloro derivative.

(a) l.w111eri~ation of Castor Oil

Castor o il (50 g) and 5 mL NaN02

so luti on (2M) were dissolved in 50 mL petroleum ether (60-80 °C).The solution was heated and then about 2 mL of 6M HNO,

·' were added dropw ise over 5 min . The mi xture was refl uxed for about 15-20 min and washed several times wi th di stilled hot wate r. Anhydrou s sod ium sulphate was used to dry the solution mi xture which was then evaporated under vacuum to remove the solvent.

The prepared isomer was purified by e lution through a silica ge l column . A mi xture of d iethyl ether and petroleum ether ( I :99, v/v)(60-80°C) was used as the e luting solvent~ .

(b) lso111erizat ion of Castor Oil after Chlorination

The ch lorinated derivative of castor o il was used to prepare the trans isomer. A s us pen s ion of 6 g hexachlorocastor o il (5.4 mmol) and 30 g Nal (0.2 mole) in 18. 1 mL hexamethyl phosphoric acid trimid (HMPT) was heated at 13SOC for 24 h.The reaction mi xture was then poured into water and extracted three ti mes w ith petroleum ether (60-80°C) . The prepared isomer was purified by e lution through a silica gel column .

The isomeri zation of the cis-to-trans isomer in castor o il as well as in its chloro-deri vati ve was c hecked by

infra red analys is, the trans-double bond showed absorbance I!J at 960 c nY 1

•

Evaluation of the Halogenated Derivatives of Castor Oil as Plasticizer in Nitrile Rubber Formulations

T he weighed quantity of rubber in g red ients were mixed 11 using a two ro ll laboratory m ill. These ingredients inc luded nitril e butadiene rubbe r, NBR (I 00 g), stearic acid (2 g), z inc ox ide (5 g) , carbon black (30 g),

CBS ( I g), sulphur (2 g), PBN ( I g), in add ition to the p las ti c ize r. S ix fo rmulati ons of rubber were prepared using d ifferent types of plasticizers. These inc luded dibutyl phthalate (DBP) (contro l), cas to r oil and the brominated as well as the chl orinated derivatives of the o il. Two different formulat ions were prepared us ing each of the hal ogenated deri vati ves as p lasticizer; the first was prepared by addition and the other by substituti on .

T he prepared rubber sa mples were tested for the curing and processing c haracteri st ics using Rheometer1"·1.' modeii OO . The mechanica l properties of the vulcani zed sheets including the tensile strength (T) and e longati on at break (E), we re also measured us ing Zwick tensil e testing machine (Zw ick 1425 ) 1 ~ .

In addition, the maximum percentage swelling of the rubber samples Q was also determined usin £. to luene,

\II '-'

accord ing to the procedure of Shvarts 15 •

The effect of ag ing of the rubber vulcani zates on the

prev ious properties , T, E and Q was also studied. tl 0 10

The rubbe r vulcanizates were heated at 90°C for 2 ,

4, 6 and 7 d ays . After each period , the aged sample ·

were tes ted for these properti es.

Since oil res istance is the most important property of nitrile rubber10, the prepared rubber samples were also tes ted for the ir oil res istance. The tested samples were immersed in motor oi l at I 00 oc for diffe rent peri ods from two to seven days. The swe lling percentage was measured after each period . It was also planned in this work to in vestigate the effect of the dose o f the oi l deri vative on the diffe rent mechanical as well as rheo logica l properties of the rubber form ul ation.

Results and Discussion

The resu Its concerni ng the charac te ri stics of the starting as well as the mod ifi ed products are g iven below. The composit ion of the deri vati ves was studied according to the results of NMR and IR ana lyses .

---~--..-.•..--... -- .....

386 J SCI IND RES VOL 60 MAY 2001

Property

Table I - Ingredients Physical and chemical properties of castor oil as compared to standard specifications

Industrial castor oiICastor oil quality

and specifications (found)

Acid value 2.2

Clarity

Hydroxyl value

Refractive index

clear

156

1.476

182.6Saponification

Solubility in alcohol (b)

Specific gravity at 40Co

Unsaponifiable matter Wt per cent

Viscosity m m2/s (=CST)

complete

0.9305

0.8

2.5

85Iodine value

standards (ASTM) (.)

2.0 (max)

clear ;,160-168

1.4764-1.4778

176-184

complete

0.950.965

0.7

6.5-8.0

84-88

Table 2 - Chemical composition of castor oill-Characterization of the Starting Material and Its Modi-fied Products

The physical and chemical characteristics of castoroil used in the present work were evaluated and are listedin Table 1. These include the ASTM standard specifica-tions of castor oil I. The fatty acid composition of this oilis listed in Table 2 which shows that ricinoleic acid rep-resents about 85.6 per cent of the total fatty acids. Ac-cording to this analysis, the approximate molecular for-mula of castor oil is CSJII0406'

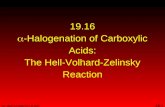

The modifications in the structure of castor oilachieved by halogenation was checked by comparing theIR and IH-NMR of castor oil to those of its derivatives.The infrared analyses of these samples are shown inFigures 1-3. In these figures, the absorbance peaks dueto the double bond at 3006 crrr' and 1660 cm' com-pletely disappeared in the samples halogenated by addi-tion. The peaks at 650 and 725 ern" (Figure 2) corre-sponds to the CHCI whereas that at 550 cm' (Figure 1)is the characteristic peak of CH2Br. The absorption peakat 1740 cm' which appeared in all samples includingcastor oil corresponds to the carbonyl group, C=O, inthe fatty acid ester molecule. The IR of the oil samplebrominated using NBS showed an additional peak closeto the previous one at 1712 ern" . This corresponds to theketo group which was produced by oxidation of the hy-droxyl group by the oxidizing action of NBSI7.i~.Suchoxidation is also confirmed by the disappearance of thepeak of -OH group at 3500 ern:' in theIR of the NBS-brominated sample.

Fatty acid Percentage

Palmitic acid C16:o

Stearic acid CIK:0

Ricinoleic acid

11.605

1.223

85.65

0.274Linolenic acid CIK:3

Arachidic acid C20:0 1.06

•Annual Book of ASTM Standards Pt 29, 0960-73, Washington, D C 1976,pp. 525, 526

bUsing 2 volumes of 95 per cent ethanol for each volume oil at 20 "e.

It should be emphasized that the hydroxyl group dis-appeared in the sample obtained by chlorination usingPCI5• However, the mechanism is different wherebythe -OH is substituted by chlorine atom rather than be-ing oxidized".The results of IH-NMR of castor oil are given in

Table 3, which have been compared with those of chioro-and bromo-derivatives. The results agree well with whatis expected due to the addition of halogen on the doublebond regarding the disappearance of the unsaturatedbonds at 0 1.8, t, (6H) 3xCH2-CH=CH-CH2-CH (OH),02.1, quart, (6H) CH=CH-CH2-CH (OH), and 05.3 (6H)-CH=CH-and the appearance of the corresponding unitsat 01.9, m, (I2H) 3x CH2-CHBr-CHBr-CH2-, and 84.2,m, (6H) 3x CH2-CHBr-CHBr-CH2-. In Table 3,03.45, m<3H)3x CH=CH-CH, -CH (OH) of castor oil was shiftedafter halogenation to 83.7, m, (3H) 3x C~-CHBr-CHBr-CH2-CH (OH)-.

YOUSEF et a/.: MODIFICATION OF CASTOR OIL 3R7

Figure 1- IR Spectra of castor oi l and its bromo derivatives

The mod ificati ons of the structure of castor o il by halogenation using PCl, and NBS was also studied by 1H-NMR . It was found-that castor oi l hal ogenated by

PCI5

showed peaks at 81.6, quart, (6H) 3xCH=CH-CH2-

CH (Cl)-CH2

, 82.4, quart (6H) 3x CH=CH-CH2-CH (CI);

83.8, pent (3H) 3x CH2-CHCI-CH2 and 85.3 , m, (6H)

3x-CH=CH- . This means that the chlori nation us ing PCI5

had no effect on the degree of the oil unsaturation but it affected di sappearance of the hydroxyl group . On the other hand, castor o il brominated using NBS showed peaks at 8 1.96br, (8H) d 2x CH,Br; 2x COCH,Br; 82.2, q , (2H) CH,-CH (Br)-CH=CH; 83.56, m, (iH), CHBr; 83.88, m, (iH), 2xCHBr; 85 .17, m, (2H) 2xCHBrCH=CH-and 85.79, m, (2H) CH=CH. These results prove that the bromination using NBS reduces the number of CH=CH units . These results indicate that the halogenation using PCI occurs by the substitution only, whereas

.'\

that by NBS, occurs partia ll y by addition and partia lly by substitution . Through the oxidat ion process of -OH to keto grou p by NBS , th e latter converts into succinamide while bromine is liberated 1

K. The liberated bromine then adds to the unsaturated bonds in castor o il. The NBS quantity remaining after complete ox idation of the OH in castor oil then substitutes the hydrogen of

( (a) Castor

I ~1v u (b) Chlorinal ion

(CI,gas)

r~\

I ~~ J \ li

\ I (c) Chlorination (PCI,) ~

Figure 2-IR spectra of castor oi l and its chloro derivati ve~

the carbon adjacent to the double bond . The quantity of the bromine added is supposed to be equi valent to the number of hydroxy l g roups oxidized.

The 1H-NMR results of cas tor o il and thei r halogenated derivati ves had the following data 8 0.75s (9H) 3xCH

3_ 81.25 pe nt (60 H )-CH 2-, 84.1 m (5H)

(CH20COR)

2-CHOCOR. At 82.05 , t, (6H) 3xROCO

CH2 s lightly shifted after halogenati on to be 82.2. t, (6H) 3xROCO-CH

2-.

The effect of castor oil halogenation on its viscosity and the characteristic physical property of casto r o il are g iven in Table 4. It is obvious that the c hl orinati on of castor oil by addition markedly increases the o il viscosity ( 1390 compared to 233 c poise) However, the ch lorination by substituti on using PCI

5 had a reversed effect.

The viscosity was markedl:v decreased by chl orination from 233 c poise to 87 c poise. T he bromination of castor oi l, on the other hand, had less effec t on the vi scosity of cas tor oil as compared to chlorination. Bromination using bromine water increased the oil viscosity to 698 whereas the bromination using NBR increased it to 318c poise .

388 J SCI IND RES VOL 60 MAY 2001

IR

(KBr) (Cm-I)

3411 (OH)

3010 (C=C vinyl group)

Table 3 - Results of IR and IH-NMR analyses of castor oil

IH-NMR

0_7, s, (9H) 3x-CH~

L25, pent (60H)-CHz-

1740 C=O of ester1_8,t,(6H)3x CH2- CH=CH - CH -qi-

- IOH

1640 (C=C)

970, 790, 760, 722 (=CH vinyl)

bending

CH 2- OCO -CH 2I -

2_05, t,(6H) CH-OCO -CH 2ICH -OCO -CH2

2_I,quart,(6H)3x CH = CH -CH2-CH-- I

OH

2.5, S (3H) 3-0H

3A5,m,(3H )3x CH = CH -CH 2-CH-

6ii

jH1OCOR

4. I, m,(5H) CH-OCOR

ICHz-OCO

5.3m (6H)-CH=CH-

Table 4 - Viscosity results of IR castor oil and halogenated derivatives

Samples Method of preparation V iscosity at40°C.centi Poise

Castor 0 il

Chlorinated castor oil using Cl , gas

using PCI;

23J

IJ90

87Chlorinated castor oil

B rom inated castor oil

Brorn inate d castor oil

u s in g nr~ wat e r

using NBS J I R

YOUSEF eta/.: MODIFICATION OF CASTOR OIL

;

I :..,

I I

~ ""'

V/it"&num~.rf:m-• ;

Figure 3-IR spectra of castor oi l, brominatecl castor oi l usin g BS before and after conjugation

The conjugati on of the doubl e bonds in the brominated sample of castor o il us ing NBS was checked according to the UV absorbance of the bromin ated sample at 233 and 268 nm before and after conjugati on. The absorbance of the brominated oil ( I 00-fold dilution) was increased by conjugation from 1.6 to 2.0 at 233 nm and from 3.3 to 3.9 at 268 nm.

The mod ification in the structure of the brom inated

cas tor oil by the conj ugation procedures was a lso followed us in g rR and 1H-NMR a na lyses. JR anal yses shown in Figure 3 showed an absorbance peak at 3390 cm·1 due to hydroxy l g roup and another peak at 30 18 cm·1 due to CH=CH group. It a lso showed two other peaks at 1735and 17 18 cm·1 for the carbony I of ester and ketone, respective ly.

The 1H-NMR of the conjugated castor o il was sli ghtly changed to 81 .95, br, (4H), d CHBrCH,CO, CH,C HBr: 83 .55, m, (3 H), 3xCHBr ; 84.95 , q , (4 1 H), CI~=CHCHBr; 85 .3, m, (3 H) CH=CH, CH=CH-CHBr; 87.25, m, (2H) CH=CH-CH=C H. The mod ified product had slightly shifted compared to 1H-NMR of castor

0 II

c1

Hl 05-CH2 ( CHz )5-CH , - CH==CH-Cf-7-CHOH- ( CH2 );-CH1

II

~H D-C0 CHz ( CH2)5- CH 2- CII ==CH-CH,-cHOH- ( CH, );-CH.1

CH ,o-~-CH, ( Cll, ~- CH 2- Cll== CH -cw;-CHOH-( CH2 );- CH 3

Another Isomer of the Conjugated Castor Treated with NBS

Scheme I

8 0.8s (9H) 3xCH,, 8 1.3 pent (60H) 30xCH, , 84.2m (5H ) (CH,OCOR) , -CHOCOR, 82 .25, t, (6H) 3x""ROCO-C H . - - ' The results of these ana lyses confirm the proposed reac-ti on (Scheme l ). The isomeri zati on of the cis-doubl e bond to its trans- isomer was found to be more successful when done startin g with the chl oro-deri vat ivc or castor o il compared wi th the non-halogenated o il. T he percentage trans- isomer prepared using the c hloro-deri vati ve was 75 per cent , compared to 8 per cent onl y when cas tor oil was used.

2-Evaluation of Castor Oil and its Halogenated Derit •otives as Plasticizers in Rubber Formulations

The rheometric characteristi cs and phys icomechani cal properties of the NBR vu lcani zates are li sted in Tabl e 5. The results show that the use of the halogenated o i Is

390 J SCI I D RES VOL 60 MAY 200 1

Table 5- Nitrile butacline rubber formul ati ons of halogenated castor oil , their rheo metric characteristics and phys ico-mechanical properti es

Ingredien ts Formul at ions

II Ill IV v VI

BR 100 100 100 100 100 100

Stearic acid 2 2 2 2 2 2

Zinc oxide 5 5 5 5 5 5

Carbon black 30 30 30 30 30 30

CBS

Suphur 2 2 2 2 2 2

PB

DBP 3

Castor oi l 3

Bromo-castor (by acid) 3

Bromo-castor (by sub) 3

Ch loro-castor (by add) 3

Chloro-castor (by sub) 3

l?heometric characterist ic o.f NBR fo rmulations

Mini. torque (L) 8.5 7 7 8.5 7 7

Max. to rque (H) 71 84 65.5 76 9 1 7 1

Cure time (tc"0

) 2 1 9.5 20.5 2 1.5 14.5 2 1

Scorch time (ls1

) 2 2.5 2.25 2 2.25 2.25

Cu re rate index CRl 5.26 14.2)\ 5.48 5. 13 8.26 5.:n

Tensile strength (MPa) T, , 19 20.65 2 1.59 21. 18 23 .37 22.87

Elongation at break (per cent ) E, 544 638 677 658 760 686

Max. swelling in toluene (per rent ) Q,0

150 152.33 15 1.2 1 152.23 156.09 154.94

Table 6- Retained values of tensil e for BR formul ations using different plas ticizers with agi ng peri ods

Types of plasticizers Aging period (clays)

0 2 4 6 7

DB P 100 94.57 89.89 86.78 85.89

Castor oil 100 96.70 93 .55 90.99 89.83

Bromo-castor (by add) 100 97.26 94.95 93.09 9 1.52

Bromo-castor (by sub. ) 100 97. 16 94.33 92.39 91.123

Chi oro-castor (by add). 100 97.81 95.97 93 .66 92.34

Chi oro-castor (by acid). 100 97.37 95.45 93.31 91.86

YOUSEF e1 a!.: MODI FICATIO OF CASTOR OIL 391

Table 7 _ RetaineJ valu es of elongation at break fo r NBR formulati ons usi ng different plas ticizers with agi ng peri ods

Types of plasticizers Aging peri od (days)

0 2 4 6 7

DBP 100 89.70 85 .84 8 1. 80 79.4 1

Castor oil 100 88.87 83.38 77. 12 73.98

Bromo-castor (by add) 100 87.59 81.97 77.54 74.44

Bromo-castor (by sub) 100 88.90 82.2 1 76.74 73.55

Chloro-castor (by add) 100 91.84 87.89 84.40 82.63

Chloro-castor (by add) 100 88.04 82.2 1 77. 11 74.05

Table 8- Retained values of max imum.swclling in toluene for NBR formul ati ons using ditlerent plas ti cizers wi th aging peri ods

Types of plasti cizers

0 2

DBP 100 92.06

Castor oil 100 94.59

Bro mo-castor (by add) 100 93 .5 I

Bromo-castor (by sub) 100 l)j 34

Ch loro-castor (by add) 100 94.62

Chloro-castor (by add) 100 94.29

instead of DBP currently used in local rubber indu stry had no remarkable effect on the rheometric characte ri sti cs o f the rubber formul ati ons with the excepti on of

hexachlorocastor oil. The use of cas tor o il w ithout any

structural modification as rubber pl asti c izer had an ef

fec t s imil ar to that of hexachl orocastor o il. Both the components were found advantageous over

DBP regarding the ir effect on the cure time ( tc~0 ), cure

rate index (CRI) and scorch time (tsJ The cure time

decreases from 21 min using DBP to 9.5 min and 14.5 min usin o- cas tor o il and its hexachloro de ri vati ve, re-b

specti vely. The cure rate index increased from 2.56 to 14.28 and 8.26 us ing casto r o i I and its chloro de ri va ti ve, respecti ve ly.

The results show that the mec hani ca l pro perti es of rubber vulcani zates in te rms of the tensile strength (T) and e lono-ati on at break (£) markedly improved by us-

b II

ing castor o il or its ha logenated deri vati ves as pl asti c iz-e rs as substitute of DBP. Ho weve r, th e e qu ilibrium swellin o- o f the vulcani zed rubber in to luene inc reased b

s lightly when casto r o il or its de ri vati ves were used in

Aging period (days)

4 6 7

8 1.66 72. 13 66.2

89.29 83.43 79.30

85.37 76.18 71.95

86.72 80.20 76.05

89.24 83 .66 80.65

88.55 82.6 1 78.6 1

the rubber formul ation due to the po la rity of these components.

The effects of the ag ing time on the tens ile strength ,

T e lono-ati on per cent , E at break as well as the equi-o' b o

librium swe lling per cent in toluene Q,"are illustrated in Tables 6-8.It can be revealed that the tensile stre ngth

and the e longation per cent a t break were a lways higher

using castor oil or it s ha logenated deri vati ves in pl ace of

DBP, even afte r ag ing for pe ri ods up to seven clays . T he max imum swe lling in to luene, on the other hand, was

a lways slightly higher us ing the prepared plasti c ize rs. This may be attributed to the presence o f pola r groups (Br or Cl) in the ma in chain o f the o il whic h mig ht have

inc reased the compatibility o f the o il with the po lar nitril e rubber, thu s bl ooming to the surface and exudation pro blems of plasti c izers for NBR vulcani zates were prevented.

It can be seen from Tables 6-8 that the re tained va lues of the tensile strength o f the rubber vulcanizates increased by using castor o il o r its ha logenated deri vati ves as p las-

392 J SCI INO RES VOL 60 MAY 2001

'if.~ 30cOJ.£Qj3:(/j

x<Ii:2

2L---~__-L__~ L-__J-__-L__~

o 2 3 4 5 6 7Immersion period, days

~DBP -+- Br oil (add.) *- Br oil (sub.)

-i>- CI oil (add.) "* CI oil (sub.) -+ Castor oil

Figure 4--The relation between maximum swelling in oil at100 "C and immersion period

ticizer. After aging for seven days, the retained value ofthe tensile strength of the prepared rubber formulationby using the halogenated derivatives ranged between 90per cent to 92 per cent compared to 86 per cent usingDBP. On the other hand, the retained value of the elon-gation at break decreased by using castor oil or its halo-genated derivatives with the exception ofhexachlorocastor oil. The retained elongation at breakusing this derivative was 82.63 per cent compared to79.41 per cent using DBP.

Regarding the rubber swelling in toluene, the retainedvalue after rubber aging was always higher when castoroil or its derivative were used as substitutes of DBP.Although hexachlorocastor oil gave a rubber formula-tion of best tensile and elongation per cent, its swelIingin toluene was always higher and its retained value was80.65 per cent compared to 66 per cent using DBP.

The effect of using castor-oil or its derivatives on theoil resistance of nitrile rubber is illustrated in Figure 4.

It can be seen that this resistance, which is considered avery important property of nitrile rubber, improved byusing the prepared plasticizers and it was optimum us-ing hexachlorocastor oil. The maximum swelling inmotor oil after immersion for seven days was found tobe 2.2 per cent by using hexachlorocastor oil as rubberplasticizer compared to 3.5 per cent using DBP.

It can be stated from the above results that castor oilor its halogenated derivatives are more suitable as plas-ticizer of nitrile rubber than DBP currently used in localindustry. This can be attributed to the polarity of thesederivatives as compared to DBP. The hexachloro deriva-tives seem to be most effective regarding the mechani-cal properties before and after aging as well as the resis-tance of the rubber to swelling in motor oil. In the fol-lowing discussion, the effect of changing the dose ofhexachlorocastor oil on the mechanical properties ofrubber is presented so as to select the best dose whichwould give optimum plasticization.

The Effect of Dose of Hexachlorocastor Oil on theProperty of Nitrile Rubber Formulation

The effect of the dose of hexachlorocastor oil on therheometric characteristics and the physical mechanicalproperties of rubber is compiled in Table 9. The ob-served decrease in cure time and increase in cure rateindex were optimum by using a dose of hexachlorocastoroil equivalent to 2 phr. The cure time was 13 min andthe cure rate index was 8.88 compared to 21 min and5.26 using DBP, respectively. Also, the increase in rub-ber swelling in toluene due to the use of thehexachlorocastor oil instead of DBP, was lowest using 2phr of this derivative.

However, the elongation at break was lowest usingthis dose although it was still markedly higher than withDBP. The effect of the dose of chloro derivative on thetensile strength was insignificant as shown in Table 9.

The effect of thermal aging on the properties of rub-ber vulcanizates prepared using different doses ofhexachlorocastor oil is illustrated in Tables 10-12. Thepercentage retained value of the tensile strength of rub-ber, elongation per cent and swelling percentage duringrubber aging for periods up to 7 days were calculatedand are listed in these tables. It can be seen that the doseof the hexachlorocastor oil had insignificant effect onthe percentage of tensile strength retained after differentaging periods. The two other properties, elongation per

YOUSEF eta/.: MODIFICATION OF CASTOR OIL

Table 9 - NBR formulations with changing concentrations or hexachl oro castor oil (by add), rhcometri c charac teri stics and physico-mechanical properties

Ingredients Formulati on

VII v VII IX

NBR 100 100 100 100 100

Stearic ac id 2 2 2 2 2

Zinc ox ide 5 5 5 5 5

Carbon black 30 30 30 30 30

CBS

Sulphur 2 2 2 2 2

PBN

DBP 3

Hexachl oro castor oi l 2 3 4 5

Rheometric characteristic of NBR fo rmulations with changing cone. of (hexachloro castor oil by add)

Mini torque (L) 8.5 7 7 7 7

Max torque (H) 7 1 94 9 1 88 96

Cure time (tc'J( ) 21 13 14.5 16 14.5

Scorch time (ts1

) 2 1.75 2.25 2.75 2

Cure rate index CR I 5.26 !Ul8 8. 16 7.54 8

Tensi le strength (MPa) T,, 19 22.98 23 .37 23.3 23. I

Elongati on at brcakc (per cent ) E., 544 703 760 766

Max. swe lling in toluene (per cent) Q,0

150. 1 I 53.6 154.6 155. 10

Table I 0- Retained va lues or tensil e strength for BR formulati ons using different concentration or licxachl oro castor oil wi th aging periods

Aging period (days)

Doses of hex a-chloro castor oil 0 2 4 6 7

DBP 100 94.57 89.89 86.78 85.89

2 phr 100 97.86 95.60 93.21 92.03

3 phr 100 97.81 95.97 93.66 92.34

4 phr 100 97.03 95.06 92.83 92.14

5 phr 100 97.0 1 94.50 92.07 91.77

800

156.75

cent and swell ing per cent in toluene, were sl ightly affected by the dose of the chloro derivative .

provement wa~ not significant on increasing the dose of this derivative .

The effect of the dose of hexachlorocastor oil on the res istance of rubber to swelling by motor oil is illustrated in Figure 5. Although , the use of this derivative markedly improved the rubber oil resistance, this im-

Conclusions Castor oil and its halogenated derivatives are suJtJble

plasticizers of nitnle rubber and hexachlorocastor oil prepared by the addition seems to be the optimum reg·m.l-

394

"' c

J SCI I D RES VOL 60 M/\Y 2001

Tab le II - Reta ined values of elongation at break for NBR formu lat ions using different concentration of hexachloro castor oi l with aging periods

Agi ng peri ods (days)

Doses of hexach loro 0 2 4 6 7 castor oi l

DBP 100 S9.70 S5.84 8 1.80 79.4 1

2 phr 100 92.7-+ 87.33 S3.2 1 81.79

3 phr 100 91 .8-+ 87.89 84.40 82.63

4 phr 100 9203 86.03 82. 11 80.80

5 phr 100 89.62 83.50 80.00 n.37

Table 12- Retained va lues of elongati on at break for BR formul ations using dirterent concentration of hexachloro castor oi l with aging periods

Doses of hexachloro 0 2 castor oil

DBP 100 92.06

2 phr 100 94.79

3 phr 100 94.62

4 phr 100 96.04

5 phr 100 95.S2

4 .------

3 .5 .

.---- - ----------- ~---

Agi ng period (days)

4 6 7

8 1.66 72. 13 66.2

88.45 82.80 79.41

89.24 83.66 80.65

9 1.16 85.73 83 .30

92.24 86.S2 84.59

ing tensile strength, cure time, cure rate index, elongation at break and the res istance of rubber to swelling by motor oi I.

Acknowledgments

~ 2.5t· :.:=:-:-------. ___ ~ ~~~ --===--~-- i

---~1 ,, I

The authors are gra teful to Prof. Dr FA Zaher, Fats and Oil Departmen t, NRC, Cairo, for helping in wri ting, and preparing of the paper in the present form .

References

1.5 Lt ~---'-~-'-~---'~___.l~~L-~.1.._-' 0 2 3 4 5 6

Immersion period, days

1

- DBP • Ct oil (add.) 2 phr

-<>- Cl o1l (add.) 3 phr -•- Cl oil (add.) 4 phr

"*" Cl oil (add.) 5 phr

7

Annua l Book o/ ASTM Stwl(/rmls, Pt 29, D960-73. Wa,hington, D.C. I976, pp. 525. 526.

2 Laks hmin arayana G, Paulose M M, Sh rip athi Rao II .

3

Vishwanadham B, Laxmina rayana J & Ramali ngaswamy P A, Project Costs for Hydrogenati on and Dehydrogenation . R, ,_,· /nd.

33 (1988) 9-11. Lower E S, Hydrogenated Castor Oil, Ril' !tal Sostan: e Grasse, 70 (1993) 87-92. Che111 Absll; 11 9 (1993) 162779.

Figure 5-The rela tion between maximum swelling in oil at I 00 "C and immersion peri od using different doses

..J. Tomoyuki I. Jurai rattana D. Pi yasan P & S.111guan S. The effect of palladium on Act ivi ty and Selectivity of Nickel Catalyst in Hydrogenation of Castor Oil. Ken'-yu Hokoku-asahi Carasu Zaidan, 56 ( 1990) 65-68.

5 Schwi tzer M K, Perspecti vcs and Prospects of t he World Castor Oi l Indu st ry, 0/r·ogineux, 38 ( 1983) 253-259. of hexac hl oro cJstor oi I

YO USEF cl a /.: MOD IFICATION OF CASTOR OIL

6 Schwitzer M K, in Cas/o r Oil edited by T H Appl ew hit e, Proceeddings World 'Conference on 0/eochemica /s in fo !he 2 / " Cenlltry (American Oil Chemists Society, Champaign, USA) 1990.

7 Encyclopedia of Polymer Science and Technology (lnterscience Publishers, Division of John Wiley & Sons Inc N Y) 1965 . 295.

8 Association ofO.fjicia/ Agricultural Chemisls , Washi ngton D.C.

9 Shani A, Functionali zati on at the Doubl e Bond Region or Jojoba Oil : I. Bromine Deri vati ves , JAm O.ffChetn Soc , 58 ( 198 1) 845-850.

I 0 Shani A, Functionalizati on at the Doub le Bond Region or .l ojoba Wax. 4. All trans Jojoba and its Deri vati ves , f1 1d Eng Chem

Prod Res Dev, 25 ( 1986) 78-82.

II Annual Book o{ASTM Swnda rd.1· D-3 182-92, Washington.

12 Annual Book of ASTM D 2084-79, Washington.

13 Annual Book of ASTM D 1646-74, Washington.

14 Annual Book of ASTM D-412-75 , Washington.

15 Shvarts A, Kau!c/111k rezina , 2 ( 1957) 3 1.

16 Kraus G, Degree of Cure in Filler Rein fo rced Vul canizates by Swelling Method , Rubber World, 135 ( 1956).

17 Corey E J & lshi guro M, Tot a l Synth es is or l+)-2-isocyanopupukeanane, Tetrahedron Le11, 30 ( 1979) 2745-274

18 Turner R B, Chem Rev, 43 ( 1948) 27 1-3 17.

19 Bayed R N, 0 1ganic ChellliSIJ )' (All yn and Bacon Inc. Boston , ew York Uni versity) 1979, p519.