Modelling the performance and durability of welds with ansys and n code cutdown

-

Upload

richard-mitchell -

Category

Engineering

-

view

133 -

download

1

Transcript of Modelling the performance and durability of welds with ansys and n code cutdown

©2011ANSYS,Inc. July5,20161

ModellingthePerformance&DurabilityofWeldswithANSYS&nCode

©2011ANSYS,Inc. July5,20162

Agenda• OverviewofWeldingonFaBgue

• DefiniBonofStressMeasuresforSeamWelds

• SeamWeldAnalysisMethods– Volvo/ChalmersMethod– ASMEBoiler&PressureVesselCodeVIII,Div2.– BS7608,AWS,EurocodeExamples:– Flatplatetransversefilletweld– TubularpipeintersecBonweldedjoint– VibraBonfaBgueofaweldedtransformermounBngbracket

©2011ANSYS,Inc. July5,20163

EffectofWeldingonDurability

Parent plate Fusion zone Heat affected zone

Weld toe

©2011ANSYS,Inc. July5,20164

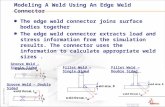

Volvo/Chalmers/nCodemethod

E(i)

E(j)

σ⊥Α

σ⊥Β

sheet B

sheet A

tB

t A

effective throat, a

• Sheetsandweldsmodeledpredominantlywithrectangular4or8nodedshells

• Sheetsdescribedbymeansurfaces• ThicknessofweldelementsequalseffecBvethroat,or

around2xsheetthickness• Elementlengthofabout5mm• Smallradiinotmodeled

©2011ANSYS,Inc. July5,20165

Damageparameter(stress)definiBon

DamageparameterisusuallyeithertheAbsMaxPrincipalstressorCriBcalPlanestressatweldtoe

Stressescanbedeterminedbasedoneither:

• Forcesandmomentsatnodesalongweldtoe

• ThenodaldisplacementsandrotaBonsoftheweldtoeelements

Forces/moments > Stresses

Displacement/rotaBon>Strains > Stresses

©2011ANSYS,Inc. July5,20166

DamageStressCalculaBon

σtop

σbot

σtop

σbot (insamedirec@onasσtop)

AbsMaxPrincipalexample

©2011ANSYS,Inc. July5,20167

SN curve interpolation using bending stress ratio

“flexible”orbendingloadingcondiBons(r=1)“sBff”ormembraneloadingcondiBons(r=0)

Flexiblejointshavemorebendingatweldtoe

SBffjointshavelowerfaBguestrength

©2011ANSYS,Inc. July5,20168

Structural stress history and bending stress ratio calculated at weld location

• CalculatethestresstensorateachpointalongtheStressClassificaBonLine(SCL)byinterpolaBonofthefiniteelementnodalnormalstresses(σxxi,σyyi,σzzi, τxyi, τyzi, τxzi)definedintheglobalX,Y,Zaxes

• TransformthestresstensortotheweldlinereferencesystemdefinedbyVt,VeandVn.ThestresscomponentsintheplaneperpendiculartoVnareσf,σee,andτte

• Calculatemembrane(σf,m,σee,m,τte,m)andbending(σf,b,σee,b,τte,b)stressesintheVt/Veplane

• Calculatethemembraneandbendingstressesonthetopandbofomsurfaces

Top BoGom

©2011ANSYS,Inc. July5,20169

Tubularweldedjoint• TwocircularintersecBngpipes,solidseamweldcomparisonwith

experimentalresults

CourtesyG.MenegheO,DepartmentofMechanicalEngineering,UniversityofPadova,viaVenezia1–35131Padova(Italy)

©2011ANSYS,Inc. July5,201610

Webinarrecording:

Watchtherecordingofthewebinarhere:

hGp://goo.gl/HQlO4R