MMSE Journal Vol.2 2016

-

Upload

mmse-journal -

Category

Documents

-

view

239 -

download

0

description

Transcript of MMSE Journal Vol.2 2016

Mechanics, Materials Science & Engineering, January 2016 – ISSN 2412-5954

MMSE Journal. Open Access www.mmse.xyz

1

Mechanics, Materials Science & Engineering, January 2016 – ISSN 2412-5954

MMSE Journal. Open Access www.mmse.xyz

2

Sankt Lorenzen 36, 8715, Sankt Lorenzen, Austria

Mechanics, Materials Science & Engineering Journal

January 2016

Mechanics, Materials Science & Engineering, January 2016 – ISSN 2412-5954

MMSE Journal. Open Access www.mmse.xyz

3

Mechanics, Materials Sciences & Engineering Journal, Austria, Sankt Lorenzen, 2015

Mechanics, Materials Science & Engineering Journal (MMSE Journal) is journal that deals in peer-reviewed, open access publishing, focusing on wide range of subject areas, including economics, business, social sciences, engineering etc.

MMSE Journal is dedicated to knowledge-based products and services for the academic, scientific, professional, research and student communities worldwide.

Open Access model of the publications promotes research by allowing unrestricted availability of high quality articles.

All authors bear the personal responsibility for the material they published in the Journal.

The Journal Policy declares the acceptance of the scientific papers worldwide, if they passed the peer-review procedure.

Mechanics, Materials Science & Engineering Journal by Magnolithe GmbH is licensed under a Creative Commons Attribution 4.0 International License.Based on a work at www.mmse.xyz.

Editor-in-Chief Mr. Peter Zisser

ISSN 2412-5954

e-ISSN xxxx-xxxx

Design and layout: Mechanics, Materials Science & Engineering Journal, www.mmse.xyz

Technical support: [email protected]

©2016, Magnolithe GmbH

© Copyright, by the authors

Mechanics, Materials Science & Engineering, January 2016 – ISSN 2412-5954

MMSE Journal. Open Access www.mmse.xyz

4

CONTENT

I. MATERIALS SCIENCE ................................................................................................ 5

THE CARBON-FLUORINE ADDITIVES FOR WELDING FLUXES ......................................... 5

INFLUENCE VOLTAGE PULSE ELECTRICAL DISCHARGE IN THE WATER AT THE

ENDURANCE FATIGUE OF CARBON STEEL ................................................................... 15

ALUMINUM COMPOSITES WITH SMALL NANOPARTICLES ADDITIONS: CORROSION

RESISTANCE.................................................................................................................. 25

II. MECHANICAL ENGINEERING & PHYSICS ............................................................. 31

PERFORMANCE OPTIMIZATION OF A GAS TURBINE POWER PLANT BASED ON ENERGY

AND EXERGY ANALYSIS .............................................................................................. 31

CERTAIN SOLUTIONS OF SHOCK-WAVES IN NON-IDEAL GASES .................................. 44

ANALYTICAL MODELING OF TRANSIENT PROCESS IN TERMS OF ONE-DIMENSIONAL

PROBLEM OF DYNAMICS WITH KINEMATIC ACTION .................................................... 57

ON INFLUENCE OF DESIGN PARAMETERS OF MINING RAIL TRANSPORT ON SAFETY

INDICATORS ................................................................................................................. 62

VIII. Information Technologies .............................................................................. 70

THE ASSESSMENT OF THE STABILITY OF THE ELECTRONICS INDUSTRY FACILITY IN THE

MAN-MADE EMERGENCIES WITH THE USE OF INFORMATION TECHNOLOGY .............. 70

X. Philosophy of Research and Education .............................................................. 78

TEACHING REITLINGER CYCLES TO IMPROVE STUDENTS’ KNOWLEDGE AND

COMPREHENSION OF THERMODYNAMICS .................................................................... 78

MULTIMEDIA TUTORIAL IN PHYSICS FOR FOREIGN STUDENTS OF THE ENGINEERING

FACULTY PREPARATORY DEPARTMENT ....................................................................... 84

PETRUS PEREGRINUS OF MARICOURT AND THE MEDIEVAL MAGNETISM ..................... 90

DEPLETION GILDING: AN ANCIENT METHOD FOR SURFACE

ENRICHMENT OF GOLD ALLOYS .................................................................................. 98

Mechanics, Materials Science & Engineering, January 2016 – ISSN 2412-5954

MMSE Journal. Open Access www.mmse.xyz

5

I. Materials Science

The Carbon-Fluorine Additives For Welding Fluxes

R.Е. Kryukov1, O.А. Kozyreva

1,a, N.А. Kozyrev

1,b

1 – Federal State Budgetary Educational Institution of Higher Professional Education «Siberian State Industrial

University», Research and Development Center «Welding Processes and Technologies», 654007, Russia,

Novokuznetsk, 42, Kirov str.

Keywords: welding, flux, metal, slag, gas-forming compounds.

ABSTRACT. Is carried out the thermodynamic estimation of the probability of the flow of the processes of the removal

of hydrogen from the weld with the welding in the fluorine-bearing flux in the standard states in the range of

temperatures 1700 – 2200 K. In this case, as the standard states for the substances – of reagents they were selected:

Na3AlF6L, SiO2L, SiF4g, NaAlO2s, Na2SiO3l, CaF2l, CaSiO3l, H2g, SiF2g, HFg, O2g, SiFg, Hg. As a result the calculations of

standard energy of Gibbs and equilibrium constants of reactions it is determined, that from the reactions of the direct

interaction of ftoragentov of slag with hydrogen and oxygen of the metal most probable appears the reaction with the

cryolite. In the mechanism of more complex interaction with the participation in the reaction, besides ftoragentov, silica

of slag and by the possible formation of the intermediate product of SiF4g more probable is the process with fluorite.

Calculations showed the expediency of using the connection Na3AlF6 together with fluorite for the removal of hydrogen

with the submerged welding. The carried out calculations became the basis of the development of the compositions of

the new flux- additives, protected by patents RF.

Introduction. The issue of new fluxes and their additives development has been attracting much

attention currently, as well as research into their influence on welding and technological characteristics

of a weld and on the concentration of oxygen and non-metallic impurities in a weld [1-5].

Submerged arc welding is attended by intensive mass transfer of liquid molten metal and slag,

forming from welding flux. Reactions of oxidation and deoxidation of manganese, ferrum, and

silicon, i.d. exchange processes involving oxygen are typical for this process. The most grades of

domestically produced fluxes, which are applied for welding low-alloyed steels are oxidizing ones

and ground on silicon-manganese oxidation-reduction processes. Here, the products of these

reactions are oxide compounds of silicon, manganese, ferrum, aluminum etc., which often can’t

surface and assimilate to slag, forming from welding flux, the level of impurity of weld metal by

non-metallic admixtures increases consequently; as the result, the complex of physical and

mechanical characteristics deteriorates. Apparently, restoratives, which form gaseous products of

reactions, are advisable to apply in order to avoid impurity of weld metal. It is carbon that can be a

restorative of this kind, and forms gaseous compounds CO2 and CO when reacting with oxidizers.

Mechanics, Materials Science & Engineering, January 2016 – ISSN 2412-5954

MMSE Journal. Open Access www.mmse.xyz

6

Materials and methods of research. Shielding is usually provided through pushing atmospheric

gases aside from weld zone by forming gases CO2 (CO); that helps to reduce or even exclude the

probability of molten metal saturation with oxygen, nitrogen or hydrogen from atmosphere. Gas-

forming compounds of carbonates like CaCO3, MgCO3, FeCO3, MnCO3 and their derivatives are

usually used for this purpose. Gas shielding is possible due to CO2 as high-temperature

decomposition of carbonates takes place according to the following reactions and temperatures [6]:

CaCO3 → CaO + CO2 (900-1200 ºC), (1)

MgCO3 → MgO + CO2 (>650 ºC), (2)

FeCO3 → FeO + CO2 (280-490 ºC), (3)

MnCO3 → MnO + CO2 (330-500 ºC) (4)

According to stoichiometric calculations the results of decomposition are as follows: 1 kg CaCO3 –

0.224 m3 CO2, 1 kg MgCO3 – 0.267 m

3, 1 kg FeCO3 – 0.192 m

3, 1 kg MnCO3 – 0.194 m

3.

Without taking into account the costs of carbonates decomposition, MgCO3 and CaCO3 are the most

optimal components, which help to get most CO2 when decomposing 1 kg of material, succeeded

by MnCO3 и FeCO3.

Furthermore, when decomposing CaCO3 and MgCO3 basic oxides CaO and MgO are formed and

improve basicity of welding flux, and that of a forming slag, respectively, whereas, when MnCO3

and FeCO3 decomposing oxides FeO and MnO are formed, which raise the degree of oxidation in

slag systems and oxygen concentration in a weld. The latter causes all negative consequences –

increasing level of impurity by non-metallic oxide components in a weld and deterioration of

mechanical properties.

Having followed all mentioned pre-conditions we have developed a flux – ANK additive, protected

it by a patent of the Russian Federation and applied in production process at Open Joint Stock

Company “Novokuznetsk Plant of Reservoir Metalware named after N.E. Kryukov” [7]. For its

manufacturing ferrosilicon FS75 (GOST 1415-78), marble М92- М97 (GOST 4416-73 (92-97%

СаСО3)), and liquid glass (GOST 13078-81) were used. Production technology was as follows.

Marble and ferrosilicon were grinded to less than 1 mm fraction. Grinded marble and silicon were

mixed in 50 to 50% mass proportion. It was dried at temperature 100-200 0С for 10 - 20 minutes,

succeeded by grinding and size grading to 2.5 mm. 3-5% of additive was introduced into fluxes.

Before a flux with an additive is used its 40 – 60 minutes annealing in the furnace is recommended

at temperature 250-350 0С.

This additive is used for roll welding of tanks. The technology involves assembling, welding,

controlling and rolling plates of tanks walls, all the processes are performed on special roll facilities

with upper and down rolling. Two-side submerged arc welding of butt joints of wall plates is

applied in the process, first on the upper tier, then on the lower one, after the plate is rolled. An

additive helped to avoid pore formation and improve quality of welds.

However, shielding gases CO and CO2 can form due to carbon, added to the flux, according to the

reactions:

(C) + [O2] = {CO2}, (6)

Mechanics, Materials Science & Engineering, January 2016 – ISSN 2412-5954

MMSE Journal. Open Access www.mmse.xyz

7

(C) + ½[O2] = {CO} (7)

Here 1.863 m3 CO2 and 1.864 m

3 CO release per each kg of carbon (in normal conditions).

The second important issue is that of weld metal dehydrogenization. As a rule, it is carried out by

introducing fluorine-containing additives (fluorite or cryolite), hydrogen combines with fluorine

and is further removed as a compound HF.

The following chemical transformations can be considered as probable reactions of removal:

1/2 (CaF2)+ [H]+ 1/2 [O] = 1/2(CaO) + HFg, (8)

1/6(Na3AlF6)+ [H]+ 1/2 [O] = 1/6NaAlO2 s+ HFg + 1/6(Na2O), (9)

As well as reactions:

2(CaF2) + 3(SiO2) = 2CaSiO3 s + SiF4g, (10)

2/3(Na3AlF6) + 5/3(SiO2) = SiF4g + 2/3NaAlO2 s + 2/3 (Na2SiO3), (11)

succeeded by reactions of dehydrogenization with SiF4:

1/2 SiF4g + [H] = 1/2SiF2 g+ HFg (12)

1/4 SiF4g + [H]+ 1/2 [O] = 1/4 (SiО2) + HFg (13)

1/3 SiF4g + [H] = 1/3SiFg + HFg (14)

1/2 SiF4g + [H] = 1/2 SiF2g + HFg (15)

Thermodynamical characteristics in standard conditions [∆rН°(Т), ∆rS°(Т), ∆rG°(Т)] needed to

assess reaction probability were calculated by well-known methods [8] in the temperature range of

welding processes 1700 – 2200 К [9] in terms of thermodynamic properties of reagents [[Н°(Т)-

Н°(298,15 K)], S°(Т), ∆fH°(298,15 K)] [10,11]. Here, chemical states Na3AlF6l, SiO2l, SiF4g,

NaAlO2 s,Na2SiO3l, CaF2l , CaSiO3 s, H2г, SiF2g, HFg, О2g, SiFg, Hg were selected as standard ones

for substances – reagents in the range 1700 – 2200 К according to fact aggregate states of phases in

the system under consideration.

The results of calculations are provided in the Table 1.

Table 1 demonstrates that reaction (9) is thermodynamically the most probable (cryolite

dehydrogenization), the second one is reaction (8) (fluorite dehydrogenization), followed by

reactions (10, 11), where silicon tetrafluoride is formed as an intermediate product of further

reactions (12) - (15); the latter result in formation of gaseous compound HF. Here, reaction (13) is

thermodynamically the most probable (SiF4 combines with hydrogen and oxygen). The

stoichiometric reactions (15), (12), (14) are the least probable ones.

Mechanics, Materials Science & Engineering, January 2016 – ISSN 2412-5954

MMSE Journal. Open Access www.mmse.xyz

8

Table 1. Standard Gibbs energy of reactions (8) – (15) and reaction equilibrium constants

according to temperature

Reaction

∆rG°(Т), kJ

К(Т)

1700К 1800К 1900К 2000К 2100К 2200К

8 -16,22 -18,61 -20,93 -23,17 -25,36 -27,47

3,2 3,5 3,8 4,0 4,3 4,5

9 -32,32 -33,82 -35,20 -36,46 -37,62 -38,68

9,8 9,6 9,3 9,0 8,6 8,3

10 41,80 35,98 30,62 25,71 21,22 17,18

0,05 0,09 0,14 0,21 0,30 0,39

11 82,41 76,11 70,40 65,22 60,56 56,38

0,003 0,006 0,012 0,020 0,031 0,046

12 86,62 78,13 69,68 61,27 52,90 44,57

0,002 0,005 0,012 0,025 0,048 0,087

13 -90,16 -89,83 -89,51 -89,21 -88,91 -88,63

589,5 404,5 289,1 213,8 162,8 127,2

14 113,04 104,93 96,86 88,82 80,80 72,82

0,0003 0,0009 0,0022 0,0048 0,0098 0,0187

15 -38,07 -40,60 -43,08 -45,49 -47,84 -50,14

14,78 15,08 15,29 15,42 15,49 15,51

Therefore, Na3AlF6 is the most reasonable to use for dehydrogenization when submerged arc

welding as if compared with fluorite.

Having taken into account the aforementioned preconditions, we have developed a technology of

submerged arc welding with carbonaceous additives. As the basis of carbon and fluorine containing

additive we took metallurgical production wastes. It was dust with the following chemical

composition (mass %): Al2O3 = 21 – 46.23; F = 18 – 27; Na2O = 8 – 15; К2O = 0.4 – 6; CaO = 0.7 –

2.3; SiO2 = 0.5 – 2.48; Fe2O3 = 2.1 – 3.27; C = 12.5 – 30.2; MnO = 0.07 – 0.9; MgO = 0.06 – 0.9; S

= 0.09 – 0.19; P = 0.1 – 0.18. Mineralogical makeup of dust was determined according to the data

of X-ray structural analysis made by difractometer DRON-2 in the mode: Fe – K α radiation,

voltage 26 kV, electrical current 30 mA.

The research into the dust of electrostatic precipitators revealed that the material consisted of bi-

dimensionally ordered carbon (d0O2=3.47Å, Lc=45.8Å), X-ray amorphous substance, cryolite,

corundum, hyolithe, and various admixtures. Diffraction patterns of roasted at 700°С material

demonstrate no indication of graphite, that is caused by nearly complete burning out of carbon-

containing mass in this temperature range, as well as significant curve flattering on the diffraction

pattern, and decrease in X-ray amorphous substance. The reason of the latter is probably chemical

Mechanics, Materials Science & Engineering, January 2016 – ISSN 2412-5954

MMSE Journal. Open Access www.mmse.xyz

9

composition of X-ray amorphous substance, which carbon compounds are main components of. At

700°С the change in indication intensity of mineralizing components (cryolite, corundum, X-ray

amorphous substance, fluorite, hematite and various admixtures) was recorded.

From the theoretical point of view the additive makes possible: 1) dehydrogenization by fluorine-

containing compounds (like Na3AlF6,), decomposing at the temperatures of welding processes and

isolating fluorine, which combines with dissolved in steel hydrogen and forms gaseous HF; 2)

intensive carbon “boiling” due to forming CO and CO2, when fluoric carbon CFx (1 ≥x>0)

combines with dissolved in steel oxygen, here, as carbon is in a bound state steel carbonization is

hardly possible; 3) improvement of arc stability due to potassium and sodium, facilitating ionization

in arc column.

To make an additive to flux carbon and fluorine containing substance was mixed with liquid glass,

then this mixture was dried, cooled down and grinded. Afterwards this additive was mixed with flux

in a special mixer according to a definite, strictly determined proportion. АN-348А, АN-60, АN-67

fluxes were taken as basic ones and their mixtures with flux-additives.

The experiments were carried out on 200500 mm 09Mn2Si steel samples 16 mm in thickness.

Fay welding of butt joints was made on two sides, as when welding wall plates of tanks on roll

facility. Sv-08Mn wire 5 mm in diameter was used as a filler metal.

Submerged arc welding of samples was made in similar modes. The samples were cut of welded

plates and subject to the following tests: X-ray spectral analysis of weld metal chemical

composition, metallographic tests of welds; total concentration of oxygen in welds, mechanical

properties, strength of joint welds and impact strength of welds were determined at temperatures -

20°С and -40°С. Concentration of carbon, sulphur, phosphorus was determined in chemical

composition of weld metal by chemical methods in terms of GOST 12344-2003, GOST 12345-

2001, and GOST 12347-77, respectively. Concentration of alloying elements in weld metal; that of

calcium oxide, silicon, manganese, aluminum, magnesium, ferrum, potassium, sodium and fluorine-

compounds in fluxes with additives and slag, obtained after welding was determined by

SHIMADZU roentgen-fluorescent spectrometer XRF-1800.

The experiments demonstrated that maximum 6% carbon and fluorine containing additive provided

carbon concentration in weld similar to its concentration in original metal (Figure 1), whereas

concentration of oxygen, hydrogen and nitrogen dropped (Figures 2, 3, 4).

Fig. 1. Influence of carbon and fluorine containing additive on carbon concentration in a weld

Mechanics, Materials Science & Engineering, January 2016 – ISSN 2412-5954

MMSE Journal. Open Access www.mmse.xyz

10

Metallographic research into polished sections of joint welds was carried out by optical microscope

OLYMPUS GX-51 in bright field and zooming ×100, ×500. The microstructure of metal was found

out by etching in 4 % HNO3 solution in ethanol. The structure of base metal in all samples consists

of ferrite grains and lamellar pearlite (4-5 µm). In base – to – added metal zone a fine-grain

structure occurs (1-2 µm), which was formed as the result of re-crystallizing when heating in course

of welding. In the microstructure of a weld there are ferrite grains stretched towards heat rejection

because of heating and speeded up cooling down. Structures of welds didn’t differ much

irrespectively of used fluxes. The level of impurity by non-metallic substances decreased in

samples, which were welded with fluxing agents, containing carbon and fluorine additives; it was

caused by reduction of total oxygen concentration.

Fig. 2. The change in oxygen in dependence on carbon and fluoride containing additive concentration

Fig. 3. The change in hydrogen in dependence on carbon and fluorine containing additive

The research into mechanical properties (yield point, strength, modulus of elongation, impact

strength at temperatures below zero) carried out on cut according to GOST 6996-66 samples,

demonstrated that the level of properties went beyond the values required in GOST 31385-2008 and

Mechanics, Materials Science & Engineering, January 2016 – ISSN 2412-5954

MMSE Journal. Open Access www.mmse.xyz

11

increased as the concentration of carbon and fluorine containing additive rose. Increasing impact

strength KCV and KCU at temperatures -20°С and -40°С, respectively (Figures 5, 6) is worth

mentioning. Flux-additives, which were developed, have been protected by the Russian Federation

patents [12, 13].

Fig. 4. The change in nitrogen in dependence on carbon and fluorine containing additive

Fig. 5. The change in impact strength KCV at temperature -20°С in dependence on carbon and

fluorine containing additive.

Summary. 1. On the ground of made calculations and carried out experiments we can conclude that carbon

containing additives to welding fluxes are possible and promising ones in order to improve welding and

technological characteristics of welded metalware.

2. The probability of dehydrogenization of a weld in fluorine containing submerged arc welding has

been assessed thermodynamically in the temperature range 1700 – 2200 К. Here, Na3AlF6l, SiO2l,

SiF4g, NaAlO2s, Na2SiO3l, CaF2l, CaSiO3 s, H2г, SiF2g, HFg, О2g, SiFg, Hg. were selected as standard

states for substances - reagents. In terms of calculation of standard Gibbs energy reactions it has

been found out that the reaction of gaseous hydrogen fluorine direct formation by cryolite is

thermodynamically the most probable one, the second probable is the group of reactions resulting in

Mechanics, Materials Science & Engineering, January 2016 – ISSN 2412-5954

MMSE Journal. Open Access www.mmse.xyz

12

formation of silicon tetrafluoride as an intermediate product for further HF formation. In this group

the most thermodynamically probable reaction is that of SiF4 with hydrogen and oxygen. In terms

of calculations Na3AlF6 is more reasonable to use for dehydrogenization when submerged arc

welding in comparison to fluorite.

Fig. 6. The change in impact strength KCV at temperature -40°С in dependence on carbon and

fluorine containing additive

3. Introduction of developed carbon and fluorine containing additive into fluxes АN-348А, АN-60

and АN-67 reduces gas content of a weld, the level of impurity by oxide non-metallic substances,

and improves required mechanical properties and impact strength (at temperatures below zero,

especially).

References

[1] Study of the relationship between the composition of a fused flux and its structure and

properties/ Amado Cruz Crespoa, Rafael Quintana Puchola, Lorenzo Perdomo Gonzáleza, Carlos R.

Gómez Péreza, Gilma Castellanosa, Eduardo Díaz Cedréa & Tamara Ortíza / Welding International.

– 2009. - Volume 23. - №2. - p. 120-131

[2] Using a new general-purpose ceramic flux SFM-101 in welding of beams/ Yu. S. Volobueva, O.

S. Volobueva, A. G. Parkhomenko, E. I. Dobrozhelac & O. S. Klimenchuk // Welding

International.– 2012.- Volume 26. - №8. - p. 649-653

[3] Special features of agglomerated (ceramic) fluxes in welding / V. V. Golovko & N. N.

Potapov // Welding International. – 2011.- Volume 25. - №11. - p. 889 - 893.

[4] The influence of the air occluded in the deposition layer of flux during automatic welding: a

technological aspect to consider in the quality of the bead / Rafael Quintana Puchola, Jeily

Rodríguez Blancoa, Lorenzo Perdomo Gonzaleza, Gilma Castellanos Hernándeza & Carlos Rene

Gómez Péreza // Welding International. – 2009.- Volume 23. - №2. - p. 132-140.

[5] Obtaining a submerged arc welding flux of the MnO–SiO2–CaO–Al2O3 – CaF2 system by

fusion / A.C. Crespoa, R.Q. Puchola, L.P. Goncaleza, L.G. Sanchezb, C.R. Gomez Pereza, E.D.

Mechanics, Materials Science & Engineering, January 2016 – ISSN 2412-5954

MMSE Journal. Open Access www.mmse.xyz

13

Cedrea, T.O. Mendeza & J.A. Pozola//Welding International.– 2007.- Volume 21. - №7. - p. 502-

511.

[6] Reaction of non-organic substances / R.А. Lidin, V.А. Molochko, L.L. Andreeva – М.: Drofa,

2007. – 637 p.

[7] Manufacture of vertical bulk –oil storage tanks for northern climates using special welding

materials/ Kryukov N.E., Koval'skii I.N., Kozyrev N.A., Igushev V.F., Kryukov R.E.// Steel in

Translation. -2012. - Т. 42. -№ 2.-P. 118-120.

[8] Thermodynamical properties of substances: Reference book. V.1. Issue 1 / Edited by V.P.

Glushko, L.V. Gurvich et al. M.: Nauka, 1978. pp. 22.

[9] Welding materials for arc welding: СReference book in 2 volumes. V. 1. Shielding gases and

welding fluxes: Konishchev B.P., Kurlanov S.А., Potapov N.N. et al. / Edited by Potapov N.N. -

М.: Machinebuilding, 1989 – pp. 104.

[10] John L. Haas, Jr., Gilpin R. Robinson, Jr., and Bruse S. Hemingway // J. Phys. Chem. Ref.

Data. – 1981. – Vol. 10. – № 3. – P. 575 – 669.

[11] NIST-JANAF Thermochemical Tables 1985. Version 1.0 [Electronic resource] : data compiled

and evaluated by M.W. Chase, Jr., C.A. Davies, J.R. Dawney, Jr., D.J. Frurip, R.A. Mc Donald, and

A.N. Syvernd. – Available at: http://kinetics.nist.gov/janaf.

[12] Patent 2467853 RF, МPК 8 V23 К35/362 Ceramic flux-additive / Kryukov N.Е., Kovalsky

I.N., Kozyrev N.А., Igushev V.F., Krykov R.Е.; Open Joint Stock Company ОАО «Novokuznetsk

Plant of Reservoir Metalware» named after N.E. Kryukov.- № 201112341602/02(034654),

Application 08.06.2011.

[13] Patent 2484936 PF, МPК 8 V23 К35/362 Ceramic flux-additive / Kozyrev N.А., Igushev V.F.,

Kryukov R.Е., Goldun S.V.; FSBEI HPE “Siberian State Industrial University”.-

№2012104939/02(007484), Application 13.02.2012.

Mechanics, Materials Science & Engineering, January 2016 – ISSN 2412-5954

MMSE Journal. Open Access www.mmse.xyz

14

Influence Voltage Pulse Electrical Discharge In The Water at the Endurance

Fatigue Of Carbon Steel

I.A. Vakulenko1, a

, A.G. Lisnyak2, b

1 – Department of Materials Technology, Dnepropetrovsk National University of Railway Transport named after

Academician V. Lazarian. Street. Lazarian, 2, Dnepropetrovsk, Ukraine, 49010, Tel. 38 (056) 373 15 56, ORCID 0000-

0002-7353-1916

2 – Department "The technology of mining machinery" Dnepropetrovsk National Mining University, pr. Karl Marx, 19,

Dnepropetrovsk, Ukraine, 49027, Tel. 38 (0562) 46 99 81, ORCID 0000-0001-6701-5504

Keywords: hardness, distribution, impuls pressures, electric digit, limited endurance

ABSTRACT. Effect of pulses of electrical discharge in the water at the magnitude of the limited endurance under

cyclic loading thermally hardened carbon steel was investigated. Observed increase stamina during cyclic loading a

corresponding increase in the number of accumulated dislocations on the fracture surface. Using the equation of Cofino-

Manson has revealed a decrease of strain loading cycle after treatment discharges. For field-cycle fatigue as a result of

processing the voltage pulses carbon steel structure improvement, followed by growth of limited endurance decrease

per cycle of deformation. With increasing amplitude of the voltage loop gain stamina effect on metal processing voltage

pulses is reduced. The results can be used to extend the life of parts that are subject to cyclic loading.

Introduction. In the process of cyclic loading of carbon steel, the extent, to which the cycle

amplitude exceeds fatigue limit, affects the character of structural change considerably [2]. For this

reason, the rate of increase in the number of crystalline defects, and evenness of their distribution in

the metallic matrix are the determinants of the conditions of the fatigue damage sites formation in

metals and alloys [14]. Considering that, dislocations are basic carrier units of plastic deformation

[3], the possibility of purposeful control over the process of their growth and redistribution under

the fatigue loading can be considered a promising direction of development of the measures on

improvement of the finite life. The information on the use of electric pulse effects [6, 10] in the

carbon steel after a certain degree of plastic deformation can serve as example. As a result, there

was such a change in the internal structure of a metallic material, which was required to achieve a

desired set of properties.

Status of the problem. At the certain stage of the development of metal materials processing

technology, in the production of complex shapes, especially of plate stock of considerable size, they

detected certain difficulties in the implementation of the technical solutions. One of the ways to solve

this problem was the proposal to use the shock wave resulted by an electric discharge in liquid [4].

Based on numerous studies [4‒8], it was found that this technology allows not only the

manufacturing of products by the formation of a complex deformed state but also managing a range

of properties. Based on this, we can confidently assume that the value of the energy of pulse

loading, its momentum distribution [7, 13] may significantly change the result to be achieved.

Considering the existence of a certain threshold dependence of the impulse of voltage being formed,

Mechanics, Materials Science & Engineering, January 2016 – ISSN 2412-5954

MMSE Journal. Open Access www.mmse.xyz

15

it is possible to obtain the result of different quality, ranging from the reinforcing effect to the metal

weakening [4, 11, 12]. In most cases, the effect of hydraulic shock caused by the electric discharge

in liquid for many metallic materials has reinforcing nature [4, 5], which is supposed to be followed

by the change in the number of accumulated dislocations. Thus, if the effect has reinforcing nature,

the increase in the dislocation density may be expected. Considering that the result depends on a

large number of individual factors, the cumulative effect often leads to qualitatively opposite

results. For example, the rise of the stress wave amplitude increases the number of dislocations [4].

On the other hand, the pulse length largely determines the conditions for the movement of the

dislocation structures. Most of the known experimental data concerns the study of the influence of

the electric discharge shock waves in liquid on the properties of metallic materials under static

loading [5]. Based on this, we can confidently assume that the assessment of the impact of this

effect on the behavior of the metal under the fatigue is quite an important issue.

Purpose. Assessment of the impact of voltage impulses of the electric discharge in liquid on the

behavior pattern of carbon steel under fatigue loading.

Methodology. The carbon steel of the railway wheel pair axle with 0.45% carbon content was the

material under research. The content of other chemical elements corresponded to the grade

composition. The samples for alternating bending test under symmetric loading cycle were metal

sheets of 1 mm thick, 15 mm wide and 180 mm length. The samples were subjected to martensite

quenching and tempering at 300°C, for 1h. The analysis of the fracture surfaces was performed

using a scanning electron microscope and fractography techniques; the dislocation density was

evaluated by X-ray methods [1].

Metal fatigue testing was performed under alternating bending under symmetric loading cycle by

means of the ten-station test machine “Saturn-10”. Electrical discharge impulse action on the

samples of steel in water was performed by the “Iskra-23”, with the amplitude of the voltage to a

maximum of 2 GPa. The total number of pulses was about 104, at the frequency of 2-3 Gts.

Results. Selection of the structural state of steel after martensite quenching and subsequent

tempering at 300°C was driven by the possibility of achieving, under the high density of

dislocations, enhanced values of fatigue resistance of a metal under cyclic loading. From the

analysis of the internal structure of the metal, it follows that after quenching and tempering at

300°C, there the stages occur in the process of dispersed carbide particles liberation at the

dislocations, both in the middle and at the boundaries of martensite laths. Besides, as follows from

the results of studies [9], the development of dislocation recombination processes resulting in a

decrease in their total amount should always result in the lowering of their mobility. Therefore, we

can confidently assume that most of the dislocations that have appeared in the metal as a result of

mentioned thermal treatment are immobile to different extents.

The analysis of the shock stress treatment effect on the fatigue behavior of a metal was carried out

in a particular sequence. Fatigue curve was build first, for the samples that had undergone the

thermal treatment (Fig. 1, curve 1), by which the finite life of the metal was determined. Further, the

newly prepared samples were loaded, under the corresponding amplitudes of the cycle to the level

of 0.6‒0.7 of the value of the finite life. Then they were subjected to the shock stress. Further, the

cyclic loading continued until the final destruction of the samples. Finite life value is the total

number of cycles including the number of cycles before the shock stress treatment and after it, up to

the final destruction of the sample (Fig. 1, curve 2).

The analysis of fatigue curves shows the expected difference in the evolution of the fine crystalline

structure of the metal depending on the treatment applied. Indeed, for the similar amplitudes of

loading there is a clear increase in the fatigue resistance of the metal that has been subjected to the

shock wave impulse.

Mechanics, Materials Science & Engineering, January 2016 – ISSN 2412-5954

MMSE Journal. Open Access www.mmse.xyz

16

a ,

iN 610 cycle.

Fig. 1. The diagrams of cyclic loading steel 45 after tempering and annealing at 300C (♦) and

after treatment of SS (■).(Stress straik).

To explain the observed increase in the finite life of the metal, the dislocation density was estimated

by the interference (110) and (211) on the fracture surfaces of the samples.

Regardless of the treatment (before and after the shock stress), the decrease in the amplitude of the

cycle is followed by the accumulation of the amount of dislocations in the volume of metal under

plane-strain loading. The absolute values of )(hkl are of great interest. Thus, during cyclic loading

at high amplitude the absolute values of the dislocation density at the fracture surface of the samples

are almost the same. It can be explained by the fact that under high cyclic overstress the formation

of elementary shifts within the structural element of steel causes significant plastic deformations

localization, simultaneously with the rapid transition of the metal to the plane-strain condition.

Further, during the subsequent decrease of a the increase in the accumulated number of

dislocations occurs, with the rate of increase 211 that is significantly higher than the corresponding

value 110 (Fig. 2, a).

The nature of the changes of 211 and 110 (Fig. 2, a) corresponds to the known experimental data

for metal loading under unidirectional static and cyclic loading [2].

By treatment of the metal that had been subjected to the preliminary cyclic loading (up to 0.6-0.7 of

the value of the finite life with certain a ) by shock wave impulses, we have received the

qualitative differences in the nature of the change of the dislocation density on the investigated

interference (Fig. 2, b). The received level of absolute values: 211 is less than 110 , and their

change rate with the decrease of a appeared quite unexpected.

In order to explain the nature of the observed effect of the shock stress on the finite life under cyclic

loading, we analyzed the fracture surface of the samples.

Ряд1; 0,2; 110

Ряд1; 0,25; 93

Ряд1; 0,35; 75

Ряд1; 0,7; 60

Ряд2; 0,2; 120

Ряд2; 0,25; 100

Ряд2; 0,35; 90

Ряд2; 0,7; 80 1

2

Mechanics, Materials Science & Engineering, January 2016 – ISSN 2412-5954

MMSE Journal. Open Access www.mmse.xyz

17

210

),( 10 смhkl

a ,

а)

210

),( 10 смhkl

a ,

b)

Fig.2. The change of dislocations density, estimated on interferences (110) - ♦ and (211) - ■

depending on amplitude of cyclic loading and preliminary treatment: without SS (a) and after SS

(b).

The general analysis of fracture pattern in the samples after 256 310 cycles with the amplitude of

950 MPa (Fig. 3) shows that the surface of fracture was formed by a mixed mechanism. It is

indicated by the presence of chips inside grains (Fig. 3, A) and formation of the faceted surfaces of

intergranular fracture (Fig. 3, B) at the fracture surface.

The mechanism of formation of the chips inside grains is associated with the high overload along

the cycle. The first phase of structural changes caused by the emergence of elementary shifts within

Ряд1; 120; 13

Ряд1; 100; 10

Ряд1; 90; 15

Ряд1; 80; 21

Ряд2; 120; 10 Ряд2; 100; 10 Ряд2; 90; 11

Ряд2; 80; 14

Mechanics, Materials Science & Engineering, January 2016 – ISSN 2412-5954

MMSE Journal. Open Access www.mmse.xyz

18

the individual grains due to the movement of the unevenly distributed dislocations. Randomly

oriented shifts lead to the rapid partition of the grain into pieces, the boundaries of which are the

series of microcavities. The fatigue microcracks appear and extend along the specified boundaries

due to the local low resistance of the metal [15]. In the case of discrepancy of surfaces of the

simultaneously growing microcracks, in the places where they meet, a step or another boundary

appears that separates the other fragments (light lines in Fig. 3).

Fig.3. Fractographic investigation of the sample after the 260x. 310 cycles at an amplitude of

950 MPa.

Formation of the facets of intergranular fracture has a different mechanism. Instead of the chip

within the grain, due to the reduction of the cyclic overload in individual grains, the microcavities

appear near the angle boundaries, which reduces the bond between individual grains in the metal.

Moreover, the movement of dislocations near the large angular boundaries for several

crystallographic systems results in a series of vacancies. Under the influence of cyclically varying

loads in the metal, the areas accumulating the vacancies near the grain boundaries turn into volumes

with high concentrations of microcavities, along which the fatigue crack grows. The more detailed

analysis shows additional features, which indicate the participation of other failure mechanisms in

the formation of the fracture. In fact, there are dimples ( F ) on the fracture surface. These elements

of the structure of the fracture surface explain the emergence of a significant number of microcracks

( E ), which grow mostly at the ferrite grain boundaries. Based on this, it can be assumed that the

sample loading conditions with an amplitude of 950 MPa correspond to low-cycle fatigue, with the

finite life of 256 thousand of cycles.

The reduction of the amplitude to 750 MPa is followed by the expected prolongation of finite life

(up to 350 thousand of cycles). The analysis of the fracture surface (Fig. 4) testifies to the mixed

mechanism of fracture just as under higher amplitude of loading. While under 950 MPa, the fracture

Mechanics, Materials Science & Engineering, January 2016 – ISSN 2412-5954

MMSE Journal. Open Access www.mmse.xyz

19

surface is formed mainly due to the chips inside grains and formation of the faceted surfaces of

intergranular fracture, under 750 MPa the chips inside grains do not appear (Fig. 4, в, A label).

Fig.4. Fractographic investigation of the sample after 370 x10 3

cycle at an amplitude of 750 MPa.

The formation of the separation areas with the crests, which look like the light lines (Fig. 4,

A label), and the intergranular fracture facets (B label) with a significant dispersion should be

considered the dominating mechanism of the fracture surface formation. The sign that confirms the

fatigue resistance improvement is the fewer number of decompositions and microcracks. At the

same time, the number of pits of different sizes and shapes increased; this indicates an increase in

the number of microcavities in the plane of the growing crack. Moreover, on the surface of the

fracture, the occurrence of the sites with an equidistant arrangement of lines can be observed. The

lines have external characteristics similar to fatigue striations (C label). Based on the analysis of the

fracture it can be assumed that under the loading amplitude of 750 MPa the behavior of the sample

corresponds to the conditions of low-cycle fatigue with the signs explaining the increase in the

number of cycles to failure.

After the shock stress processing of the samples, the fracture surfaces have a slightly different

structure (Fig. 5).

According to the external characteristics, the elements of the fracture surface (Fig. 5) has been

formed by the mixed mechanism with almost the same range of particle dimensions as compared

to the sample that has not undergone the shock stress (Fig. 3). The fracture pattern analysis

(Fig. 5) shows the absence of the signs indicating the chip formation within the grains, which was

observed in Fig. 3. At the same time, a considerable part of the fracture surface is occupied by the

facets of intergranular fracture (Fig. 5, A label). There is approximately the same number of

micro-cracks as in the sample that has not undergone the shock stress (Fig. 3), which are located

along the grain boundaries (Fig. 5, B label), decompositions (C), separation areas with the crests

(D) and dimples (F).

Mechanics, Materials Science & Engineering, January 2016 – ISSN 2412-5954

MMSE Journal. Open Access www.mmse.xyz

20

Fig. 5. The fracture surface of the sample with an amplitude 1000 MPa, after the total number of

260 x10 3 cycle with UN interim treatment.

As for the presence of the fatigue striations as in the case of the sample shown in Fig. 3, it is quite

difficult to determine uniquely, although there are similar sections (E). By means of the

comparative analysis of the fracture surfaces and the obtained level of finite life, it is quite difficult

to determine the influence of shock stress for the high-stress low-cycle region. On the other hand, it

is known that in proportion to the degree of cyclical overload the influence of the static component

on the development of fatigue phenomena increases. The static component that determines the

effect of the deformation and precipitation hardening treatment on the structural changes, in fact,

can mask the effect of the shock stress treatment. The confirmation of the above explanations may

be received under the lower degree of the cyclic overload.

Fig. 6 presents the fracture pattern of the sample that survived 370 thousand cycles at an amplitude

of 900 MPa, which has undergone the intermediate shock stress processing. In comparison to the

sample with the same number of cycles to failure but without shock stress treatment (Fig. 4), the

degree of dispersion of the fracture elements that has undergone the shock stress is higher. Firstly,

the facets formed on the fracture surface have a more equiaxial shape (Fig. 6, a, A label). Compared

to the fracture surface of the sample shown in Fig. 4, there are large areas with very small dimples

(Fig. 6, b, B label); their formation mechanism is based on the coagulation of microcavities [2]. At

the same time, there is a certain number of facets with crests of separation (C) and equidistant

arrangement of the metal decomposition (D), with a low number of the facets of intergranular

fracture (E). In the case of reduction of the test results to the equal cycle amplitude, the finite life of

the metal after the shock stress treatment increases by about 30 %.

Summary. The voltage impulse treatment of metal produced by the electric discharge in water

contributes to the increase of finite life of the carbon steel under cyclic loading. With the rise of the

cycle amplitude, the gain in fatigue resistance resulted by the shock stress declines.

Mechanics, Materials Science & Engineering, January 2016 – ISSN 2412-5954

MMSE Journal. Open Access www.mmse.xyz

21

а)

b)

Fig. 6. The fracture surface of the sample with an amplitude of 900 MPa, after the total number of

370 x103 cycle with UN interim treatment.

References

[1] Gine A. Rentgenografiya kristallov [Roentgenography of crystals]. Moscow, Gosudarstvennoye

izdatelstvo fiziko-matematicheskoy literatury Publ., 1961, 604 p.

Mechanics, Materials Science & Engineering, January 2016 – ISSN 2412-5954

MMSE Journal. Open Access www.mmse.xyz

22

[2] Nott Dzh.F. Osnovy mekhaniki razrusheniya [Fundamentals of fracture mechanics]. Moscow,

MetallurgiyaPubl., 1978. 256 p.

[3] Yefremenko V.G., Murashkin A.V., Ivanchenko Ye.P. Sovershenstvovaniye sostava i

termicheskoy obrabotki staley dlya nozhey kholodnoy rezki listovogo prokata [Improvement of

composition and heat treatment of steels for knives for cold cutting of sheet metal]. Stal – Steel,

2007, no. 1, pp. 75-77.

[4] Meyers M.A., Murr L.B. Udarnyye volny i yavleniya vysokoskorostnoy deformatsii metallov

[Shock waves and phenomena of high-rate deformation of metals]. Moscow, Metallurgiya Publ.,

1984. 510 p.

[5] Chachin V.N. Elektrogidravlicheskaya obrabotka mashinostroitelnykh materialov [Electro-

hydraulic processing of engineering materials]. Minsk, Nauka i tekhnika Publ., 1978. 184 p. [In

Russian]

[6] Yao K-F., Wang J., Zheng M. A research on electroplastic effects in wire-drawing process of an

austenitic stainless steel. Scripta Materialia, 2001, vol. 45, issue 15, pp. 533-539. doi:

10.1016/s1359-6462(01)01054-5.

[7] Ait Aissa K., Achour A., Camus J. Comparison of the structural properties and residual stress of

AIN films deposited by dc magnetron sputtering and high power impulse magnetron sputtering at

different working pressures. Thin Solid Films, 2014, vol. 550, pp. 264-267. doi:

10.1016/j.tsf.2013.11.073.

[8] Conrad H. Effects of electric current on solid state phase transformations in metals. Materials

Science and Engineering : A, 2000, vol. 287, issue 2, pp. 227-237. doi: 10.1016/s0921-

5093(00)00780-2.

[9] Dhadeshia H.K.D.H. Bainite in Steels. Cabridge, The University Press Publ., 2001. 454 p.

[10] Vakulenko I.A., Nadezdin Yu.L., Sokirko V.A. Electric pulse treatment of welded joint of

aluminum alloy.Nauka ta prohres transportu. Visnyk Dnipropetrovskoho natsionalnoho

universytetu zaliznychnoho transportu– Science and Transport Progress. Bulletin of Dnipropetrovsk

National University of Railway Transport,2013, no. 4 (46), pp. 73-82. doi:10.15802/stp2013/16584.

[11] Tang G., Zhang J., Zheng M. Experimental study of electroplastic effect on stainless steel wire

304L.Materials Science and Engineering : A, 2000, vol. 281, issue 1-2, pp. 263-267. doi:

10.1016/s0921-5093(99)00708-x

[12] Morgan W.L., Rosocha L.A. Surface electrical discharges and plasma formation on electrolyte

solutions. Physics of Low-Temperature Plasmas, 2012, vol. 398, pp. 255-261. doi:

10.1016/j.chemphys.2011.06.037.

[13] Razavian S.M., Rezai B., Irannajad M. Numerical simulation of high voltage electric pulse

comminution of phosphate ore. Intern. Journal of Mining Sci. and Tech., 2015, vol. 25, issue 3, pp.

473-478. doi:10. 1016/j.ijmst.2015.03.023.

[14] Vakulenko I.A., Proydak S.V. The Influence Mechanism of Ferrite Graine Size on Strength

Stress at the Fatigue of Low-Carbon Steel. Nauka ta prohres transportu. Visnyk Dnipropetrovskoho

natsionalnoho universytetu zaliznychnoho transportu – Science and Transport Progress. Bulletin of

Dnipropetrovsk National University of Railway Transport, 2014, no. 1 (49), pp. 97-104. doi:

10.15802/stp2014/22668 [In Russian].

Mechanics, Materials Science & Engineering, January 2016 – ISSN 2412-5954

MMSE Journal. Open Access www.mmse.xyz

23

Aluminum Composites With Small Nanoparticles Additions: Corrosion

Resistance

L.E. Agureev1a

, V.I. Kostikov2, Zh.V. Eremeeva

2, A.A. Barmin

3, S.V.Savushkina

4, B.S. Ivanov

5

1 – Researcher, Department of Nanotechnology, Keldysh Research Center, Russia

2 – Doctor of Science, Associate Professor, Moscow State University of Steel and Alloys, Russia

3 – Ph.D., Leading Researcher, Department of Nanotechnology, Keldysh Research Center, Russia

4 – Ph. D., Senior Researcher, Department of Nanotechnology, Keldysh Research Center, Russia

5 – Engineer, Department of Nanotechnology, Keldysh Research Center, Russia

Keywords: nanometric particles, aluminum composites, PM method, corrosion resistance. corrosion rate

ABSTRACT. Research of corrosion resistance of the aluminum powder composites containing microadditives (0.01 –

0.15% is executed about.) zirconium oxide nanoparticles. Extreme dependence of speed of corrosion of aluminum

composites in 10-% solutions of sulfuric and nitric acid from the maintenance of nanoadditives is shown. It has been

shown the dynamics of mass loss of aluminum composites with nanoparticles of ZrO2 during corrosion tests in acids

solutions. The lowest corrosion rate of 3.36 mm/a of nitric acid was observed in the sample containing ZrO2 0.01 vol.%

nanoparticles. For the case of sulfuric acid with the best result of 2.21 mm/a showed the material with 0.05 vol.% nano-

additive.

Introduction. Nanotechnologies allow to create the strong and lightweight materials steady against

various aggressive influences. Influence of nanoparticles on structure of material is caused by high

superficial energy. There is a huge number of the works devoted to creation of composite materials,

both with metal, and with a ceramic matrix, the nanoparticles strengthened by various concentration

[1-7]. The light and strong materials, like aluminum alloys, for creation of various bearing designs

of spacecraft have high value For astronautics [8-11]. In many works, the researchers conducted the

development of aluminum composites containing nanoparticles of different nature in concentrations

of more than 5 vol.%. It is rarely possible to find work devoted to low concentrations of nano-

additives in aluminum [12-18]. This work is dedicated to the creation of aluminum composites with

small amounts (0.01-0.15 %vol.) of nano-oxide ZrO2 by powder metallurgy techniques.

Attention to small concentrations of the nanoparticles was based on the following provisions:

– high surface energy of nanoparticles;

– ease of uniform distribution of small amounts of nanoparticles and their disaggregation within the

matrix;

– high impact of nanoparticles on the structure and properties of interfacial layers (matrix-MFS-

nanoparticle).

The theory of irreversible processes and catastrophe theory say that small changes of operating

parameters can jump the most important characteristics of the system [19,20]. Nanoparticles

possessing high superficial energy, brings it in material and to interphase layer, influencing

Mechanics, Materials Science & Engineering, January 2016 – ISSN 2412-5954

MMSE Journal. Open Access www.mmse.xyz

24

functional characteristics of composite in one direction or another. In this regard, a researcher

separate issue is the determination of threshold effects of nanoparticles on the material and the

search for the optimal technology of its receipt, depending on performance requirements.

The objective of the work was creation of aluminum composites, hardened with small additions of

metal oxide nanoparticles like ZrO2, and determination of its corrosion resistance in acids solutions.

According to ideas of a number of famous scientists on the structure and properties of an interphase

layer in solids nanoparticles having a high surface energy and making changes to structure of a

matrix, even at very small concentration at the level of 0.001-0,. about. % can cardinally change

characteristics of material [21-24]. In tab. 1 influence of nanoparticles on properties of materials is

briefly explained.

1. Experimental procedure. The charge used: as a matrix - aluminum powder with mean diameter

of 4 μm (ASD-4, "SUAL", Russia), as reinforcer - nanopowder of zirconia (dav = 50 nm, Ssp = 32

m2/g), Keldysh Research Center, Russia). The technology of preparation of composites consisted in

the following. At the beginning aluminum powder was sieved through a sieve with a cell of 14

microns, then mixed with alcohol in a ratio of 1:4. Then, placed in an ultrasonic bath while stirring

the mixture by rotary stirrer. Nanoparticles dispersed in ultrasound, after which the dispersion was

added to the stirred alumina powder in alcohol. Quantity of nanoadditives varied from 0.01 to 1.5

vol.% Mixing lasted for 20-40 min. Drying of suspensions took place on air at a temperature of 60 °

C within 24 hours. The resulting blend compressed into a cylindrical mold with a pressure of 400

MPa. Next, sintering was performed in forevacuum at 640 ° C during 120-180 minutes.

The corrosion resistance was measured as follows. The total exposure time of samples was 15

hours. Samples were weighed prior to the experiment and during the measurements on scales up to

4-th sign. Samples were immersed in 10% solution acid (nitric acid or sulfuric acid). The difference

in mass (primary - to experiment and obtained by checkweighing) was determined by mass loss of

samples and plotted on it. At each check weighing and date recorded.

By results of tests of samples of aluminum composites for corrosion resistance values of speed of

corrosion (γ) on a formula were calculated [25]:

1000

24365

x, mm/a,

where x1 – mass loss rate, g/(m2∙h);

ρ – density of material, g/cm3.

2. Results and discussions. The results are shown in Fig. 1-4. Particularly interesting is the results

on corrosion resistance in a solution of nitric acid. The lowest rate of mass loss of 3.36 mm/a was

observed in the sample containing nanoparticles of ZrO2 0.01 vol.% . For the case of sulfuric acid

with the best result of 2.21 mm/a showed the material with 0.05 vol.% of the nano-additive.

The worst level of resistance in H2SO4 showed a sample with 0.15 vol.% of nanoparticles. Perhaps

this is due to the number and size of the brought defects (cavities) by mixing aluminum powder

with nano-additives . Nevertheless, it should be noted that all of the samples in comparison with

pure aluminum sintered showed considerably greater resistance to corrosion in both acid solutions.

While first (pure aluminum) at all dissolved in nitric acid after 15 hours and in sulfuric through 10.

Mechanics, Materials Science & Engineering, January 2016 – ISSN 2412-5954

MMSE Journal. Open Access www.mmse.xyz

25

Fig. 1. The dependence of the aluminum composites corrosion rate of the content nanoparticles

ZrO2 (test in a 10-% nitric acid solution).

Fig. 2. Composites mass loss over time in a solution of nitric acid.

Summary. Samples of aluminum composites with ZrO2 nanoparticles were examined for corrosion

resistance in 10-% solutions of nitric acid and sulfuric acid. The lowest corrosion rate of 3.36 mm/a

of nitric acid was observed in the sample containing ZrO2 0.01 vol.% nanoparticles. For the case of

sulfuric acid with the best result of 2.21 mm/a showed the material with 0.05 vol.% nano-additive.

Acknowledgements. Authors thank collectives NITU "MISIS" and Keldysh Research Center for

the help in development of aluminum composites.

Mechanics, Materials Science & Engineering, January 2016 – ISSN 2412-5954

MMSE Journal. Open Access www.mmse.xyz

26

Fig. 3. The dependence of the aluminum composites corrosion rate of the content nanoparticles

ZrO2 (test in a 10-% sulfuric acid solution)

Fig. 4. Composites mass loss over time in a solution of sulfuric acid.

References

[1] Berestenko V.I., Torbov V.I., Torbova O.D. Poluchenie ul'tradispersnyh poroshkov dioksida

cirkonija v plazme SVCh razrjada. Tezisy dokladov IV Vsesojuznogo simpoziuma po plazmohimii,

g. Dnepropetrovsk, 1984 g., s. 59-60. - Berestenko V.I., Torbay V.I., Torbova O.D. Getting

ultrafine powders of zirconia in microwave plasma discharge. Abstracts of IV All-Union

Symposium on Plasma Chemistry, Dnepropetrovsk, 1984, p. 59-60. [In Russian]

[2] Kevorkijan, V.M. Aluminum composites for automotive applications: a global perspective /

VJVL Kevorkijan // JOM; -19991- №11.- P. 54- 58.

Mechanics, Materials Science & Engineering, January 2016 – ISSN 2412-5954

MMSE Journal. Open Access www.mmse.xyz

27

[3] Tang, F. The microstructure-processing-property relationships in an A1 matrix composite

system reinforced by Al-Cu-Fe alloy particles / Thesis D.Ph. -Iowa State University. - Ames, Iowa.

- 2004.

[4] Kang Y.C., Chan S.L.-I. Tensile properties of nanometric Al2O3 particulate-reinforced

aluminum matrix composites // Materials chemistry and physics, 85, 2004. P. 438-443.

[5] Ma Z.Y., Tjong S.C., Li Y.L. et al. High temperature creep behavior of nanometric Si3N4

particulate reinforced aluminium composite .// Materials Science and Engineering, A225, 1997. -P.

125-134.

[6] Mazahery A., Osfadshabani M. Investigation on mechanical properties of nano-Al2O3-

reinforced aluminum matrix composites .// Journal of Composite Materials, 45 (24), 2011. -P. 2579-

2586.

[7] Roduner Je. Razmernye jeffekty v nanomaterialah. –M.: Tehnosfera, 2010. -252 s.- E. Roduner

size effects in nanomaterials. -M .: Technosphere, 2010. -252 p. [In Russian]

[8] Kostikov V.I., Varenkov A.N. Sverhvysokotemperaturnye kompozicionnye materialy. –M.:

Intermet Inzhiniring, 2003. -560 s. - Kostikov V.I., Varenko A.N. Ultra high temperature

composites. -M .: Intermet Engineering, 2003. -560 p. [In Russian]

[9] Tehnologija proizvodstva izdelij i integral'nyh konstrukcij iz kompozicionnyh materialov v

mashinostroenii./ Nauchnye redaktory A.G.Bratuhin, V.S.Bogoljubov, O.S.Sirotkin. –M.: Gotika,

2003. -516 s.- The production technology and integrated manufacturing of composite structures in

mechanical engineering. / Scientific Editors A.G.Bratuhin, V.S.Bogolyubov, O.S.Sirotkin. -M .:

Gothic, 2003. -516 p. [In Russian]

[10] Pilotiruemaja jekspedicija na Mars./ Pod red. A.S.Koroteeva. –M.: Rossijskaja akademija

kosmonavtiki imeni K.Je.Ciolkovskogo, 2006. -320 s. - Manned expedition to Mars. / Ed.

A.S.Koroteeva. -M .: Russian Academy of Cosmonautics Tsiolkovsky, 2006. -320 p. [In Russian]

[11] Alifanov O.M., Andreev A.N., Gushhin V.N. i dr. Ballisticheskie rakety i rakety-nositeli. –M.:

Drofa, 2004. -512 s. - Alifanov OM, Andreev AN, VN Gushchin and others. Ballistic missiles and

launchers. -M .: Bustard, 2004. -512 p. [In Russian]

[12] Kalashnikov, I.E. Razvitie metodov armirovanija i modificirovanija struktury

aljumomatrichnyh kompozicionnyh materialov [Tekst]: avtoref. dis. na soisk. uchjon. step.

dokt.tehn.nauk (05.16.06)/ Kalashnikov Igor' Evgen'evich; IMET RAN. –Moskva, 2011. -26 s. -

Kalashnikov IE Development of methods of reinforcement and modification of the structure of

aluminum-matrix composite materials [Text]: Author. Dis. on soisk. Kazan. step. dokt.tehn.nauk

(05.16.06) / Kalashnikov Tamm; IMET RAS. -Moscow, 2011. -26 p. [In Russian]

[13] Kurganova, Ju.A. Razrabotka i primenenie dispersno uprochnjonnyh aljumomatrichnyh

kompozicionnyh materialov v mashinostroenii [Tekst]: avtoref. dis. na soisk. uchjon. step.

dokt.tehn.nauk (05.16.06)/ Kurganova Julija Anatol'evna; IMET RAN. –Moskva, 2008. -26 s.-

Kurganova, Y. Development and application of dispersion hardened aluminum-matrix composite

materials in engineering [Text]: Author. Dis. on soisk. Kazan. step. dokt.tehn.nauk (05.16.06) /

Kurganova Juliya; IMET RAS. -Moscow, 2008. -26 p. [In Russian]

[14] Grigorovich V.K., Sheftel' E.N. Dispersionnoe uprochnenie tugoplavkih metallov. –M.: Nauka,

1980. -302 s.- Grigorovich V.K., Sheftel E.N. Precipitation hardening refractory metals. -M .:

Nauka, 1980. -302 p. [In Russian]

Mechanics, Materials Science & Engineering, January 2016 – ISSN 2412-5954

MMSE Journal. Open Access www.mmse.xyz

28

[15] Sliney N.E. Kompozicionnye materialy dlja podshipnikov i uplotnitelej gazovyh turbin //

Sovremennoe mashinostroenie, 1991, №3, s. 175-201. - Sliney N.E. Composite materials for

bearings and seals of gas turbines // Modern Machinery, 1991, №3, p. 175-201. [In Russian]

[16] Sliding, wear response of an Al - Cu alloy the influence of SiC particle reinforcement and test

parameters / Prasad B.K., Jha A.K., Modi O.P., Das S., Dasgupta R., Yegneswaran A.N. // J.Mater.

Sci. Lett.- 1998.-17, № 13, p. 1121-1123.

[17] Hosking F.M., Portillo F., Wunderlin R., Mehrabian R. Composites of aluminum alloys;

fabrication and wear behaviour // J.Mater.Sci. -1982.- 17, №2. P.477-498.

[18] Rohatgi P. Cast aluminum - matrix composites for automotive applications // JOM. -1991. - 43,

№4.- P.10-16.

[19] Prigozhin I., Nikolis G. Samoorganizacija v neravnovesnyh sistemah: Ot dissipativnyh struktur

k uporjadochennosti cherez fluktuacii. –M.: Mir, 1979. -512 s.- Prigogine I., Nicolis G. Self-

organization in nonequilibrium systems: From dissipative structures for ordering through

fluctuations. -M .: Mir, 1979. -512 p. [In Russian]

[20] Arnol'd V.I. Teorija katastrof. Teorija katastrof. «Sovremennye problemy matematiki.

Fundamental'nye napravlenija. T. 5(Itogi nauki i tehniki VINITI AN SSSR». –M., 1988, s. 5-218. -

Arnold V.I. Catastrophe Theory. Catastrophe Theory. "Contemporary Mathematics. Fundamental

Directions. T. 5 (Results of Science and Technology VINITI. "-M., 1988, pp. 5-218. [In Russian]

[21] Obrazcov I.F., Lur'e S.A., Belov P.A. i dr. Osnovy teorii mezhfaznogo sloja. Mehanika

kompozicionnyh materialov i konstrukcij, 2004, t. 10, №3, s. 596-612.- Samples IF, Lurie SA,

Belov PA et al. Basic theory of the interfacial layer. Mechanics of Composite Materials and

Structures, 2004, v. 10, №3, p. 596-612. [In Russian]

[22] Tajra S., Otani R. Teorija vysokotemperaturnoj prochnosti materialov. –M.: Metallurgija,

1986. -280 s.- Taira S., R. Otani theory of high-strength materials. -M .: Metallurgy, 1986. -280 p.

[In Russian]

[23] Chuvil'deev V.N. Neravnovesnye granicy zjoren v metallah. Teorija i prilozhenija. –M.:

FIZMATLIT, 2004. -304 s.- Chuvildeev VN Non-equilibrium grain boundaries in metals. Theory

and Applications. -M .: FIZMATLIT, 2004. -304 p. [In Russian]

[24] Ohji T., Jeong Y.-K., Choa Y.-H., Niihara K. Strengtheing and toughening mechanisms of

ceramic nanocomposites .// Journal of American Ceramic Society. - 1998. - №81. - P. 1453-1460.

[25] Handbook of Corrosion Data / Ed. by B.D.Craig, D.S.Anderson. – Ohio: ASM International,

998 p.

Mechanics, Materials Science & Engineering, January 2016 – ISSN 2412-5954

MMSE Journal. Open Access www.mmse.xyz

29

II. Mechanical Engineering & Physics

Performance Optimization of a Gas Turbine Power Plant Based on Energy and

Exergy Analysis

Ghamami M.1, a

, Fayazi Barjin A.1, Behbahani S.

1

1 – Department of Mechanical Engineering, Isfahan University Technology, Isfahan, Iran

Keywords: Gas turbine, Exergy, Multi-objective, optimization, Fireflies algorithm, thermoflow.

ABSTRACT. The purpose of this study is energetic and exergetic analysis of combined cycle power plant, study of the

variables that affect the efficiency and performance and provide a solution to improve the efficiency and performance of

the gas turbine. Therefore, after modeling gas cycle, the impact of environmental conditions and performance of gas

turbine cycle will be checked, eventually we achieve two objective optimization of gas cycle that optimized by firefly

algorithm in six cold months of the year. The objective functions are exergy efficiency and cost of the gas cycle

maintenance, fuel cost and destroyed exergy cost. The proposed optimized result show increase in net output power of

the gas cycle, energy and exergy efficiency and decrease in air pollution amount.

Introduction. Gas turbine is one of the power generating machines that have been widely used in

various industries such as power plants, refineries and oil and gas industries. Since a high

percentage of the power requirements of the country, is provided in the gas power plants and due to

the fact that fossil fuels are the energy requirements of these power plants, thus the performance

improvement of these power plants is very important. From about 70 years before gas turbines have

been used to generate electricity, in the last twenty years the production of these type of turbines

has increased by twenty times. Thermodynamic Simulator of gas cycle and combined cycle, is a

useful tool to predict the behavior of each components of the cycle, by which the basic parameters

of the processes in the cycle can be obtained. Exergy analysis is a good way to evaluate the quality

of the energy with the aid of laws of conservation of mass and the first law of thermodynamics, and

is on the basis of the second law of thermodynamics. The tool is used for design, analysis and

optimization of thermal systems. The main objective of exergy analysis, finding solutions to

eliminate or reduce thermodynamic defects in the processes. We can reduced exergy destruction by

identifying the irreversibility factors and situation. Many studies have been done in this field,

research done in this field can be mentioned the following:

Siddiqui et al. [1] In their article they simulated a 100 MW gas cycle of one of the power plants in

Iran is hot and dry regions ,by thermoflow software ,and investigated the effect of steam injection

into the combustion chamber based on the exergy concept in order to improving gas turbine cycle.

Sadeghi et al. [2] they studied and simulated the effects of light and heavy fuel on operational

parameters of the gas turbine and combined cycle in Kazeroon power plant.

Kim and Hwang [3] examined the performance of a gas turbine with recovery in half-load situation,

by considering and comparing different mechanisms to control the turbine. Salary et al. [4] have

studied exergy analysis of 112 MW Power Plant in Ahvaz Zergan. They optimized the cycle by

Mechanics, Materials Science & Engineering, January 2016 – ISSN 2412-5954

MMSE Journal. Open Access www.mmse.xyz

30

increasing the turbine inlet temperature in terms of energy and exergy. Abdul Khaliq [5], used

exergy method to analyze gas turbine cycle with inlet air cooling and has shown that most exergy

destruction occurs in the combustion chamber, he also showed that by use of cooling the

compressor inlet air, energy efficiency and the cycle Exergy will be increased. Ehyaei et al. [6] at

the same time studied exergic, economic and enviromental analysis affected by Fog cooling system

in the gas cycle of Rajayee power plant. Sanaye and Jafari [7] work in optimizing field, they have

examined effect of inlet air cooling in gas turbine cycle by absorption refrigeration. The two-

objective optimization of the system is done by the genetic algorithm. kaviri et al. [8] have done

thermodynamic modeling and two-objective optimization of a combined cycle power plant. Ahmadi

[9] study on thermodynamic analysis of a gas cycle power plant and obtained best design

parameters by using multi-objective optimization.

In this study, energetic and exergetic analysis of gas turbine power plants have done and solutions

to improve efficiency and performance of gas turbine are suggested. Factors affecting the efficiency

of power plants have been studied and finally variables to improve the efficiency of power plants

have been selected.

Exergy (or ability to perform work). The maximum work that a system may do during a

reversible process from initial state to reach a dead end is called exergy. Exergy of a system in a

given state depends on environmental conditions and system properties, and for a control volume,

it’s equal to or reversible work with a dead end. Exergy has potential, physical and chemical

components. For the steady flow devices, kinetic and potential exergy can be assumed to be zero.

The sum of physical and chemical exergy, is called thermal exergy [10].

Ph Chex ex ex (1)

Physical exergy is defined by Equation 2.

( ) ( )Ph o o oex h h T s s

(2)

Chemical exergy of mixtures is obtained from equation (3) [11].

∑ ( ) ∑

( )

, (3)

(4)

Exergy analysis by using of the first and second laws of thermodynamics on the components of a

system, makes it possible to identify the place and production of irreversibility and unfavorable

thermodynamic process of the system, In this way, in addition to evaluate the different components

of thermodynamic cycle, approaches to increase efficiency and output are identified [13].

Efficiency of Thermodynamic Second Law (Exergic efficiency). The first law efficiency is

defined by an ideal isentropic process that never happens in practice. It makes no mention of the

best case, and isn't sufficient to measure the actual system performance alone. To assess the

deviation from the best possible processes, second law efficiency is defined. The second law

efficiency determines how much work ability or potential used in a process [11]. In fact, it

determines how much of exergy given to the system, by a process is achieved and how much of it is

wasted in the form of irreversibility. The second law efficiency is defined the ratio of useful exergy

Mechanics, Materials Science & Engineering, January 2016 – ISSN 2412-5954

MMSE Journal. Open Access www.mmse.xyz

31

to exergy input and output intensity of irreversibility is defined as (5) the difference between output

exergy and input exergy [13].

(5)

(6)

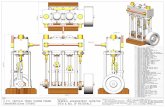

Thermodynamic Modeling of gas cycle and power plant. Thermodynamic modeling of gas cycle

power plant have been done by using thermodynamic relations. Plant that studied in this paper,

included 4 gas unit manufactured by Mitsubishi Japan MW-701D models with nominal capacity of

each is 128.5 MW and in total 514 megawatts. By installation of 4 retriever boilers and two steam

turbo generator that each has nominal capacity of 100 MW, power plant Transformed to combined

cycle power plant. In order to simulate the combined cycle power plant, we set the data related to

environmental conditions (Table 1).

Table 1. Environmental condition in power plant

Value Environmental condition

31 centigrade Temperature

0.8964 bar Pressure

RH=29% Relative humidity

1022 meter Above sea level

Thermoflow software is one of the most powerful software in design and analysis of power plant

cycles, which is capable to model various stages of the power plant, including thermodynamic

analysis, engineering design and simulating equipment. Combined cycle block consists of two gas

turbines, two recovery boilers and a steam turbine. By choosing Siemens W701 D engine which is

available in the software engines, combined cycle block is simulated in normal loads and in

software. Table 2 shows the software output.

Table 2. Power plant output in normal times (90%)

Gas oil Natural gas Type of gaseous fuel cycle

520844 526576 Net power output of the plant

(kW)

7948 7894 Plant heat rate (kJ/kWh)

45.3 45.6 Plant thermal efficiency (%)

In order to verify the results of the software simulation, the values obtained from the simulation and

actual data are compared in Table 3.

Figure 3 shows the flow of incoming and outgoing energy to one block in combined cycle of power

plant, also, it shows where the input fuel energy is intended in terms of heat value of fuel. Input

energy consists of latent and sensible energy of air and chemical energy of fuel. Most thermal losses

is related to the condenser, because discharges the heat taken from the cooling water to the

environment. After condenser most heat losses is related to the exhaust flue gas that is at about 118

Celsius degrees, which enters too much heat into the environment without using them.

Mechanics, Materials Science & Engineering, January 2016 – ISSN 2412-5954

MMSE Journal. Open Access www.mmse.xyz

32

Fig. 1. Operating parameters plant in case of 90% load

Fig. 2. Performance and placement components of HRSG plant in case of 90% load

In tables 3, net output power is expressed in kilowatts (kW) scale and heat rate is expressed in kJ /

kWh scale. The rate is expressed on a scale of kilograms per second (kg/s). By comparing the study

results provided by the simulation and power plant results it can be seen that there is a good

adaption between the results. In six cold months (October to the end of April), due to a dramatic

reduction in household electricity consumption compared with six warm months of the years, the

demand for electricity from power plants in the country declined. The main priority in the six cold

months, is increase in exergy efficiency of gas cycle and reduce the annual cost.

Mechanics, Materials Science & Engineering, January 2016 – ISSN 2412-5954

MMSE Journal. Open Access www.mmse.xyz

33

Fig. 3. Diagram of Energy flow (input and output plant power)

Table 3. Data comparing of power plant in case of 90% load

Error )%( Power

plant

Software

simulation Parameter

+1.08

526576 532250 Net power output

-0.14 7894 7883 Heat Rate

+0.15 45.6 45.67 Thermal efficiency (%)

+0.11 6.35 6.361 Fuel flow

0.11 338 339.1 Air flow

0.57 12.2 12.27 The compressor pressure ratio

0.8 11.2 11.29 Turbine pressure ratio

0.21 1385 1387.9 Turbine inlet gas temperature (K)

With the increase in air temperature, the gas turbine and the compressor's power reduces, due to the

more steep decline of power in gas turbine compared with the compressor, the net output power of

the gas cycle is reduced. With the increase in air temperature, mass flow of gas turbine exhaust

gases reduces, less steam is produced in the recovery boiler and there will be a total loss in power of

steam turbine. By reducing the power of steam-gas cycle, the net output of power plant appear with

declined more sharply. For one degree Celsius rise in ambient air temperature, pure output power of

the gas cycle, steam turbine and power plant will averagely reduce 0.63 and 0.27 and 0.53,

respectively. Comparison between output powers with respect to temperature is shown in Figure 4.

Mechanics, Materials Science & Engineering, January 2016 – ISSN 2412-5954

MMSE Journal. Open Access www.mmse.xyz

34

Fig. 4. Special compressor pressure ratio and can shift with ambient temperature

Optimization. After reviewing the parameters affecting the performance of plants, defining

optimization problem based on target functions and parameters can be done. Optimization problem

in finding answers or solutions on a set of possible options aimed at improving the standard or

standards of the issue. Multi-objective optimization problem arise from the decision-making

methods in the real world that one decision maker faces a set of contradictory and conflicting

objectives and criteria. In these types of issues, unlike the single-objective optimization problems

and because of the multi-purpose (often conflicting), rather than just a solution optimized set of

questions arises.

In the multi-objective optimization, after the introduction of design variables and determine the

objective functions, optimal points are determined and the impact of design on objective functions

are provided. Many factors affect the performance of gas turbine, therefore, gas turbine cycle has