MLF 7-4 (May 2013)

-

Upload

kmi-media-group -

Category

Documents

-

view

225 -

download

0

description

Transcript of MLF 7-4 (May 2013)

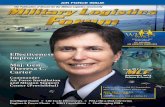

MRAP Programs O DLA Hiring Practices O Predictive Maintenance Collaboration with South Korea O Public-Private Partnerships

The Publication of Record for the Military Logistics Community

COCOM Sustainer

Brig. Gen. John F. WhartonCommanding GeneralU.S. Army Sustainment Command

Exclusive Interview with:

Lt. Gen. Bruce LitchfieLdCommanderU.S. Air Force Sustainment Center

www.MLF-kmi.com

May 2013Volume 7, Issue 4

PRSRT STDU.S. POSTAGE

PAIDLEBANON JCT., KY

PERMIT # 805

Special pull-out Supplement

u.S. Air force SuStAinment center

Cover / Q&AFeatures

Brigadier general John F. Whartoncommanding General

u.S. army Sustainment command

16

May 2013Volume 7, Issue 4

Departments Industry Interview2 editor’s PersPective10 suPPly chain19 resource center

Mitch stevensonSenior account manager, logistics Solutions operationSaic

4routine Predictionsplanning ahead now includes better forecasting of equipment failure. a comprehensive life cycle maintenance plan ensures safe, reliable and mission-capable operations.By J.B. Bissell

10the three “P”spublic-private partnerships create a direct link between industry

best practices and government requirements. together with an industrial partner, the work is divided among the two, providing advantages to each.By Peter BuxBaum

12 MaxiMizing the it investMentWhat is the life cycle of a desktop or laptop computer, and where is the tipping point between repair or replace? Whether it’s a new

service offering, a component swap out, an extended warranty or an upgrade, the goal is to achieve maximum return on investment.By Cheryl GerBer

24looking ForWard tacom and Red River army Depot collaborate to expand the Republic of Korea army’s depot capabilities as part of a pacific pivot strategy.By Kellin szKuBie

25investing in Qualitythe logistics enterprise recognizes the critical role of workforce. Dla, in order to provide support to all the agency’s customers, employs a cadre of logisticians, acquisition specialists, technicians, mission support specialists and other support staff. By susan lowe

AIr Force SuStAInMent centerSpecIAl pull-out SuppleMent

lt. gen. Bruce litchFieldcommanderu.S. air Force Sustainment center

MILITARY LOGISTICS FORUM

20

“Supporting

COCOM

operations is

our number

one priority,

and sustaining

Army and

joint forces in

combat is the

absolute most

important thing

we do.”

- Brig. Gen. John F. Wharton

1

exclusive intervieW With

long live the MraPmajor sustainment decisions still need to be made. How many mRaps will be retained, and in what configurations? How will their life cycle be managed and what role, if any, will private firms play in life cycle management of mRaps?By henry Canaday

7

By using a target in the budget as a snapshot, you can always draw conclusions that take you in the wrong direction. If you were to take a look at the Army’s procurement budget for construction equipment and watercraft, for example, you could argue that the world is fine. In 2012, construction equipment received $166 million. It received only $134 million in fiscal year 2013, but the request for FY14 tops $206 million. A similar trend follows watercraft. Receiving about $10 million each year for FY12/13, funding jumped more than four-fold to over $48 million.

But if you turn the page, you’ll see the bigger picture. Overall, Army procurement funding falls about $3 billion from FY12 to FY14—from about $9.5 billion to $6.4 billion. As history repeats itself, procurement will see tough times. Operations and maintenance should fare better: It’s always easier to slap on a fresh coat of paint and new tires to keep the wheels turning—and the wolves from the door. Research will be the middle child; it will probably only receive its due if it makes enough noise. Program performance will play a bigger role in RDT&E than the others. Projects that fail to hit their goals will not be carried along like some in the past. “Cut early and cut deep” will be the banner of the day.

That being said, during the past few budget downturns, U.S. military equipment had not been pushed to the limits as much as it has this go-around. The equipment has been used harder and longer than anticipated, meaning that it will take more time and money to bring the platforms back to meet future operational readiness.

To save some transportation money and earn some pocket change, it might also be a good idea to put a few “for sale” signs up on a couple (hundred! thousand?) MRAPs in Afghanistan before we pay to ship them back to the States. The retrograde from Afghanistan will be similar to Iraq in name only. The geography, politics and environment are all more significant factors than they were in Iraq—and there is an added expense that goes along with each of those factors. Fortunately, the drawdown is not a surprise, not without significant planning and certainly not without the review and study of lessons learned from Iraq.

Jeffrey D. McKaughaneditor-in-ChieF

EDITOR’S PERSPECTIVE

Publication of Record for the Military Logistics Community

EditorialEditor-In-ChiefJeff McKaughan [email protected] EditorHarrison Donnelly [email protected] Editorial ManagerLaura Davis [email protected] EditorsSean Carmichael [email protected] Hobbes [email protected] Baldwin • Christian Bourge Peter Buxbaum • Henry Canaday Cheryl Gerber • Hank Hogan • Marc Selinger Karen Thuermer

art & dEsignArt DirectorJennifer Owers [email protected] Graphic DesignerJittima Saiwongnuan [email protected] Designers Scott Morris [email protected] Papineau [email protected] Paquette [email protected] Waring [email protected]

advErtisingAssociate PublisherJane Engel [email protected]

KMi MEdia groupPublisherKirk Brown [email protected] Executive OfficerJack Kerrigan [email protected] Financial OfficerConstance Kerrigan [email protected] Vice PresidentDavid Leaf [email protected] McKaughan [email protected] Castro [email protected] & Communications ManagerHolly Winzler [email protected] AssistantCasandra Jones [email protected] Show CoordinatorHolly Foster [email protected]

opErations, CirCulation & produCtion

Operations AdministratorBob Lesser [email protected] & Marketing AdministratorDuane Ebanks [email protected] Gill [email protected] SpecialistsRaymer Villanueva [email protected] Walker [email protected]

a proud MEMbEr of:

subsCription inforMation

Military Logistics Forum ISSN 1937-9315

is published 10 times a year by KMI Media Group. All Rights Reserved.

Reproduction without permission is strictly forbidden. © Copyright 2013.

Military Logistics Forum is free to qualified members of the U.S. military, employees of the U.S. government and non-U.S. foreign service

based in the U.S. All others: $65 per year. Foreign: $149 per year.

CorporatE offiCEsKMI Media Group

15800 Crabbs Branch Way, Suite 300 Rockville, MD 20855-2604 USA

Telephone: (301) 670-5700 Fax: (301) 670-5701

Web: www.MLF-kmi.com

Military logistiCs foruM

Volume 7, Issue 4 • May 2013

www.GIF-kmi.com

Geospatial Intelligence

Forum

www.BCD-kmi.com

June 2012Volume 1, Issue 1

www.BCD-kmi.com

Border Threat Prevention and CBRNE Response

Border Protector

Michael J. Fisher

ChiefU.S. Border PatrolU.S. Customs and Border Protection

Wide Area Aerial Surveillance O Hazmat Disaster ResponseTactical Communications O P-3 Program

Integrated Fixed Towers

Leadership Insight:Robert S. BrayAssistant Administrator for Law EnforcementDirector of the Federal Air Marshal Service Transportation Security Administration

SPECIAL SECTION:

Border & CBRNE Defense

www.MAE-kmi.com

Military AdvancedEducation

www.MIT-kmi.com

Military Information Technology

www.GCT-kmi.com

Ground Combat

Technology

www.MLF-kmi.com

Military Logistics Forum

www.M2VA-kmi.com

Military Medical & Veterans

Affairs Forum

www.MT2-kmi.com

Military Training Technology

www.SOTECH-kmi.com

Special Operations Technology

www.TISR-kmi.com

Tactical ISR Technology

www.CGF-kmi.com

U.S. Coast Guard Forum

KMI MedIa Group LeadershIp MaGazInes and WebsItes

The Upmost in Reliability.

www.jlg.com877-JLG-LIFT

Product Inquiries: [email protected] Parts & Service: [email protected]

JLG’s broad range of access equipment delivers the high performance, effi ciency and support military and government sectors require. All products are backed by JLG’s comprehensive Ground Support services – offering the parts, training and service needed to uphold productivity. From facility upkeep to aircraft access and onboard ship maintenance, JLG designs, builds and supports the higher level of equipment project teams can rely on.

JLG is proud to provide fl exibleGSA and DLA programs to assistin the purchase of equipment.

JLG_MilLogForum_AtlasII.indd 1 10/22/12 3:17 PM

When you’re dealing with multi-million dollar, state-of-the-art military vehicles such as Navy submarines and Air Force fighters—or even inexpensive-by-comparison HMMWVs—the old adage of “if it ain’t broke, don’t fix it” does not apply.

In general, the U.S. military’s receptiveness to replacing/repairing components before they fail varies greatly from program to program. “Those programs that have embraced predictive maintenance are reaping significant cost avoidance savings—and some MRO contrac-tors are seeing this in reduced repair volumes,” said Dan Gonzales, StandardAero’s vice president of business development-U.S.

Predictive maintenance involves statistical algorithms. Often, the recommendations from predictive maintenance are counter-intuitive. Consequently, there is must be a degree of education to prospective predictive maintenance users and provide case studies to build their trust in predictive maintenance methods.

“Predictive maintenance allows us to confidently forecast the number of MRO arisings, reasons for removal, and material needs,” said Gonzales. “More importantly, it allows us to optimize workscopes to help achieve customer operating cost and reliability goals. We have demonstrated savings of many millions of dollars for our customers through predictive maintenance.”

As a business intelligence tool, predictive maintenance not only allows a company to accurately assess the size and timing of emerging MRO markets, but it also allows them to develop proactive solutions for emerging customer issues. “Our reliability engineering team is viewed as a critical company resource. Looking forward, StandardA-ero would not likely enter new engine MRO markets without first conducting a predictive maintenance assessment of the opportunity.”

StandardAero employs predictive maintenance techniques on many of the engines it repairs—and several types that it does not repair. “We have also developed predictive maintenance tools for entire aircraft,” said Gonzales. “To date, we have developed and validated predictive maintenance tools on over ten different engine types and two aircraft types. Frequently, operators of under-performing systems approach us to use our predictive maintenance tools to determine how reliability can be restored cost-effectively. In most cases, the corrective actions are not intuitive and surprisingly inexpensive.”

The company has found that both new and mature systems ben-efit from predictive maintenance. While mature systems tend to have more data available to support modeling efforts, StandardAero’s view is that large amounts of programmed money can be saved through the application of predictive maintenance early in a system’s life cycle.

There can never be too much information and history when it comes to this process. “We are fortunate in that our internal sys-tems collect an enormous amount of high-quality MRO data,” said Gonzales. “We also mine customer data sets and even collect data for customers.”

According to StandardAero, a typical project could involve over one million maintenance records. “By harnessing ‘big data’ we are

able to produce high-fidelity, validated predictive maintenance tools,” Gonzales added. “We have developed a whole range of software tools to help us develop and validate predictive maintenance tools. Some of our innovations are patented.”

To further their capabilities, StandardAero is looking at three areas.

“We are building on predictive maintenance methods to improve the accuracy of material forecasts,” said Gonzales. “We know that linear consumption models don’t produce satisfactory results. By accurately modeling the aging of components and systems, we are improving our material forecasts.”

“We are starting to develop methods to update predictive main-tenance tools with recent information about a system’s health,” he continued. “This creates many new possibilities that could change the way maintenance programs are designed and executed.”

“We are finding inexpensive ways to collect data,” he concluded. “For example, with the Royal Canadian Air Force and MacSema Ltd, we have developed a bolt-on, vibration-powered monitoring system. The system is entirely powered through energy harvesters and elimi-nates the need for wiring, making the addition of a monitoring system to a legacy engine much simpler.”

“Our military fleets require a well-planned schedule of mainte-nance, overhaul, repairs and upgrades,” said Susan Hebrank, market-ing services coordinator with CribMaster. “The Navy, for example, has a comprehensive life cycle maintenance plan for their submarines to ensure safe, reliable and mission-capable operations. Periodic mainte-nance and modernization begins immediately after construction and continues throughout the life of every vessel. On-time completion of these and other maintenance-type tasks plays an important role in being mission-ready.”

In other words, military mechanics can’t wait around for some-thing to malfunction; they’re charged with fixing things before they’re broken. And while it’s impossible to always accurately predict mechan-ical futures, the advent of certain predictive maintenance technologies makes the task much more feasible.

According to Hebrank, the company’s software contains a suite “of features that can be used to organize and assign scheduled main-tenance tasks that need to be done.” That’s oversimplifying things, of course. In addition to functionality for scheduling work, logging labor, forecasting cost and pre-ordering materials for upcoming jobs, the robust package has tools that allow users to track asset downtime, manage repair records, follow inventory status and more.

“It also stores repair and purchase records as they relate to each asset being maintained, including tools, time and any materials used,” added Hebrank. “Plus, work orders can be scheduled to run at regular intervals or set up ad hoc to support unplanned jobs.”

In all, the CribMaster preventive maintenance module can provide more than 190 standard upkeep-related reports to help create seam-less timetables for essential routine service.

Planning ahead now includes better forecasting of equiPment failure.by J.b. bissell, mlf corresPondent

www.MLF-kmi.com4 | MLF 7.4

That routine begins with mechanics and their teams inputting all the vital information about what each vehicle needs and when it needs it. “Work orders are created using a template that is composed of tasks and the spare parts and inventory required to perform those tasks,” said Hebrank. Once this is completed, the software takes over predicting future routine maintenance needs.

“The system automatically monitors all preventive maintenance schedules for each asset in the fleet, and provides easy access to all historical data related to repair records,” continued Hebrank. “It ensures that there is reserved inventory available based on upcoming work orders, and the predictive ordering feature ensures arrival of the inventory prior to the work to be done. Finally, work orders may be scheduled against one or multiple assets.”

Ultimately, staying a few steps ahead of the maintenance needs of one or multiple assets not only keeps military vehicles mission ready, but it also helps reduce emergency repair costs. “Whether it’s a tanker or a submarine, the goal is simple: Get it returned to the fleet as quickly and efficiently as possible,” Hebrank said. “CribMaster’s Inven-tory Management Solutions, including the preventive maintenance module, streamlines the management of these processes to save time and money.”

Part of getting a tanker or submarine back to the fleet as quickly as possible, though, is maintaining an efficient work cycle while it’s actu-ally in the shop, and as much recording and tracking and predicting as CribMaster’s software does before the real work begins, it’s just as helpful—maybe more so—once the tangible labor starts.

“When paired with secure point-of-use inventory dispensing devices that utilize advanced technologies and CribMaster inventory management software, the system reduces unproductive time search-ing for tools, ensures optimum inventory levels and increases user accountability,” Hebrank explained.

“Transactions are recorded in real time for increased visibility, and the workflow process is streamlined by eliminating the walk-and-wait time to get project materials from the tool storage area. Additionally, authorized users have 24/7 access to inventory to complete the task at hand, which greatly reduces work stoppage.”

This, coupled with the system’s ability to manage work order instructions, PPE, MRO or any other type of indirect material, along with the wide range of critical data displays, creates a nearly automated process throughout which authorized users can easily locate the prod-uct, part or tool they need without hindering the overall workflow.

Keeping track of tools not only is important for maintaining an efficient workflow, it’s a crucial piece of operational safety.

Enter CribMaster’s tool tracking package. It’s a complementary piece of the inventory management software that uses RFID technol-ogy and secure dispensing devices to monitor tools as they go in and out of their cabinets—and move throughout an entire maintenance facility.

“Anytime an authorized user removes a tool from the cabinet, an ‘Items Out’ icon appears on the touchscreen,” explained Hebrank. “Pressing this button will display critical information—such as the items missing, the person that removed it, the time it was removed, where the mechanic is working, and more—directly on the screen. A running history of the tool is kept, and when something is missing, the search to find it is drastically reduced.” O

WHEN PEACE OF MIND IS AN ABSOLUTE REQUIREMENT

MANAGING YOUR MATERIALS

CribMaster, the complete solution.visit www.cribmaster.com/missionreadyor call us at 1.888.419.1399 for more details

For more information, contact Editor-in-Chief Jeff McKaughan at [email protected] or search our online archives for related stories

at www.mlf-kmi.com.

www.MLF-kmi.com6 | MLF 7.4

Mine resistant ambush protected (MRAP) vehicles were deployed fast to meet critical needs and successfully upgraded and maintained in the field under difficult conditions. With the Iraq war over and the U.S. part of the Afghanistan conflict ending, some of these highly special-ized vehicles will be scrapped, some pre-positioned abroad, some sold, some used for training and some stored at U.S. depots.

mraP life cycle shifts toward organic management by the services.

by henry canaday

mlf corresPondent

Special Section: Life Cycle Management

Long Live the MRAP

www.MLF-kmi.com MLF 7.4 | 7

Major sustainment decisions still need to be made. How many MRAPs will be retained, and in what configurations? How will their life cycle be managed and what role, if any, will private firms play in life cycle management of MRAPs? These deci-sions will be made under severe budget stress. And they will increasingly be made by the services—chiefly the Army and Marines—that operate MRAPs.

“The MRAP family of vehicles continues to make tremendous, life-saving contribu-tions across the joint force,” emphasized Michael Clow, spokesman for the Program Executive Office Combat Support & Combat Service Support. Since the program’s incep-tion, the joint program office (JPO) has fielded over 27,000 MRAPs to the services, regularly upgrading them based on threat changes and testing data.

On October 1, 2012, the MRAP pro-gram entered a one-year transition phase designed to identify enduring, service-spe-cific requirements and to transition pro-gram responsibilities and oversight from the JPO to the services that operate MRAPs. “As part of assuming responsibilities for specific variants and configurations, indi-vidual services are evaluating requirements and implementing appropriate sustainment plans,” Clow said. “For the Army, MRAP family vehicles may support a range of future mission requirements and will be integrated into Army units for convoy pro-tection, network integration and training activities, as well as for Army pre-positioned stocks.” Clow said standardized configura-tions of MRAP vehicles in the Army force structure and sustainment processes should enable more regular sustainment planning and execution.

Clow said the major challenges the Army faces at present are sustaining ongo-ing support to warfighter requirements while ensuring the smooth transition of enduring program functions to the Army and other services. “This includes mov-ing sustainment activities from existing contractor support to a pure organic main-tenance and depot repair and overhaul sus-tainment structure, consistent with Army practices and available funding.”

The Marine Corps has developed a life cycle sustainment plan to manage and maintain its enduring requirement of MRAPs, which includes a mix of Cougars, M-ATVs and Buffalo variants. Jerrilee de

Geus, deputy product manager for MRAP logistics at Marine Corps Systems Com-mand, said the approved requirement for the foreseeable future includes 401 Cougar CAT Is, 24 Cat I Cougar TOWs, 273 Cat II Cougars, 15 Cat II Cougar ambulances, 28 Cat III Buffalos and 490 M-ATVs.

“The Marine Corps is working right now on selecting the best vehicles to meet the enduring requirement, divesting excess MRAPs and determining the best level of preservation, while maintaining stored vehicles in a high readiness state,” de Geus explained. “The Marine Corps is also working diligently on the coordination of vehicle retrogrades, the closure of JPO MRAP repair sites in theater, and the reuti-lization of tools and equipment procured and required to support the urgent MRAP requirement.” To date, the JPO has pro-vided contractor logistics support (CLS) for maintenance and repairs, both in theater and in the United States, for all services. De Geus said that during the first two years of transition from JPO to service-led life cycle management, the Marine Corps will continue to use CLS support. She reported that the Marine Corps has performed a performance-based logistics (PBL) analysis to determine the best way forward for the best value. The result is a hybrid strategy that will become fully organic by fiscal year 2016.

It looks like both the Army and Marines will shift toward organic life cycle manage-ment. But private firms have played a vital role in MRAP sustainment to date. Several are eager to help where they can with future MRAP life cycle management.

Navistar makes the Maxx-Pro MRAP family, including the lighter MaxxPro Dash and the MaxxPro wrecker. Judy Boeding, director of logistics, operations and ful-fillment at Navistar, believes that the government and industry will look at improv-ing life cycle planning for the MRAP fleet by focusing on upgrading vehicles with enhanced capabilities and streamlining configurations. “Having fewer, more capable configurations will result in lower life cycle costs in many areas, includ-ing facilities, part supply, retrogrades, and even routine and preventative maintenance

as maintainers become intimately familiar with fewer configurations.”

Boeding noted that PBL contracts could provide the government with fixed, steady-state costs that would enable it to forecast budgets more accurately. In addition to providing services such as parts and routine maintenance, PBL allows the government to upgrade capability and performance, overhaul major assemblies or reset fleets, all without spikes in spending when enhance-ments occur. “The customer could select from many services and determine where their sweet spot is to enhance the effective-ness of both operational readiness and cost.”

Boeding stressed that Navistar is ready to do whatever it takes to support U.S. and allied militaries with field service represen-tatives (FSRs), capability insertions, resets, supply support and stock optimization. “Our FSRs are bumper-to-bumper subject matter experts who work with military per-sonnel to ensure high levels of operational readiness,” Boeding said. “We have instruc-tors who ensure military personnel have the proper training and knowledge to operate and maintain vehicles.” Navistar also pro-vides expertise for mechanics, welders and engineers.

In addition to helping with routine maintenance and repairs, Navistar staff can assess battle damage to determine whether a vehicle should be repaired, reset or decom-missioned. Boeding said Navistar FSRs per-form upgrades and capability insertions, and the company offers products such as truck-in-a-box and knockdown kits, which

can be assembled in the field. In addition to direct support, Navistar has a dedicated mili-tary dealer network that sup-ports the Defense Logistics Agency (DLA) and local mili-tary bases.

“To further enhance operational readiness with supply support, we have a Defense Distribution Cen-ter dedicated to our military customers,” Boeding noted.

“This is in addition to our nine commer-cial parts distribution centers.” Navistar recently partnered with the DLA, signing a strategic supplier alliance that elevates its relationship from that of a customer and supplier to a strategic partnership with DLA.

Special Section: Life Cycle Management

Judy Boeding

www.MLF-kmi.com8 | MLF 7.4

“We will be in Afghanistan to support our warfighters as long as there is a require-ment,” Boeding stressed. Navistar will con-tinue to be on the ground in 26 countries to support its products, all 34,000 of them.

“Forward support of vehicles and for-ward storage of spare parts improves the efficiency of MRO operations and ensures the military gets their vehicles back faster,” she said.

DynCorp’s primary role in MRAP life cycle management is repair and mainte-nance of vehicles. Its FSRs in the U.S. and abroad offer a global presence, providing the critical support needed to keep vehicles functioning at high mission-capable rates, explained Communications Vice President Ashley Burke. “Our FSRs have been trained and know how to work on the dozens of variants currently being fielded by the U.S. military and our allies,” Burke emphasized. “Our support stretches from CONUS Army and Air Force bases and U.S. maintenance depots to the front lines of ongoing overseas military operations.”

Burke sees the biggest challenges in MRAP support in maintenance and logis-tics issues associated with having so many MRAP variants, plus the transition of the MRAP fleet from the JPO to the service branches, scheduled for late 2013. “These challenges, in conjunction with decisions on the drawdown in Southwest Asia and what to do with more than 20,000 vehicles, will need to be resolved before we can effectively plan a long-term MRAP life cycle strategy.”

DynCorp believes that, given the urgent need for MRAPs, both government and industry did an excellent job in producing, fielding and maintaining the vehicles. For the long term, the company argues that suc-cessful life cycle management will require articulating a clearly defined end-state “in which all parties have a clear understanding of their roles and responsibilities,” Burke said. “Obviously, current events can reshape that end state almost overnight. Continual coordination and communication between the parties will help ensure that MRAPs are ready to support warfighter missions any-where, anytime, for years to come.”

PBLs could meet performance goals for a weapon system like MRAPs through a support structure based on long-term performance agreements with clear lines of authority and responsibility. “This strategy

takes into account everything from variant locations and availability of repair parts, to the associated footprint of the weapon sys-tem itself,” Burke said. “Trade-off decisions are based on cost, useful service life and the effectiveness of the individual system.” DynCorp thinks the military services may initiate a PBL-like strategy for MRAP sup-port when the challenges and necessary decisions come into clearer focus.

For the U.S., BAE Systems produced the RG31 and RG33 families of MRAPs. It makes three MRAPs operated by the U.S. Marine Corps, the Caiman, RG31 and the RG33. BAE has a long, rich history of build-ing and providing maintenance support for MRAP vehicle programs, noted spokesper-son Shannon Booker. “We will continue to work with our customers as they determine the life cycle management needs for the MRAP variants.”

Oskosh Defense manu-factures the MRAP all-terrain vehicle (M-ATV). The M-ATV contract was awarded on June 30, 2009, and Oshkosh ramped up production to more than 1,000 vehicles per month by the end of 2009, recalled John Bryant, senior vice president of defense pro-grams at Oshkosh.

“In concert with this accelerated delivery timeline, warfighters in the field needed life cycle support that could be delivered as rapidly as the vehicles, which began arriving in Afghanistan only three months after contract award,” Bryant said. “Oshkosh was there to provide those capabilities.”

Support included delivering training materials, which are typically developed in 18 to 24 months, within one month. Osh-kosh staff members were also in theater as vehicles arrived to provide expert training for vehicle operators and mechanics. “Addi-tionally, we supplied hundreds of authorized stockage list and prescribed load list part kits in tandem with the vehicles,” Bryant noted.

Oshkosh has continued to support M-ATVs in theater. It worked with the military to design and deliver underbody improvement kits (UIK) to enhance the M-ATV protection capabilities in response to evolving threats in theater. More than 5,000 UIKs were installed on M-ATVs in-theater.

The company is also prepared to sup-port the vehicles as they return home. Many returning M-ATVs have been modified, either to counter evolving threats or for specific uses. Bryant said Oshkosh can help the mili-tary bring these differently modified vehicles into a common configuration to improve supportability over the long term.

“Oshkosh could also work with Army and Marine Corps depots to reset the returning M-ATVs,” Bryant said. “Resetting vehicles would help insert M-ATVs into the mainte-nance structure of the military at home and optimize the life cycle cost of the vehicles.” Oshkosh has extensive experience with vehi-cle reset and recapitalization, having mod-ernized more than 11,000 vehicles for the U.S. military in the last 15 years.

“As the U.S. military transitions por-tions of its MRAP fleet to its core force

structure focused on a new strategy, long term life cycle plans will need to be adjusted to optimize support,” Bryant said. “Oshkosh stands ready with the systems, processes and experience to optimize life cycle support.”

Bryant said Oshkosh experience stretches over the complete range of life cycle support, both for its own tac-tical wheeled vehicles and for

those produced by other manufacturers. He said Oshkosh has delivered cost-saving solu-tions to military customers from procure-ment stage through life cycle.

Due to tighter budgets, force restruc-turing and tens of thousands of returning vehicles, Bryant argues the military could consider a PBL approach to MRAP fleet sustainment. PBL contracts allow the mili-tary to define outcomes, such as readiness or availability, and then measure the costs of reaching them. If the military uses PBLs to sustain MRAPs, Oshkosh would ensure objectives and deliver best-value sustain-ment. “Given current fiscal challenges, a PBL approach could significantly reduce govern-ment infrastructure and process demands and shift costs and risks on industry instead,” Bryant said. O

For more information, contact Editor-in-Chief Jeff McKaughan at [email protected] or search our online archives for related stories

at www.mlf-kmi.com.

Special Section: Life Cycle Management

John Bryant

www.MLF-kmi.com MLF 7.4 | 9

The main thrust of the Army Materiel Command’s public-private partnerships (PPPs) is to support the overhaul Army equip-ment. Together with an industrial partner, the work is divided among the two, providing advantages to each. But AMC’s partner-ship program goes beyond that. Army industrial sites are actually put to use to perform subcontracting work to civilian companies making civilian products.

That may sound like it has nothing to do with military logistics, but there is a connection. AMC officials point out that this civilian subcontracting work keeps the organic Army industrial workforce busy and trained in skills similar to what they use for their military work. It also defrays AMC overhead and reduces marginal labor costs, allowing AMC to control prices it charges to its military customers. These advantages, along with others, underlie the AMC partnership program, which, as noted, typically is involved in pro-viding goods and services for military, and not civilian, purposes.

AMC defines a public-private partnership as an “agreement between an Army facility and one or more private industry to per-form work or utilize the Army’s facilities and equipment.” This can take many different contract forms, including performance-based logistics (PBL) contracts, which are properly thought of as quasi-partnerships. Now that the wars in southwest Asia are over or wind-ing down, Army industrial site workloads are declining and AMC is making a big push to sustain and grow its partnership program.

“The mission of the AMC Partnership Program is to improve capabilities and performance of AMC’s industrial sites through cooperation between the public and private sectors,” said James Dwyer, deputy chief of staff for logistics at the Army Materiel Com-mand. “There are a number of benefits to partnering with AMC, including gaining access to advanced technology industrial equip-ment. We have invested $1.3 billion in our industrial sites in the last decade.” Other advantages cited by Dwyer include the use of hard-to-receive hazardous waste permits, decreased capital investment cost for the industry partner, and access to a trained and competent workforce.

“In most instances, today’s public-private partnerships are limited to defense depot-level maintenance and repair activities,” noted Daniel Cernoch, senior manager for logistics and sustainment at Lockheed Martin Corporation, “yet there is significant room to expand this model to assume additional responsibilities.”

Both the Army and its industrial partners have goals and objectives that they seek to derive from their partnerships. “For the Army, it helps us improve operational efficiency,” said Dwyer. “The more work we get, the more we can defray our overhead costs so our rates go down. This lowers the costs for products we produce for soldiers. We also learn best business practices from industry partners, which helps us to be more innovative in the future.”

In the case of most PPPs, a facility of the Army organic industrial base produces products or provides services that are sold to a company that has a defense contract. In other words, the Army facility acts as a contractor to the prime defense contractor. AMC runs 20 industrial facilities around the country, including depots, arsenals, and ammuni-tion plants and centers. These facilities have capabilities in overhaul and remanufacturing, engineering and fabrication, heavy and light machining, and heat treatments and finishes, among other things.

“As part of an integrated product support strategy, we believe we can reduce risk and create an agile, highly effective defense logistics operation through a partnership that incentivizes performance and leverages industry’s strengths in inventory management, supply chain execution and new technology implementation,” said Cernoch. “The public-private partnership model can reduce the government’s long-term costs of support by enabling industry to reduce product support capacity investments, such as labor, plants and equipment resulting in improved operating efficiencies for industry by using a government partner’s capacity. The government’s benefit is improved capacity utilization. Investing in or leveraging a partner’s capabilities makes good business sense both for the government and its industry partner.”

The first legislation allowing the military to enter into PPPs was the Federal Technology Transfer Act of 1986, which allowed federal laboratories to enter into cooperative research and development

The Three “P”sPublic-Private PartnershiPs create a direct link between industry best Practices and government requirements.by Peter buxbaum, mlf corresPondent

www.MLF-kmi.com10 | MLF 7.4

agreements with private companies and academic institutions. A 1993 law allowed Army facilities to sell manufactured articles to or perform services for entities outside of DoD under certain conditions. The first contract under that provision came in 1996. In 2000, Congress directed the Army to conduct a demonstration program that would “encourage commercial firms, to the maximum extent practicable, to use these Army arsenals for commercial purposes.” Full-blown authorization to engage in those types of partnerships came in 2005.

“We are not restricted to partnering with defense firms,” noted Dwyer. “At the Rock Island Armory in Nevada, they make products for Caterpillar that go into their bulldozers. They also make castings that are used by steel and aluminum companies.”

“Two basic contract vehicles are used to document partnership agreements: direct sales and work share, which is also known as team-ing,” said Cernoch. “The primary difference between these methods is how payments flow to the government in its role as public partner and the impact these different contracting arrangements can have on government and industry’s ability to establish an effective working relationship as partners.”

In a direct sales agreement, the private partner pays the public part-ner for work that is performed. With a work share contract, the public partner is paid by the government program office for work performed. Cernoch believes that direct sales agreements foster the proper level of accountability on behalf of both parties.

Among AMC’s public-private part-nerships is an arrangement with Gen-eral Dynamics for the overhaul of the M1 tank. “The tank goes to Anniston [Army Depot in Alabama], we take it apart, clean it up, do the repair on some of the secondary items,” said Dwyer. “Then we ship the parts to General Dynamics in Lima, Ohio, where they reassemble the tank and upgrade the technology.”

A similar arrangement prevails with BAE Systems for the overhaul of the Bradley fighting vehicle. In this case, the Army does the pre-liminary work at Red River Army Depot in Texarkana, Texas, before the vehicle is send to a BAE plant near York, Pa. “In this case, Red River is a subcontractor to BAE,” noted Dwyer.

AMC has partnerships with Honeywell International for the over-haul of the M1 Abrams engine at Anniston and for the T55 engine which is used on the Chinook heavy-lift transport helicopter. “In the case of the M1 engine, we turn the wrenches and they provide the parts,” said Dwyer. “We turn out an engine of much higher quality than before the contract started.”

In the case of the T55 engine, Honeywell provides engineering services and parts supply to the Corpus Christi Army Depot while Army workers do the repairs. The engine is disassembled and the parts are cleaned, repaired and routed back to the assembly shop. Once the engine is reassembled it is sent for testing before being returned back to assembly where they are packed into engine containers for final sale.

Over 500 T-55 engines have been overhauled under this program at CCAD. The updated engines have the abilities to better withstand harsh weather conditions.

Honeywell advocates the use of more performance-based logistics contracts with the military that take an enterprise approach, accord-ing to company spokesperson Nathan Drevna. PBLs usually involve

long-term logistics support contracts that were based on incentives to achieve specific performance goals.

“Honeywell stands ready to support the next generation of PBL programs that implement effective commercial sustainment strategies focused on common components used by multiple services under one contract,” he said.

Drevna said that PBLs should be long-term contracts of 10 years or more, be focused on warfighter-defined outcomes, and use a fixed price plus incentive fee contract based on defined performance metrics. “Contractors should be incentivized to invest in reliability, process and other improvements,” he added. “Contractors should address obsoles-cence challenges during contract period. Accelerating the award of PBL contracts under these tenets will generate significant savings, providing a best value sustainment solution for the government while supporting DoD’s austerity efforts.”

Some of Lockheed Martin’s military partnerships also involve PBLs. “An example of this is the collaborative partnership we have with Hill Air Force Base for maintenance of the F-22 Raptor fighter,” said Cer-noch. “This public-private partnership received a Secretary of Defense PBL award for innovative practices that drove 15 percent improved mis-sion rates and reduced repair times by 20 percent. We are proving that these partnerships, when effectively managed, pay dividends both in cost savings and higher levels of readiness for our government’s forces.”

Lockheed Martin’s contract with the Defense Logistics Agency Defense Supply Center-Philadelphia is an example where a PPP rela-tionship can be expanded, according to Cernoch. “This end-to-end supply chain management program leverages best-in-class commercial market practices for inventory forecasting and management and cost-effective parts availability for a stock-bin fill rate of 97.1 percent,” he said.

In 2008, DoD established an Industrial Integration Integrated Prod-uct Team (IPT) to improve utilization of public and private industrial capacity. “The IPT and other government-industry working groups are focused on PPP implementation, business case analysis and metrics,” said Cernoch. “Lockheed Martin has contributed ideas and other support to this work. These teams will help define and refine DoD’s guidance so there is a more consistent interpretation of the law as it applies to public-private partnerships. We expect this to improve the collaborative process between industry and its government partners. Partnerships that incentivize performance and leverage industry’s strengths in inventory management, supply chain execution and new technology implementation will reduce risk while fostering agile and highly effective defense logistics operations.”

As for AMC, “we are looking to grow the number of partnerships geometrically,” said Dwyer. “Our workload is declining because the wars are coming to an end, and we have fixed costs and overhead just like everybody else in business.” In fact, an AMC document shows that while the number of its partners has grown from 430 in 2008 to 481 in 2012, its revenues from partnerships have dropped from over $700 million to $200 million in the same period.

“We would like to double or triple our partnerships over the next four years,” said Dwyer. “If business is declining for us it is probably also declining in the civilian sector. We think we can combine to make it a win-win. They can do some work for us and we can do some work for them.” O

For more information, contact Editor-in-Chief Jeff McKaughan at [email protected] or search our online archives for related stories

at www.mlf-kmi.com.

James dwyer

www.MLF-kmi.com MLF 7.4 | 11

Technology providers have developed innovative ways of delivering maintenance and repair to extend the lives of installed fleets and postpone the need to buy entirely new systems. Whether it’s a new service offering, a component swap out, an extended warranty or an upgrade, the goal is to achieve maximum return on investment.

Most suppliers of military computer sys-tems establish a contract with Tobyhanna Army Depot (TYAD), the largest full service electronics maintenance and repair facility in DoD. Dell, DRS, Getac and Panasonic all have contracts with TYAD to maintain and repair their systems, including parts, repair and refurbishment, in theater.

However, for nonvolatile military situ-ations, technology providers are now offer-ing the option to issue return merchandise authorizations (RMAs) through novel and expanded service offerings, making the deci-sion to sustain existing systems easier.

One of the most pioneering initiatives is the recently formed partnership between Getac and Federal Express TechConnect. Another, just launched in April, is Dell’s Pro Support Plus Enterprise Class Service. Pana-sonic and DRS have shaped their approaches to maintenance and repair in other ways to accommodate requests to maintain existing systems rather than buying new ones.

Leveraging its record of reliability in commercial logistics, FedEx TechConnect began in September 2012 to manage the warranty service for Getac’s rugged note-book and tablet PCs. Getac provided onsite training to TechConnect technicians and certified them to perform repairs on Getac’s systems using a 70-point inspection method.

Getac is the first OEM to partner with TechConnect for the repair, refurbishment and delivery logistics of Getac systems. The FedEx TechConnect service is open to all Getac customers, including the Air Force in Germany, which contains a FedEx location.

“FedEx could not rely on hardware manufacturers with their slow turnaround time so they set up their own technology repair and maintenance system internally. It’s located at the end of the runway at their main hub in Memphis for overnight delivery of repairs,” said Jim Rimay, president of Getac.

The repair and shipping ticket are one and the same. “They embedded the repair ticket in their track package system,” he noted.

“It was challenging for us to get parts so we got in the OEMs’ sandbox where, here-tofore, they alone have owned service and support,” said Tod Taylor, managing director of sales and marketing, FedEx TechConnect. “We have always been an early adopter of technology. We put as much emphasis on information flows as physical flows,” he said. “To facilitate the RMAs at our repair service center, we use our transportation network to get them in and out within 24 to 48 hours,” he said.

While Getac still runs the call center, TechConnect launched the web portal last year and has continued to build it out. “We’re in the process of implementing the full portfolio of our service offering with chat, email, text, video conferencing and whatever they want to do,” said Taylor.

Dell’s Pro Support Plus Enterprise Class Service offers robust reporting, technical

account management, senior engineers available for resolution and proactive main-tenance. “We’ll monitor the environment with alerts in advance, then dispatch the labor and fix it before you knew it was bro-ken,” said Marco Martinez, services market-ing manager, Dell Public.

Dell also trains and authorizes personnel to certify systems in Dell’s Tech Direct repair and maintenance program, which also offers basic repair/replace service with 10/5 sup-port or pro with 24/7 support. Accidental damage is an optional overlay. “We now put Dell Sky technicians on planes for mission critical warranties and next business day response,” added Martinez.

Panasonic experienced the same con-cerns as FedEx when trying to obtain parts from manufacturers to extend the lifetime of systems. “We are stocking parts beyond seven years from the end of the manufac-turing date because many manufacturers don’t have the part to do the repair,” said Kyp Walls, director product management, Panasonic North America.

DRS approaches maintenance and repair with a focus on future proofing, active upgrading and persistent training. As the sole provider of the FBCB2 (Force Battle Command Brigade and Below-Army) or Blue Force Tracking (Marines) ultra rugged, JV-5 systems, mounted in military vehicles and helicopters, DRS builds for specific mis-sion critical situations. The vehicle comput-ing and display systems contain expansion capability to allow for future technology improvements. “The systems are purpose-built for specific missions. We design them to fit the exact needs of the environment

what is the life cycle of a desktoP or laPtoP comPuter and where is the tiPPing Point between rePair or rePlace?

by cheryl gerber

mlf corresPondent

Maximizing the IT Investment

www.MLF-kmi.com12 | MLF 7.4

For more information, contact Editor-in-Chief Jeff McKaughan at [email protected] or search our online archives for related stories

at www.mlf-kmi.com.

they are going into,” noted Bill Guyan. DRS, vice president of strategy.

To maintain and repair these systems in theater, DRS is engaged in persistent train-ing. “We work closely with Tobyhanna to be sure that their U.S.-based and deployed service teams are trained to conduct system repairs and upgrades whenever and wherever they may be required,” said Guyan.

With an awareness of life cycle cost, DRS designs systems to allow for the insertion of capability upgrades and expansion. “Upgrad-able system designs can permit significant expansion of the serviceable life of a system, limit the variation in fielded fleets and permit the refresh of a fleet of systems for a fraction of the cost associated with fleetwide replace-ments,” he said.

In recent years DRS has been upgrading the Army’s Movement Tracking System MRT tablet computer fleet of about 25,000 systems to enable interoperability with a new high capacity BFT-2 SATCOM system. DRS also has been upgrading the U.K. Army’s Bowman fleet of 13,000 rugged data terminals from Pentium III to Core 2 duo processor. “Each of these upgrades avoided the need to procure new replacement computers and has pro-vided savings to our customers,” said Guyan.

The majority of maintenance and repairs seems to consist of hard drives, screens and cases. “Hard drives are the one item that is most likely to fail, the very thing you don’t want to fail—your data,” said Walls.

Rugged laptops and tablets can be exposed to extreme temperatures and vola-tile, unpredictable battlefield situations. In the event of a failure, hard drives can default to their replicated, partitioned data or spare drives can be swapped in. “We store a golden image of the system configuration, replicated and partitioned in the same hard drive with a restore/recovery image,” said Rimay. “We run a utility to restore it with a copy if the disk image has been corrupted.”

A partition separates a section of a physi-cal disk into another virtual device, creating two partitions the operating system treats as a different drive letter, although both are physically located on the same drive.

Just as a spare tire can prevent lost time in travel, so can a spare hard drive prevent lost data in transit. “We recommend that our customers keep pre-imaged spare hard drives on site. If they don’t, we overnight a replacement from one of our 170 worldwide distribution centers,” said Martinez.

When hard drives are damaged, they often just get replaced, like cases and screens.

Although hard disk drives (HDD) have been standard in many systems, solid state drives (SSD) have been displacing HDDs in recent years, to the point where most technology providers now offer both. SSD are faster, lighter and consume less power than HDD. They can be more resistant to shock and vibration, since there are no moving parts in them. Still, several issues with SSDs have stalled their full adoption. SSDs have less capacity and are more expensive than HDDs. Encryption with an HDD is easier than an SSD. HDDs can overwrite encrypted data on top of old data, while data in an SSD must be erased first a with a “secure erase” feature or have total partition encryption.

“Solid state drives are not guaranteed to survive rugged conditions. They have an issue with low temperatures. For both SSD and HDD, we use hard drive heaters on fully rugged laptops to preheat the drives to pre-vent damage to the drive itself so they don’t have an issue with data corruption. If you try to turn on the drive when it’s frozen, you’ll damage the drive,” said Walls. “We make the hard drives removable so the user can lock them up at night or swap them out.”

Once a case cracks, the technology it held together is exposed and there is no choice but to replace it. Consequently, rug-ged laptop and tablet providers pay extra attention to case design. “We use aircraft-grade lightweight aluminum to provide rug-ged housing that will not crack in cold weather, like magnesium housings found in industrial solutions can,” said Guyan.

Panasonic uses a combination of materi-als depending on the degree of ruggedness required. “We use magnesium alloy cases on our rugged and semi-rugged laptops. It’s 20 times stronger than the ABS plastic used in consumer electronics and five times stron-ger than titanium. But it’s difficult to mold and must be molded under high pressure, so it’s used sparingly,” noted Walls.

The reliability of touchscreens has improved in recent years with chemically-strengthened and/or Gorilla glass. But touchscreens also now carry additional lay-ers of functionality. “If you crack a screen on your laptop, there are other electronics in that screen, like wireless antennas and touchpads, that have added a level of com-plexity to computing,” said Walls.

“We include not only a touch layer on top of the LCD but also a digital layer called a digitizer so you can do note taking, annotations and signature capture. More than the common, fat-tipped stylus, we give

the customer a pointed pen that makes it feel like they are writing with a real pen on paper,” he said. Digitizer screens are an optional upgrade in the Toughbook series.

The increased complexity of touch-screens carries additional risk. “The dif-ficulty of repair hasn’t changed with the increased complexity. But screen failure rate is higher now that they are more prone to failure with more components in them,” he said.

Customer usage also greatly impacts the rate of repair and maintenance. Technology providers sometimes see customers using systems in ways they weren’t meant to be used. A commercial-grade laptop cannot hold up to rugged conditions, for instance. “The acquisition cost perspective can be short-sighted when the reliability and lon-gevity won’t be there in extreme conditions you can’t always predict,” said Walls.

Toughbooks were made and tested for 6-foot drops, although they can sometimes take more than that. “They weren’t made for 12- to 18-foot drops repeatedly over the course of months if people are literally throwing the equipment around. Service people recognize that technology is sensi-tive, but they don’t always have the option to treat systems with sensitivity,” he said.

Rugged computers can outlast their war-ranties if they aren’t subjected to repeated impact that exceeds their tested parameters. “Many of our customers have the ‘if it ain’t broke, don’t fix it’ mentality, so they have no reason to rush out and buy the latest tech-nology every three to five years when it goes off warranty. Even out of warranty, Tough-book failures are still pretty low,” he said.

Dell sees customers max out their three to five year warranties, purchase one or two year extensions then max out the extensions. Specific technologies drive the choice to buy new technology and stop maintaining existing systems. “The iPad changed the game—and not the functionality as much as the expectation in how I do my job,” said Martinez. “There’s a touch capability entitle-ment, an ingrained expectation of having a touchpad on a computing system now,” he said. Mobile touchscreen technology seems to be one point at which customers choose to stop maintaining their existing systems and start to buy new ones. O

www.MLF-kmi.com MLF 7.4 | 13

Effectiveness Deliverer

Lt. Gen. Bruce A. Litchfield

CommanderAir Force Sustainment Center

Air ForCE SuStAinmEnt CEntEr

2013

Lieutenant General Bruce A. Litchfield is commander of the Air Force Sustainment Center (AFSC), Air Force Materiel Command (AFMC), Tinker Air Force Base, Okla. As AFSC com-mander, he ensures the center provides operational planning and execution of Air Force supply chain management and depot maintenance for a wide range of aircraft, engines, missiles and component items in support of AFMC missions. He is respon-sible for operations which span three air logistics complexes, three air base wings, two supply chain management wings and multiple remote operating locations, and incorporating more than 32,000 military and civilian personnel. In addition, he oversees installation support to more than 75,000 personnel working in 140 associate units at the three AFSC bases.

Litchfield entered the Air Force in 1981 as a distinguished graduate from the ROTC program at Norwich University, Vt. His career spans diverse logistics and acquisition assignments supporting weapon systems at wing, major command, Air Staff and the Joint Staff levels. He has commanded squadron and group levels in addition to commanding two wings and was the director of logistics, Headquarters Pacific Air Forces, Hickam AFB, Hawaii. Prior to his current assignment, he was the com-mander, Oklahoma City Air Logistics Center, Tinker AFB.

Litchfield earned a Bachelor of Science degree in electrical engineering from Norwich University, and a Master of Science degree in administration, Georgia College in 1983. He attended the Squadron Officer School, Maxwell AFB, Ala., in 1985 and the Program Management Course, Defense Systems Manage-ment College, Fort Belvoir, Va., in 1992. In 1995 he was a dis-tinguished graduate, Master of Arts degree in national strategy, at the Naval Command and Staff College, Naval War College, Newport, R.I. He attended the Air War College, Maxwell AFB, in 1998. In 2004, he attended the National Security Management Course, Syracuse University, N.Y., and in 2009 the Program for Senior Managers in Government, John F. Kennedy School of Government, Harvard University, Cambridge, Mass.

Litchfield’s major awards and decorations include: the Legion of Merit with two oak leaf clusters; the Defense

Meritorious Service Medal; the Meritorious Service Medal with four oak leaf clusters; the Air Force Commendation Medal; and the Air Force Achievement Medal.

Q: The Air Force Sustainment Center has had operational time under its belt. Is the center performing the mission as expected?

A: I’d like to make an unequivocal statement. We operated better on day one under the new sustainment center construct than we did under the previous construct, so I’m very pleased with how things are going and how we’re executing our mission. If you look at what the Air Force expects of us, I believe they want two things—they want effective delivery of readiness and they want it in an efficient manner. I call that cost-effective readiness.

In order to do that, there are two things that we have to get right in the sustainment center: that’s our ability to plan, and then our ability to execute that plan. We’ve gone to great extent to improve our planning process, the integration between our supply chain and the maintenance operations, and to get a high-confidence plan that we can execute.

Lieutenant GeneralBruce A. Litchfield

CommanderAir Force Sustainment Center

Effectiveness DelivererDelivering Daily Cost Effective Readiness to the Air Force

Q&AQ&A

www.MLF-kmi.com Air Force Sustainment Center | MLF 7.4 | 1

AiR FoRCE LiFE sUsTAiNMENT CENTERAiR FoRCE sUsTAiNMENT CENTER

2013

Gen. Janet C. WolfenbargerCommander

Lt. Gen. Andrew E. BuschVice Commander

Dr. Steve ButlerExecutive Director

Chief Master Sgt. Michael J. WarnerCommand Chief

Headquarters

Maj. Gen. H. Brent Baker Sr.

Commander, Ogden Air Logistics Complex

Col. Frederick D. Thaden

Vice Commander, 75th Air Base Wing

Col. Kathryn L. KolbeCommander, 75th Air

Base Wing

Chief Master Sgt. Jason L. France

Command Chief, 75th Air Base Wing

OGdeN aIr LOGIstICs COmpLex &

HILL aIr FOrCe Base

Colonel Walter J. LindsleyDirector of Staff

AiR FoRCE sUsTAiNMENT CENTER

aIr FOrCe sustaINmeNt CeNter

Colonel Mitchel H Butikofer

Commander, 78th Air Base Wing

Brig. Gen. Cedric GeorgeCommander

Robins Air Logistics Complex

Colonel Patricia RossVice Commander,

78th Air Base Wing

Chief Master Sgt. Sandra K. LepineCommand Chief

rOBINs aIr LOGIstICs COmpLex & rOBINs

aIr FOrCe Base

Brig. Gen. Donald E. “Gene” Kirkland

Commander, Oklahoma City Air Logistics Complex

Col. Steven J. Bleymaier

Commander, 72nd Air Base Wing

Col. Stephen D. WoodVice Commander,

72nd Air Base Wing

Chief Master Sgt. Brian D. Lavoie

Command Chief, 72nd Air Base Wing

Steven AlsupDirector

448th Supply Chain Management Wing

OkLaHOma CIty aIr LOGIstICs COmpLex

& tINker aIr FOrCe Base

Lt. Gen. Bruce A. Litchfield

Commander

Angie TymofichukDirector

Engineering & Technical Management Directorate

Ross E. MarshallExecutive Director

Col. Allan E. DayVice Commander

Chief Master Sgt. Kevin D. Vegas

Command Chief

William SwigertDirector

Personnel

Robert BroylesDirector

Contracting Directorate

Don DavisDirector

Financial Management Directorate

Gilbert MontoyaDirector

Logistics Directorate

JoAnne DavisDirector

Small Business Office

Col. David HaaseCommander

635th Supply Chain Operations Wing

Tangible results show that we’ve produced approximately 45 percent more aircraft in the first two quarters of FY13 than we did in FY12. To a great extent, this is because of the way we put together our sustainment center. Our mantra is the AFSC Way—and I think the AFSC Way is turning out to be a formula for success at all of our sustainment bases.

Q: Have there been any immediate and noticeable effects of the budget reductions and limitations on the center? Have you expe-rienced—or do you expect to experience—a brain drain of key skills?

A: The immediate effects really come in terms of our infrastructure support. We had to reduce the budget to our infrastructure, which had an immediate effect on our ability to do preventive mainte-nance and repair facilities. You can walk around the facilities and see places that aren’t being kept up to the standards that we nor-mally associate with the Air Force.

In terms of “brain drain”, we are seeing the fact that some of our highly skilled engineers are looking at other options. We have, right now, a small number who have taken jobs in the private sec-tor that we haven’t expected.

The other thing that we’re seeing is when we offer a job to a new employee, the acceptance rate is below what we are used to. We can clearly see the uncertainty and the instability in our fiscal environment, manifested by furloughs and sequestration, is having an impact on hiring. The longer this goes on, my assessment is you’re going to see that spread to a broader part of our workforce, but right now we see it in small numbers in our highly skilled positions.

Q: How would you characterize the meshing of the cultures of the former centers into the single organizational structure?

A: I’m going to spin your gyros a little bit on this one. I think what we did is create a new culture. We didn’t try to mesh old cultures. Earlier, I mentioned the AFSC Way. That “new culture” comes complete with a leadership model that we implemented at the stand-up of the sustainment center—and that was new to all the organizations, all the commands, all the eight wings that we have in the center.

This really starts with what I would consider the leadership focus that we want to have, creating an environment for success.

We put in place the priorities that we want—speed, quality and safety, along with cost effectiveness. Then we defined how we could achieve those targets through the people we have on board, through the resources we manage, and through the processes that we can focus on in terms of how we get our work output.

All of that is targeted against a common goal across the sustain-ment center.

I just visited all three of our sustainment bases, and whether I was at Robins, Tinker or Hill, whether I was talking to management or the workers on the floor, we were speaking the same language, we were measuring things the same way, and we were executing our workload in a standard fashion. It really has been a textbook way of merging the organizations. I fully believe that this is directly attributed to the wonderful planning effort that we had in place

before the stand-up. It didn’t come after the stand-up; we worked for many, many, many months to ensure that we had everything right on day one. It was a great team that I can attribute to that success.

Q: Do you expect any significant capital improvement either to facilities and/or equipment during the next 12 months?

A: Let me break that question down a little bit. We don’t have any new MILCON [military construction] that we’re projecting in the foreseeable future.

We do have modernization efforts that are going on that will allow us to stand up new capabilities that are nearing completion. If you go to Hill, you have the new radar cross-section testing facility that’s being put in place for the F-22 and F-35. If you go to Robins, they’re just opening up a new plating facility to handle the workload down there, and of course at Tinker we’re still ongoing in the conver-sion of the GM plant into a state-of-the-art maintenance and repair operation.

These projects are allowing us to take on new capabilities and new workloads as systems come into the depot. These are significant improvements and that will allow us to maintain our competitive-ness in the business.

Q: Has the center gained any additional work, added capacity or responsibilities since activation?

A: Yes, we have a big growth area in our software environment. At all three centers, software is a growing concern, which you can very well expect. When I came into the Air Force, roughly 15 percent of our weapon systems were controlled by software; today it’s somewhere close to 80-90 percent. Software is very expensive, and it’s a growth area that we really have to get into in order to sustain the readiness of our force.

We’re also looking at the F-35 coming on board this year, both in terms of the aircraft, the F-135 engine, as well as some of the com-ponents to go along with the aircraft.

Modification work is another area of growth for us. The old weapon systems that we’re keeping on board are continually being upgraded, and we’re doing a magnificent job on those modifications and turning those systems back to the field more capable than when they came in.

One of the other areas that we’re growing into is the remotely piloted aircraft, and we expect to see more growth in this arena.

Q: How are your supply chain wings organized?

A: We have a supply chain wing [a management wing] at Tinker AFB, and it has groups at Tinker, Robins and Hill. We have a supply chain operations wing at Scott AFB.

The 448th Supply Chain Management Wing at Tinker is respon-sible for ensuring the Air Force has all the parts that it manages, bringing them into the inventory whether it’s through new buys, organic maintenance or even contract maintenance.

The 635th Supply Chain Operations Wing at Scott AFB is responsible for distributing the Air Force inventory to all the bases, ensuring they have all they need to keep their weapon systems and aircraft operational.

www.MLF-kmi.com4 | MLF 7.4 | Air Force Sustainment Center

AiR FoRCE sUsTAiNMENT CENTER

The 448th is more of the strategic wing to bring the Air Force assets into the inventory, and the 635th Supply Chain Operations Wing is responsible for distributing across our Air Force, to all the bases that need those supply end items.

Q: Is the center involved in any ‘going green’ initiatives as far as energy con-servation?

A: I have three priorities that I talk about every time I go to any one of our bases, and one of them is energy reduction/consumption. If I look at our sustainment bases, I believe we’re ranked first, third and seventh in terms of total energy use at Robins, Hill and Tinker respectively.

I don’t think that’s a good thing and I want to find ways to reduce our energy consumption.

You would expect us to be high energy consumers because of the enor-mity of the bases and the industrial operations that we do. What we’re really focusing in on is not only the normal in terms of energy consump-tion, heating and lighting and such, but we’re really working on process energy as well. We’re also looking at the ability to control the consumption of energy and what it takes us to produce the end items that we do—and we’re finding great successes there.

We’re finding that we’re the indus-try leader in process energy analysis and reduction. We’ve even briefed the National Academy of Science on the work that we’ve been doing, so I’m very proud of how we’re reducing the overall consumption of our energy.

I don’t necessarily call that ‘green,’ because a lot of people would say that green is building new. What we’re really trying to do is better utilize what we have by reducing our consumption. We’re also reducing cost, and that fits into one of our strategic priorities of cost-effective readiness, so if we can reduce the cost of what we produce, it’s better for our Air Force all around.

Q: You recently talked about preparing for the future and look-ing out for your wingman. What is the center doing to help its employees do those things?

A: I’d like to draw you a visual picture in that you’ll find when we start out talking about our employees, we put them at the center

of our intentions. The mechanic or the supply chain manager or the contract manager or the engineer that is actually doing the work is in the center of our bull’s eye: that’s who we are here to support, that’s what the leadership model is all about.

What we really want to do is to enable the person at the cen-ter of bull’s eye, not only in the job that they do, but ensuring when they come to work, they’re in a safe working environment. I don’t believe that anybody who comes to work, anywhere in our Air Force, should accept the risk of maybe long-term health problems or losing a finger or a toe.

To that end, we run a program that we operate with OSHA called the Voluntary Protection Program. The program focus is to get engagement of the workforce so that they help us

Top: A Coast Guard C-130 undergoes maintenance at Warner Robins Air Logistics Complex, Robins Air Force Base, Ga. [Photo by Sue Sapp, courtesy of U. S. Air Force]Above: F-22 life cycle management will fall on the Sustainment Center. [Photo by Staff Sgt. William P. Coleman, courtesy of U.S. Air Force]

www.MLF-kmi.com Air Force Sustainment Center | MLF 7.4 | 5

AiR FoRCE LiFE sUsTAiNMENT CENTER

ensure a safe working environment. In areas where we are at a high level of maturity, we’ve received the OSHA ‘star status’ for our workforce—which exceeds industry standard for safety.

As we look at our workforce, we want to make sure they have the resources they need to do the job. No one will have everything they want, but we want to ensure they have what they need. Our responsibility is to ensure that we under-stand the work they’re doing, and that they have all the tools, the equipment, the safety procedures, in place to make sure they’re effective in what they do. The bottom line is that when our folks are at work, they have an environment they’re comfortable and confident in.

In terms of the wingman construct, we look at resiliency. If I were to break that down for you, there are four dimen-sions to what we do: mental, physical, spiritual and emotional. We work with our employees, if someone has a prob-lem, whether it’s financial, emotional or family, to make sure they have the coun-seling available and we can get them the help they need.

If you ask me about how we care about our people, how we take care of our people, I think it’s through a mul-tidimensional approach in terms of put-ting them at the center of our attention. How we keep them safe while they’re at work and make sure that their work environment is as safe as practically possible. We also want to make sure that they can handle the ups and downs that come in any person’s life. This is the multispectral approach to how we take care of our people.

Q: Is there anything else you would like to add?

A: I believe that the cost of readiness will determine the size of the Air Force that we can afford, and the size of the Air Force that we can afford determines our ability and preparedness to fight and win the next war. Across the sustainment center, our primary responsibility is to deliver readiness to the Air Force, and do it in a cost-effective manner.

While we are heavily engaged, post-9/11—actually I would consider it the past 20 years, post-Desert Storm—but clearly since 9/11, we’ve been engaged in combat, there’s no doubt that we’ve been delivering effective capability to our warfighter. Now that we’ve pulled out of Iraq and we’re looking at the drawdown in Afghanistan, I think our focus now is on cost-effective readiness. I

think that’s what our sustainment center has been able to contrib-ute to our Air Force.

We work this on a daily basis—not only to deliver effective readiness, but do it in a cost-effective manner while still producing the high-quality products our warfighter needs

I’m very proud of the 33,000 members that we have across the sustainment center and what they’re doing and their contri-butions in those efforts. It’s really been remarkable the number of improvements we’ve been able to put in place and that the workforce has been able to execute—it’s something to behold. The more I get out and see it firsthand, the more impressed I am. Every day I come to work thinking that today is going to be a better day than yesterday. O

Top: Mechanical engineers demonstrate the sophisticated Leica laser scanner system at Tinker Air Force Base, Okla. [Photo by Margo Wright, courtesy of U.S. Air Force]Above: Like the F-35, if it flies, it will pass through the hangar doors of the Air Force Sustainment Center. [Photo by Lawrence Crespo, courtesy of the U.S. Air Force]

www.MLF-kmi.com6 | MLF 7.4 | Air Force Sustainment Center

AiR FoRCE sUsTAiNMENT CENTER

Compiled by Kmi media Group staffSUPPLY CHAIN

More Lift

The Product Manager, Engineering Systems, Marine Corps Systems Command, recently announced that they are seeking information from potential sources to satisfy its requirement for an extended boom forklift (EBFL) replace-ment vehicle.

The Marine Corps currently has a require-ment for 729 EBFLs, purchased through JLG Industries during the time period of 2001 through 2010. The existing fleet has reached its service life.

As part of the EBFL replacement effort, the Marine Corps has adopted new require-ments. Specifically, they have a requirement to ensure that all EBFLs are capable of loading and unloading rotary aircraft with standard warehouse and 7,000-pound, 463L pallets. This requirement necessitates the forklift have a reduced or reducible height not to exceed 84 inches when loading and unloading rotary wing aircraft. The PM also has a requirement for an armored solution for the EBFL operator cab. All EBFLs must be configurable to receive an armored cab. The Marine Corps will require 100 armored cabs.

AV-8 Engine ILSThe Naval Air Systems Command has announced that it intends to award a sole-source

delivery order to Rolls Royce PLC, Bristol, England, to provide integrated logistics support (ILS) for the Pegasus (AV-8) engine (F402-RR-408A/B) for the Joint Program Office, which consists of the United States Marine Corps, Spanish Navy and Italian Navy.

According to NAVAIR, Rolls Royce is the original designer, developer and manufacturer of the F402 (AV-8B) series engine and is the only source with the requisite knowledge, experience and technical expertise to continue to provide the required supplies and services. Rolls Royce is the only source with the technical data, facilities and capabilities required to provide the asso-ciated system and sustainment support for the F402 (AV-8B) series engine requirements. Rolls Royce maintains configuration control over the F402 engine and will not provide unlimited rights to the government. No other manufacturer could design, develop and properly integrate F402 engine upgrades to meet the contract delivery schedules required to resolve issues in the fleet with the current configuration. Rolls Royce was selected as the prime contractor for the original engine development resulting from full and open competition.

Afghan C-130H Support