Mlf 8 1 final

-

Upload

kmi-media-group -

Category

Documents

-

view

238 -

download

1

description

Transcript of Mlf 8 1 final

AMCOM O Passive RFID O Microgrids and PowerSmart Handheld Devices O Afghanistan Drawdown

Predictability Provider

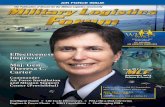

Lt. Gen. Raymond V. MasonU.S. Army Deputy Chief of Staff, G-4

Special pull-out Supplement

U.S. Army militAry SUrfAce Deployment AnD

DiStribUtion commAnD

www.MLF-kmi.com

February 2014Volume 8, Issue 1

Exclusive Interview with:

mAj. Gen. thomAS j. richArDSonCommanderU.S. Army Military Surface Deployment and Distribution Command

AUSA Winter iSSUe

The Publication of Record for the Military Logistics Community

With its � rst new semi-rugged notebook, VT Miltope takes mobile military computing for business to new levels… and anywhere you need to be.

SRNC-17 Features and Functions: • 17.3" High Resolution Display • 4th Generation Intel® Core Platform • Enhanced Chassis Ruggedization • High Capacity Solid State Disk Adaptability

Reliable in the Extreme

mymiltope.comMADE IN THE USA

HANDHELDS • LAPTOPS • TABLETS • SERVERS • PRINTERS • STORAGE • WIRELESS

Semi-Rugged Notebook Computer

SRNC-17

0039_MyMiltope_Logistics Forum Ad_Raft_X1a.indd 1 2/4/14 8:19 AM 2/4/14

Cover / Q&AFeatures

Lieutenant GeneraL raymond V. mason

U.S. Army Deputy Chief of StaffG-4

17

February 2014Volume 8, Issue 1

Departments Industry Interview2 editor’s PersPectiVe4 LoG LeadershiP Lessons14 suPPLy chain27 resource center

mike LennonAccount Executive for the U.S. ArmySAP

MILITARY LOGISTICS FORUM

28

HPW3000THE BEST ENGINE

FOR TODAY’S BLACK HAWK AND APACHE

AND TOMORROW’S VERTICAL LIFT

Learn more about the ITEP engine program and the HPW3000 Engine at ATECPower.net.

Client: ATECAd Title: Bringing more powerPublication: Military Logistics ForumTrim: 1.8” x 5.5” • Bleed: 2.05” x 5.75”

26646_ATEC_Best Engine_MilLogisticsForum_1_8x5_5.indd 12/3/14 2:20 PM

6smart handheLd deVicesIn 2013, International Data Corporation tallies worldwide smartphone shipments to surpass 1 billion units, representing 39.3 percent growth over 2012. Today over 70 percent of all device sales worldwide are smartphones or tablets. People in the military who are familiar with these devices and their benefits in their personal lives want to reap these same benefits in the context of their mission or work.By Karen e. Thuermer

9amcomThe U.S. Army Aviation and Missile Command is responsible for life cycle management of Army missiles, helicopters, unmanned ground vehicles and unmanned aerial vehicles. By henry Canaday

11 microGrids and PowerMore environmentally friendly and efficient, microgrids are making a difference. By definition, a microgrid has the ability to provide electricity on its own and without being attached to the grid that powers the rest of civilization.By PeTer BuxBaum

24PassiVe rFid stiLL emerGinGAsset tracking is essential to efficient logistics and can be enabled by many technologies. Active radio frequency identification and barcodes are being widely used. But passive RFID and other technologies are also being considered.By henry Canaday

U.S. Army mIlItAry SUrFAce Deployment AnD DIStrIbUtIon commAnDSpecIAl pUll-oUt SUpplement

Exclusive interview withmAjor GenerAl thomAS j. rIchArDSonCommanderU.S. Army Military Surface Deployment and Distribution Command

Who’s Who pictorial of U.S. Army Military Surface Deployment and Distribution Command

1

226

Your single-source solution for material and services.

www.SupplyCore.com

teaminG to drawdown aFGhanistan oPerationsWhile there is a long history of civilians directly supporting military operations, contractors have never been more prevalent or more critical to mission success than in the recent wars in Iraq and Afghanistan. In both wars, contractors were called upon by the military to feed the troops, build base camps, maintain facilities and provide dozens of other logistical support services.By STeve WhiTComB

The men and women of the Defense Logistics Agency will be the first to tell you that they don’t do their job for the pat on the back that may—or may not—come. But they recently earned their stripes and came out on top of a DoD Inspector General’s report. The DLA will look at this business as usual—and that’s the most interesting aspect: It is!

As background, it is recognized that DLA supports more than 2,250 weapon systems and supplies more than 84 percent of the military’s spare parts—repre-senting nine supply chains and 5 million items. In FY12 they processed $44 billion in sales and service, which would put them in the top 15 percent of the Fortune 500 if on that chart.

The DoD Inspector General recently released the findings of an audit of DLA’s fulfillment of time-definite delivery items to ensure that they met the required standard of four days. DoD regulations further define the TDD concept as representing 85 percent of the aggregate times that the wholesale supply system is capable of delivering the required materiel to its customers.

This particular audit focused on the delivery mission-critical batteries, which are managed from DLA’s Land and Maritime activity in Columbus, Ohio.

The IG’s report stated that, “DLA fulfilled CONUS warfighter requisitions for batteries designated as mission-critical by military services. DLA met the 4-day CONUS TDD standard for 82 of 96 CONUS critical battery requisitions reviewed. For the 82 requisitions, DLA properly estimated and planned battery demand, procured the subject batteries, and maintained sufficient stock to fill the mission-critical requisitions within the 4-day standard.”

To put this in perspective, DLA managed 74,773 battery requisitions in FY12. That’s about 204 requisitions a day for batteries alone. Congratulations to DLA for hitting the mark!

Turning to the pages of this issue, Lieutenant General Mason’s interview brings home in great detail the Army’s logistics outlook for the near term: where the emphasis is, what the contingencies are what the expectations are. I have to admit that one segment that stands out is his conversation—shared from a previous mentor of his, Bob Dail, former director of DLA—about how there is value in scarcity. The explanation brings the meaning home and is a great philosophy at work and at home.

jeffrey D. mcKaughanediTor-in-ChieF

EDITOR’S PERSPECTIVE

Publication of Record for the Military Logistics Community

Editorial

Editor-In-ChiefJeff McKaughan [email protected]

Managing EditorHarrison Donnelly [email protected]

Online Editorial ManagerLaura McNulty [email protected]

Copy EditorSean Carmichael [email protected]

CorrespondentsHeather Baldwin • Christian Bourge Peter Buxbaum • Henry Canaday Cheryl Gerber • Hank Hogan • Marc Selinger Karen Thuermer

art & dEsign

Art DirectorJennifer Owers [email protected] and Materials ManagerJittima Saiwongnuan [email protected]

Senior Graphic DesignerScott Morris [email protected]

Graphic Designers Andrea Herrera [email protected] Paquette [email protected]

advErtisingAssociate PublisherJane Engel [email protected]

KMi MEdia groupChief Executive OfficerJack Kerrigan [email protected]

Publisher and Chief Financial OfficerConstance Kerrigan [email protected]

Editor-In-ChiefJeff McKaughan [email protected]

ControllerGigi Castro [email protected]

Trade Show CoordinatorHolly Foster [email protected]

opErations, CirCulation & produCtion

Operations AdministratorBob Lesser [email protected]

Circulation & Marketing AdministratorDuane Ebanks [email protected]

CirculationBarbara Gill [email protected]

Data SpecialistsRaymer Villanueva [email protected]

a proud MEMbEr of:

subsCription inforMation

Military Logistics Forum ISSN 1937-9315

is published 10 times a year by KMI Media Group. All Rights Reserved.

Reproduction without permission is strictly forbidden. © Copyright 2014

Military Logistics Forum is free to qualified members of the U.S. military, employees of the U.S. government and non-U.S. foreign service

based in $75 per year. Foreign: $159 per year.

CorporatE offiCEsKMI Media Group

15800 Crabbs Branch Way, Suite 300 Rockville, MD 20855-2604 USA

Telephone: (301) 670-5700 Fax: (301) 670-5701

Web: www.MLF-kmi.com

Military logistiCs foruM

Volume 8, Issue 1 • February 2014

www.GIF-kmi.com

Geospatial Intelligence

Forum

www.BCD-kmi.com

June 2012Volume 1, Issue 1

www.BCD-kmi.com

Border Threat Prevention and CBRNE Response

Border Protector

Michael J. Fisher

ChiefU.S. Border PatrolU.S. Customs and Border Protection

Wide Area Aerial Surveillance O Hazmat Disaster ResponseTactical Communications O P-3 Program

Integrated Fixed Towers

Leadership Insight:Robert S. BrayAssistant Administrator for Law EnforcementDirector of the Federal Air Marshal Service Transportation Security Administration

SPECIAL SECTION:

Border & CBRNE Defense

www.MAE-kmi.com

Military AdvancedEducation

www.MIT-kmi.com

Military Information Technology

www.GCT-kmi.com

Ground Combat

Technology

www.MLF-kmi.com

Reverse Auctions O Defense Transportation O Afghanistan RetrogradeILS O Supply Chain Efficiencies O DMSMS O Senior Logisticians

The Publication of Record for the Military Logistics Community

Resource Aligner

Vice Adm. William A. “Andy” Brown Deputy CommanderU.S. Transportation Command

SPECIAL PULL-OUT SUPPLEMENTUSTRANSCOM

www.MLF-kmi.com

November/December 2013Volume 7, Issue 10

Exclusive Interview with:

GAIL JORGENSONAcquisition Director USTRANSCOM

Military Logistics Forum

www.M2VA-kmi.com

Military Medical & Veterans

Affairs Forum

www.MT2-kmi.com www.NPEO-kmi.com

Military Training Technology

Navy Air/Sea PEO Forum

www.SOTECH-kmi.com

Special Operations Technology

www.TISR-kmi.com

Tactical ISR Technology

www.CGF-kmi.com

U.S. Coast Guard Forum

KMI MedIa Group LeadershIp MaGazInes and WebsItes

A new perspective for AffordAble reAdiness

We live in a world that demands a new kind of company

leidos.com

linkedin: Leidos

facebook: Leidosinc

Youtube: Leidosinc

twitter: @Leidosinc

14-0

668

| L

eid

os

Cre

ativ

e

About LeidosLeidos is a science and technology solutions leader working to address some of the world’s toughest challenges in national security, health, and engineering. The Company’s 23,000 employees support vital missions for our government and the commercial sector, develop innovative solutions to drive better outcomes, and defend our Nation’s digital and physical infrastructure from ‘new world’ threats.

Evolved from SAIC’s decades-long expertise in national security, Leidos delivers a unique perspective dedicated to helping protect our country and secure our future.

KeY operAting locAtions

United States:

Washington, D.C.

Baltimore, MD.

San Diego, CA.

Boston, MA.

Orlando, FL.

Dayton, OH

St. Louis, MO.

Pensacola, FL.

Knoxville, TN.

Oklahoma City, OK.

International:

Afghanistan

Kuwait

Germany

Canada

Japan

Korea

Australia

United Kingdom

Italy

Iraq

© Leidos. All rights reserved.

Leidos — Delivering scientific and technology solutions for government and commercial customers in national security, engineering, and health

1990'sInnovation and Evolving Markets

f Largest U.S. employee-owned research and engineering firm

f Listed as a Fortune 500 company

1970'sServing the National Interest

Formed Technology Systems Group in the Washington, D.C., area to perform studies of information from nuclear weapon dust clouds.

Evolved from the legacy of SAIC, Leidos is a solutions company that combines the innovative application of technology, science, and engineering with deep mission and domain understanding of its customers and markets. We focus on solutions delivery to the national security, health, and engineering markets.

Leidos is a coined name, clipped from “kaleidoscope.” It is easy to say and feels international in tonality. It alludes to our ability to approach challenges from different angles to uncover a solution.

Our world-class customers’ needs and expectations change at a rapid pace. Because we strive to adapt and look at them from different angles, we are able to unleash technologies that move with and challenge industry standards.

our trAnsformAtion

While SAIC was tied by internal competition, organizational conflicts of interest, mergers and acquisitions focused capital deployment, and a high cost structure, Leidos is structured to optimize shared resources and leverage technology to better serve our customers, as well as enrich and advance our way of life and shared future.

nAtionAl securitY

f Critical mission support for the intelligence community

f C4ISR research and development for the Department of Defense

f Industry-leading cybersecurity capabilities

f Broad technology, development, and integration capabilities

f Delivers a wide range of logistics, product support and supply chain management solutions

HeAltH And engineering

f Healthcare information technology, electronic health records, and advanced data analytics

f Health and life science/clinical research

f Energy grid and critical infrastructure design and integration

1980'sServing the National Interest

f Navy’s largest metrology contractor

f Flight crew simulator training developed

f Developed optical sensor protection from hostile laser threats

2000'sA New Century of Change

f Ranked top physics company by Physics Today

f Acquisitions and Mergers: Benham Investment Holdings, LLC , R.W. Beck Group, Inc., Cloudshield Technologies, Inc., Vitalize Consulting Solutions, and maxIT Healthcare Holdings

f Ranked 24th among Top 100 Military Friendly Employers

FOUNDED

1969J. Robert Beyster, Ph.D.

“This whole success story was

not a planned thing. We just

wanted to find a place where

technology people could do

important work.”

— Dr. J. Robert Beyster

Our transformation2013Creating Two Great American Success Stories

New SAIC — Delivering enterprise IT and technical services to the federal government, state/local and commercial markets.

2014Providing the

US Military with reliable operational availability at a low

life-cycle cost

Leidos — Delivering scientific and technology solutions for government and commercial customers in national security, engineering, and health

1990'sInnovation and Evolving Markets

f Largest U.S. employee-owned research and engineering firm

f Listed as a Fortune 500 company

1970'sServing the National Interest

Formed Technology Systems Group in the Washington, D.C., area to perform studies of information from nuclear weapon dust clouds.

Evolved from the legacy of SAIC, Leidos is a solutions company that combines the innovative application of technology, science, and engineering with deep mission and domain understanding of its customers and markets. We focus on solutions delivery to the national security, health, and engineering markets.

Leidos is a coined name, clipped from “kaleidoscope.” It is easy to say and feels international in tonality. It alludes to our ability to approach challenges from different angles to uncover a solution.

Our world-class customers’ needs and expectations change at a rapid pace. Because we strive to adapt and look at them from different angles, we are able to unleash technologies that move with and challenge industry standards.

our trAnsformAtion

While SAIC was tied by internal competition, organizational conflicts of interest, mergers and acquisitions focused capital deployment, and a high cost structure, Leidos is structured to optimize shared resources and leverage technology to better serve our customers, as well as enrich and advance our way of life and shared future.

nAtionAl securitY

f Critical mission support for the intelligence community

f C4ISR research and development for the Department of Defense

f Industry-leading cybersecurity capabilities

f Broad technology, development, and integration capabilities

f Delivers a wide range of logistics, product support and supply chain management solutions

HeAltH And engineering

f Healthcare information technology, electronic health records, and advanced data analytics

f Health and life science/clinical research

f Energy grid and critical infrastructure design and integration

1980'sServing the National Interest

f Navy’s largest metrology contractor

f Flight crew simulator training developed

f Developed optical sensor protection from hostile laser threats

2000'sA New Century of Change

f Ranked top physics company by Physics Today

f Acquisitions and Mergers: Benham Investment Holdings, LLC , R.W. Beck Group, Inc., Cloudshield Technologies, Inc., Vitalize Consulting Solutions, and maxIT Healthcare Holdings

f Ranked 24th among Top 100 Military Friendly Employers

FOUNDED

1969J. Robert Beyster, Ph.D.

“This whole success story was

not a planned thing. We just

wanted to find a place where

technology people could do

important work.”

— Dr. J. Robert Beyster

Our transformation2013Creating Two Great American Success Stories

New SAIC — Delivering enterprise IT and technical services to the federal government, state/local and commercial markets.

2014Providing the

US Military with reliable operational availability at a low

life-cycle cost

A new perspective for AffordAble reAdiness

We live in a world that demands a new kind of company

leidos.com

linkedin: Leidos

facebook: Leidosinc

Youtube: Leidosinc

twitter: @Leidosinc

14-0

668

| L

eid

os

Cre

ativ

e

About LeidosLeidos is a science and technology solutions leader working to address some of the world’s toughest challenges in national security, health, and engineering. The Company’s 23,000 employees support vital missions for our government and the commercial sector, develop innovative solutions to drive better outcomes, and defend our Nation’s digital and physical infrastructure from ‘new world’ threats.

Evolved from SAIC’s decades-long expertise in national security, Leidos delivers a unique perspective dedicated to helping protect our country and secure our future.

KeY operAting locAtions

United States:

Washington, D.C.

Baltimore, MD.

San Diego, CA.

Boston, MA.

Orlando, FL.

Dayton, OH

St. Louis, MO.

Pensacola, FL.

Knoxville, TN.

Oklahoma City, OK.

International:

Afghanistan

Kuwait

Germany

Canada

Japan

Korea

Australia

United Kingdom

Italy

Iraq

© Leidos. All rights reserved.

© Leidos. All rights reserved.

leidos.com/logistics

New Perspectives for Mission Success

your partner for logistics solutions

The U.S. military needs reliable operational availability at a low life-cycle cost. To provide

this affordable readiness, Leidos delivers a wide range of logistics, product support, and

supply chain management solutions. Readiness is complex, and our tailored, affordable

solutions make it easy to focus on what’s important — your mission.

Leidos, a company that started with the proud traditions of SAIC, now forges a new path

with the same people making integrated logistics easy.

An oft-quoted comment from the phi-losopher George Santayana goes: “Those who cannot remember the past are con-demned to repeat it.” I’m a believer in the cyclic nature of history. In the 40-plus years I’ve been involved with military logis-tics, I’ve participated in or witnessed three cycles of budget-driven force reductions and subsequent “rebuilding” of logistics capabilities lost during those reductions. We are in the throes of the third cycle now, and I keep recalling how we wrote great studies on lessons learned in the first two. We discussed what had happened and how we could do it better the next time, but I cannot recall a concerted effort to expedi-tiously codify into our logistics DNA the hard-won gains we had made leading up to those reductions. This left us having to reinvent the wheel at times, and expend scarce resources in the process.

My sense is the last 10 or more years of expeditionary combat logistics support has taught logisticians from all of the services the value and force-multiplier effect of joint logistics. From my soda straw view of the world, it seems to me the most likely scenarios for near- and mid-term national security threats all point to joint opera-tions as the most probable response. So what can logisticians do now, in a practical sense, to ensure we do not have to repeat/relearn our logistics past because we are unable to remember how we did it before?

Given the above propositions, I believe logisticians can do a lot to engage in and expand joint logistics capabilities, even in this current, budget-driven force

reduction period. They can be ready to do it again, as well as to maximize the efficiency of reduced resources in all the services for the foreseeable future. First, I believe the services should move to have more joint logistics officer assign-ments in those defense agencies which live and breathe jointness everyday: agen-cies such as the Defense Logistics Agency, U.S. Transportation Command, and the Defense Security Cooperation Agency.

Another way to codify joint logistics would entail more cross-service assign-ments. For example, Air Force aircraft maintenance officers and senior NCOs would be assigned to multi-year tours on a Navy aircraft carrier, or assigned to an Army aviation regiment and vice-versa. This would provide an ever-growing pool of professional logisticians who have been there, done that as they learn and share best military logistics business practices with their peers from the other services. Such a program would also provide a ready source of support personnel who could backfill over-committed logisticians from one service in a specific theater of operations. By way of example, if combat operations are being waged at sea, Army and Air Force logisticians who had partici-pated in this program could backfill Navy logisticians in another theater not engaged in the conflict. Those Navy logisticians would then be available to supplement the Navy forces actively engaged in combat operations, wherever they may be occur-ring. Such an arrangement could help all the military services develop trained and

capable (with minimal refresher training) joint logisticians, ready to support another service if that service is heavily committed as the lead echelon in a combat operation.

Another idea: Expand the service’s logistics career broadening assignments to rotate logisticians among all of the service depots. Personal experience taught me that, if nothing else, these assign-ments significantly increased mutual understanding and dialogue between the field and the depots within a service. Why not extend those same benefits among all the services?

What about using some of the $150 million Congress wants to provide Army arsenals to address the issue of their non-competitive rates to establish joint technical training centers at these three national treasures? Training would be available (for a fee) to both public and pri-vate sector agencies. This approach would allow the arsenals to exercise and preserve their globally-unique technical capabili-ties while providing a training source to satisfy the need for skilled technicians in both the public and private sectors.

The bottom line is this: Today, many active duty uniformed and civil service logisticians have “been there, done that” in a joint warfighter support environ-ment. For this cycle, let’s examine and implement ways the services can be bet-ter prepared to add: “…and ready to do it again” now. Our adversaries won’t wait for defense resources to rebound; why should we? O

LOG LEADERSHIP LESSONS Compiled by Kmi media Group staffLOG LEADERSHIP LESSONS

Been There, Done That; Ready To Do It Again

Colonel Mark Roddy, USAF (Ret.), is the CEO of DawnMar Associates Inc. His active duty service as a career logistician and his work in the private sector as an information technology consultant reflect over 40 years of logistics and information technology expertise. Roddy is also a past national president of the Logistics Officer Association.

www.MLF-kmi.com4 | MLF 8.1

The Upmost in Reliability.

www.jlg.com877-JLG-LIFT

Product Inquiries: [email protected] Parts & Service: [email protected]

JLG’s broad range of access equipment delivers the high performance, effi ciency and support military and government sectors require. All products are backed by JLG’s comprehensive Ground Support services – offering the parts, training and service needed to uphold productivity. From facility upkeep to aircraft access and onboard ship maintenance, JLG designs, builds and supports the higher level of equipment project teams can rely on.

JLG is proud to provide fl exibleGSA and DLA programs to assistin the purchase of equipment.

No one can dispute that the growth of mobile devices over the past few years has been astounding. In fact, for 2013, Inter-national Data Corporation (IDC) tallies worldwide smartphone shipments to surpass 1 billion units, representing 39.3 percent growth over 2012. Today over 70 percent of all device sales worldwide are smartphones or tablets.

Contributing to this growth is the fact people are using mobile devices quite dif-ferently than they used desktops or laptops. Mobile devices provide people with location-based, contextual services. They also enable people to get information they need from anywhere, at any time, and share it with whom they want to have access.

These uses are also fueling the wide-spread adoption of mobile devices within DoD as the preferred computing platform.

“People in the military who are famil-iar with these devices and their benefits in their personal lives want to reap these same benefits in the context of their mission or work,” commented Umesh Vemuri, head of enterprise sales engineering, public sector at Google. “Enabling the military logistics com-munity with mobile devices that can deliver location-based, contextual services to people is critical to increasing data sharing, reducing decision timelines and ultimately enabling a globally responsive supply chain to support the warfighter.”

Nett Warrior Program

There are numerous examples of how smart handheld devices are already being used within military scenarios. The Nett War-rior Program is one such example. Operating in conjunction with the Soldier Require-ments Division at the Maneuver Center of Excellence, the program exemplifies how handheld smart devices and technologies are being used in combat by the Army.

Jason Regnier, deputy product manager of Nett Warrior, describes one of the main combat purposes of putting computing power on dismounted leaders as to provide a means for digital, networked situational awareness and command and control that goes beyond voice over radios.

“For the first time, we can give all battle-field leaders a view of the friendly and enemy situation, not just those in a tactical opera-tions center or in command vehicle,” Regnier said. “The fact that the smart handheld device is in a form factor that soldiers are familiar with [e.g., smartphones] and their operation is kept simple and intuitive like their personal phones is an added bonus that increases sol-dier acceptance.”

The Nett Warrior program, named in honor of Medal of Honor recipient Colonel Robert Nett, leverages commercial smart devices to provide an integrated dismounted leader mission command and situational awareness system for use during combat operations. The Nett Warrior program focuses on the integration and evaluation of commer-cial smart devices for the mission command and situational awareness system, improved navigation and reduced fratricide through the visualization of friendly forces. The integra-tion process employs recent combat veterans for soldier integration and feedback, enhanc-ing the human factors and fightability.

Currently, commanders in tactical opera-tions centers and vehicle commanders have mission command and situational awareness, but dismounted leaders do not. “The primary driver for the current suc-cess has been SWAP-C [size, weight, power and cost] reductions,” Regnier said.

Nett Warrior started out under the Land Warrior pro-gram in the late 1990s at a

weight of nearly 40 pounds. It was reduced in 2011 to just under 9 pounds, but still took up a lot of space.

“The current Nett Warrior system weighs in at 3.5 pounds,” Regnier added. “The real-ization of Moore’s Law [i.e., computer proces-sors double in complexity every two years] also meant that more computational and display capability could be delivered to an individual in a much smaller package.”

Smart device systems provide situational awareness and understanding, allowing for faster and more accurate decisions in the tactical fight. “This translates into soldiers being at the right place at the right time, with the right information, thereby making them more effective, more lethal and more survivable in the execution of their combat mission,” Regnier said. “They are able to navigate and close on an objective in the dark with a more complete understanding of where the blue forces are—preventing fratri-cide—where the enemy is known or thought to be, and how to execute the mission.”

In addition to the primary tasks of mis-sion command and situational awareness, the Army is looking at using these same smart devices with applications for artillery and fires, machine foreign translation, medical applications and logistics functions.

“Currently the Nett Warrior supports Army standard supply point and resupply messages at the platoon level, and we expect

interest and capabilities in the combat logistics areas to grow,” Regnier explained.

Regarding security, the Nett Warrior system is required to operate at the secret level due to the classifi-cation of the operational data.

“The program is in compliance with the full suite of military require-ments described in Army

game chaNgers for military logisticiaNs.

Umesh Vemuri

By KareN e. thuermer, mlf corresPoNdeNt

www.MLF-kmi.com6 | MLF 8.1

Regulation 25-2 and other security-related regulations and processes from OSD and the Army CIO-G6,” he said. “The devices are no longer phones, and all communications is performed through secure tactical encrypted radios [not commercial cell towers or WiFi]. The smart devices are secure enough to pre-vent intercept and decryption by the enemy.”

The Nett Warrior systems are also required to meet the full suite of tactical mili-tary requirements for electromagnetic inter-ference and compatibility, as well as military standard environmental tests for vibration, salt, sun, temperature and so on.

“There are a few exceptions to the ini-tial requirement, such as relief on 2-meter underwater immersion, nuclear survivability and extreme temperature ranges,” Regnier said. “However, we are developing special pur-pose cases for those needs or looking at the new, commercially available cases that skiers or outdoor enthusiasts are buying.”

Ruggedizing the system must be balanced against life cycle costs and the desire to keep pace with the commercial market to lever-age rapidly evolving technology. This was a huge step within the Army in allowing some environmental requirements to be relaxed in order to use commercial smart devices.

“Put simply, we don’t expect the phones to last as long as most traditional military equipment. It is cheaper to replace a system with a newer smart device which will have a faster processor and added capabilities versus hardening a device so that it lasts 10 years,” Regnier commented. “What is surprising to the program office is how well the unmodi-fied phones with currently available protec-tive cases performed in testing and in combat. Of the 4,000 fielded for testing and in combat, we have had fewer than 50 broken devices.”

Another example where smart devices in the military are being implemented is the Joint Long Term Evolution (LTE) Deployable-Tactical Cellular System (JOLTED TACTICS), a cellular and Internet Protocol-based sys-tem designed to provide robust communica-tions to dismounted special operations forces teams and general purpose forces company and below tactical users.

According to Army Lieutenant Colonel Scott Brooks, C2 integration lead, Technical Integration & Services Branch, C4 Assess-ments Division, JOLTED TACTICS started about four years ago when the special opera-tions community worked with third genera-tion (3G) networks.

“Based on successes they had, as well as capability gaps that war fighting commanders

found 3G was unable to fulfill, DoD provided momentum for JOLTED TACTICS.”

Consequently, JOLTED TACTICS is lever-aging innovations in fourth generation (4G) LTE cellular technologies and mobile Ka-band spread spectrum satellite communica-tions to deliver megabits of data to mobile and dismounted teams equipped with mobile devices such as smartphones or netbooks. Using LTE-based technology, dismounted warfighters can use applications such as streaming media, voice over Internet Proto-col, email, and instant messaging for immedi-ate situational awareness.

U.S. Special Operations Command and Naval Air Systems Command are consider-ing using JOLTED TACTICS for fixed wing aircraft and unmanned aerial systems range extension. The JOLTED TACTICS capability is being evaluated by the U.S. Navy under their 4G LTE Afloat Sea Trial for use in surface ship to ship and internal ship com-munications.

VeNdor offeriNgs

A host of vendors, from network provid-ers to device manufacturers, demonstrate how handheld smart devices fit well with military logicians.

Experts at Verizon maintain that a cel-lular network for smart devices is a game changer. With a robust network that covers nearly the entire United States with 4G LTE and 3G, Verizon can provide the military real-time information for asset management.

“There are multiple uses from surveil-lance to tracking a specific item,” explained Adam Rosenbaum, product and marketing manager for Verizon Enterprise Solutions. “With the build out and adoption of 4G LTE, users now can have even more data and data visibility.”

To keep the network secure, Verizon utilizes an encryption and authentication mechanism that are built into the network.

“We protect our users and our network upstream by ensuring mobile devices have gone through a certification process to get their devices and capability onto our net-work,” Rosenbaum described.

A particular benefit for military opera-tions, Verizon offers a mobile private network that segments user traffic off the public network. “It utilizes the Verizon network, but traffic is separated from the public traf-fic by dynamic mobile routing,” explained Rosenbaum. “Customer authentication is performed for all mobile form factors.”

Verizon also works with its vendors and OEMs to ensure they design their devices with security in mind so that they offer best in class capability right out of the box. “Consequently, we offer devices that are FIBS 140-2 validated in addition to accessories for multi-factor authentication,” he said.

FIPS 140-2 is the National Institute of Standards and Technology standard that addresses the use of cryptographic algorithms in IT systems.

An example of one of Verizon’s devices is the common access card that slides onto the device and can be used for authentication in cases such as DoD-provided enterprise email.

Another product Verizon offers is the mobile workforce manager, which provides a mobile device management capability. This is a scalable, cloud-based service that manages and controls user access and provisioning across multiple devices based on one’s own security compliance policies.

“At the end of the day, cellular technology allows logisticians to extend their enterprise,” Rosenbaum commented. “Folks working in the field now have access to information, logistics data and mobile dispatching. They are also able to utilize devices to troubleshoot problems and access a technical manual—even video conference with an expert. It even offers a tele-maintenance capability.”

Verizon Wireless Field Force Manager is an app that offers greater visibility as to where assets or soldiers are located, particularly when out in mobile pool. Field Force Man-ager helps provide proof of service, automate timesheets and job dispatch, collects service information and much more. Essentially, it helps increase management insight and opti-mizes operations.

“It also integrates with GPS for naviga-tion so that you streamline your dispatching and have the ability to provide quicker ser-vice,” he added.

Verizon’s Networkfleet enables the track-ing, monitoring and managing vehicle fleets. Networkfleet offers an easy-to-use dashboard that can easily pull up information on an individual vehicle or the entire fleet. Fleet managers can pull up the mapping data in their choice of street map, satellite or hybrid view. Managers can also receive alerts if the system detects a problem with the vehicle’s engine, speed or performance.

“Networkfleet is also able to provide real-time tracking and interpret bar codes,” Rosenbaum added. “It has a robust capability to find out where an item is and integrate into a back-end information system.”

www.MLF-kmi.com MLF 8.1 | 7

Vemuri points out that given the fact that Android is the world’s most popular mobile platform, with more than 1 billion device activations worldwide, many manufacturers are building mobile devices on the Android platform. “They continue to release new high quality devices on a regular basis,” he said.

DoD has been using Android devices for over two years as part of an effort to bring modern mobile devices to military employ-ees. In fact, Samsung provides a hardened version of Android, known as Knox, which was developed to meet the military’s security requirements.

“Chromebooks are a new breed of com-puters that run on Google’s Chrome OS, an operating system that is fast, simple and secure, and engineered to run a wide range of Web-based applications,” Vemuri said. “Chromebooks can support DoD’s thin- and zero-client initiatives. They are ideally suited for virtual desktop infrastructure solutions, whether offered by commercial vendors or custom-built solutions.”

To address security needs, both Chrome-books and Android have been designed from the ground up with security at the forefront. Chromebooks use the principle of defense in depth to provide multiple layers of protection for data, users and networks from malware, viruses and other threats.

“Every boot process involves a self-check, to ensure the system hasn’t been tampered with,” Vemuri explained. “Each tab executes in its own sandbox process, making it is isolated from others, and an attack on one cannot affect others. And data is stored safely in the cloud, so a lost computer no longer means lost work or data released in the open.”

Android was designed with multi-layered security that provides the flexibility required for an open platform, while providing protec-tion for all users of the platform.

“Android seeks to be the most secure and usable operating system for mobile platforms by re-purposing traditional operating system security controls to protect user data, protect system resources and provide application isolation,” Vemuri added.

To achieve these aims, Android provides a number of key security features, including security at the OS level through the Linux kernel, mandatory application sandbox for all applications, secure interprocess communi-cation, application signing and application-defined and user-granted permissions.

Durability is always an issue, particularly in the military. But Vemuri points out that in the traditional model, an organization would

purchase a device and spend a significant amount of money “ruggedizing” the device to increase durability.

“This approach was right-fully rooted in the view that data is central and protecting the local device would pro-tect the data,” he said. Hence, spending significantly more to ruggedize the device was justi-fied to ensure ongoing access to the data. While increasing durability, how-ever, ruggedizing a device could not address loss or theft, not to mention the significant cost of keeping the device up to date.

“Today’s reality is that the data no longer has to reside on a specific device,” he said. “Data for which a person has appropriate rights should be available to her from any device.” To do this, first, the data is stored in the cloud; second, the data itself is pro-tected both at rest and in transit; and third, software-based protections are implemented in the devices.

“Given this, the focus shifts from durable devices to durable data to ensure access to the data even in circumstances where a device is destroyed,” Vemuri explained. “Chrome-books, which are available for as little as $200, illustrate this quite well. Lost, stolen, dam-aged, or destroyed Chromebooks can be easily replaced and have little impact on budgets when compared with the high cost of ‘rug-gedizing’ and maintaining ‘rugged’ devices.”

Johnny Overcast, director of government sales for Samsung Telecommunications America, points out that Samsung devices can be used for a number of logistic purposes, such as bar code scanning and quality assur-ance. For example, the camera on the Galaxy line of devices can be used to scan traditional 2-D bar codes and 3-D/QR bar codes. Data can be fed directly into spreadsheets, forms or applications, and can be relayed in real time. Orders for supplies can be made on the spot with Galaxy connected tablets, eliminating many errors in data capture.

“Additionally, cost savings for devices is important with shrinking IT budgets,” Over-cast said. “Samsung offers mobile devices that are multifunctional, helping IT departments replace expensive devices that only serve one purpose, like bar code scanning.”

According to Overcast, Samsung offers the best range of smartphones and tablets to allow maximum productivity and security for military logistics professionals, whether working from an office or in the field. “From

the large-screen Galaxy Note line to the best-selling Galaxy S series to ruggedized smart-phones, Samsung’s lineup provides users with an unpar-alleled choice in screen size, form factor and functionality,” he said.

Regarding security, Sam-sung provides mobile security for the many regulated orga-nizations through Samsung

Knox. “Knox ensures integrated security from

the hardware layer to the application layer, arming Samsung Mobile devices with fea-tures that deliver security and compliance even for highly regulated industries,” he said.

Leveraging both hardware and operat-ing-system-based security enhancements, Knox creates a secure container on Samsung mobile devices that can be used to protect sensitive information, such as work email and files. “Knox provides peace of mind for IT departments, as well as company employees, by ensuring sensitive business information is managed and protected, while employ-ees’ personal information is kept private and secure,” Overcast added.

Samsung also offers enhanced features and premium accessories that turn mobile devices into purpose-driven tools.

“Samsung Mobile is the first mobile device manufacturer to establish a strate-gic relationship with OtterBox to supply a complete and complementary portfolio of accessory solutions for enterprise custom-ers,” Overcast emphasized. “Samsung also built the Galaxy S4 Active with a dust- and water-resistant exterior to provide a sturdier design without sacrificing high-performance functionality.”

Additionally, Samsung ensures peak per-formance through the full device lifecycle. Samsung MobileCare for Enterprise simpli-fies the maintenance, support and manage-ment of Samsung Mobile devices through training, technical support, certified repair and extended warranty care.

As these examples demonstrate, smart-phone devices and networks are game chang-ers for the military, since they enable the end user to accomplish the mission better and faster. O

jonny overcast

For more information, contact Editor-in-Chief Jeff McKaughan

at [email protected] or search our online archives for related stories

at www.mlf-kmi.com.

www.MLF-kmi.com8 | MLF 8.1

The United States Army Aviation and Missile Command (AMCOM) is responsible for life cycle management of Army mis-siles, helicopters, unmanned ground vehicles and unmanned aerial vehicles.

AMCOM faces major challenges in many areas, including main-taining its diverse fleet of helicopters. The drawdown from Iraq and now Afghanistan, coupled with reduced budgets, is largely respon-sible for these challenges, said AMCOM officials. But AMCOM’s Cor-pus Christi Army Depot (CCAD) has met the challenges by treating the organic industrial base as a business and finding smarter, more efficient ways to invest in its people and technology.

With a complete organizational restructuring, strategic plan-ning and fundamental cultural change, CCAD has developed a high-volume operation for the future. The CCAD workforce has demonstrated the synergistic effects of an enterprise approach to operations. By reorganizing and transforming its business cul-ture, AMCOM officials say CCAD has positioned itself to survive the force drawdowns and the downturn in military spending.

The depot has successfully promoted a professional recom-mitment to its core values of financial responsibility, customer service, product quality, employee empowerment and organiza-tional improvement.

CCAD has set a standard, known as the Balanced Scorecard, by which all production and support areas are continually mea-

sured. This initiative enables the depot to achieve organizational change, increase production and lower costs to survive the effects of reduced budgets and fewer troops in Iraq and Afghanistan.

It was these strides that made CCAD’s UH-60 Black Hawk recapitalization program such a success, according to AMCOM officials. This represents just one example of how CCAD is achiev-ing the highest possible return on capital assets and investments.

The depot has become the keystone for sustaining the Army’s Black Hawk fleet. Its recapitalization program maintains the Army’s combat readiness by improving the aircraft already in the inventory. CCAD modernizes the Army’s Black Hawks by updat-ing older models to meet the evolving requirements of modern warfare. Recap is part of the Army’s efforts to reduce platform sustainment costs. It also avoids the expense of replacing aging helicopters with new ones.

CCAD’s Black Hawk recap program, by avoiding the cost of replacing aging helicopters, saves the taxpayers about $12 million with each rebuild. Since 2003, this recap program has saved the taxpayer more than $20 billion, while cutting time and costs and making smarter choices in workload.

CCAD’s new proactive and efficient culture has enabled the workforce to recapitalize more Black Hawks than ever before. CCAD has achieved this at a lower cost and in a shorter amount of time by evolving systems and processes in workshops with

maNagiNg rotary WiNg suPPort aNd maximiziNg efficieNcy.By heNry caNaday

mlf corresPoNdeNt

MLF 8.1 | 9 www.MLF-kmi.com

innovative technology, lean methodologies and best business practices to accomplish the mission. The Aircraft Support Division, for example, reduced turnaround time 17 percent in fiscal 2012, and the division has continued the trend to shorter turnaround to this day. This reduces the overall costs of Army aviation and converts every dollar saved into more capability for the Army.

In short, AMCOM’s Corpus Christi Army Depot workforce has achieved savings in cost, schedule and human capital while maintaining superior quality.

In terms of the commercial equivalent, the depot has achieved International Organization for Standardization 9001:2000 qual-ity-management system certification. That is, the depot meets the quality-management system requirements for an aerospace maintenance organization.

CCAD meets this standard as it consistently provides prod-ucts that satisfy customer and other applicable requirements. The depot also aims to enhance customer satisfaction through effective application of the quality-management system, includ-ing processes for continual improvement and assurance of conformity.

There are also challenges in managing the supply chain, that is, inventories and part supplies for these assets, which are of many different ages. AMCOM officials said supply chain management is an enduring key focus area as AMCOM continues improvement efforts in enterprise resource planning integration and elimination of outdated legacy processes.

AMCOM has begun new efforts in demand planning with analyses that combine tables of distribution and allowances reconciliation; sales and operations planning; and authorized stockage list inventory reduction. These efforts yield greater speed in providing parts and components to AMCOM customers, at reduced cost.

AMCOM has also embarked on an enterprise approach to sustainment that highlights four initiatives, each with identified supporting goals.

First, conduct maintenance at the correct level. This is sup-ported by conducting pre-shop analysis to determine the best maintenance approach and reduce the no-evidence-of-failure rate on failed components.

Second, enable soldiers to return to core maintenance and supply competencies. This is supported by fully exploiting the mix of soldiers, civilians and contractors and by applying AMCOM’s enterprise approach to maintenance and supply-point operations

Third, for the force structure, AMCOM is improving its logis-tics capability to overcome anti-access or area denial, improving power-projection capabilities and optimizing the mix of active and reserve components and its support to each component.

Fourth, for modernization, AMCOM is reducing its unique equipping solutions, investing in energy innovation and embed-ded prognostics, reducing life cycle sustainment costs and improving accountability and auditability.

These four initiatives take on added significance in light of the fact that 10 major weapon systems, including the Javelin and UH-72 Lakota, will be transitioning to sustainment in the near future.

As AMCOM approaches 2030, funding this transition to sustainment will be a major challenge, which it is addressing through all of the cost-saving and efficiency measures identified above. Put simply, AMCOM’s energy, resilience and commitment to excellence will continue to be crucial in attaining its objective of providing sustainable, affordable combat power.

AMCOM officials said the Logistics Modernization Program (LMP) is helping AMCOM to meet future challenges by trans-forming the Army’s logistics operation into a collaborative, efficient and effective enterprise. The command has teams of experts who have designed a new organizational structure that reflects the six core processes of LMP: order fulfillment; demand and supply planning; procurement; asset management; materiel maintenance; and financial management.

AMCOM’s sustainment logistics role begins with the comple-tion of materiel fielding and is the core direct-funded component of its mission. This role includes readiness reporting and analy-sis, logistics assistance, national level maintenance and national level supply activities.

National level maintenance includes management of the two Army maintenance depots, CCAD and Letterkenny Army Depot, that provide repair, overhaul, rebuild and modification for aviation and missile systems and equipment. It also includes operating the National Maintenance Point for all maintenance management, provisioning, technical publications, tools, and test-equipment activities required to sustain assigned systems throughout their service life.

Furthermore, supporting the soldiers of 2030 will require continued excellence in delivering AMCOM’s core competencies, tighter integration of its materiel enterprise to deliver the best possible support within tight budgets and a two-fold business process reinvention.

This reinvention is looking at integrating logistics functions, supply, maintenance, logistics assistance and readiness, with a strong science and technology program focusing on zero-main-tenance weapon systems.

AMCOM is working closely with Redstone Arsenal’s Aviation and Missile Research Development and Engineering Center, using a building-block approach to exploit technology and enable transitional capabilities for achieving maintenance-free systems. The two units are developing monitoring and maintenance support technologies to enable optimized designs, enhanced condition-based maintenance and improved maintainability.

Supporting other focus areas in the development of ultra-reliable components, systems and operations means that sustain-ment objectives need to be incorporated into the requirements of the programs within each technical area, as well as sustainment programs that integrate all of its pieces. The goal is high mis-sion reliability and low maintenance burden through reliable usage-based designs, health-based adaptive controls, prognosis-based inspections and maintenance scheduling and intelligent networked sensors. O

For more information, contact Editor-in-Chief Jeff McKaughan at [email protected] or search our online archives for related stories

at www.mlf-kmi.com.

www.MLF-kmi.com10 | MLF 8.1

Last May, the U.S. Army commissioned the first U.S. Department of Defense grid-tied microgrid. The project was funded by DoD’s Environmental Security Technology Certification Program (ESTCP). The Fort Bliss microgrid is designed to advance sev-eral goals: to reduce greenhouse gas emis-sions and energy costs while providing the capability to operate independent of the electric utility grid when the grid has been compromised.

By definition, a microgrid has the ability to provide electricity on its own and without being attached to the grid that powers the rest of civilization. Stand-alone generators have long supplied power requirements for facilities in forward loca-tions. Technology advancements can now network those generators intelligently to maximize efficiency and minimize costs.

DoD has more recently been strategiz-ing about deploying microgrids to fixed bases in the continental United States and

perhaps elsewhere as well. Environmental concerns partially inform this strategy. Other aspects of the interest in microgrids include cost reduction and assuring that the operations of critical facilities are assured in case the grid goes down.

“Deploying microgrids to military bases in the United States allows them to operate without being sus-ceptible to an attack on the grid,” said Bob Dail (Lieu-tenant General, USA, Ret.), chief commercial officer of Supreme Group and a for-mer Army logistician. “In the 21st century, an attack on critical infrastructure is one of the biggest threats we face.”

“Electrical grids are vulnerable to cyber attacks as well as man-made and natural disasters,” said Bill Anderson, director of strat-egy and business develop-ment at Eaton and a former assistant secretary of the Air Force. “In the event of such an attack, power on military bases can go down for more than a few hours or days. This would nega-tively impact the ability of the United States to project power.”

“Microgrids represent an additional step to hard-ening perimeters around critical infrastructure,” said Dail. “The U.S. military has already deployed microgrids at a few key command and

By Peter BuxBaum

mlf corresPoNdeNt

bob Dail

bill Anderson

more eNViroNmeNtally frieNdly aNd efficieNt, microgrids are maKiNg a differeNce.

www.MLF-kmi.com MLF 8.1 | 11

control nodes, including in the capital region.”

In the case of the Fort Bliss project, Lockheed Martin was selected by ESTCP to demonstrate an intelligent microgrid at a U.S. Army brigade combat team complex. Lockheed Martin was awarded the contract in 2010.

“An intelligent microgrid manages the distribution of electrical power generated by various sources, continuously balanc-ing loads and supplies while ensuring that all elements of the grid perform at peak efficiency, whether they’re connected to a larger grid or operating in an isolated mode,” said Jim Gribschaw, director of energy programs at Lockheed Martin Mis-siles and Fire Control. “The microgrid helps to stabilize power grids, reduce greenhouse gas emissions and cut energy costs, as well as enhance energy security of government installations.”

Both deployed and fixed military com-plexes have a growing need to reduce energy consumption and efficiently use available energy sources, Gribschaw noted. “The ESTCP sought to demonstrate a solu-tion that provides greater than 10 percent reduction in greenhouse gas emissions and energy consumption,” he said.

Smart power distribution systems play a prominent role in the 2011 DoD plan, “Energy for the Warfighter: Operational Energy Strategy,” designed to transform the way fuel is used in theater. Imple-menting that plan through an action memo, the U.S. Central Command stated: “To better manage base camp energy demands, U.S. Forces-Afghanistan has identified requirements that include energy efficient generators, power distribu-tion systems, shelters, and a capability to measure energy usage for more effective energy management. Opportunities exist to improve power generation and electrical distribution systems.”

Anderson believes that implement-ing microgrids powered by local feedstocks working in coordination with the local grid is the best solution to the risk of a long-term grid outage resulting from man-made attacks or natural disasters. “The microgrid would operate parallel to the primary grid when it is healthy and disconnected as an autonomous islands when required,” he said.

Eaton has already demonstrated that smart microgrid technology can reduce energy consumption at forward operating bases. “Demonstration projects beginning in 2007 showed fuel savings of 25 to 30 percent,” said Jim Dankowski, a national

business development man-ager at Eaton. “That means taking that amount out of supply lines and putting fewer troops at risk.”

With regard to fixed bases, commanders want to know that their mission-critical activities have the ability to remain up and running during prolonged outages. “The idea devel-oped that microgrids should

provide a source of continuous power to the base and not just backup power. This can offset the costs of obtaining power for the grid and allows the power to be avail-able continuously in disconnected mode in the event the grid goes down,” Dankowski explained.

The question then becomes how to finance these kinds of infrastructure investments on a widespread basis. “If you are bringing private industry into the picture, there has to be a profit motive,” noted Dail.

Because of the expense involved and the limited discretionary budget dollars

available to DoD, it would be unlikely for the government to be able to finance these kinds of investments, whatever their mer-its. “These systems are very expensive, and the federal government doesn’t have the money for new projects,” said Anderson. “Paying $50 million for one of these sys-tems is not in the cards right now.”

The solution, according to Anderson, is to structure deals in such a way as to attract private financing for the projects. “The microgrid project would have to gen-erate sufficient cash flow,” he said. “That way we would not be asking the govern-ment for money but would be providing a project that is privately financed. When the grid goes down, the private source is already there and wired into critical assets to make power available at all times.”

Eaton has been asked to demonstrate this type of scheme for the U.S. military and is currently scouting locations. “We are working right now with bases and communities where the revenue structure would seem to work,” said Anderson.

In fact, community involvement would be key to acceptance of such a project. “In many cases, many people who work on the base live in the nearby community,” said Dankowski. “An agreement would have to be structured so that the base alone doesn’t get power from the microgrid in the event of an emergency, but that important com-munity assets, such as a gas station, a

In addition to power generation, the secret to an efficient system is smart distribution and management. [Photo courtesy of DoD]

jim Gribschaw

www.MLF-kmi.com12 | MLF 8.1

grocery store and a pharmacy, are also connected to the microgrid.”

“Through proper incentives it is pos-sible to meet government requirements with a private-public partnership,” said Dail, who is the former director of Defense Logistics Agency and deputy commander of the U.S. Transportation Command. “In that way, it is possible to achieve a public purpose by means of private investment.”

Dail believes such a plan can work to protect key government infrastructures both in and out of DoD. “It is critical to be able to sus-tain operations in the event of an interdiction,” he said. “This type of arrangement could also prove valuable in overseas bases such as in Bagram, Afghanistan, and Incirlik, Turkey.”

Dail estimates that perhaps half a dozen key logistics nodes might also be worthy of being served by a microgrid. “I don’t see logistics units on microgrids,” he said, “but I do see logistics information network as suited for microgrids. USTRANSCOM and DLA servers support those organizations as well as the services’ materiel commands. The collection and storage of data on those systems are key to operations.”

The most important technology ele-ments that would make the Eaton scheme work are intelligent components that work to balance power coming off the grid and the microgrid. “You have to be able to balance the power so you can bring it on cleanly,” said Dankowki. “The second piece is how to manage power on the system to direct it to where it needs to be. That is what we were trying to accomplish with three DoD demonstration projects. We are not the only ones doing this, but we strongly feel that we are past the demon-stration phase and that we can move to full commercialization.”

The Fort Bliss microgrid consists of onsite backup generation, a 120-kilowatt solar array, a 300-kilowatt energy storage system, utility grid interconnection and Lockheed Martin’s Intelligent Microgrid Control System. “The energy storage sys-tem is especially critical in maintaining a reliable stream of energy in islanded con-figurations [when the microgrid is operat-ing independently] while also providing economic benefits when grid-tied,” said

Gribschaw. “The system also stores energy to respond to high periods of energy demand and to produce reliable power.”

The same kind of idea has been imple-mented by other companies, in particular in service of forward bases. The DRASH Intelligent Power Technology (IPT), a digi-tal power management system, has been tested by several branches of the U.S. military. “IPT permits operators to create

networked microgrids in the field,” said Ron Houle, vice president for government relations at DHS. “Testing has shown its ability to sig-nificantly reduce current military fuel consumption over current technologies in the field, but also reduce maintenance and provide users with greater flexibility as well.”

Army studies have shown that IPT can reduce fuel consumption by as much as 60 percent, and the system has been recommended for full fielding. The system can be found supporting pro-grams such as Terminal High Altitude Air Defense, and Harbormaster Command and Control Center.

“As near as I know, we are the only ones who have been able to bring analog generators into a dig-ital grid,” said Houle. “We have developed a controller that allows our grid to sync with analog generator sets.”

HDT Expeditionary Sys-tems Inc. has developed a microgrid with an eye toward maximizing effi-ciency. “The HDT microgrid is single-phase, like 120 VAC house power,” said Chris Colelli, an HDT business manager. “Almost all environmental con-trol units are three-phase, and they are the largest single energy user in a forward operating base because they are attached to large generators that are dedicated to the units and run constantly.”

The HDT single-phase microgrid works with the company’s new single-phase 1.5-ton environmental control units (ECU). “Our microgrid is a hybrid of gen-erators, solar panels and lithium batteries, which means the ECU is operating on hybrid energy,” said Colelli. “The ECU can run even when the generator isn’t on.

Logistically, that enables users to use smaller generators, smaller ECUs and smaller microgrid components. Fuel sav-ings go way up and the logistical burden goes way down. The system becomes right sized for its application.” HDT’s two big-gest customers are the U.S. Army and the Marine Corps.

The HDT microgrid’s solar panels catch solar energy and charge the microgrid’s batteries as the sun comes up. As the load on the microgrid increases, the control unit may provide power from a combina-tion of batteries and the solar unit. If the batteries are depleted, one or more genera-tors kick on to provide power and replenish the batteries. When the batteries are full, the generators turn off and the microgrid returns to full battery support.

HDT’s microgrid allocates power across the system via a proprietary algorithm that operates what the company calls a buy-and-sell scheme. Units that need more power can buy it from elsewhere in a 12-shelter system. “The system knows if the batteries are full or low,” said Colelli, “so individual units can talk to each other to determine who has power, who doesn’t, and who needs it. The metric we go for is to keep the generator on 30 percent of the time. Depending on the load and level of

solar energy being captured, they might not have to be turned on at all during a given cycle.”

According to Gribschaw, the Fort Bliss project is dem-onstrating the microgrid’s ability to provide power when utility power isn’t avail-able, while also providing economic benefits. “Upon successful completion, Lock-heed Martin’s Intelligent Microgrid demonstration

will help pave the way to the implementa-tion of this technology to a wider range of Department of Defense facilities,” he said. “The Fort Bliss microgrid demonstrates the value microgrids provide in the evolving energy dynamics and ensure our custom-ers can power their most critical operations through any challenge.” O

For more information, contact Editor-in-Chief Jeff McKaughan

at [email protected] or search our online archives for related stories

at www.mlf-kmi.com.

chris colelli

ron houle

www.MLF-kmi.com MLF 8.1 | 13

Compiled by Kmi media Group staffSUPPLY CHAIN

DLA Foundation Announces Scholarship ProgramThe Defense Logistics Agency (DLA)

Foundation has announced that it plans to issue its first scholarship awards in 2014, a full year ahead of the originally planned date.

Formed in late 2012, the foundation is a non-profit philanthropic organization whose members include employees and retirees who have served with DLA. Board members and friends of the foundation have held various activities in 2013—including a charity golf tournament and a wine-tasting event at a Washington area restaurant—that will fund the scholarships. Such funds are intended to help defray the cost of post-high-school education for qualified applicants. The board intends to award a half-dozen or more schol-arships of $1,000 per awardee in the initial year.

To be considered a candidate for a DLA Foundation scholarship, a candidate must be a high school graduate, a high school senior who will graduate upon completion of his or her senior year or a college student who has completed at least a semester of undergraduate school. All candidates must be able to provide proof of their acceptance into an accredited college as a full-time student. A candidate will be recognized as full time if he or she is enrolled in 12 semester credit hours or equivalent quarter hours. The candidate must be a close family member—defined as a child, step-child, grandchild, niece or nephew—of a current or former DLA employee, whether civilian or military.

To rank among the most highly competi-tive in the selection process, high school graduates applying for college or university

for the first time should have a minimum 3.0 cumulative grade point average on a 4.0 scale. Those candidates already attending a college or university should currently maintain a minimum 3.0 cumulative grade point average on a 4.0 scale to be optimally competitive for the one-year scholarships. Scholarships will be awarded based upon a cumulative evalu-ation of candidates’ academic and extracur-ricular achievements and personally written essays. Scholarships will be awarded for undergraduate degree programs only.

The DLA Foundation will publish the application deadline and the schedule for evaluations and award announcements at www.dlafoundation.org in early 2014. Applicants will also find application forms and pertinent information about the selection process on the website.

Joint High Speed Vessel Joins 6th Fleet

The Navy’s first joint high-speed vessel recently departed Joint Expeditionary Base Little Creek-Fort Story on its maiden deployment to the U.S. 6th Fleet area of respon-sibility.

USNS Spearhead ( JHSV 1) is expected to remain in U.S. 6th Fleet until May 2014 and sail to the U.S. 4th Fleet area of responsibility through the end of fiscal year 2014. While deployed, the ship will undergo planned experimentation and testing to deter-mine the ship’s capabilities.

“The JHSV ship class will play an important part in the future of our joint forces in terms of affordability, flexibility, speed and agility,” said Rear Admiral T.K. Shannon, commander, Military Sealift Command. “Its performance to-date is solid and I think its first deployment will offer us a great opportunity to further demonstrate the important capabilities this new class brings to our fleet.”

PBL Award for USMC’s COC Program

General Dynamics Information Technology, a busi-ness unit of General Dynamics, has received the 2013 Secretary of Defense Performance-Based Logistics (PBL) Award for its work on the U.S. Marine Corps’ Combat Operations Center (COC) program.

General Dynamics, along with the Marine Corps Systems Command and Space and Naval Warfare Systems Center Atlantic, was recognized for delivering demon-strated comprehensive logistical planning and execu-tion skills on the COC program. This government and industry team successfully developed and implemented tailored PBL strategies to sustain a total of 260 COC systems in the continental U.S., outside the continental U.S. and deployed in Operation Enduring Freedom. By employing an innovative PBL approach, the team enhanced the effectiveness of the sustainment strategy, resulting in dramatic cost reductions while maintaining exceptional availability including: a 21 percent opera-tions and sustainment cost reduction, resulting in a $7.1 million savings per year; a 39 percent reduction in forward-deployed support personnel; and system avail-ability of over 90 percent.

“We congratulate the Marine Corps Systems Command and Space and Naval Warfare Systems Center Atlantic on receiving this prestigious award,” said Bernie Guerry, senior vice president for General Dynamics Information Technology’s Intelligence Solutions division.

www.MLF-kmi.com14 | MLF 8.1

U.S. Army militAry SUrfAce Deployment AnD DiStribUtion commAnD

2014

materiel mover

maj. Gen. thomas J. richardson

commanding GeneralU.S. Army military Surface Deployment and Distribution command

maersklinelimited.com

Global Challenges: American Ingenuity

99% Operational Reliabili� Today’s U.S. Merchant Marine

250 Colleagues AshoreOver 5,000 American Mariners Employed

Over 30 Years Serving the Nation

U.S. Flag Transportation Worldwide

Ship Management and Chartering for the U.S. Military

Marine Engineering and Conversions

Major General Thomas J. Richardson assumed command of the Military Surface Deployment and Distribution Command at Scott Air Force Base, Ill., on March 27, 2012.

Richardson was born in Saint Louis, Mo. He entered the U.S. Army upon graduation from Stephen F. Austin University in 1980, and was commissioned in the Quartermaster Corps.

He has held a wide variety of command and staff positions during his 31-year career. The general recently returned from Iraq where he was the J4 for U.S. Forces – Iraq. Other key assignments include: commander, Land & Maritime DLA; U.S. Pacific Command J4; executive officer to the deputy commander, Army Materiel Com-mand; commander, 64th Corps Support Group; Deputy J4, U.S. European Command; and commander, 296th Forward Support Battalion, 3rd Brigade Combat Team, 2nd Infantry Division, Fort Lewis, Wash.

His military education includes the Quartermaster Basic and Advance Courses, Combined Arms Staff School, Army Command and General Staff College, and the Industrial College of the Armed Forces. He holds a Bachelor degree in Business Administration from Stephen F. Austin State University; a Master of Military Arts and Science from U.S. Army Command and General Staff College; and a Master of Science in Strategic Resource Management from National Defense University.

His joint assignments include: commander, Defense Supply Center Columbus, Defense Logistics Agency, Columbus, Ohio, from August 2009 to September 2010; director for Logistics, Engineering and Security Assistance, J-4, U.S. Pacific Command, Camp H.M. Smith, Hawaii, from June 2007 to August 2009; and, joint logistics staff officer, and later, chief, Logistics Operations Division, and later deputy director, Logistics and Security Assistance Directorate, J-4, U.S. European Command, Germany, from June 1999 to July 2002.

Richardson’s operations assignments include: director, J-4, U.S. Forces-Iraq, Operation New Dawn, Iraq, from October 2010 to December 2011; commander, 64th Corps Support Group, Fort Hood, Texas, and Operation Iraqi Freedom, Iraq, from June 2003 to June 2005; and, Task Force S-4 observer/controller, Operations Group, Combat Maneuver Training Command, Seventh Training Center, U.S. Army Europe and Seventh Army, Germany, and support

operations officer, Seventh Army Training Command Mobile Train-ing Team and Operation Desert Storm, Saudi Arabia, from August 1989 to June 1992.

His decorations and badges include the Defense Superior Service Medal (with 2 Oak Leaf Clusters); Legion of Merit (with Oak Leaf Cluster); Bronze Star Medal; Meritorious Service Medal (with 3 Oak Leaf Clusters); Army Commendation Medal (with 2 Oak Leaf Clus-ters); Army Achievement Medal; and Parachutist Badge.

Q: Describe SDDC’s role in the Afghanistan retrograde.

A: As the Army service component command to U.S. Transporta-tion Command, we touch almost 90 percent of all cargo along the USTRANSCOM transportation pipeline through various modes of transportation, including trucks, rail, planes and ships. According to 2013 Defense Department estimates, more than 700,000 pieces will need to be moved out before the president’s 2014 deadline. That includes everything from mine-resistant ambush protected vehicles and HMMWVs to unit equipment, and more.

That said, a vast majority of equipment will be moved out of Afghanistan, and no matter what you call it—retrograde, reset, redis-tribution, redeployment or resupply—and no matter what service

Major General Thomas J. RichardsonCommanding General

U.S. Army Military Surface Deployment and Distribution Command

Materiel MoverManaging Cargo Movements Efficiently and Seamlessly

Q&AQ&A

www.MLF-kmi.com U.S. Army Military Surface Deployment and Distribution Command | MLF 8.1 | 1

U.S. ArMy MILITAry SUrFACE DEPLOyMENT AND DISTrIBUTION COMMAND

2014

Maj. Gen. Thomas RichardsonCommanding General

Virginia KingDirector, Personnel

& Logistics

Col. James RupkalvisCommander

Col. David BanianCommander

Command Sgt. Maj. Cedric Thomas

Command Sergeant Major

Stacy ParrishDirector, Intelligence

Command Sgt. Maj. Scott Reed

Command Sergeant Major

Command Sgt. Maj. Kevin McKeller

Command Sergeant Major

William BuddenDeputy to the Commander

Col. Glenn BacaDirector, Operations

SDDC HEADQUARTERS

BRigADES

DiRECTORATES

596TH TRAnSpORTATiOn BRigADE595TH TRAnSpORTATiOn BRigADE

Col. Matthew ReddingCommander

Command Sgt. Maj. Cynthia Howard

Command Sergeant Major

598TH TRAnSpORTATiOn BRigADE

U.S. ArMy MILITAry SUrFACE DEPLOyMENT AND DISTrIBUTION COMMAND

Bruce BuslerDirector

Brig. Gen. Garrett YeeDeputy Commanding General

for Mobilization

Debbie Harvey-DavisDirector, Strategy & Analysis

Curt ZarganDeputy Director

Col. David GaffneyDeputy Commander

Capt. Darrell MathisDirector, Information

Technologies

Melvin HollandDirector,

Strategic Business

Col. Ines WhiteChief of Staff

Linda WilsonDirector,

Resource Management

Capt. Aaron StanleyDirector,

Personal Property

Brig. Gen. Michael MannCommanding General

Command Sgt. Maj. Joseph Brown