measutal-digital deflection gauge.pdf

Click here to load reader

Transcript of measutal-digital deflection gauge.pdf

HEAD OFFICE69-3, Sinchon-Dong, Changwon-City, Gyeongnam, Korea. 641-370Phone. +82-55-260-6923 / +82-55-260-6250Fax. +82-55-260-6783

EUROPE OFFICEHeidenkampsweg 100,8.OG 20097 Hamburg, GermanyPhone. +49-40-2533-5656 / Fax. +49-40-2533-5661

SINGAPORE OFFICE78, Shenton Way, #16-04, Singapore 079120Phone. +65-6222-5515 / Fax. +65-6222-5525

www.doosanengine.com

Digital Type Deflection Gauge for Crankshaft

Advanced

Contents

1. Measutal Software Installation 14

1.1 Minimum System Requirements 14

1.2 Bluetooth Installation 14

1.3 Measutal Software Installation 27

2. Measutal Software User Guide 31

2.1 Project Management 32

2.2 Engine Management 34

2.3 Report 37

2.4 Com Port Setting 38

2.5 Communication Link 38

2.6 Management function 38

2.7 General Date 39

2.8 Deflection Data 41

2.9 Deflection Curve 42

Keypad Description 6

Icons 7

Display 7

Main Functions 8

Basic Components 10

Instructions in Using the Measutal Measuring Unit

Instructions in Using the Measutal Software Program

SAFETY PRECAUTIONS1) When use the display unit under sunlight, texts on LCD

can be seen unclearly.

2) Please insert the batteries (to measuring and display unit)correctly.

Keypad DescriptionIconsDisplayMain FunctionsBasic Components

Instructions in Using the Measutal Measuring Unit

REPLACING THE BATTERY

WARNING : To avoid mechanical demage, separate the Measuring Unit from

the device before opening the back cover or the battery case.

1. When the battery become exhausted or drops below the operating voltage,

will appear in the upper corner of the display.

The battery should be replaced.

2. Do not operate your Meter until the back cover and battery case are in place

and fastened securely.

MAINTENANCE

This “Measutal” is designed to provide years of dependable service, if the

following care introductions are performed.

1. Keep the Meter dry, if it gets wet, wipe it out.

2. Handle the Meter gently and carefully.

Dropping it can damage the electronic parts or the case.

3. Keep the Meter clean, wipe the case with a damp cloth, do not use chemicals.

4. Use only a fresh battery of the recommended size and type.

Remove an old or weak battery so it does not leak and damage the unit.

5. If the Meter is to be stored for a long time, the battery should be removed

to prevent damage to the unit.

6. Save these instructions for later use.

WARNING

Use extreme caution in the use of this device.

Improper use of this device can result in injury or harmful demage.

Follow all safeguards suggested in this manual, in addition to the normal

safety precautions used in working with mechanical device.

Do not service, if you are not qualified to do so.

VIEW

ㅣㅣDisplay Unitㅣㅣ

ㅣㅣINITIAL DISPLAYㅣㅣ

ㅣㅣMeasuring Unitㅣㅣ

ZERO SET BUTTON

Resets readings to zeroHas searching function in function mode

POWER BUTTONTurns the measuring unit on/off

Contact tip

DATA SET BUTTON

POWER BUTTONTurns the display unit on/off

DISPLAYDeflection dataBattery status iconFunction Mode MenuCommunication status

Shows the battery status (Display Unit)

Shows battery status (Measuring Unit)

Measured data

Battery indicator of the display unit

“NO DEVICE” message is flickering.- It means the measuring unit is off. Turn on the measuring

unit by pressing the power button.

ㅣㅣDATA VIEW MODEㅣㅣ

Battery indicator of measuring unit

After the measuring unit is turned on, “0.00” appears on the display.

- This means the measuring unit is on and ready to use.- Adjustments can be made using the zero set, data set,

and the back light buttons.

ㅣㅣFUNCTION MODEㅣㅣ

Function mode menuThe items in the function mode menu are as displayed in this picture.

- Selecting ‘1. SHOW ALL DATA’ displays the saved data.- Selecting ‘2. DELETE ALL DATA’ deletes the saved data.- ‘3. EXIT’ turns the function mode off.

Measutal

Stores the displayed dataTurning function mode

ICON DESCRIPTIONFUNCTION BUTTON DESCRIPTION

BACK LIGHTBUTTON

Turn the back light on/offHas searching function in function mode

6 / 7

MAIN FUNCTIONS 8 / 9

LCD display

ZERO SETTING

Press ZERO SET Button( )

※Press this button once thedisplay unit is turned on.

LCD display

Press LIGHT Button( )

Measuring Unit

POWER Button ON( ) Red LED ON( )

Display Unit

POWER Button ON( ) Initial display Data display

▶

Initial view Data view

Power ON/OFF

BACK LIGHT

FUNCTION MODE

SAVE DATA

VIEW SAVED DATA

MAIN FUNCTIONS

Press DATA SET Button

Select The Cylinder To Save by pressing ( ) & ( ) Buttons

Select The Point To Save by pressing ( ) & ( ) Buttons

Go to Function Mode Select‘ 1. SHOW ALL DATA’ Press DATA SET ButtonChange The Current Data of Each Cylinder

by pressing ( ) & ( ) Button

※Select 3 to exit.

Data view mode

▶ ▶

▶

ㅣㅣSelect Cylinderㅣㅣ ㅣㅣSelect Measuring Pointㅣㅣ

10 / 11

LCD display Saved data view

Data save mode(1) Data save mode(2)

Press and hold DATA SET Button more than one sec ( )

LCD display

DELETE DATA

Go to Function Mode Select ‘ 2. DELETE ALL DATA’ Press DATA SET Button

※Select 3 to exit.LCD display

Display Unit Measuring Unit

Batteries

1. Measutal Software Installation2. Measutal Software User Guide

Instructions in Using the Measutal Software Program

BASIC COMPONENTS

Install CD

Extansion Bars

BOX Manual Magnetic jig

1.1 Minimum System Requirements

• Hardware

- Intel® Pentium® 4 or AMD AthlonTM- 512 MB of system memory; 1 GB or more for best performance- Optical drive for software installation

(CD-ROM or DVD-ROM drive)- USB Port

• Software

- Windows® Vista- Windows® 2000- Windows® XP with Service Pack 2 (SP2)- Windows® XP Professional x64 Edition- MS-Office 97 or later

1.2 Bluetooth Installation

Bluetooth Driver should be installed on the computer in order toestablish connection between the Measutal Hardware Device and theMeasutal Software,

1.2.1 Measutal Software Installation using the driver CD

Insert the driver CD into your CD-ROM. An AUTORUN Windowshould pop up on your screen. If AUTORUN does not show up, run“install.exe”. Follow the following steps to proceed with theinstallation.

1. Measutal Software Installation 14 / 15

Step 2. Choose “I accept the terms and license agreement” and click on the “Next” button to proceed to the next window.

Step 1. In the AUTORUN window, click on the “Bluetooth Dongle Setup Software”.

Bluetooth Dongle

Setup Software

1. Measutal Software Installation 16 / 17

Step 3. Click the “Next” button.

Step 4. Click the “Install” button.

Installation may take several minutes.

Step 5. When a “Bluetooth not found” dialogue box appears, plug the Bluetooth dongle into a USB port into your computer and Click OK.

1. Measutal Software Installation 18 / 19

The process will then proceed to the installation of the remainingcomponents. This will take a few more minutes.

Step 1. Click the “Next” button

Step 6. Click the Finish button to complete the Blue tooth dongle software setup.

1.2.2 Bluetooth Configuration

1. Measutal Software Installation 20 / 21

Step 2. Enter computer name and type as shown above.The name you assign to this computer will be displayed to otherBluetooth devices when this computer is set to be discoverable. The default name is the name assigned by the operating system. The computer type setting determines the type of icon that is used to represent this computer to other Bluetooth devices.

※※Note : Turn on Display Unit before step 3.

Step 3. Check the “Bluetooth Serial Port” box.In the Bluetooth service selection, you can select other services by checking the box/es next to the service name, just make sure that the Bluetooth Serial Port box is checked. This is necessary so you can use the Measutal Bluetooth device. Step 5. Click the Skip button.

Step 4. Select the Measutal device icon ( ) and then click the Next button.

1. Measutal Software Installation 22 / 23

You must check the checkbox next to ‘Dev’ as shown in the abovewindow and click “configure”. The Bluetooth Properties will appear.

Step 6. Uncheck “Secure Connection” box

In the above window, the “Secure Connection” box must be unchecked.Click OK to finish the process. The Measutal Device can then be usedwith the software once it is connected to the computer.

Important!!When you can’t access the Measutal device because of Security

connection, follow this procedure.

Step 1. Double click the Bluetooth icon in the Start menu or on My Computer.

disconnect connect

1. Measutal Software Installation 24 / 25

Step 2. Click “view devices in range”.

Step 3. Double click the the Measutal Device icon.

Step 4. Click Dev and then Select View or modify configuration

Step 5. Select Local Service and Deactivate Secure Connection

1. Measutal Software Installation 26 / 27

Step 6. Select Client Applications and Deactivate Secure Connection

Step 7. Double Click Dev and Confirm whether the device is connected

Not Connected Connected

1.3 Measutal Software Installation

Insert the Measutal Software CD into the CD-ROM. Find and runMeasutal Data Management Software.exe in the CD. Install the fileafter conforming with the license terms and agreement. Enter youruser name, company name, and serial number as shown in thefollowing picture. Follow the following steps.

An initializing window will show up in the screen.

450 Dev B 450 Dev B

Step 1. Click the Data Management Software

Data Management

Software

1. Measutal Software Installation 28 / 29

Step 2. Click the Yes button.

Step 3. Enter your User name and Serial Number and then click the “Next” button. Step 5. Input the Program Folder.

Step 4. Again, click “Next”. Choose a directory folder where you want to install the files. The default folder location is C:\Program Files\Measutal Data Management Software.

1. Measutal Software Installation 2. Measutal Software User Guide 30 / 31

※ For additional information or assistance please contact us at Doosanengine, Inc.

69-3, Sinchon-Dong, Changwon-city, Gyungnam, Korea 641-370

T. 82-55-260-6670

F. 82-55-260-6400

E. HYPERLINK “mailto:[email protected]”[email protected]

Open the Measutal Software. The software interface appears as shownbelow.

The display is divided into 9 parts: Project Management①, Engine Management②, Report③, Comm port setting④, Communication Link⑤,Management Function⑥, General data⑦, Deflection Data⑧, andDeflection Curve⑨.

Step 6. Click the “Finish” button to complete the Measutal Data Management Software setup.

2. Measutal Software User Guide 32 / 33

2.1 Project Management

Measutal Software enables the user to manage deflection data andproject files. This allows the user to create a project file that hasengine deflection data.

2.1.1 New Project

When you click on “New Project” button, a pop-up window willshow up. Measutal Software provides total deflection managementsystem in all marine engines. The deflection value of various enginescan be put into the Measutal Software. Measutal Software classifiesdeflection data according to engine type such as main engine andgenerator engine. Input the project or plant name and the number ofengines. Using the Set button, you can activate the engineinformation window shown below. Enter the engine type and thenumber of engines and cylinders. Press OK. The project is generatedin the path C:\Measutal. After entering the fist engine information,click “next” to input the next engine information.

① Input the engine type and numer of main engine and sub engine

② Click “set” to activate engine information.

④ Click OK to create a project folder.

③ Input the

engine type and

cylinder numer

The location of

the project you

create is in the

Measutal folder.

The engines

entered are also

located in this

directory.

2. Measutal Software User Guide 34 / 35

2.1.2 Opening an Existing Project

When you click on the “Open Project” button a pop-up windowappears as shown below. The left side shows the project list and howmany engines are in the project. The opposite side shows the enginetype and the cylinder number. Click OK to open the selected project.

2.1.3 Delete Project

From the menu, projects can be deleted together with all the enginesdata in it.

2.1.4 Current Project & Engine

This shows the current project and engine type.

2.2 Engine Management

You can choose whether Measutal Software get the deflection datafrom Measutal device or not and save or load it.

2.2.1 New Measurement

To download the crankshaft deflection data from the MeasutalDevice, click on “New Measurement” button and activate the lowerComm port setting, Communication Link, and Management Functionmenu.

2.2.2 Downloading Data

Click on the “Load Data” to download data into the Measutalsoftware. The Measutal software will tabulate the data and calculatethe deflection value.

① Choose the main engine or sub engine.

② The selected engine type and cylinder number

2. Measutal Software User Guide 36 / 37

2.2.3 Save Data

“Save data” button stores the deflection data that is acquired fromMeasutal device. The save path is c:\Measutal and the file nameconsists of project name, engine name and date when the data wassaved. A pop up window will appear to confirm whether the data hasbeen saved or not, such as the one shown below.

2.2.4 Delete Data

Use this function when you want to delete the deflection data of anengine.

2.2.5 Current Data, Current Engine & Num

This menu shows the current project and engine type.

2.3 Report

The “Report” button generates an excel sheet which include resultsfrom the table. Ms-office Excel should be installed in the computer toenable this function. Save the resulting Excel sheet as it is notautomatically saved in the project folder. Below is an example of areport generated in Excel format.

2. Measutal Software User Guide 38 / 39

2.4 Comm Port Setting

The Measutal device communicates with the Measutal Softwarethrough a Bluetooth communication module. It is therefore importantthat the Measutal Software is set with parameters such as Serial port,Baud-rate, Data-bit, Stop-bit, and Parity.

2.5 Communication Link

The Bluetooth port can be opened after setting the Comm port up.When the Bluetooth port is not yet open, the display panel in theMeasutal device shows a flicking “NO DEVICE” sign. The Measutaldevice and Measutal Software can be connected after the Bluetoothport is opened. The connection can be made using the connectingbutton. Before connecting the device and software, a “Wait” signshows up in the Measutal device panel. The Close port button shutsdown the port and disconnects the communication.

2.6 Management function

Data can be transferred from the Measutal Device to the Softwarewhen both are connected to each other. The “Get Data” button isused to execute this process. The “Erase” button is used to deletedata from the device memory while the “Turn Off Display Unit” isused to turn the Measutal Device off.

2.7 General Data

2.7.1 Date

Save date can be set using thecalendar. Engine deflection data issaved at the date set in the calendar.

2.7.3 Temperature

Enter the Crank Chamber temperatureinto the Engine condition, engineroom temperature to Ambient,Lubrication oil temperature toLubricating Oil, and the CoolingWater temperature to HT CoolingWater.

2.7.2 Engine information

Engine information shows the enginetype and the cylinder number in theProject..

2. Measutal Software User Guide 40 / 41

2.7.4 Time

‘Continuous running hours before measuring’ refers to how long theengine has been stopped before running while ‘total running hours’ isthe total operating time since it was manufactured.

2.7.5 Draft

Input the draft of the ship in the foreside and afterside.

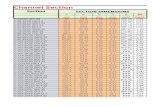

2.7.6 Crank position table

The table below shows a measurement result from a crankshaft. Theinformation include BP, P, T, E, and BE. The calculated Verticaland Horizontal deflection value are also shown in the table. The unitused is 1/100mm.

2.8 Deflection data

The vertical and horizontal deflection are graphically shown togetherwith the maximum allowable crankshaft deflection. The currentgraph can be compared with another graph in the project folder.

2.8.1 Add deflection data

In order to compare recent deflection data with previous data, Clickthe “Add Deflection Data” button. And select date.

2. Measutal Software User Guide

2.9 Deflection curve

This curve graphically shows the extent of crankshaft deflectionrelative to the vertical and horizontal. The current graph can becompared with another graph by using the Add Deflection databutton.

2.9.1 Add deflection curve

In order to compare recent deflection curve with previous data, Clickthe “Add Deflection Data” button. And select date.

Crank throw gap dimension

MEMO

Medium Speed Diesel Engine

(Unit : mm)

Model 21/31 23/30 27/38 28/32 32/40 48/60

Gap 114 108 132 114 280 276

Low Speed Diesel Engine

Model S50MC-C S50MC S60MC-C S60MC S70MC-C S70MC L70MC

Gap 162 183 194 220 226 256 256

Model K80MC-C S80MC S80MC-C L80MC K90MC-C K90MC S90MC K98MC-C

Gap 261 293 300 299 309 336 337 326

Model RTF60C RTA84 RTA96C

Gap 186 260 404