Measuring and Tracking DFSS’ Technical Benefits

-

Upload

vijaybijaj -

Category

Documents

-

view

5.485 -

download

5

description

Transcript of Measuring and Tracking DFSS’ Technical Benefits

Measuring and Tracking DFSS’ Technical Benefits

Presented at WCBF DFSS Conference

14-Sept-06

Las Vegas, NV

J. Slutsky

World Wide Dir. of DFSS

Bausch & Lomb

2

IntroductionJeff Slutsky

Global Director of Design for Six Sigma, Bausch & Lomb

World Wide DFSS/Product Development Consultant3M, Samsung, Maytag, Hoover, Westinghouse Air Brake, Trane Air Conditioning, Cummins Engine, StorageTek, Becton-DickinsonKorea, Germany, France, England, US, Malaysia

Eastman Kodak/Johnson&Johnson Health CareControl Systems Design Manufacturing Engineering, Senior

Systems Development Engineer

Adj. Professor, Rochester Institute of TechnologyGraduate and undergraduate courses in Control Systems and

Product and Production Systems Development

Co-author of the text, “Design for Six Sigma”

Voice: (585) 721-1600

3

Topics1.Goals and Conflicts

2.Critical Parameter Management (CPM) at B&L

3.The Capability Growth Index (CGI)

4.CGI Example

5. Summary

4

• To ensure fulfillment of the right set of stakeholders and the right set of needs– Accurately filling the strategic product portfolio

• To ensure tight coupling between the stakeholder needs and the engineered functions intended to fulfill those needs– Avoiding excellently performing systems that

no one wants

Major Goals of DFSS

5

• To ensure that the engineered functions are robust to the noises that cause variation in those functions

• Resulting in consistent performance over the product’s life in the intended-use environment

• Enables development to follow a disciplined, predictable and controllable process

• Allowing data-based management of money, time, resources and risk

Major Goals of DFSS

6

• To Release the Product…

On Time

On Budget &

With Adequate Quality

Major Goals of Senior Management

7

See any conflicts between these goals?

A common one exists between…

the management-driven schedule’s demand to “ship it now!”

and the engineer’s desire to “make it perfect”

Conflicts

8

Common Struggle

SystemEngineer(s)

Engineering Teams

Program Director

Senior Management

We need it by…

“But, we could do better if we only had more…”

It’s almost ready!

It’ll be ready by…

Is it ready?

Well, it workedtoday!

Is itready?

9

How is this Usually Resolved?

&

We’re out of one or both…Yup, it’s ready… ship it!

Critical Parameter Management (CPM) provides better criteria

10

CPM at B&L

SystemEngineer(s)

Engineering Teams

CP Manager

Program Director

Senior Management

We need it by…!

Here’s the data

YES, it’s ready!.. And here’s why

YES!, You’ll have it by…

CGI is 98%

Is itready?

“We could do better. But why? We’re there”

System Level Capability Growth Index (Goal is 100%)

0%10%20%30%40%50%60%70%80%90%

100%

SubSys1 SubSys2 SubSys3 SubSys4 System CGI

Dev Phase 1

Dev Phase 2

Dev Phase 3

Is itready?

Is itready?

11

CPM at B&L

SystemEngineer(s)

Engineering Teams

CP Manager

Program Director

Senior Management

We need it by…!

Here’s the data

NO!, You’ll have it by…

CGI is 65%

Is itready?

“We must do better, and we know why, where and how”

NO, it’s not ready!.. And here’s why

Is itready?

Is itready?

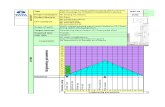

System Level Capability Growth Index (Goal is 100%)

0%10%20%30%40%50%60%70%80%90%

100%

SubSys1 SubSys2 SubSys3 SubSys4 System CGI

Dev Phase 1

Dev Phase 2

Dev Phase 3

12

What is CPM?

A method to manage the complex, many-to-many functional relationships in a product/production system

CPM links critical to function responses (CFR’s) to the manufacturing process variables

13

The Scope of CPM

CPM begins when the stakeholder needs have been captured

CPM ends when the product is retired

14

CPM at B&L

The CP manager calculates and reports the CP metrics to the Systems Engineer every week

This, along with other system metrics, are reported up to management every week

15

CPM at B&L

The System’s robustness and readiness for the next phase is constantly known by the development team and by management

A key metric is the Capability Growth Index (CGI)

16

What Is The CGI?

• The CGI is a summary statistic that quantifies the capability of many critical to function responses (CFR’s)

System/Subsystem

function5 function7

function6 function8

CGI

CFR1

CFR2

CFRn

Notes:

The CGI is not a good estimator of parts per million (PPM) since we’re adding standard deviations

Knowledge of each CFR’s probability distribution is required to convert capability to PPM

17

Subsystem Capability Growth Index (Goal is 100%)

0%10%20%30%40%50%60%70%80%90%

100%

CFR1 CFR2 CFR3 CFR4 CGI

Dev Phase 1

Dev Phase 2

Dev Phase 3

Capability Growth Index

The Subsystem-level CGI grows throughout the development process

This subsystem is at 95% of its goal

18

Capability Growth Index

System Level Capability Growth Index (Goal is 100%)

0%10%20%30%40%50%60%70%80%90%

100%

SubSys1 SubSys2 SubSys3 SubSys4 System CGI

Dev Phase 1

Dev Phase 2

Dev Phase 3

The System-level CGI grows throughout the development process

This System is at 98% of its goal

19

Calculating the CGI

• Step 1. The Capability Metric• The CGI uses a capability metric to quantify the

robustness of a system/subsystem’s critical to function responses (CFR’s)

• During the Design phase (noiseless conditions)

– The Capability metric is Cpk

– The goal during this phase is 2

• During the Optimize phase (noisy conditions)

– The Capability metric is Ppk

– The goal during this phase is 1.67

20

The CGI & Noise• During the Design phase…

– Noises are turned off– The goal is Cpk = 2, since the system is being operated

under noiseless and nominal conditions

• During the Optimize phase…– Noises are turned on– The goal is Ppk = 1.67, since the system is being

operated under stressful conditions

• Do you know your noises and their effects?

• Can you turn them off and on, at will?

21

Sample

Sam

ple

Mean

18917115313511799816345279

488

486

484

482

480

__X=484.231

UCL=486.881

LCL=481.582

Sample

Sam

ple

StD

ev

18917115313511799816345279

6.0

4.5

3.0

1.5

0.0

_S=3.360

UCL=5.281

LCL=1.439

1

1111

111

1111

1111

11

11

11

1

1

11

11

1

1

11111

1

1

1

1

11

1

1

11111

1

1

111

11

1111

111

1

111

1111

1111

11

1111

11

11

1

1

1111

11111

1111

1

1111

1

111

1

1

1

111

11

1

111111111

1

11

1

1

1

111

11

1

11

11

11

1

11

11

1

1

Xbar-S Chart of Pressure

Noise Off

Variation increase due to noise

Noise On

Effects of Noise

Mean shift due to noise

22

Calculating the CGI

Step 2. Capping the Capability Metric

• The capability metric must be capped at the phase goal

• This ensures that CFR’s with a capability greater than the phase goal do not unrealistically inflate the CGI

IF capability metric phase goal

Then capped capability metric = capability metric

IF capability metric > phase goal

Then capped capability metric = phase goal

23

Calculating the CGI

Step 3. The Comparison Ratio

Goal Phase

Metric Capability Capped Ratio Comparison

Convert each comparison ratio to a percentage

%100*ratio Comparison Ratio Comparison %

Calculate each comparison ratio

24

Calculating the CGI

Step 4. Percent Contribution

Convert each % comparison ratio to a percent contribution

n

ratio n%Compariso onContributi %

Where n = number of CFR’s in the System/Subsystem

25

Calculating the CGI

Step 5. The Capability Growth Index

)tion(%contribu Index Growth Capabilityn

1ii

Where: i = 1, … n = number of CFR’s

Calculate the CGI

26

Calculating the CGIStep 6.

Graph the CGIReport the changes up to Systems EngAgree on actions based on the changesRepeat steps regularly (weekly, even if there’s no change)

System Level Capability Growth Index (Goal is 100%)

0%10%20%30%40%50%60%70%80%90%

100%

SubSys1 SubSys2 SubSys3 SubSys4 System CGI

Dev Phase 1

Dev Phase 2

Dev Phase 3

27

An Example

Subsystem1

function5 function7

function6 function8

1Cpk

2Cpk

4Cpk

CGI

CFR1

CFR2

CFR4

The CGI goal is 100% for the SubsystemCFR- Critical to function response

Step 1- Assume:

•We’re in the Design phase

Capability metric is Cpk & the phase goal = 2

•A subsystem with 4 CFR’s, (n=4)

28

An ExampleAssume:

Each CFR has the following Cpk’s measured under noiseless conditions

CFR 1: Cpk = 0.7

CFR 2: Cpk = 1.4

CFR 3: Cpk = 1

CFR 4: Cpk = 2.3

Step 2. Cap the capabilities at the phase goal

Capped CFR 1: Cpk = 0.7

Capped CFR 2: Cpk = 1.4

Capped CFR 3: Cpk = 1

Capped CFR 4: Cpk = 2 capped at the Design phase goal of 2

29

An Example

Step 3. Calculate the Comparison Ratio

CFR 1 (Capped Cpk) / 2 = 0.7/2 = 0.35

CFR 2 (Capped Cpk) / 2 = 1.4/2 = 0.7

CFR 3 (Capped Cpk) / 2 = 1/2 = 0.5

CFR 4 (Capped Cpk) / 2 = 2/2 = 1.0

Convert each comparison ratio to a percentage CFR 1: 0.35 x 100 = 35%

CFR 2: 0.7 x 100 = 70% CFR 3: 0.5 x 100 = 50% CFR 4: 1.0 x 100 = 100% - CFR 4 is at its goal!

30

An ExampleStep 4. Calculate each CFR’s % contribution

Divide capped % comparison ratio by the number of CFR’s

CFR 1: 35%/4 = 9%

CFR 2: 70%/4 = 18%

CFR 3: 50%/4 = 13%

CFR 4: 100%/4 = 25%

Step 5. Sum each percentage to get the CGI

CGI = 64%

The goal is 100%

Which CFR would you work on first, last, never?

It’s helpful to report this graphically

31

An ExampleStep 6.

Graph the CGIReport the changesAgree on actions based on the changes

Subsystem Capability Growth Index (Goal is 100%)

0%10%20%30%40%50%60%70%80%90%

100%

CFR1 CFR2 CFR3 CFR4 CGI

Current week

32

An Example

Which CFR would you work on first, last, never?

How would you report status up to management?

Subsystem Capability Growth Index (Goal is 100%)

0%10%20%30%40%50%60%70%80%90%

100%

CFR1 CFR2 CFR3 CFR4 CGI

Current week

33

An Example

Roll up each subsystem CGI into a System CGI

System Level Capability Growth Index (Goal is 100%)

0%10%20%30%40%50%60%70%80%90%

100%

SubSys1 SubSys2 SubSys3 SubSys4 System CGI

Current Week

Which Subsystem would you work on first, last, never?

How would you report status up to management?

34

Summary

CPM provides a data-based method to manage the conflict between the management-driven schedule’s demand to “ship it now!” and the engineer’s desire to “make it perfect”

The role of CP manager is crucial in providing the data and ensuring that it is obtained under the right conditions of noise

35

All material based on the book;

“Design for Six Sigma in Technology and Product Development”

Creveling, Slutsky, Antis,

Prentice-Hall, 2003

36

Thank You