Mass Transfer 3rd Module

description

Transcript of Mass Transfer 3rd Module

-

LEACHING

Leaching is concerned with the extraction of a soluble constituent from a solid by means of a solvent.

The process may be used either for the production of a concentrated solution of a valuable solid

material, or in order to remove an insoluble solid, such as a pigment,from a soluble material with which

it is contaminated.

If the solute is uniformly dispersed in the solid, the material near the surface will be dissolved first,

leaving a porous structure in the solid residue. The solvent will then have to penetrate this outer layer

before it can reach further solute, and the process will become progressively more difficult and the

extraction rate will fall.

If the solute forms a very high proportion of the solid, the porous structure may break down almost

immediately to give a fine deposit of insoluble residue, and access of solvent to the solute will not be

impeded.

Generally, the process can be considered in three parts:

first the change of phase of the solute as it dissolves in the solvent,

secondly its diffusion through the solvent in the pores of the solid to the outside of the particle,

thirdly the transfer of the solute from the solution in contact with the particles to the main bulk

of the solution.

Any one of these three processes may be responsible for limiting the extraction rate, though the first

process usually occurs so rapidly that it has a negligible effect on the overall rate.

Factors influencing the rate of extraction

There are four important factors to be considered:

1) Particle size.

Particle size influences the extraction rate in a number of ways.

The smaller the size, the greater is the interfacial area between the solid and liquid, and

therefore the higher is the rate of transfer of material and the smaller is the distance the solute

must diffuse within the solid as already indicated.

On the other hand, the surface may not be so effectively used with a very fine material if

circulation of the liquid is impeded, and separation of the particles from the liquid and drainage

of the solid residue are made more difficult.

It is generally desirable that the range of particle size should be small so that each particle

requires approximately the same time for extraction and, in particular, the production of a large

amount of fine material should be avoided as this may wedge in the interstices of the larger

particles and impede the flow of the solvent.

-

2) Solvent.

The liquid chosen should be a good selective solvent and its viscosity should be sufficiently low

for it to circulate freely.

Generally, a relatively pure solvent will be used initially, although as the extraction proceeds the

concentration of solute will increase and the rate of extraction will progressively decrease, first

because the concentration gradient will be reduced, and secondly because the solution will

generally become more viscous.

3) Temperature.

In most cases, the solubility of the material which is being extracted will increase with

temperature to give a higher rate of extraction.

Further, the diffusion coefficient will be expected to increase with rise in temperature and this

will also improve the rate of extraction.

In some cases, the upper limit of temperature is determined by secondary considerations, such

as, for example, the necessity to avoid enzyme action during the extraction of sugar.

4) Agitation of the fluid.

Agitation of the solvent is important because this increases the eddy diffusion and therefore the

transfer of material from the surface of the particles to the bulk of the solution,

Further, agitation of suspensions of fine particles prevents sedimentation and more effective

use is made of the interfacial surface.

-

MOVING BED LEACHING

In the machines that are used for this type of leaching, the solids are moved through the solvent with

little or no agitation.

BOLLMAN EXTRACTOR

The bollman extractor (figure) contains a bucket elevator in a closed casing.

There are perforations in the bottom of each bucket.

At the top right-hand corner of the machine ,the buckets are loaded with flaky solids such as soybeans

and are sprayed with appropriate amounts of half miscella as they travel downward.

Half miscella is the intermediate solvent containing some extracted oil and some small solid particles.

As solids and solvent flow cocurrently down the right-hand side of the machine ,the solvent extracts

more oil from beans.

The fresh solvent is added during the upward movement of the baskets so that this part operates

countercurrent.

The already preloaded solution is withdrawn from the bottom of the extractor and enters the downward

moving baskets so that this part of the extractor operates in a cocurrent way.

The full miscella is withdrawn at the bottom of the extractor.

In the baskets self filtration takes place, so that no further treatment of the miscella is necessary

Simultaneously the fine solids are filtered out of the solvent, so that clean full miscella (oil in solvent

solution) can be pumped from the right hand sump at the bottom of the casing.

As the partially extracted beans rise through the left side of the machine ,a stream of pure solvent

percolates countercurrently through them.It collects in the left-hand sump and is pumped to the half-

miscella storage tank.

Fully extracted beans are dumped from the buckets at the top of the elevator into a hopper from which

they are removed by paddle conveyors.

-

HILDEBRANDT EXTRACTOR

A U-shaped screw conveyor with a separate helix in each section.

The helices turn at different speeds to give considerable compaction of the solids in the horizontal

section.

Solids are fed to one leg of the U and Fresh solvent to give counter current flow.

The solid material is extracted according to the immersion method.

Screwconveyors are installed in the extractor for transporting the solid material.

Again the solvent flows countercurrent to the solid materials through the extractor

APPLICATION OF LEACHING

1) Preparation of tea from tea leaves

2) Extraction of gold from NaCN as solvent

3) Removal of Oil from Oil cake using hexane as solvent

4) Extraction of sugar from sugar beet using hot water

5) Extraction of perfumes from flowers

-

ADSORPTION

Adsorption is the adhesion of atoms, ions, biomolecules or molecules of gas, liquid, or dissolved solids to

a surface.

This process creates a film of the adsorbate (the molecules or atoms being accumulated) on the surface

of the adsorbent.

It differs from absorption, in which a fluid permeates or is dissolved by a liquid or solid.

The term sorption encompasses both processes, while desorption is the reverse of adsorption. It is a

surface phenomenon.

The binding to the surface is usually weak and reversible.

Solid Substance used for adsorption is called Adsorbant.

Molecules adsorbed on the surface are called Adsorbate.

Application of Adsorption

1. Removal of Toxic gases from other gases in refineries

2. Removal of colour from sugar

3. Dehumidification of aor

4. Removal of moisture from gasoline

5. Water Purification

Adsorbents

Characteristics and general requirements

Adsorbents are used usually in the form of spherical pellets, rods, moldings, or monoliths with

hydrodynamic diameters between 0.5 and 10 mm.

They must have high abrasion resistance, high thermal stability and small pore diameters, which results

in higher exposed surface area and hence high surface capacity for adsorption.

The adsorbents must also have a distinct pore structure which enables fast transport of the gaseous

vapors.

Types of Adsorbants

Oxygen-containing compounds Are typically hydrophilic and polar, including materials such as

silica gel and zeolites.

Carbon-based compounds Are typically hydrophobic and non-polar, including materials such as

activated carbon and graphite.

Polymer-based compounds - Are polar or non-polar functional groups in a porous polymer matrix.

-

CHARACTERIZATION OF ADSORPTION BY SOLIDS

1. Amt of substance adsorbed per unit mass of the adsorbant depends on the equipment

concentraion, Pressure and Temperature of adsorbate

2. Larger the area greater the adsorption

3. Amt of substance adsorbed per unit mass of adsorbant depends on the chemical nature of the

adsorbant and the physical state

4. Adsorption can be highly selective

5. Adsorption is generaly reversible

APPLICATION OF COMMERCIAL ADSORBANTS

Silica Gel- Drying of gases , Organic Solvents

Carbon- Removal of N2 from air, Removal of odour from gas, and then Solvent Vapours

Zeolite- drying of process air, CO2 removal from natural gas,

CO removal fromreforming gas, air separation, catalytic cracking, and

catalytic synthesis and reforming

Polymers And Resin-Water Purification,Recovery And Purification of Steroids

Clay-Treatment of Edible Oil,Removal of Organic Pigments,Refining of Mineral Oils

CHEMISORPTION

Chemisorption (or chemical adsorption) is adsorption in which the forces involved are valence forces of

the same kind as those operating in the formation of chemical compounds.

Some features which are useful in recognizing chemisorption include:

the phenomenon is characterized by chemical specificity;

heat of adsorption is large and it is in the order of heat of the reaction

it is usually Irreversible

restricted to active site on the surface

Qty of substance adsorbed per unit mass of the adsorbant is less

where the activation energy for adsorption is large (activated adsorption), true equilibrium may

be achieved slowly

since the adsorbed molecules are linked to the surface by valence bonds, they will usually

occupy certain adsorption sites on the surface and only one layer of chemisorbed molecules is

formed

Rate of adsorption is negligible at low temp and increases with increase in temperature

-

Rate is controlled by resistance to surface tension

Adsorption at low Pressure is large and slightly increases with high pressure

PHYSISORPTION

or -physical adsorption- is adsorption in which the forces involved are intermolecular forces (van

der Waals forces) of the same kind as those responsible for the imperfection of real gases and

the condensation of vapours, and which do not involve a significant change in the electronic

orbital patterns of the species involved..

Some features which are useful in recognizing physisorption include

1. Force of attraction btw Molecules is very less

2. Heat of adsorption is less which is in the order of heat of condensation

3. Reversible

4. Entire surface is available for adsorption

5. Low activation energy

6. Rate of adsorption is very rapid at low temperature and decreases with high temperature

7. Rate is controlled by resistance to mass transfer

8. Adsorption at low Pressure is low and high at high Pressure

9. Surface Coverage is complete and can be extended to Multi stage

Adsorption Isotherms

Surface coverage of adsorbate is a function of adsorptive gas or vapour pressure = adsorption isotherm

(constant temp)

It is the equilibrium relation connecting the concentration of adsorbant in the solid phase and the conc

of adsorbate in the liquid phase

Conc of adsorbant in the solid phase = Kg of substance adsorbed Kg of adorbent

In the case of gas,concentration is expressed in Pressure or Mole%

In the case of soln,concentration is expressed in terms of ppm or mole %

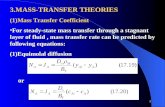

FRENDLICH ISOTHERM

The first mathematical fit to an isotherm was published by Freundlich and Kster (1894) and is a purely

empirical formula for gaseous adsorbates,

-

=

where x is the quantity adsorbed, m is the mass of the adsorbent, P is the pressure of adsorbate k and n

are empirical constants for each adsorbent-adsorbate pair at a given temperature.

The function has an asymptotic maximum as pressure increases without bound. As the temperature

increases, the constants k and n change to reflect the empirical observation that the quantity adsorbed

rises more slowly and higher pressures are required to saturate the surface.

Log C= log k + nlog (x/m)

Adsorption hysteresis

In this type of hysteresis, the quantity adsorbed is different when gas is being added than it is when

being removed. The specific causes of adsorption hysteresis are still an active area of research, but it is

linked to differences in the nucleation and evaporation mechanisms inside mesopores. These

mechanisms are further complicated by effects such as cavitation and pore blocking.

In physical adsorption, hysteresis is evidence of mesoporosity-indeed, the definition of mesopores (2-50

nm) is associated with the appearance (50 nm) and disappearance (2 nm) of mesoporosity in nitrogen

adsorption isotherms as a function of Kelvin radius.

An adsorption isotherm showing hysteresis is said to be of Type IV (for a wetting adsorbate) or Type V

(for a non-wetting adsorbate), and hysteresis loops themselves are classified according to how

symmetric the loop is.

Adsorption hysteresis loops also have the unusual property that it is possible to scan within a hysteresis

loop by reversing the direction of adsorption while on a point on the loop. The resulting scans are called

"crossing," "converging," or "returning," depending on the shape of the isotherm at this point.

-

Fixed Bed Adsorption (Percolation)

The cyclic-batch operating mode using fixed bed, as shown in the Figure below, is widely used with both

gas and liquid feeds

Separation in a fixed bed is, in virtually all practical cases, an unsteady state rate-controlled process.

This means that conditions at any particular point within the fixed bed vary with time. Adsorption only

occurs in a particular region of the bed, known as the mass transfer zone (MTZ), which moves through

the bed.

Applications of fixed bed adsorption, also called percolation, include the removal of dissolved organic

compounds from water.

The main advantages of fixed bed system are

the simplicity of equipment needed

they are relatively inexpensive to fabricate.

The main disadvantage of fixed bed systems

Pressure drop across the bed is large

Poor Heat transfer to long heating and cooling times which creates the need for large beds

Factors which determine the no and arrangement of fixed bed include

Total feed flow rate

Allowable pressure drop

Method of adsorbant regeneration

Capital investment

-

Pressure swing adsorption

Pressure swing adsorption (PSA) is a technology used to separate some gas species from a mixture of

gases under pressure according to the species' molecular characteristics and affinity for an adsorbent

material.

It operates at near-ambient temperatures and so differs from cryogenic distillation techniques of gas

separation.

Special adsorptive materials (e.g., zeolites) are used as a molecular sieve, preferentially adsorbing the

target gas species at high pressure.

The process then swings to low pressure to desorb the adsorbent material.

Process

Pressure swing adsorption processes rely on the fact that under pressure, gases tend to be attracted to

solid surfaces, or "adsorbed".

The higher the pressure, the more gas is adsorbed; when the pressure is reduced, the gas is released, or

desorbed.

PSA processes can be used to separate gases in a mixture because different gases tend to be attracted

to different solid surfaces more or less strongly.

If a gas mixture such as air, for example, is passed under pressure through a vessel containing an

adsorbent bed that attracts nitrogen more strongly than it does oxygen, part or all of the nitrogen will

stay in the bed, and the gas coming out of the vessel will be enriched in oxygen.

When the bed reaches the end of its capacity to adsorb nitrogen, it can be regenerated by reducing the

pressure, thereby releasing the adsorbed nitrogen.

It is then ready for another cycle of producing oxygen enriched air.

This is exactly the process used in portable oxygen concentrators used by emphysema patients and

others who require oxygen enriched air to breathe.

-

Using two adsorbent vessels allows near-continuous production of the target gas.

It also permits so-called pressure equalisation, where the gas leaving the vessel being depressured is

used to partially pressurise the second vessel.

This results in significant energy savings, and is common industrial practice.

Adsorbents

Aside from their ability to discriminate between different gases, adsorbents for PSA systems are usually

very porous materials chosen because of their large surface areas. Typical adsorbents are activated

carbon, silica gel, alumina and zeolite

Applications

removal of carbon dioxide (CO2) as the final step in the large-scale commercial synthesis of

hydrogen (H2) for use in oil refineries and in the production of ammonia (NH3). Refineries often

use PSA technology in the removal of hydrogen sulfide (H2S) from hydrogen feed and recycle

streams of hydrotreating and hydrocracking units.

Another application of PSA is the separation of carbon dioxide from biogas to increase the

methane (CH4) content. Through PSA the biogas can be upgraded to a quality similar to natural

gas.

-

CRYSTALLISATION

Crystallization is the (natural or artificial) process for the formation of solid crystals from a uniform

solution.

More than 80% of the substances used in pharmaceuticals, fine chemicals, agrochemicals, food and

cosmetics are isolated or formulated in their solid form.

Crystallization is in general the last chemical purification step in the production of ingredients.

Since the properties of a solid material (polymorphism) can dramatically affect the process or the

products compliance and effect (dissolution rate for example), monitoring and controlling the isolation

of solids for the various applications through crystallization is of paramount interest.

Crystallization is also a chemical solid-liquid separation technique, in which mass transfer of a solute

from the liquid solution to a pure solid crystalline phase occurs.

MAGMA

2 phase mixture which consists of mother liquor (of the solution) with the crystals of all the sizes which

are obtained in a crystallizer.

EQUILLIBRIUM

In Crystallization, equillibrium is attained when solution becomes saturated.

Most materials follow the curve similar to Curve 1(ie Solubility increase with temperature)

Curve 2 shows little change in solubility with T

Curve 3-inverted solubility curve (ie solubilty decreases with increase in temperature)

IMPORTANCE OF CRYSTAL SIZE

Crystal size plays an important role and also good yields and purity.

Caking of crystals

Crystalline materials frequently cake or cement together on storage and crystal size, shape, moisture

content, and storage conditions can all contribute to the caking tendency.

caking is caused by a dampening of the crystal surfaces in storage because of inefficient drying or an

increase in atmospheric humidity above some critical value that depends on both substance and

temperature.

-

Caking may be minimised by efficient drying, packaging in airtight containers, and avoiding compaction

on storage. In addition,crystals may be coated with an inert dust that acts as a moisture barrier

Swenson-walker crystallizer

A Swenson forced-circulation crystalliser operating at reduced pressure is shown.

A high recirculation rate through the external heat exchanger is used toprovide good heat transfer with

minimal encrustation.The crystal magma is circulated fromthe lower conical section of the evaporator

body, through the vertical tubular heat exchanger,and reintroduced tangentially into the evaporator

below the liquor level to create a swirlingaction and prevent flashing.

Feed-stock enters on the pump inlet side of the circulation system and product crystal magma is

removed below the conical section.

-

MEMBRANE SEPARATION PROCESSES

A membrane is a thin barrier which allows selective passage of different species through it.This

selectivity is utilized for separation.

The selectivity is due to: Size, Shape,Electrostatic charge, Diffusivity, Physicochemical interactions,

Volatility Polarity/solubility.

APPLICATIONS

Product concentration, i.e. removal of solvent from solute/s

Clarification, i.e. removal of particles from fluids, a special case being sterilization which refers to

removal of microorganisms from fluids

Removal of solute from solvent, e.g. desalting, desalination, demineralization, dialysis

Fractionation, i.e. separation of one solute from another

Gas separation, i.e. separation of one gas from another

Pervaporation, i.e. removal of volatiles from non volatiles (usually solvents)

MEMBRANE MATERIAL

Organic polymers

Polysulfone (PS) Polyethersulfone (PES) Cellulose acetate (CA) Regenerated cellulose Polyamides (PA)

Polyvinylidedefluoride (PVDF) Polyacrylonitrile (PAN)

Inorganics

Gamma-alumina, alpha-alumina, Borosilicate glass, Pyrolyzed carbon Zirconia/stainless steel, Zirconia

carbon.

-

DRIVING FORCE IN MEMBRANE PROCESSES

Transmembrane pressure (TMP),Concentration gradient, Chemical potential, Osmotic pressure, Electric

field,Magnetic field, Partial pressure, pH gradient

TYPES OF MEMBRANE SEPARATION PROCESSES

REVERSE OSMOSIS

In the reverse osmosis (RO) process, water passes through a membrane,leaving behind a solution with a

smaller volume and a higher concentration of solutes. The solutes can be contaminants or useful

chemicals or reagents, such as copper, nickel, and chromium compounds, which can be recycled for

further use in metals plating or other metal finishing processes.

The recovered water (penneate) can be recycled or treated downstream, depending on the quality of

the water and the needs of the plant.

-

As shown in Figure, the water that passes through the membrane is defined as permeate and the

concentrated solution left behind is defined as retentaie (or concentrate).

The RO process does not require thermal energy, only an electrically driven feed pump. RO processes

have simple flow sheets and a high energy efficiency.

However, RO membranes can be fouled or damaged. This can result in holes in the membrane and

passage of the concentrated solution to clean water, and thus a release to the environment. In addition,

some membrane materials are susceptible to attack by oxidizing agents, such as free chlorine.

Applications

Drinking water purification

household drinking water purification systems, including a reverse osmosis step, are commonly used for

improving water for drinking and cooking.

Such systems typically include a number of steps:

a sediment filter to trap particles, including rust and calcium carbonate

optionally, a second sediment filter with smaller pores

an activated carbon filter to trap organic chemicals and chlorine, which will attack and degrade TFC

reverse osmosis membranes

a reverse osmosis (RO) filter, which is a thin film composite membrane (TFM or TFC)

optionally, a second carbon filter to capture those chemicals not removed by the RO membrane

optionally an ultra-violet lamp for disinfecting any microbes that may escape filtering by the reverse

osmosis membrane

Water and wastewater purification

Rain water collected from storm drains is purified with reverse osmosis water processors and used for

landscape irrigation and industrial cooling in Los Angeles and other cities, as a solution to the problem of

water shortages.

In industry, reverse osmosis removes minerals from boiler water at power plants.The water is boiled

and condensed repeatedly. It must be as pure as possible so that it does not leave deposits on the

machinery or cause corrosion. The deposits inside or outside the boiler tubes may result in under-

performance of the boiler, bringing down its efficiency and resulting in poor steam production,

hence poor power production at turbine.

It is also used to clean effluent and brackish groundwater. The effluent in larger volumes (more than

500 cu. meter per day) should be treated in an effluent treatment plant first, and then the clear

-

effluent is subjected to reverse osmosis system. Treatment cost is reduced significantly and

membrane life of the RO system is increased.

The process of reverse osmosis can be used for the production of deionized water.

RO process for water purification does not require thermal energy. Flow through RO system can be

regulated by high pressure pump. The recovery of purified water depend upon various factor including -

membrane sizes, membrane pore size, temperature, operating pressure and membrane surface area.

Reverse Osmosis - Pros and Cons

The semi-permeable membrane used in reverse osmosis contains tiny pores through which water can

flow.

The small pores of this membrane are restrictive to such organic compounds as salt and other natural

minerals, which generally have a larger molecular composition than water.

These pores are also restrictive to bacteria and disease-causing pathogens.

Thus, reverse osmosis is incredibly effective at desalinating water and providing mineral-free water for

use in photo or print shops.

It is also effective at providing pathogen-free water. In areas not receiving municipally treated water or

at particular risk of waterborne diseases, reverse osmosis is an ideal process of contaminant removal.

The reverse osmosis process contains several downsides which make it an inefficient and ineffective

means of purifying drinking water. The small pores in the membrane block particles of large molecular

structure like salt, but more dangerous chemicals like pesticides, herbicides, and chlorine are

molecularly smaller than water

These chemicals can freely pass through the porous membrane. For this reason, a carbon filter must be

used as a complimentary measure to provide safe drinking water from the reverse osmosis process.

Such chemicals are the major contaminants of drinking water after municipal treatment.

Another downside to reverse osmosis as a method of purifying drinking water is the removal of healthy,

naturally occurring minerals in water. The membrane of a reverse osmosis system is impermeable to

natural trace minerals. These minerals not only provide a good taste to water, but they also serve a vital

function in the bodys system. Water, when stripped of these trace minerals, can actually be unhealthy

for the body.

Reverse osmosis also wastes a large portion of the water that runs through its system. It generally

wastes two to three gallons of water for every gallon of purified water it produces. Reverse osmosis is

also an incredibly slow process when compared to other water treatment alternatives.

-

ULTRAFILTRATION

Ultrafiltration is most commonly used to separate a solution that has a mixture of some desirable

components and some that are not desirable.

Typical rejected species include sugars, bio-molecules, polymers and colloidal particles.

UF processes operate at 2-10 bars though in some cases up to 25-30 bars Pre. have been used.

UF usually implies separation of macromolecules such as protein from low molecular weight solvents

Ultrafiltration is a technique for separating dissolved molecules in solution on the basis of size which

means that molecules larger than the membrane pore size rating will be retained at the surface of the

membrane.

The accumulation of retained molecules may form a concentrated gel layer. The impact of gel-layer

formation is that it can significantly alter the performance characteristics of the membrane. This is

commonly called concentration polarization.

Fundamentally, the gel layer will limit filtrate flow rate and any increase in pressure will have no

beneficial effect

Application

Oil emulsion waste treatment.

Treatment of whey in dairy industries.

Electro coat paint recovery.

Concentration of textile sizing.

Concentration of gelatin.

Enzyme & pharmaceutical preparations

Pulp mill waste treatment.

Production of ultra pure water for electronics industry.

-

MICROFILTRATION

Microfiltration is a separation technique for removing micron sized particles, like bacteria, yeast cells,

colloids, and smoke particles, from suspensions or gases.

The process uses membrane filters with pores in the approximate size range 0.1 to 10 micro meter,

which are permeable to the fluid, but retain the particles, thus causing separation.

The MF membranes are made from natural or synthetic polymers such as cellulose nitrate or acetate,

polyamides, polysulfone, polycarbonate, polypropylene,etc.

Examples of micro filtration applications are:

Cold sterilisation of beverages and pharmaceuticals

Clearing of fruit juice, wines and beer

Separation of bacteria from water (biological wastewater treatment)

Effluent treatment

Separation of oil/ water emulsions

Pre-treatment of water for nano filtration or Reverse Osmosis

ION EXCHANGE

Ion exchange is a reversible chemical reaction where an ion from a solution is exchanged for a similarly

charged ion attached to an immobile solid particle.

The basis of separations is that components to be separated distribute unequally between the solution

and the solid particle.

ION EXCHANGE RESINS

Ion exchange resins are polymers that are capable of exchanging particular ions within the polymer with

ions in a solution that is passed through them. This ability is also seen invarious natural systems such as

soils and living cells.

The synthetic resins are used primarily for purifying water, but also for various other applications

including separating out some elements

RESIN TYPES

Ion exchange resins are classified as cation exchangers, which have positively charged mobile ions

available for exchange, and anion exchangers, whose exchangeable ions are negatively charged.

Both anion and cation resins are produced from the same basic organic polymers. They differ in the

ionizable group attached to the hydrocarbon network. It is this functional group that determines the

chemical behavior of the resin.

-

Resins can be broadly classified as strong or weak acid cation exchangers or strong or weak base anion

exchangers. In an ion exchange process, cations or anions in a liquid solution (usually aqueous) replace

dissimilar and displaceable ions of the same charge contained in the ion exchange resin.

Strong acid resins are so named because their chemical behavior is similar to that of a strong acid. The

resins are highly ionized in both the acid (R-SO3H) and salt (R-SO3Na) form of the sulfonic acid group.

They can convert a metal salt to the corresponding acid by the reaction

2 (R-SO3H) + NiCl2(R-SO4)-Ni + 2 HCl

These resins would be used in the hydrogen form for complete deionization; they are used in the

sodium form for water softening (calcium and magnesium removal). After exhaustion, the resin is

converted back to the hydrogen form (regenerated) by contact with a strong acid solution, or the resin

can be convened to the sodium form with a sodium chloride solution. For the above reaction,

hydrochloric acid (HCl) regeneration would result in a concentrated nickel chloride (NiCl) solution.

In a weak acid resin the ionizable group is a carboxylic acid (COOH) as opposed to the sulfonic acid group

(SO3H) used in strong acid resins. These resins behave similarly to weak organic acids that are weakly

dissociated

APPLICATIONS OF ION EXCHANGE

Treatment of water for drinking, use (commercial, industrial, and residential), and wastewater

treatment.

Ion exchangers can soften the water, deionize it, and even be used in desalination.

In industrial uses, pure water is often crucial for the successful development of a product.

Preparation of various acids, bases, salts, and solutions is also aided by ion exchange. Analytical

chemistry uses ion exchange in chromatography.

The recovery of valuable metals is also possible with resins.

Industrial drying of treatment of gases is accomplished often with ion exchange.

The food industry uses ion exchange in a variety of ways, ranging from wine-making to sugar

manufacture.

Ion exchange is used to prevent coagulation in blood stores and in dextrose, as well

-

HOLLOW FIBER MEMBRANES

Hollow fiber membranes are membranes with a diameter of below 0.1 m. the chances of plugging of a

hollow fiber membrane are very high.

The membranes can only be used for the treatment of water with a low suspended solids content.

The packing density of a hollow fiber membrane is very high

Hollow fiber membranes are nearly always used merely for Reverse osmosis.

Hollow Fiber Ultrafiltration membrane is an asymmetric semi-permeable membrane made of high

molecular chemical material by special technology.

It presents hollow capillary tube shape (or hollow fiber shape), micro-pore covers tube wall densely.

Feed liquid is flowing in or out the membrane under the influence of pressure, dissolvent or small

molecular can permeate membrane and become product liquid by collection, while large molecular

(protein, each kind of enzyme, nucleic acid, polysaccharide and so on) colloid particle (such as emulsion,

micro-ion) and bacterium are cut off of the membrane and are taken off by the circulating flowing feed

liquid to become concentrating liquid. That is the process of separating, concentrating, and purifying

substance.

Advantages of Hollow Fibre Membranes

Hollow fiber is one of the most popular membranes used in industries. It is because of its several

beneficial features that make it attractive for those industries. Among them are :

Modest energy requirement : In hollow fiber filtration process, no phase change is involed.

Consequently, need no latent heat. This makes the hollow fiber membrane have the potential to

replace some unit operation which consume heat, such as distillation or evaporation column.

-

No waste products : Since the basic principal of hollow fiber is filtration, it does not create any

waste from its operation except the unwanted component in the feed stream. This can help to

decrease the cost of operation to handle the waste.

Large surface per unit volume : Hollow fiber has large membrane surface per module volume.

Hence, the size of hollow fiber is smaller than other type of membrane but can give higher

performance.

Flexible : Hollow fiber is a flexible membrane, it, it can carry out the filtration by 2 ways, either is

inside-out or outside-in.

Low operation cost : Hollow fiber need low operation cost compare to other types of unit

operations

DISADVANTAGES

Membrane fouling : Membrane fouling of hollow fiber is more frequent than other membrane

due to is configuration. Contaminated feed will increase the rate of membrane fouling,

especially for hollow fiber.

Expensive : Hollow Fiber is more expensive than other membrane which available in market. It is

because of its fabrication method and expense is higher than other membranes.

Lack of research : Hollow fiber is a new tachnology and so far, research done on it is less

compare to other types of membrane. Hence, more research will be done on it in future

because of its potential.

Thermal diffusion

Diffusion is the movement, under the influence of a physical stimulus, of an individual component

through a mixture. The term thermal itself denotes that the diffusion is caused due to temperature

gradient. Molecular diffusion which is induced bytemperature is referred to as Thermal Diffusion

Sweep diffusion

If a condensable vapor (steam) is allowed to diffuse through a gas mixture, it carries one of the

components along with it, thus making a separation by the operation known as Sweep diffusion

membrane fouling

A limitation to the more widespread use of membrane separation processes is membrane fouling, as

would be expected in the industrial application of very finely porous materials.

Fouling results in a continuous decline in membrane permeation rate, an increased rejection of low

molecular weight solutes and eventually blocking of flow channels.

On start-up of a process, a reduction in membrane permeation rate to 3010 per cent of the pure water

permeation rate after a few minutes of operation is common for ultrafiltration.

-

Such a rapid decrease may be even more extreme for microfiltration. This is often followed by a more

gradual decrease throughout processing. Fouling is partly due to blocking or reduction in effective

diameter of membrane pores, and partly due to the formation of a slowly thickening layer on the

membrane surface.

The extent of membrane fouling depends on the nature of the membrane used and on the properties of

the process feed.

The first means of control is therefore careful choice of membrane type.

Secondly, a module design which provides suitable hydrodynamic conditions for the particular

application should be chosen. Process feed pretreatment is also important. The type of pretreatment

used in reverse osmosis for desalination applications .

In biotechnological applications pretreatment might include prefiltration, pasteurisation to destroy

bacteria, or adjustment of pH or ionic strength to prevent protein precipitation.

When membrane fouling has occurred, backflushing of the membrane may substantially restore the

permeation rate. This is seldom totally effective however, so that chemical cleaning is eventually

required. This involves interruption of the separation process, and consequently time losses due to the

extensive nature of cleaning required.

Thus, a typical cleaning procedure might involve:

flushing with filtered water at 3550 .C to displace residual retentate; recirculation or back-flushing

with a cleaning agent, possibly at elevated temperature; rinsing with water to remove the cleaning

agent; sterilisation by recirculation of a solution of 50100 ppm of chlorine for 1030 minutes (600

1800s) at (293303 K) (2030 .C); and flushing with water to remove sterilising solution.

More recent approaches to the control of membrane fouling include the use of more sophisticated

hydrodynamic control effected by pulsated feed flows or non-planar membrane surfaces, and the

application of further perturbations at the membrane surface, such as continuous or pulsated electric

fields.

-

Hemodialysis

In medicine, hemodialysis (also haemodialysis) is a method for removing waste products such as

creatinine and urea, as well as free water from the blood when the kidneys are in renal failure.

Hemodialysis is one of three renal replacement therapies (the other two being renal transplant;

peritoneal dialysis).

Hemodialysis can be an outpatient or inpatient therapy. Routine hemodialysis is conducted in a dialysis

outpatient facility, either a purpose built room in a hospital or a dedicated, stand alone clinic. Less

frequently hemodialysis is done at home. Dialysis treatments in a clinic are initiated and managed by

specialized staff made up of nurses and technicians; dialysis treatments at home can be self initiated and

managed or done jointly with the assistance of a trained helper who is usually a family member

The principle of hemodialysis is the same as other methods of dialysis; it involves diffusion of solutes

across a semipermeable membrane. Hemodialysis utilizes counter current flow, where the dialysate is

flowing in the opposite direction to blood flow in the extracorporeal circuit.

Counter-current flow maintains the concentration gradient across the membrane at a maximum and

increases the efficiency of the dialysis.

Fluid removal (ultrafiltration) is achieved by altering the hydrostatic pressure of the dialysate

compartment, causing free water and some dissolved solutes to move across the membrane along a

created pressure gradient.

The dialysis solution that is used may be a sterilized solution of mineral ions

Urea and other waste products, potassium, and phosphate diffuse into the dialysis solution. However,

concentrations of sodium and chloride are similar to those of normal plasma to prevent loss. Sodium

bicarbonate is added in a higher concentration than plasma to correct blood acidity. A small amount of

glucose is also commonly used.

-

ElectrodialysisMembrane technology

Electro Dialysis (ED) is a membrane process, during which ions are transported through semi permeable

membrane, under the influence of an electric potential.

The membranes are cation- or anion-selective, which basically means that either positive ions or

negative ions will flow through. Cation-selective membranes are polyelectrolytes with negatively

charged matter, which rejects negatively charged ions and allows positively charged ions to flow

through.

By placing multiple membranes in a row, which alternately allow positively or negatively charged ions to

flow through, the ions can be removed from wastewater.

In some columns concentration of ions will take place and in other columns ions will be removed. The

concentrated saltwater flow is circulated until it has reached a value that enables precipitation. At this

point the flow is discharged.

This technique can be applied to remove ions from water. Particles that do not carry an electrical charge

are not removed.

Cation-selective membranes consist of sulphonated polystyrene, while anion-selective membranes

consist of polystyrene with quaternary ammonia.

Sometimes pre-treatment is necessary before the electro dialysis can take place. Suspended solids with

a diameter that exceeds 10 m need to be removed, or else they will plug the membrane pores. There

are also substances that are able to neutralize a membrane, such as large organic anions, colloids, iron

oxides and manganese oxide. These disturb the selective effect of the membrane.

Pre-treatment methods, which aid the prevention of these effects are active carbon filtration (for

organic matter), flocculation (for colloids) and filtration techniques.