Manual on Boiler Tube Failure

-

Upload

yogeshmangal1974 -

Category

Documents

-

view

143 -

download

8

Transcript of Manual on Boiler Tube Failure

Chapter - 1

INTRODUCTION

A country’s production of electricity is a basic indicator of its size & level of

developments. Although a few countries export electric power, mostly generation

is for domestic consumption.

In 1983 the first electric supply undertaking was established in India by a

company, which constructed a small generating station in the city of Surat in

Gujrat. This was perhaps one of the earliest electric supply companies anywhere in

the world. This undertaking got as far as lighting the main streets of the city by arc

lamps, but unfortunately in the next year disastrous floods of the river Tapi

submerged its generating plant. In the year 1896 an undertaking started operation

at Calcutta. Thus the beginning of electric supply industry in India was mainly due

to private company effort.

According to reports (1998)

The total installed capacity : 89,166.87MW

Thermal power : 55,969.48MW = 62.76%

Hydro : 21,891.08MW = 24.55%

Nuclear : 2,225.00MW = 2.49%

Diesel, wind & gas : 9,081.31MW = 10.18%

100%

Installed power generation capacity, however does not give a correct

indication of the quantum of the reliable generation capacity (utilization factor). As

the thermal power units are periodically required to be close down (called planned

outages) for mandatory repair, inspection & overhauling. Consequently the

availability of TPP is reduced to about 60% even under the best condition of

operation & management. (The ratio of reliable capacity / installed capacity is

called utilization factor). In India the average utilization factor is about 46% .So as

such there exists a room for improving the availability. This would probably off

set the gap in present demand & supply more economically.

The forced shut down of a boiler due to failure of components severely

affects the progress through non-availability of power which is the basic need for

growth in national economy. Some of the outages are due to tube failures in

pressure parts most of which can be minimized by proper care and preventive steps

of its causes.

The actual cost of repairing failed tubes is less than the cost of generation

loss due to outage, so it becomes imperative to repair & bring the unit quickly into

service. Also, it is equally important to identify the cause of failure so as to take

corrective action and preventive measures so that the failure does not recur. Tube

failure is most significant causes of bringing down the plant availability in utility

fossil-fired boilers. Shutdown of a 200MW unit on account of tube failure will

cause a loss of several lakhs rupees, even when the shutdown is only for three

days. Further, during outage of boiler, if the secondary damages due to the tube

failure is not detected additional failure during start up or afterwards can occur,

thus prolonging shutdown & increasing the generation loss.

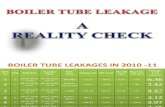

1. Forced / unplanned / planned outages in power plant amount to 15%.

2. Forced / unplanned / planned outages resulting out of boiler are 60% or more of

the above (1).

3. Outages due to boiler tube leakage are 75% or more of the above (2).

About The Process

Boiler is a composed of number of tubes. It covers the following heating zones.

1. Water Walls

2. Super-Heaters

3. Re- Heaters

4. Economiser

Water Walls

Almost all-modern power boilers are equipped with water walls. In large

boilers water walls completely occur in the interior surface of the furnace

providing practically complete elimination of exposed refractory surface. Water

walls serve as means of heating and evaporating the feed water supplied to the

boiler from economiser. Water walls usually consist of large number of vertical

tubes arranged tangentially or approximately. They are connected at the top and

bottom of headers. These tubes receive water from the boiler drum by means of

down comers connected between drum and water wall lower header. In boiler the

water walls absorb approximately 50% of heat released by combustion of fuel in

the furnace. Heat so absorbed is used in evaporation of all or a relatively large

percentage of water supplied to the boiler. The mixture of steam and water is

discharged from top of water wall tubes into the upper wall header and then passes

through riser tubes to the steam drum.

Types of water walls

a) Tangent tube construction

b) Membrane wall construction

Super- Heaters

SH are meant to raise the steam temperature above the saturation

temperature by absorbing heat from flue gas. By increasing the temperature of the

medium (steam) the useful energy that can be recovered increases thus efficiency

of the cycle is improved. So in modern Boilers SH are widely used to increase a

cycle efficiency economically. The maximum temperature to which steam can be

heated is dictated by the metallurgy & economy in initial cost and maintenance

cost. Present trend is to limit the steam temperature value to 540oC both in SH as

well as reheater. SH also eliminates the formation of condensate during

transporting of steam in pipelines and inside the early stages of turbines , which is

harmful to the turbine blades and pipelines.

Water Walls

Reheater

RH is used to raise the temperature of cold steam from which, part of the

energy has been extracted in H.P.T. This is another method of increasing the

cycle . The efficiency increases with number of stages of reheating. Reheating

requires additional equipment (i.e.) heating surface, boiler turbine connecting

piping, safety equipment like safety valve, NRV, isolating valve, steam

temperature regulating equipment , instruments etc. Because of these additional

investment, complexity in operation and reduced availability of such system offsets

the gain in efficiency of the system gets minimised. Hence single RH can be

economically applied only for capacity above 100 MW & two RH for capacity

above 500MW. The limit is also dictated by the predicted fuel price over the period

of operation.

Types of SH & RH

These heating surfaces can be classified into convection and radiant type

according to heat transfer process.

Even though the surfaces get heat by both radiation and convection, the ratio

between them varies according to the location and temperature of flue gases at that

location. The Reheater and SH placed above furnace which can view the flame is

called Radiant type .The other surfaces are called as convection type. Radiant

surfaces are located at high temperature region .

They are widely pitched to reduce the velocity of gas and bridging the

surface by the ash . They are arranged inline with least longitudinal pitch. They are

called platen SH. The SH and RH can be arranged either horizontally or allowed to

hung vertically. The vertical arrangements are simpler in supporting and allows for

expansion . This arrangement is pendent type. Horizontal SH needs supporting of

tubes at multi points to avoid sagging . Expansion movement should also be

permitted with advantage of draining.

The SH which is placed at lower flue gas temperature region is called as

Low Temperature Super heater (LTSH). The SH & RH can also arranged as

ceiling or wall and they are termed as ceiling superheater or wall SH etc.

accordingly.

Arrangements of SH and RH

Generally the heating surface can be arranged in line or staggered. Staggered

arrangement requires fewer surfaces for the same duty but draft loss will be more.

Also on load cleaning of surfaces, will not be effective . Hence In line or staggered

arrangement is selected based on fuel fouling characteristic, operating cost of draft

loss and cost of tube material used at location.

The surface can be designed to place in such way that the flow direction of

flue gas and steam is in line parallel or opposite. Counter flow arrangement has

advantages of minimum surface area requirement but the metal temperature at the

leaving section is high compared to parallel flow. Counter flow arrangement is

used in most cases except in final section where the metal temperature limitations

call for parallel flow.

Economiser

The function of an economiser in a steam-generating unit is to absorb heat

from the flue gases & add this as sensible heat to the feed water before the water

enters the evaporative circuit of the boiler.

Earlier the economisers were introduced mainly to recover the heat available

in flue gas that leaves the boiler. Provision of this additional heating surface

increased the efficiency of steam generation, thus saving in fuel consumption. So

the name “economiser” was christened. In the modern boiler (used for power

generation ) feed water heaters are used to increased the efficiency of the unit &

feed water temperature. So the relative size of economiser is less than earlier unit.

This is a good proposition as the heat available in boiler exit flue gas can be

economically recovered using air heater, which is essential, for pulverized fuel

fired boiler.

Location & Arrangements

It is usual to locate economiser ahead of Air Heaters & following the

primary SH or RH in the gas stream. Hence it will generally be contained in the

same casing as the primary SH or RH tubes.

Counter flow arrangement is normally selected so that heating surface

requirement is kept minimum for the same temperature drop in the flue gas.

Economiser coils are designed for horizontal placement, which facilitate draining

of the coil & favours the arrangement in the second pass of boiler. Water flow is

from bottom to top so that any steam formed during heat transfer can move along

with water & prevent the lock up steam, which will cause overheating, & failure of

economizer tube.

Types of construction of economiser Tube

1) Plain Tube

Plain tube economisers have several banks of tubes with either in- line or

staggered type formation.

2) Welded fin- tube

Large no. of variations in this type was available in earlier days . Cast Iron

shrouds were shrunk on mild steel tubes for use as economiser in stoker fired

boiler. This type had good resistance against gas side corrosion but were heavy in

weight. Modern boiler uses only plain or fin welded design as gas side corrosion is

not faced due to high feed water temperature.

Materials Used for Boiler Tubes

Metallic iron is rarely found in nature. The principle ores of iron are

heamatite (Fe2O3), magnetite (Fe3O4), limonite (2Fe2O3 3H2O) & siderite

(FeCo3). The first step in the production of iron & steel is reduction of the ore with

coke & limestone in blast furnace to produce an impure form of iron called pig

iron. Pig iron is then remelted in a cupola furnace to produce cast iron. C.I. are

alloys of iron & carbon containing approximately 2% to 4.5% carbons. Steels like

cast iron , are alloys of iron and carbon containing upto 2%. Carbon . Steel is cast

in an initially malleable mass. Steel production consists of removal of slag of

excessive amount of carbon silicon & manganese, & impurities such as sulphur &

phosphorus by chemical reactions. This is followed by addition of controlled

quantities of carbon , silicon , manganese & aluminium to produce required

composition. Other alloying elements are added in case of alloy steels.

Steels in the molten state can contain in solution relatively large quantities of

gases, particularly oxygen & hydrogen . The solubility diminishes with falling

temperature & gases released during cooling may be entrapped in the solidifying

steel, giving rise to extensive porosity. All cast ingots contains a small proportion

of cavities but these have little significance & are welded up by a pressure welding

process during rolling or forging. It is necessary to remove most of the gases

whilst the steel is still molten.

Effects of Alloying

The effects of alloying elements are numerous . a list of a few of the more

important effects is given below.

1) To alter the transformation temperatures and time.

2) To modify the room temperature & Elevated temperature strength of given

structures by

a) Stiffening the crystals.

b) Introducing complex precipitates, which tend to harden the steel.

3) To modify the type of oxide film formed on the surface of the steel & there by

affects its corrosion resistance.

Alloying elements can be broadly classified into two groups

a) Austenite Stabilisers: Which have the effects of extending the temperature

range over which austenite is formed. Such elements are carbon, manganese,

nickel, copper & cobalt.

b) Ferrite Stabilisers: Which have the effect of extending the temperature range

over which alpha & delta ferrite are formed. This consequently reduces

temperature range over which austentile is formed. Such elements are Silicon

Chromium, Molybdenum, Tungsten, Titanium & Niobium.

Some of these elements for example chromium, molybdenum & vanadium

also form carbides, which replace or modify the iron carbide in the structure.

Additions of the austenite stablising elements reduce temperature at which

the austenite to ferrite change occurs and will consequently facilitate the formation

of martensite with slower rates of cooling , that are necessary with plain carbon

steels. This also means that for a given cooling rate, larger cross- sections can be

fully hardened uniformly throughout their section.

A) Chromium

Chromium, although in itself a ferrite & carbide former, has a side effect of

making the structural changes very sluggish. This suppresses the austenite to

ferrite change in heat treatment easily . It is therefore extensively used in steels to

be hardened & tempered. A further important property of chromium particularly

marked when present in quantities above about 5% is to improve resistance to

corrosion & oxidation.

Resistance to corrosion & oxidation of steel depends on the film of oxide

formed on its surface . In carbon & many low – alloy steels, this oxide film offers

little or no resistance to atmospheric corrosion. At elevated temperature i.e. upto

575 degree C these steels have good resistance to oxidation in air or flue gases but

above this, the rate of oxidation increase rapidly. The presence of chromium,

however, in excesses of about 5% promotes the formation of a more protective

oxide film . Although 5% is insufficient to obtain useful resistance to atmospheric

& aqueous corrosion, it is enough to improve the oxidation resistance up to about

600c. Further increasing the chromium content produces a more resistant oxide

film & at 13% satisfactory resistance to mild corrosion media such as wet steam is

achieved. Application of this type of steel are steam turbine blades, propeller &

pump shafts, impellers & water turbine runners. Increasing the chromium content

above 13% produces improved resistance to more corrosive media & at 28%

chromium , satisfactory oxidation resistance at 1100 degree C can be obtained.

B) Nickel

In order to be able to utilize the good corrosion – resisting properties of

these high chromium steels and at the same time attain satisfactory engineering

properties, it is necessary to re-establish the austentite region. This can be done by

adding nickel. With an 18% chromium steel the addition of about 2% of nickel

does this and produces a steel which can be hardened and tempered. This is the

well – known S80 steel (En 57) which is widely used for pump shafts in the marine

field.

Maintaining a chromium level of 18%, the addition of increasing amounts of

nickel extends the re- established austentite region until at 8% nickel the

temperature of the change from austenite to ferrite is suppressed below room

temperature and the structure at room temperature consists of grains of austenite.

These steels are termed austenite and include the well-known 18/8 stainless steel.

Since the austenite-ferrite change, on which hardening and tempering are

dependent, is suppressed below room temperature, these austentite steels are

similar to the high chromium ferritic steels in that they cannot be hardened by

normal heat treatment. They are different from the ferritic high chromium steels in

that they are extremely ductile, and ideally suited for deep pressings and similar

applications. In addition, since they are austenitic, they are non- magnetic and they

have a high coefficient of thermal expansion and a low thermal conductivity.

Although these steels are not hardenable and have relatively low tensile

strength at room temperature, they do have good elevated temperature tensile

properties which, when combined with their good corrosion resistance suit them to

application demanding this combination. These include superheater tubing and

steam piping where the metal temperatures are in excess of 550C, gas turbine

components, and numerous types of pressure vessels employed in the chemical and

allied industries.

C) Carbon

Carbon is not generally regarded as an “alloying” element because steel

would not be steel without carbon. Nevertheless, it is appropriate in a discussion of

alloying elements to note the specific effects of carbon on the properties of steel.

In general, an increase in carbon content produces higher ultimate strength

and hardness but lowers ductility and toughness of steel alloys. The curves in

figure indicate the general effect of carbon on the mechanical properties of hot –

rolled carbon steel.

Carbon also increase air – hardening tendencies and weld hardness,

especially in the presence of chromium in low – alloy steel for high – temperature

applications. The carbon content is usually restricted to a maximum of about

0.15% in order to assure optimum ductility for welding, expanding, and bending

operations. To minimize intergranular corrosion caused by carbide precipitation,

the carbon content of austenitic (18-8 type) alloys is limited in commercial

specification to a maximum of 0.08%, or even less, i.e. 0.03% in the extremely

low- carbon grades used in certain corrosion- resistant applications.

In plain carbon steels in the normalised condition, the resistance to creep at

temperature below 440C appears to increase with carbon content upto 0.4%

carbon . At higher temperature there is but little variation of creep properties with

carbon content.

An increase in carbon content lessens the thermal and electrical

conductivities of steel and increases its hardness on quenching.

C) Silicon

Silicon contributes greatly to the production of sound steel because of its

deoxidizing and degasifying properties. When added in amounts up to 2.5%, the

ultimate strength of the steel is increased without loss in ductility. Silicon in excess

of 2.5% causes brittleness, and amounts higher than 5% make the steel

nonmalleable.

Resistance to oxidation and surface stability of steel is increased by the

addition of silicon. These desirable effects partially compensate for the tendency of

silicon to lower the creep properties of steel. Silicon increases the electrical

resistivity of steel and decreases hysteresis losses. Silicon steels are, therefore,

widely used in electrical apparatus.

E) Manganese

Manganese is an excellent deoxidizer and sulfur neutralizer, and improves

the mechanical properties of steel, notably the ratio of yield strength to tensile

strength at normal temperatures. As an alloying element, manganese serves as an

inexpensive means of preventing “red shortness” (brittleness, now more commonly

known as “hot shortness”). It improves rolling properties, hardenability, and

resistance to wear. However, manganese increases the crack sensitivity of

weldments particularly with steels of higher carbon content.

Unlike silicon, manganese benefits the creep properties of steel. It does not

appear to have any specific influence on the resistance to oxidation or corrosion of

steel.

F) Titanium and Columbium (Niobium)

These are potent carbide-forming elements. Titanium is also a good

deoxidizer and denitrider. These elements are most effective in the chromium-

nickel austenitic alloys (18-8 type) where they react more readily with carbon than

does chromium. This allows the chromium to remain in solid solution and in the

concentrations necessary to maintain the “stainlessness” (corrosion resistance) of

the steel.

Titanium and columbium (or columbium plus tantalum) are sometimes used

to reduce air- hardening tendencies and to increase resistance to oxidation in steel

containing upto 14% Cr. These elements seem to have a beneficial effect on the

long – time high – temperature properties of chromium- nickel stainless steels.

Both columbium and titanium have been used in some of the “super alloys” to

improve high- temperature properties.

Chapter - 2

BOILER TUBE FAILURE MECHANISMS

Identification

1) Short term Overheating (Stress Rupture)

For a specific tube material, there is a maximum allowable stress at a

particular temperature. If the tube metal temperature increases beyond this point,

creep will occur and the tube will eventually fail by stress rupture.

Superheaters and reheaters can experience interruptions and/or reductions in

steam flow that can increase tube metal temperatures that lead to stress rupture

failures.

With ferritic steel, a "fish mouth" or longitudinal rupture, with a thin edge

fracture is most likely. With other tube materials, still other appearances are

possible. The causes for this type of failure are the following

(Fig. 2.3).

Abnormal coolant flow from a blockage in the tube

Blockage due to debris in the tube

Blockage due to scale in the tube

Blockage due to condensate in the tube following an incomplete boil out

Excessive combustion gas temperatures

High temperatures from over-firing during start-up.

2) High Temperature Creep (Stress Rupture)

A small fracture may be associated with a blister, while a large fracture

could have a thick-edged, "fish mouth", longitudinal crack. The area around the

fracture may have an alligator hide appearance, with significant oxide scale

penetration. The root causes for high temperature, longer term failure such as

these are the following

High heat flux into a section of the boiler that could have used a higher grade of

steel

Excessive hot gas flow through an area that is plugged

Excessive heat absorption from an adjacent lug, or other welded attachment

Partial pluggage from blockage or internal scale

3) Dissimilar Metal Welds (Stress Rupture)

The weld failures will normally have one side of the weld that responds to a

magnet, while the other does not. The weld crack will be circumferential at the

weld, over on the side that responds to the magnet; the ferritic side. The cause of

failure relate the stress of the two metals expanding differently

And the following

Stress from internal steam pressure

Stress from the vertical weight on the weld

Stress from the constraints of how the tube is supported or attached

Internal thermal gradients, which add up to the total stress. The higher the

value, the sooner the weld fails.

4. Caustic Corrosion (Water-side Corrosion) (Fig. 2.4a)

There are two types of caustic corrosion: caustic embrittlement and caustic

gouging. Caustic embrittlement is an intergranular attack along grain boundaries

leading to sudden failures. Caustic gouging is a general eating away of the

protective magnetite film until the tube wall is thinned to failure. Caustic

embrittlement is relatively uncommon in comparison to caustic gouging.

Caustic embrittlement is characterized by intergranular cracking with very

little metal loss. It normally occurs in stressed and restricted areas where boiler

water containing caustic soda can reach high concentration levels (100,000 to

200,000 ppm NaOH). The most common occurrence of caustic embrittlement is

on tubes that the rolled into boiler drums. If leakage occurs around the rolled-in

tube, the escaping steam leaves the tube-drum interface highly concentrated with

soluble boiler water salts. If caustic is present, then the potential for caustic

embrittlement exists. Three conditions are necessary for caustic embrittlement:

high metal stress, concentrating mechanism and free caustic.

There is no question that more boilers suffer from caustic gouging. This

water side corrosion literally eats away the protective magnetite film along boiler

tubing.

Caustic corrosion can cause either a pinhole leak or what looks more like a

small, bulged, thin edge rupture. The tube fails when the tube is so thin that it

cannot take the internal pressure any longer. There is often a thick deposit on the

inside of the tube, but the leak could purge much of the deposit. These failures are

usually found where the heat flux is greatest and are the result of the following

Condenser leaks

Deposits of caustic contaminants from the feed water system

Upsets in the boiler water chemistry.

The two conditions necessary for caustic gouging are : a concentrating

mechanism must be initiated and free caustic must be present in the boiler water.

Dirty tubes are far more susceptible to caustic gouging because the deposits trap

and concentrate the boiler water. Proper adjustment of boiler water chemistry is

required to prevent caustic gouging.

5. Hydrogen Damage (Water-side Corrosion)

Hydrogen damage is a serious and costly type of water side corrosion that

affects generating tubes in sub critical boilers operating above 124.11 bar or 1800

psig. Lower pressure units can also experience hydrogen damage, but it becomes

more uncommon as the operating pressure is reduced.

Hydrogen damage will occur whenever acidic conditions exist in the boiler

Clean tubes are far less susceptible to hydrogen damage than heavily

deposited tubes. Certain types of adherent and nonporous deposits appear to

promote localized hydrogen attack more readily.

The failures remove a chunk of tube, almost like a window that has been

placed in the tube. The failure has a thick edge fracture that removes the heavy

deposit that lead to the failure. The failure's root cause is

(Fig. 2.5)

Boiler water chemistry that has turned acidic, rather than its normally caustic

level. Hydrogen damage will not occur under alkaline conditions.

In-leakage of condenser water which tends to be acidic

Contamination from a chemical cleaning procedure

Higher heat flux which helps to form the deposit in the first place. Note that

if the deposit is not there to begin with, the excursion to low pH by itself

will not cause hydrogen damage.

The dirtier the boiler water, the sooner failures could occur.

Hydrogen damage seldom causes any significant wastage of the tube wall,

making it difficult to detect using ultrasonic devices. Sometimes hardened dense

oxide plugs of magnetite dispersed with copper form directly over hydrogen

damaged areas.

6. Pitting – Localised corrosion (Water-side corrosion)(Fig.2.6)

Water containing dissolved oxygen is highly corrosive to many metals ;

therefore everything must be done to minimize the introduction of oxygenated

water into the boiler and pre-boiler systems. Oxygen corrosion can dramatically

affect various components in operating and non-operating boilers. Much of the

suspended crux that enters an operating boiler is the direct result of oxygen attack

of components in the pre-boiler system.

Localized pitting is found where oxygen is allowed to come in contact with

the inside of the tubes, which is just about anywhere. It appears as a steep edged

crater with red iron oxide surrounding the pit. The tube surface near the pit may

show little or no attack. Sometimes there is a series of smaller pits. The typical

cause starts with

High levels of oxygen in the feed water, i.e. poor deaeration at start-up

Filling of condensate in low point, such as bends, when the steam cools

Outages where air gets inside the assembly from adjacent repairs, or vents

being left open as the steam condenses

7. Stress Corrosion Cracking (Water-side Corrosion) (Fig. 2.7)

These thick-edged fractures can be either circumferential or longitudinal,

depending on how the stress is oriented. Typically the chemical attack is on the

inside of the tube and works its way out through the growing crack. Far less

commonly, the chemical attack exists on the outside (fire side) and works its way

inward. The root cause is the coupling of more than one factor working on the

same location

Contaminants can come from boiler steam drum carry over

Contaminants can come from contamination in the desuperheater spray

External contaminants come from acidic components to the fuel

Additionally there must be a stress possibly from a bend in the tube

Weld attachments from initial assembly

Or possibly from cyclic unit operation

8. Low temperature corrosion (Fire side) (Fig. 2.8)

External surfaces of furnace tubes that are exposed to a moist environment

containing flue gases can experience acid corrosion. Certain acidic salts (ferrous

sulfate for example) can hydrolyze in moist environment to produce low pH

conditions that will attack carbon steel.

Sulfur trioxide (SO3), present in the cooler flue gas areas, can react with

water vapour to produce sulfuric acid. If the temperature is below the dew point,

sulfuric acid condenses along metal surfaces and corrodes the metal. Water

washing can also produce acid attack.

A gouged exterior and a thin ductile failure characterize this form of failure.

When the pressure becomes too great, the pressure inside blows out a hole. The

root cause for low temperature failures are

The presence of sulfur in the oil, which has an opportunity to condense on

the last rows of economiser tubes

The condensing of sulfur and ash when the exit gas temperature is low.

9. Water wall corrosion (Fire side) (Fig. 2.9)

Fire side water wall corrosion covers a broad array of corrosive forces from

the intense combustion process. A broad, general thinning occurs with the surface

of the tube having fairly deep longitudinal and lateral gouges or cracks. The thin

wall ductile rupture will go length wise down the tube. The surface of the tube will

typically have a hard dark slag deposit. The causes are

A zone of combustion where there is too little oxygen

High level of chloride or sulfides in the fuel being burned

10. Vibration Fatigue (Fig. 2.10)

In locations where boiler tubes are welded to support lugs, a thick edge

failure can form at the toe of the weld. This fracture is circumferential, running at

right angles to the weld. The root cause is

The vibration of the tube, caused by the steady flow of exhaust gases

Along with a lug location that induces a rigid point that will concentrate the

force into a short distance.

11. Thermal Fatigue (Fig. 2.11)

The flexing action of thermal fatigue produces multiple surface cracks,

laterally across the tube which results in a thick edge fracture. The fatigue is

caused by

Sudden cooling of the tube metal, either from within or externally

Rapid change in the feed water temperatures to the economiser, i.e.

maloperation of the pre-boiler system

12. Corrosion Fatigue (Fig. 2.12)

Like the previous fatigue mechanism, cyclic stresses produce a series of

parallel surface cracks, however this time the corrosive environment adds to the

deterioration by forcing an oxide wedge into the cracks, further leveraging the

fracture. The thick edge fracture will be coated with an oxide layer. Pits can often

be found on the inside surface of the cracks. The causes have two key ingredients,

corrosion and stress

There is either induced stress from the way the tube connects to another

pressure part or, there is induced stress from the way the tube is tied to a

structural support,

There is residual stress left over from fabrication

Internal pits from dissolved oxygen or acidic corrosion from the pre-boiler

circuit aggravate the cracking process in the water cooled tubes.

External corrosion in steam cooled units aggravates the cyclic flexing where

the tube enters the header.

13. Maintenance Cleaning Damage (Quality Control) (Fig. 2.13)

When accumulations need to be removed with force, it is possible that tubes will

be gouged, or dented. This point of stress will be a weak link that eventually gives

way. Some of the most common causes are

Hammering on a tube or its supporting lug

Chiseling at fused material

Poking and vacuuming ash/dust/debris out of tight spaces

Aqua-blasting

14. Chemical Excursion Damage (Quality Control) (Fig. 2.14)

Initially, the damage will appear as a general pitting of the tubes' internal

surface, but in time the chemical contamination will act on the most sensitive

locations and result in such mechanisms as hydrogen damage, stress corrosion

cracking, caustic corrosion, corrosion fatigue, etc. The causes are

Mal operation or mechanical malfunctions of the pre-boiler water treatment

system.

Insufficient neutralization of boiler wash chemicals prior to returning a unit

to service.

15. Material Defects (Quality Control) (Fig. 2.15)

When the wrong material is installed, the result can be a stress rupture, and

if the defect is a flaw, the failure may appear as a fatigue failure. In either case,

the cause is -

Poor QA on the part of the manufacturer

Material fabrication

Storage

Installation

16. Welding Defects (Quality Control) (Fig. 2.16)

If the defect is most notable on the inside, it can become a failure from the

internal scale build-up, and resultant corrosion, or corrosion fatigue failure. If the

defect is with the integrity of the weld itself, the failures often appear as a brittle

failure, where stress is concentrated in a small area. Causes again relate to quality

control

The procedure

Weld material used

Preparation of the tube ends before the first pass

17. Steam/Condensate Erosion

When a failure is allowed to continue for several hours or days, the result

can amount to more time and energy needed to make repairs. The root cause is –

Decision making in how quickly a unit is brought off-line once a failure is

found

Insufficient documentation to justify the economics of not waiting to bring

the unit off-line to attend to the tube failure.

18. Exfoliation (Fig. 2.17)

The above list of 17 failure mechanism does not necessarily include all

possible failure modes, and some tubing problems do not necessarily reduce

availability by virtue of a tube failure, as in the example shown below. The

spalling of the indigenous oxide on superheater, reheater tubes and steam piping is

referred to as exfoliation. With exfoliation, the tube wastage is from the inside out,

and the damaged component is in the turbine's internals. The root cause is not

known, however, consider the following

Bottling-up of stream in the tube when the unit trips, resulting in forced

migration of steam into the black oxide scale layer within the tube.

Difference in the coefficient in expansion between the internal magnetite

layer and the tube metal, resulting in spalling of scale when the unit cycles

Quenching of the tube internals when the unit is in a start-up mode.

Chapter – 3

METALLURGICAL FAILURE INVESTIGATIONS OFBOILER TUBES IN THERMAL POWER PLANTS

INTRODUCTION

Although failures/leakages may occur in a relatively low percentage of the

total boiler tubes used in a power plant, they may cause a critical breakdown

resulting in forced shutdown of generation. Failures are of extreme importance to

plant operators, maintenance Engineers, fabricators and suppliers alike. People

learn by mistakes and hence a correct diagnostic analysis of failure help in their

future prevention.

All of the types of failures that may occur and all of the conditions that

promote them are too numerous to list. However, in a broad generalization one

may say that the following factors may cause service failures :

i) Deficiencies in design lay out, manufacture and erection of the

equipment;

ii) Poor material quality and deficiencies in fabrication;

iii) Incorrect material selection;

iv) Deficiencies in operating conditions;

v) Deficiencies in maintenance.

Often a combination of the above factors may be responsible for failures.

A failure investigation and subsequent analysis should determine the

primary cause of failure, and based on the determination, corrective action should

be initiated that will prevent similar failures.

Stages of an analysis

Although the sequence is subject to variation depending on the nature of a specific

boiler tube failures, the principal stages that comprise the investigation and

analysis of a failure are as follows :

i) Collection of background data and history

ii) Visual or preliminary examination of the damaged/failed tube

iii) Non-destructive inspection

iv) Selection of specimens from the tubes :

a) For microscopic examination and analysis (fracture surface,

secondary cracks and other surface phenomena);

b) For mechanical testing including hardness and tensile testing

c) Chemical Assessing (bulk, local surface corrosion products, deposits

or coatings, etc.);

v) Analysis of the evidence, formulation of conclusions and drafting the

report.

SPECIFIC CASE STUDIES

Case I: Failures Involving Tube Ruptures

Sudden rupture of a tube in a steam generator is a serious failure, because the

steam generator must be shut down immediately to avoid -

(a) Erosion and steam-cut on adjacent tubes by escaping steam;

(b) Overheating of other tubes banks because of a loss of boiler circulation;

(c) Damage to other components in the system resulting from loss of working fluid.

Such sudden ruptures can be caused by overheating.

a) Economiser Intermediate Box Drain Tube

The economiser intermediate box drain tube in the power plant had suffered a

rupture along the longitudinal axis of the tube (Fig. 1). The length of the ruptured

portion was approximately 330 mm. The tube had opened out in the manner of a

'thick-lip' rupture. There was a tightly adhering 'black-scale' on the outer surface

of the tube. Boiler quality carbon steel, conforming to the specification B.S. 3602-

1962 grade Hot Finished Seamless – 27, was used as the material of construction

for the economiser tube.

Metrological measurement of the tube had established considerable amount

of 'thinning and bulging" out of the wall of the subject tube.

Microstructural examination of the specimen selected judiciously from the

extreme edge of the rupture covering the external surface revealed "inter

crystalline" penetration of oxide scales (oxide-rooting) to an appreciable depth

from the external surface of the tube (Fig. 2).

It also exhibited considerable decarborization of the material,

Microstructure in and around the rupture area of the tube represented globular

carbides indicating "spherodization" of the carbide constitute of pearlite within and

at the boundary of the ferrite grains (Fig. 3). Further, the microstructure away

from the ruptured zone illustrated a ferrite-pearlite structure which is normal of this

type of steel (Fig. 4).

In the present case, the economiser tube was placed horizontally.

Sometimes "Steam Blanket" preferentially might be formed inside the tube wall.

This in turn, might have deteriorated the heat transfer characteristics of the subject

tube material, and caused localized 'over heating'.

The tube had failed as a result of prolonged localized overheating. Due to

'overheating' and consequential 'oxidation' and 'spheroidization' the material could

not withstand the working stress, and failure occurred. This type of failure can be

minimized by improving upon the tube layout design. The economiser tube may

be changed into a vertical position instead of horizontal as in the present case to

avoid possible formation of steam-blanket in the pipe wall.

b) Secondary Superheater Tube

The boiler in the power plant used pulverized coal as fuel. For the

construction of superheater tubes, boiler quality steel (specification B.S. 3059/12)

was used. The tube had ruptured characteristically with a 'fish mouth' type which

was about 39 cms. long and 8 mm wide at its maximum. The rupture had

extended along the length of the tube and was accompanied by noticeable localize

dwelling (Fig. 5). The characteristic features of the rupture indicated that the

rupture had taken place after localized 'ballooning' of the tube wall. There were no

seals either on the outside or inside surface of the tube. Further, variation in wall

thickness in the zone rupture was noticed.

Microscopic examination of the specimens taken from the vicinity of rupture

showed coalescence of fine particles of alloy carbides in the matrix of ferrite

(Fig. 6), while normal microstructures consisting of fine dispersion of alloy carbide

particles in a matrix of ferrite at the areas away from the ruptured zone (Fig. 7).

This evidence clearly indicates that the effected area has been continuously heated

below the lower critical temperature (A1) of the steel for a prolonged period in a

very localized area of the material. Due to 'spheroidization', the material strength

in the affected region could not cope-up with the operating stress at the elevated

temperature for long duration. Thus the tube material was subjected to slow and

progressive plastic deformation under the influence of operating stress and

temperature, which resulted in the weakening of the tube, and its eventual rupture.

To minimize the occurrences of such failures, proper temperature

monitoring systems by installing built-in thermocouples on the tube walls should

be incorporated.

Case II – Poor material Quality and Deficiency in Fabrication

The present case documents an interesting analysis of failure of secondary

superheater tube in a power plant due to poor material quality and processing

defects.

The material used for the secondary superheater tube conforms to ASTM A

335 (Grade P5) Boiler quality steel. The damaged tube had a crack of about

53 cms long, and had extended along the length of the tube. There were no seals

either on the outside or inside surface of the tube. No swelling was observed in the

cracked zone.

Further, on dissection of the tube longitudinally, typical crack on the bore

surface was noticed .The bore surface of the tube was also found to be uneven and

noticeable ribs (alternate elevation and depression on the tube wall) were detected.

It was also evident that longitudinal and discontinuous crack propagated along

one of the pronounced ribs. There was no evidence of corrosion or fitting on the

bore of tube.

Microstructural analysis of the samples selected from the vicinity of crack

and away from it revealed almost identical structures, i.e. fine dispersion of alloy

carbides particles in a matrix of ferrite (Fig. 10). This illustrated that the tube was

not overheated as the microstructure was quite agreeable to this class of material as

developed in commercial production of the tubes.

To substantiate the case of failure, metrological measurements in regard to

the well thickness at different locations of the tube in the vicinity of crack and at its

sound portion as well as the roundness error on the inside diameter at the sound

portion were done. The observations showed heterogeneity in measured values.

The roundness error on the inside diameter of the round region of the cracked tube

was in the order of 0.60 mm. This is represented graphically in Fig.11.

Development of ribs on the bore surface of the tube during tube production

might have a contributory effect towards the failure of this nature during services.

In addition to above causes, leakages/ruptures of boiler tubes in the power plants

can occur due to (a) embrittlement arising out of hydrogen damage, (b) water side

corrosion by feed water, (d) fire side corrosion resulting from combustion of fossil

fuel, (d) abrasives erosion of superheater tubes results from impact by particles of

fly ash entrained in the flue gases, (e) stress corrosion cracking of the tubes where

feed or condensate can collect.

Remarks

The foregoing illustrations have discussed many causes related to failure. Many

failures in steam systems involve more than one failures process the so called

multiple mode failures. Certainly many types of failures were not discussed and

no attempt could be made to illustrate all the types of failures possible. The causes

that promote failures can indeed be many and complex and attempt has been made

to illustrate and discuss some of the more common failures and the related causes.

Usually the most spectacular or dramatic failures are carefully studied while

little emphasis is placed on the common failures. Many analysis of plant or

operational failures usually add upto high separational costs due to time loss

resulting from make-shift maintenance or repairs in order to continue operation.

Thus metallurgical analysis of such failures is all the more important.

Chapter - 4

SOME CAUSES OF BOILER TUBE FAILURE WHEN SEENTHROUGH A POWER STATION CHEMIST'S EYE

INTRODUCTION

In power plant operation a Chemist is intimately mixed up with tube

failures. It may be due to faulty water conditioning or improper operation. In

general , every tube failure may be due to any of the following three reasons :

a) Material failure

b) Mal - operation

c) Improper water conditioning

In case of material failure, blame goes to the manufacturer, for mal-

operation and improper water conditioning it is human error. In the present

chapter , based on experience, it has been tried to show how improper water

conditioning can cause tube failures.

NEED FOR WATER CONDITIONING

1. The main need is to protect the internals from corrosion – which cause ultimate

failure. There are several types of corrosion possible, like

i) Dissolved O2 pitting

ii) Stress corrosion

iii) Ductile corrosion

iv) H2 embrittlement etc.

There are three zones, where same water is conditioned differently. They are –

a) Feed System

b) Drum

c) Steam and Condensate

Various parameters are laid by the boiler manufacturers, time to time,

depending upon the metallurgy of the surfaces through which water/steam flows.

These parameters vary depending upon the pressure of boiler and temperature of

the Steam Cycle. In the table below, effective parameters are shown.

Particulars Boiler Pressure 60 kg/cm2 and under Boiler Pressure from 60 kg/cm2 and above

PH Cond. H Silica PH Cond. H Silica

Make up 7.0 0.5 Nil Nil 7.0 0.5 Nil Nil

Feed 8.8 – 9.0 Upto 4.0 Nil Nil 8.9 – 9.0 Upto 2.5 Nil Nil

Drum 9.5 –9.9 Upto 100 Nil * 9.3 – 9.5 Upto 25 Nil *

Steam 8.8 –9.0 Upto 4.0 Nil 0.02 8.9 – 9.0 Upto 2.5 Nil 0.02

Condensate 8.5-8.7 Upto4.0 Nil Nil 8.5 – 8.7 Upto 2.5 Nil Nil

Scale : Cond. : Conductivity in Micromhos , Silica in ppm, silica, hardness in ppm CaCO3.

* : As per pressure silica curve

The change of pH 7.0 in make-up to 9.5 in drum is maintained by dosing suitable chemicals at different

places of the water cycle. The parameters are designed to suit the internals of the system, so that a corrosion free

surface is maintained. The dosings are mainly of two types volatile and non-volatile.

Sr.No.

Type of Dosing

Chemical Dosed Place of Dosing Ultimate Effect

1. Volatile Ammonia MorpholineCyclohexyl amine

Feed System at the suction of feed pump

To increase pH

2. Volatile Hydrazine hydrate inhibited or treated hydrazine

Feed System at the suction of feed pump

&In condensers at the suction of Extraction pump

To scavange oxygen&

To increase pH

3. Non-volatile

Tri-sodium Phosphate Sodium Hydroxide

Drum To increase pH to maintain residual phosphate.

4. Non-volatile

Sodium Hydroxide &Sodium-di hydrogenPhosphate, HexametaPhosphate

Drum To decrease pH, to maintain residual phosphate

When dosed properly, the required parameters can be obtained and

conditioning becomes proper, resulting a trouble free service.

MAIN CAUSE OF TUBE FAILURES EVEN AFTER PROPER DOSING

There can be two types of main causes of failures. These are –

a) Improper Chemicals

b) Excess or incorrect amount of dosing

Improper chemicals not only deviate main aim of water conditioning it raise complication also, the effect of

improper chemical dosings are summerised as under with particular reference to the probable impurities.

Chemical Possible Impurities Effect or Dosing

Ammonia Hardness, Silica Very slow increase in pHRapid increase in conductivity.Injection of silica in System/

Phosphate Free Sodium Hydroxide and chloride Unstable pH conditionIncrease in conductivity Foaming action in drum,Free sodium hydroxide in Steam

All above conditions lead to tube failure,

Effect of Excess Dosing

Chemical Normal Reaction Effect Remarks on effect

Ammonia Simple additionNH4OH + H2O – NH4OH H2O

High pH & Conductivity (Dilution)

Caustic corrosion

Hydrazine N2H4 + O2 = N2 + 2H2O

2N2H4 = N2 + H2 + 2NH3

2N2H4 +H2O = 2NH4OH + N2

Oxygen Scavenging

Hydrogen in steam

Ammonia formation

None

Stress corrosion

None

Phosphate Na3PO4 + H2O = NaOH + NaH2PO4

High pH & Conductivity

Caustic attack carry over foaming causing starvation

When we analyse the remarks on last column following points are raised on

tube failure:

a) Caustic attack

b) Hydrogen attack

Caustic Attack

Although the pH of the media is high and safe for most of the tubes, yet

excess of it may cause soap-bubble effect at a particular point leading to carryover

and or volatile caustic carryover from drum and improper distribution of heat flux

at any point due to the same.

The caustic attack due to sodium hydroxide is very much deteriorating than

due to ammonia. Whereas, excess of ammonia may give raise to a possible

formation of nitric acid as :

NH3 + 202 = HNO3 + H2O

The possibility is very less due to the presence of excess hydrazine hydrate,

which takes care of any oxygen available in the system.

The caustic attack due to the presence of excess sodium hydroxide is very

much harmful due to the phenomenon known as steam blanketing, resulting static

or slow moving slug of steam generation causing rupture in the tube due to

irregular heat transfer.

Hydrogen Attack

This is very serious, sometimes we find unnecessary increase in hydrogen

level in steam, this leads to corrosion as per per-oxide theory.

The H2 released combines immediately with free O2 to from hydrogen per-

oxide (H2O2). This reacts with Fe(OH)2 and forms Fe(OH)3.

2Fe(OH)2 + H2O2 = 2Fe(OH)3

But hydrogen aid polarization which reduces electro-chemical reaction.

OTHER FACTORS LEADING TO TUBE FAILURE

The main amongst this is unnecessary increase in dissolved oxygen level.

Dissolved oxygen, tends to create hydroxyl ions with the available electrons.

O2 + 2H2O + 4ē= 4 (OH)¯

And each hydroxyl ions so form, tends to stabilize with positively charged metal

ions aiding to corrosion/deposit,

M(Metal) = M+ + e

M+ + (OH) ¯ = M(OH)

The metal hydroxide which is relatively less soluble has a tendency of forming a

deposit, resulting improper heat transfer and failure of tubes.

Dissolved carbon dioxide present in water/steam forms H2CO3 commonly known

as carbonic acid, this then forms metal carbonates and ultimately forms metal

hydroxide. The effect of CO2 on iron (Fe) is as under –

CO2 + H2O = H2CO3

2Fe + 2H2CO3 = 2Fe CO3 + 2H2

2FeCO3 + 5H2O + O = 2Fe (OH)3 + 2H2CO3

as H2CO3 is double in volume the process multiplies leading to further corrosion.

CORROSION

Control of the water and/or steam environment inside economiser, boiler,

superheater and reheater tubes is a pre-requisite for trouble free performance of a

fossil-fired steam generator. When water and steam chemistry are not maintained

within limits recommended by the boiler manufacturer or a qualified consultant,

corrosion damage may occur in water walls and economiser tubes.

Water wall corrosion problems generally can be avoided in boiler if –

1. Recommended water treatment controls are followed;

2. Corrosion products formed in the feed water system are kept within specified

limits;

3. Feed water oxygen concentration is properly controlled and

4. Precautions are taken during chemical cleaning operations to prevent metal

attack.

Deposition problems can be avoided if –

1. Hydraulic test water, superheater fill water, and desuperheater spray water are

free of solids. It is preferable to use DM water for these operations.

2. Drum internal and drum water level controls are maintained in good working

order.

3. Silica concentration in the boiler water is held within acceptable limits.

The iron oxide coating in the internal surfaces of boiler tubes are to be

maintained. This oxide (magnetite Fe3O4) is normal product that forms on steel

exposed to boiler water . It protects the surface from corrosion. The magnetite

coating is damaged most often by boiler water salt that become corrosive when

concentrated. Graph 1 shows the relative corrosion rate of carbon steel as acid and

alkaline concentrations varies in the boiler water.

In the pH range from low acid to low-alkaline concentrations the oxides on

boiler tubes are fully protective. When the pH is excessively high or low, the

protective oxide is consumed by the corrosive action of the acid or alkaline salts in

the water. Corrosion rates under these conditions accelerate with increasing

concentration. Thus the primary purpose of a boiler water treatment program is to

maintain a low concentration of potentially corrosive salts, so that the oxide

coating remains intact.

LOW-pH DAMAGE

Corrosion failure occurs when acid or alkaline salts are concentrated.

Hydrogen induced brittle fracture occurs beneath a relatively dense deposit and is

most likely to occur when boiler water pH is too low. Though some metal loss

may be caused by corrosion mechanisms, the steam generator tube usually

fractures long before it has corroded to the point at which tensile failure would

occur.

Some of the hydrogen produced in the corrosion reaction diffuses into the

tube metal where it combines with carbon in the steel. Methane is formed and it

exerts internal pressures within the steel, causing grain-boundary fissuring. Brittle

fracture occurs along the partially separated boundaries. In many cases an entire

section is blown out of the damaged tube. Restoration of proper boiler water

treatment may not be sufficient to prevent further hydrogen attack, unless the dense

corrosion product deposits are removed. Even repeated chemical cleanings

sometimes will not remove them. Arbitrary replacement of tubes, in the general

areas where metal attack exists, becomes necessary. Generally, hydrogen damage

is difficult to detect using non-destructive means. Ultrasonic thickness checks may

pinpoint some damaged areas, but positive identification of all failure prone tube is

not possible.

HIGH-pH DAMAGE

Ductile failures caused by a gouging type of corrosion usually occur when

the concentration of hydroxide salts such as sodium hydroxide in the boiler water

is too high. Ultrasonic tube-wall thickness checks can detect tubes with metal loss.

Proper boiler water treatment can minimize further corrosion.

MINIMISING CORROSIVE ATTACK

Corrosion concentrations of salts generally exist at tube surfaces only when

these inter-related conditions are present.

a) An acidic or alkaline producing environment prevails.

b) The boiler operates outside of the established boiler water treatment

recommendations, allowing abnormal acidic or alkaline conditions to persist.

c) A means of concentrating the acidic or alkaline salts exists.

CAUSES OF HIGH AND LOW pH

The primary cause of acidic and caustic boiler water condition is condenser

leakage. Raw cooling water that leaks into the condenser essentially ends up in the

boiler water. The water source determines whether the in-leakage is either acid

producing or caustic producing. Fresh water from lakes and rivers, for example,

usually provides dissolved solids that hydrolyze in the boiler water environment to

form a caustic, such as Sodium Hydroxide. By contrast, sea water and water from

Re circulating cooling water systems, with cooling towers contain dissolved solids

that hydrolyze to form acidic compounds.

Strict tolerance levels on condenser leakage should be established for all

high pressure boilers. Set a limit of 0.5 ppm for short periods only. Shut down the

steam generator immediately if the plant's surface condenser leakage produces

more than 2 ppm of dissolved solids in the feed water.

Another potential source of acidic and caustic contaminants is the make up

demineralizer, where regenerate chemicals such as sulphuric acid and caustic soda

may inadvertently enter the feed water system. Chemicals incorrectly applied

during boiler water treatment also can be corrosive. For example, Sodium

hydroxide is used in conjunction with sodium-phosphate compound to treat boiler

water. Corrosion can occur if the sodium hydroxide and sodium phosphate are not

added to the water in the proper proportion.

WATER TREATMENT CONTROLS

To protect steam generator tubes against corrosion two widely used boiler

water treatments are available, however, even in the event of moderate

contamination. They are volatile and coordinated phosphate/pH control.

Briefly, volatile treatment uses a volatile neutralizing amine, such as ammonia, to

maintain a pH that will not disrupt the magnetite coating on the boiler tubes. It

does not contribute additional dissolved solids to the boiler water. Thus, it

minimizes the amount of solids that can be carried into the superheater by the

steam. But it does not give any protection against contaminants, such as salts

carried into the boiler by condenser cooling water.

Phosphate treatment in drum type units maintains pH in the proper alkaline

range to protect the magnetite film and it reacts with salt contaminants to prevent

the formation of free caustic or acidic compounds. Coordinated phosphate/pH

control is maintained by using a combination of di-sodium phosphate and tri-

sodium phosphate or sodium hydroxide to give a residual phosphate concentration

of upto 10 ppm, with a corresponding pH as shown in the Graph 2.

If the phosphate and pH control points are below the curve no potentially

damaging free caustic is produced. The concentrating mechanism most often

responsible for corrosion damage involves internal deposits. As heat is transferred

through the tube wall to the water/steam mixture in the tube, a temperature

gradient is established. That is, the temperature of the internal surface of the tube is

slightly higher than that of the bulk fluid. When boiler water evaporates, dissolved

solids such as sodium hydroxide, concentrate in the thin film between the tube wall

and the bulk fluid. Graph 3 & 4 show that with only 15oF difference between the

bulk fluid and tube wall temperatures, sodium hydroxide might concentrate

dramatically at the tube surface. When porous internal deposits are formed in

areas of high heat absorption, it is possible to produce very high stable

concentrations, because the deposit acts as a diffusion barrier.

This concentration mechanism explains why corrosion damage normally

occurs on the tube internal surface facing the fire and tends to be most severe in the

highest heat absorbing area.

Pre-boiler corrosion occurs when oxygen and pH values deviate from

established limits. Oxygen control is, perhaps more critical than pH-especially

during start-up, shut-down, and idle periods. Low pressure feed water heaters and

related extraction piping often are under negative pressure during low load

operation. Thus any leaking valves, pumps, flanges, etc. provide a path for air into

the system. Idle units may even become saturated with oxygen if proper

precautions are not exercised. Oxygen concentration in feed water should be

maintained at less than about 5 ppb during unit operation to minimise the

formation of pre-boiler corrosion products. The following are few of the ways to

minimise oxygen infiltration during idle and start up periods and to reduce the

transport of corrosion products to the boiler.

1. The boiler and as much of the pre-boiler system as possible should be

blanketed with steam or nitrogen when the unit is out of service. If a long

outage is contemplated, fill the boiler and feed water system to the greatest

extent possible with the corrosion inhibitor. Excellent results have been

obtained with solutions containing 200 ppm of hydrazine and 10 ppm of

ammonia for lay up period of more than one year. For pre-boiler systems

containing copper alloys, reduce the dosage to 50 ppm of hydrazine and 0.5

ppm of ammonia to avoid copper attack by ammonia.

2. Make sure an adequate supply of steam is available to the deaerator during unit

start-up so that oxygen can be purged from the feed water. If no adequate

auxiliary steam source is available, peg the deaerator with steam from the

boiler drum until turbine extraction steam is available.

3. Introduce aerated storage water into the feed water system only through the

dearerating section of the condenser, if all deaeration is accomplished there.

4. Connect aerated storage water into the feed water system only through the

dearerating section of the condenser, or through the aerator.

5. Consider a partial flow condensate polisher for cycling units. Its use together

with that of the pre-boiler systems recycle line, permits removal of both

erosion products and oxygen from the feed water during steam-generator start-

up operations.

Importance of Water Analysis

A comprehensive water analysis program should be maintained to assure

that feed water and boiler water chemistry are held within prescribed limits, and

conduct water tests as per programmed schedule, for pH, oxygen, silica, copper

and total iron, and total solids.

The gas side corrosion occurs in oil fired boilers. High temperature

corrosion occurs due to the presence in oil of sodium and vanadium, the oxides of

which form flux with the protective oxide of the material, thereby causing further

attack on the material by the gas. This can be prevented by using low vanadium

content oil or by employing certain additives like MgO powder in the oil. The

MgO powder can be sprayed through a separate nozzle into the furnace or

magnesium wires can be burnt in the furnace. Low temperature or dew point

corrosion occurs in oil fired boilers in the air heaters or economizers if the flue gas

temperature approaches the dew point temperature. Sulphur in the oil transforms

to SO3 in the furnace and then to sulphuric acid with the water vapour in the flue

gas at low temperatures and causes corrosion. Low temperature corrosion can be

avoided by controlling the inlet temperature of the feed water to the economizer, or

counter flow existing in economizer with respect to gas is made as reversed or

parallel flow of water, which gets higher temperature at low temperature gas end

and helps preventing low temperature corrosion.

Minimizing Pitting of Boiler Tubes

Excessive dissolved oxygen in the boiler water and excessive temperature

during chemical cleaning, can cause severe local attack pitting. Crevices, like

those formed by backing rings, or minor variations in metallurgical structure, may

act to promote localized corrosion. Normal, but higher than the average peak

stress also can contribute to preferential pitting. Pitting attack of various types can

affect the internal surfaces of all tubes. The pitting attack usually is quite shallow

and does not adversely affect the tube integrity, but occasionally it may be locally

severe and even penetrate the tube wall. Crack like interconnected pitting is a

common form of attack, too. Penetrations of this type can develop into corrosion

fatigue cracks, but it is not unusual for them to propagate through the wall as a

result of corrosion alone. Most leaks associated with corrosion pitting are like to

occur at or near weld or attachments.

Prevention

Pitting caused by dissolved oxygen can be prevented by maintaining feed

water oxygen level within the 5 ppm limit while attack by chemical cleaning

solvents can be eliminated by carefully following the cleaning procedures. During

shut-down periods, it is necessary to protect all internal surfaces, wet lay up,

together with a positive nitrogen pressure cap of about 3 – 5 psig, will protect

metal surfaces from corrosion. Some of the pitting attack may have been caused

by the presence of oxygen and moisture during shut down periods. Those that do

occur usually can be attributed to improper wet lay up, or to the introduction of

contaminants into the heat transfer sections.

Avoiding Steam side Deposition

A more common problem affecting the internal surfaces of steam side

components, such as the superheater and reheater, deposits. They can cause

overheating failures by insulating the tube from the cooling effect of the steam.

Such failures usually occur as creep blisters at the low spot in pendant surfaces.

But deposits also have caused failures on vertical tubes. Occasionally, they

partially or totally block steam flow in a particular circuit. Solids carried by the

steam into the turbine also can be damaging.

Boiler manufacturers help limit solids carry over by paying considerable

attention to the design of drum components. To avoid solids contamination from

operational point of view three factors are of particular importance.

1. The need for high quality Hydrostatic Test Water

Water used for hydrostatic tests will be evaporated from non-drainable

sections during the next firing period, and the solids or salts in the water will

concentrate. Hence, water added to the superheater or reheater should be of

condensate quality and dosed with hydrazine (200 ppm) and ammonia to

produce a pH of 10.

2. The need for High Quality De-superheating spray water

Any solids in the spray water will adhere to superheater surfaces or be

carried through the unit in the steam and be deposited in the turbine. Since

the source of spray water is the boiler feed water system, feed water should

be treated only with volatile chemicals for pH control. All solid chemicals

used for treatment must be introduced into the system down stream of where

the spray water is removed.

In the event condenser leakage causes the total amount of dissolved solids in

the hot well to exceed 500 ppb, increase the rate of blow down and

discontinue the use of spray water. Use other means for controlling steam

temperature including load reduction until the condenser is repaired and the

total solids level in the hot well is below 500 ppb.

3. The third and most important operating factor is to keep solids contained in

the boiler feed water from entering the superheater. Steam drum internals

reduce the mechanical carry over of moisture content upto 0.1%. Vapours

carry over is completely selective since it depends on the solubility or

volatility of a specific constituent in the steam. Except silica vaporous carry

over of solids dissolved in the boiler water is negligible below an operating

pressure of 2600 psig assuming that the concentration of solids are within

recommended limits. The volatility of silica is much higher than that of

other solids and it increases exponentially with boiler pressure.

In conclusion, you can avoid many potential operating problems by

continuously monitoring steam quality. Increase in solids level – even if

within prescribed limits, may provide an early indication of some carryover

abnormality.

Failures Due to Manufacturing Defects

Raw Material Defect

Either mix up of material or raw material defect also accounts to tube failures.

Due to mix up of material of different specification than designed one comes to the

service and failure occurs. And raw material defect comes in the rolling of tubes

itself and a lap or eccentricity formed thus causes tube failures at elevated

temperatures.

Material defect due to defective rolling of tubes is shown in figures below :

Eccentric Rolling Defects Lap Formed Tube

Sufficient care during rolling of tubes and correct material selection can

avoid failures due to such defects.

Procedures for failure investigations and collection of failed sample

The causes for failures are evaluated by removing carefully the failed

material (e.g. tube) along with deposits if present. It is preferable to pack them

with polythene wrappers and box, such that no corrosion and mechanical damage

occur during transit. If the deposits are loose, water side and fire side deposits are

collected in separate polythene bags with rigid tags. The flame cut region should

be at least 200 mm away from the region of failure since heat produced during

flame cutting will change the microstructure, if the cut region is close to failed

region. For comparison, it is preferable to have a good portion (about 300 mm) of

the tube (along with deposits if it is present) which is considerably away from

failed region. The samples of materials which failed due to brittle fracture should

be taken out (if it possible) and the fractured facets should be protected by using

rust preventive coatings. In some cases in site micro-examination is carried out

when the specimen could not be removed. This technique is also used for fracture

investigations. In certain cases it becomes essential for the metallurgist or chemist

to visit the site and have first hand information regarding the location and overall

nature of failed tubes or any other components. He has to watch the performance

under the existing condition at site. This will help in the interpretation of complex

failures.

Procedures for Metallurgical Investigations

The tools and techniques for failure investigations are chosen as to suit the

individual requirements. Generally the following procedures are followed:

a) Dimension and thickness measurement at important locations comparison

with the original or good material.

b) Standard mechanical tests; usually tensile, drift flattening, hardness etc.

c) Spectral and chemical analysis of deposits, water, fuel, ash etc.

d) Investigations with microscope for evaluating the nature of failures – special

corrosion tests for stainless steel components.

e) Advanced techniques; Electron microscopy for detailed information on fine

structures and creep damages, x-ray diffraction for the analyzing of ash,

deposits, scales etc., creep testing and burst testing for the determination of

residual creep life etc. are used for complex case histories.

Data Required for Investigation

The log book is to be referred at site for one or more of the following

information which will be required for effective investigation of failed

components.

a) Operating pressure and temperature of the pressure parts close to failed

region location of the failed tube, data of failure etc.

b) Composition of the fuel

c) Composition of the flue gas

d) Amount of excess combustion air

e) Analysis of feed water and steam condensate type and amount of

contaminants in make up water

f) Normal power output and fluctuation in steam demand

g) Frequency and method of cleaning water side and fire side surfaces of tubes.

-o0o-

REPAIR GUIDELINES

Introduction

All plant personnel should bear in mind the legal formalities involved in the

repair of boiler pressure parts. The responsible parties, before making repairs or

alterations of a pressure part, must notify the legally responsible inspection agency

and obtain approval before starting the work. The responsible inspection agency

may be the boiler insurance carrier or state or municipal inspection agency. In

some cases, it may be a federal agency. The responsible parties must follow this

procedure even though a pressure part fails during the manufacturer's warranty

period. The boiler manufacturer may recommend a repair procedure, but it must

be approved by the responsible inspection agency. Generally, the manufacturer's

recommendation will be accepted, but the inspection agency still has the legal

responsibility for approval.

Welding Repair or Low Carbon Steel Tubes

Cut out a damaged tube at least 50 mm (2') on each side of the defective

area. The minimum replacement tube length should be not less than 152 mm (6').

Do not use backing rings to weld any heat-absorbing tubes carrying water or a

mixture of steam and water. Without a backing ring, make the first pass of the

weld using gas tungsten arc or oxyacetylene. The weld passes may be completed

by either process, or by shielding metal arc. If access is difficult, use window

welds for repair work. The first pass of a window weld must be made by gas

tungsten arc of oxyacetylene (Fig. 1).

Fit-up of the weld joints is important. Although it is difficult to obtain

accurate cuts on furnace tubes, it is important to get the existing tube ends squared

and correctly chamfered and to cut the replacement tube to the correct length. Use

a tube-end scarfing tool when possible. Allow for shrink in welding. Remember

that the weld metal and parent metal are melted in the welding process and the

molten metal shrinks as it solidifies.

A butt weld in a tube will shorten the total length about 1.6 mm (1/16").

Use a clamp or guide lug to hold one end of the replacement tube in

alignment while the first weld is made.

Do not tack weld both ends of the replacement tube, particularly if the

existing tubes are rigidly supported.

As a general rule, first complete the weld at the lower end of the

replacement tube.

Do not start welding the upper end of the replacement tube until both the

replacement and existing tubes have cooled to ambient temperature.

Alloy Tube Repairs

If a damaged alloy tube must be replaced, it is always preferable to weld the