Maiq 5s Benefits 0311

-

date post

08-Apr-2018 -

Category

Documents

-

view

224 -

download

0

Transcript of Maiq 5s Benefits 0311

-

8/7/2019 Maiq 5s Benefits 0311

1/28

Total Productive Maintenance

TProMTProM Total Process Management (TProM)

1

Total Process Management

Shared-Posted by:

IShar Omar (isomar@maiQ)(Principal Consultant )

Email: [email protected]

Website: www.maiq-2u.blogspot.com

1

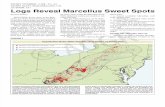

OVERVIEW:5S -Quality & Safe Work-area / Environment (Q-S-E)

Management System

-

-

8/7/2019 Maiq 5s Benefits 0311

2/28

Total Productive Maintenance

TProMTProM Total Process Management (TProM)

2

Slide Share Objectives ;

To review the 5S Management System

( WHAT is 5S ? )

To review the concepts and benefits of 5S .

( WHY 5S ? ) .

5S - Quality Safety Work-area /

Environment (QE) Management System

2

-

8/7/2019 Maiq 5s Benefits 0311

3/28

Total Productive Maintenance

TProMTProM Total Process Management (TProM)

33

5S Management System

INTRODUCTION

5S has been proven as an effective but basic management technique to

improve organizations efficiency and competitiveness.

- education, governmentoffice, manufacturing, transportation, home etc

To be a world class organization, the systematic continual improvement

program is required to:

Identify, reduce and then eliminate waste .

Improve the individual/staff skill and Team Work

Improve the operation efficiency and working environment

Establish a platform that drive improvement productivity, quality,

-

8/7/2019 Maiq 5s Benefits 0311

4/28

Total Productive Maintenance

TProMTProM Total Process Management (TProM)

4

The Three Different Types ofWorkplace ;The Three Different Types ofWorkplace ;

A 3rd class workplace:

has people who make a mess and no one cleans up.

A 2nd class workplace:

has people who make a mess and another group of people clean up.

A 1st class workplace:

has people who dont make a mess and yet everyone cleans up.

-

8/7/2019 Maiq 5s Benefits 0311

5/28

Total Productive Maintenance

TProMTProM Total Process Management (TProM)

5

WHICH SENARIOS DO YOU PREFER ?

SCENARIOS Nbr1 ?

or

SCENARIOS Nbr 2 ?

5

-

8/7/2019 Maiq 5s Benefits 0311

6/28

Total Productive Maintenance

TProMTProM Total Process Management (TProM)

6

SCENARIO 1:

The Bad and the Ugly

6

-

8/7/2019 Maiq 5s Benefits 0311

7/28

Total Productive Maintenance

TProMTProM Total Process Management (TProM)

7

SCENARIO 2 :

TheBeauty-With 5S

7

-

8/7/2019 Maiq 5s Benefits 0311

8/28

Total Productive Maintenance

TProMTProM Total Process Management (TProM)

8

PART 1:

WHAT IS 5S ?

8

-

8/7/2019 Maiq 5s Benefits 0311

9/28

Total Productive Maintenance

TProMTProM Total Process Management (TProM)

9

What is 5S?

5S is short for:

Sort, Set in Order, Shine, Standardize and Sustain

5S represents 5 disciplines for maintaining a visual workplace

(visual controls and information systems).

9

-

8/7/2019 Maiq 5s Benefits 0311

10/28

Total Productive Maintenance

TProMTProM Total Process Management (TProM)

10

1.SORT

(SISIH)

2.SET

INORDER

(SUSUN)

3.SHINE

(SINAR-SAPU)

4.STANDARD-IZE

(SERAGAM)

5.SUSTAIN

(SENTIASA

AMAL)

5S FOCUSSES on FIVE STEPS

5S

10

-

8/7/2019 Maiq 5s Benefits 0311

11/28

Total Productive Maintenance

TProMTProM Total Process Management (TProM)

11

5S?5S?

The Origin of The Term 5SThe Origin of The Term 5S

5S is a set of five Japanese words. Each word starts with a sound of

se-i orshi.

They are Se-i-ri, Se-i-to-n, Se-i-so, Se-i-ke-tsu, and Shi-tsu-ke.

SEIRI , SEITON , SEISO SEIKETSU , SHITSUKE

-

8/7/2019 Maiq 5s Benefits 0311

12/28

Total Productive Maintenance

TProMTProM Total Process Management (TProM)

12

What is 5S ?

5S is regardedas the Quality& Safe WorkArea /Environment(Q-S-E) Management( Workplace ManagementSystem )

5S is a basis in business performance excellence management.

5S program goals are toward enhancing the quality, productivity, safe,

health, cost, moraleenhancementand job satisfaction.

5Sreposition the High Performance WorkArea - as KEY DRIVING

FACTOR in business success .

5S involves a structured and continual improvement concept inmanaging work-area / business environment ( physical )

5S is no longer regarded as a non-profitable activity or another HOUSE

KEEPING program !

.

12

-

8/7/2019 Maiq 5s Benefits 0311

13/28

Total Productive Maintenance

TProMTProM Total Process Management (TProM)

13

BEFORE

Cleaned

Organized

Well Identified

Save time

NO frustration in searching

AFTER

Dusty,

Unorganized

Poor Identification

Time wasted

Frustration in searching

STEP 1 & STEP 2 :

Sort & Set in Order

13

-

8/7/2019 Maiq 5s Benefits 0311

14/28

Total Productive Maintenance

TProMTProM Total Process Management (TProM)

14

Below : The File Rearranged and tagged

in good order / manner

STEP 1 & STEP 2 :

Sort & Set in Order

14

-

8/7/2019 Maiq 5s Benefits 0311

15/28

Total Productive Maintenance

TProMTProM Total Process Management (TProM)

15

STEP 3 -Shine :

Example

15

-

8/7/2019 Maiq 5s Benefits 0311

16/28

Total Productive Maintenance

TProMTProM Total Process Management (TProM)

16

ST

EP

4 - Standardize

: Example

16

-

8/7/2019 Maiq 5s Benefits 0311

17/28

Total Productive Maintenance

TProMTProM Total Process Management (TProM)

17

STEP 5 Sustain:Example

17

RECOGNITION TEAM PERFORMANCEACHIEVEMENT

DISPLAYED

AUDIT

-

8/7/2019 Maiq 5s Benefits 0311

18/28

Total Productive Maintenance

TProMTProM Total Process Management (TProM)

18

PART 2:

WHY 5S ?(Concept & Benefits)

18

-

8/7/2019 Maiq 5s Benefits 0311

19/28

Total Productive Maintenance

TProMTProM Total Process Management (TProM)

19

5S CONCEPT

WRONG RIGHT

HouseKeeping

WorkArea

Management

@ KPI

Continual

Improvement

Innovative-Creative

Circle

19

-

8/7/2019 Maiq 5s Benefits 0311

20/28

Total Productive Maintenance

TProMTProM Total Process Management (TProM)

20

5SFundamental Objective

To Enhance the Corporate Culture

By Managing The Quality Safe Of Work Place /

Environment (QE) For

Business Process Efficiency

20

-

8/7/2019 Maiq 5s Benefits 0311

21/28

Total Productive Maintenance

TProMTProM Total Process Management (TProM)

21

Improve PeopleCapability

-Knowledge

- Skills

- Attitude & Principle

- Quality ofWork

-Teamwork

- Communication

Improve ProcessEfficiency

- Maintain Basic Condition

- Reduce Stoppages

- Reduce Breakdown

-ReduceAccident ( Safety )

- Reduce Losses

Improve System

- Quality System & Control

- OSH System

- Process Control- Maintenance Management

- Inventory & Cost

Improve Environment

-Image

-W/PlaceOrganization

- Clean & Safe W/place

- Zero Contamination

JOURNEY TOWARDBUSINESS EXCELLENCE

( ex: Education Services)

BENEFITS OF IMPLEMENTING 5S !!!

BOTTOMLINE

RESULT;

KPI

21

-

8/7/2019 Maiq 5s Benefits 0311

22/28

Total Productive Maintenance

TProMTProM Total Process Management (TProM)

22

SIX SIGMA

QUALITY

TOTAL

QUALITY

MANAGEMENT (TQM)

MANAGEMENT

SYSTEM

-ISO9000(QMS)

-ISO14001 (EMS)

-OHSAS18001(OSH)

-HACCP & GMP

COST/FINANCIAL

MANAGEMENT

TPM( Total Productive

Maintenance)

LEAN

PROCESS

MGT

( JIT )

5S

5S : THE FOUNDATION TO MANAGEMENT SYSTEMS

22

-

8/7/2019 Maiq 5s Benefits 0311

23/28

Total Productive Maintenance

TProMTProM Total Process Management (TProM)

23

ROAD MAP OF 5S

CONTINUAL CREATIVITY And INNOVATION

P

R

E

PA

R

A

T

I

O

N

ENABLERS RESULT

SORT

SET IN ORDER

SHINE

STANDARDIZE

SUSTAIN

CONTINUAL

IMPROVEMENT

SELF-ASSESSMENT/AUDIT

And

CERTIFICATION

PLAN DO CHECK ACT

PHASE 1 PHASE 2 PHASE 3 PHASE 4

23

-

8/7/2019 Maiq 5s Benefits 0311

24/28

Total Productive Maintenance

TProMTProM Total Process Management (TProM)

24

Diagnosis Sistem 5S sedang diamalkan

PERSIAPAN MENJELANG ANUGERAH KEBANGSAAN

1. SISTEM

DOKUMENTASI

YANG EFEKTIF

2. MENJADI

AMALAN &

BUDAYA

DI TEMPAT

KERJA

3. FOKUS

ELEMENT

KREATIVITI &

INOVASI

4. KAJI SELIDIK @

KEBERKESANAN

DARI ASPEK:

Pelawat

Pelanggan

Pekerja

IMPAK KECEMERLANGAN PADA ORGANISASI :MENYELURUH

ANUGERAH 5S KEBANGSAAN

Model : Persiapan Ke arah

Anugerah 5S

24

-

8/7/2019 Maiq 5s Benefits 0311

25/28

Total Productive Maintenance

TProMTProM Total Process Management (TProM)

25

THE KEYS TO SUCCESSFUL 5S PROGRAM

Total commitment to the program by Top Management and every members in

OUM is required .

Employees must be empowered to initiate corrective action ( be an inventor).

A fact is 5S may take few months to implement, to shows impact and it is an

on-going and forward looking process .

Changes in employee mind-set toward their job responsibilities must take

place.

Be Creative and Innovative in Solving Problem.

Recognized the Accomplishment regardless big or small achievement !!!

DRIVE for 5S ( QE) MANAGAMENT CERTIFICATION !!!

25

-

8/7/2019 Maiq 5s Benefits 0311

26/28

-

8/7/2019 Maiq 5s Benefits 0311

27/28

Total Productive Maintenance

TProMTProM Total Process Management (TProM)

27

SelamatSelamat MenggunaMengguna--pakaipakai !!!!!!

Dari:Dari:

CikguCikgu ISOmarISOmar(([email protected]@yahoo.com.my ))

www.maiqwww.maiq--2u.blogspot.com2u.blogspot.com

-

8/7/2019 Maiq 5s Benefits 0311

28/28

Total Productive Maintenance

TProMTProM Total Process Management (TProM)

ACADEMIC QUALIFICATIONS

. M.Sc in Micro Electronics (UKM)

. Diploma in Electrical-Electronics (UiTM)

PROFESSIONAL QUALIFICATIONS

. EOS/ESD Quality Management Certified By NARTE

Trainer The Trainer

Public Speaking CertificationCorporate University Realization Consultant

WORKING EXPERIENCE

.16years in Training, Process Management, QualityManagement , R&D at Motorola ( 1984-2001)

10 years as Manufacturing Center Of Excellence

( MCOE)Program Leader (Worldwide at Motorola)

TRAINING-TEACHING EXPERIENCE

@ Public / Industries ( 2001-2011)

. OUM- MIGHT METEOR

Technoprenur ; SIRIM-EPU, Kolej Komuniti@MHE

. GEMS programs @ Khazanah-MOF

. INSEP program @ UM-AMI-MOF

. QPADU,SHRDC, NSSDC, IMTAQ, IPA,

. maiQ Corp

KEY CLIENTS SERVED ( Training & Coaching )

(i) Services: AL Rajhi Bank , OUM,UM,UKM,SIRIM

(ii) Manufacturing: SUMITOMO,ASIAN NDK, DELPI,MOTOROLA, NIITO,ROHM-WAKO,ART RIGHT,

TOP GLOVE, Shin-Etsu,

(iii) GLC : FELDA, MIMOS, TPM

(iv) R&D; Promosys, VSS, Neural Mfg, M&M,

(v) Other Clients in Public Training Programs.

KEY TRAINING / CONSULTANCY PARTNERS :

UMCed, UiTM, SIRIM, MIGHT-METEOR,DIBTA, Q-PADU

CONSULTANCY PROJECTS UNDERTAKEN ;

ISO9001: Al Rajhi Bank, Click Logistic, Nueral Mfg

ISO17025 ( Lab) : Hydrotech

Technology Realization for SME companiesex: Neural Mfg ( Bio Metric ), GMS ( Vision

Technology), MMSB ( Automatic Tyre Buffing MC)

. Business Funding Acquisition Plan for SMEs

(a) Neural (b) GMS (c) Speed Auto (d) AZENCO

. Process Capability Improvement on Fertilizer factory -PKSJ

Packaging Design & Development - PKSJ

Product CertificationLearning Center: Hexatrade SB,

IShar Omar

(isomar@maiQ )