Maintenance manual no. MM-0140 Single reduction ...graphicvillage.org/meritor/MM0140.pdf · for the...

Transcript of Maintenance manual no. MM-0140 Single reduction ...graphicvillage.org/meritor/MM0140.pdf · for the...

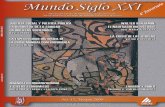

Maintenance manual no. MM-0140

Single reduction Differential Carrier Series 7 - MS15 - MS16 - MS17 - MR15Revised April 2003

an ArvinMeritor brand

Table of contents

05 Section 1: Introduction06 Description06 Specifications and data 07 Single reduction differential carrier “standard” version

MS16-MS1708 Single reduction differential carrier “curvic” version

MS16-MS1709 Single reduction differential carrier “curvic” version

MS15-MR1510 Exploded view “standard” version MS16-MS1711 Parts list “standard” version MS16-MS1712 Exploded view “curvic” version MS16-MS1713 Parts list “curvic” version MS16-MS1714 Exploded view “curvic” version MS15-MR1515 Parts list “curvic” version MS15-MR15

17 Section 2: Maintenance18 Single reduction differential carrier:

removal and installation 19 Repairing the single reduction differential carrier 27 Installing the one-piece spigot bearing on the drive pinion

with snap ring 29 Calculating thickness of shim pack 33 Hypoid gear set - tooth contact patterns 38 Lock nut sensor switch 39 Replacing pinion-pac seal 41 Torque chart

43 Section 3: Troubleshooting

pg.

2 ArvinMeritor Differential Carrier Series 7

Service Notes

Before You BeginThis publication provides installation and maintenance proceduresfor the Single Reduction Differential Carrier Series 7 MS15-MS16-

MS17-MR15, produced by ARVINMERITOR HVS

The information contained in this publication was current at thetime of printing and is subject to revision without notice or liability.

You must understand all procedures and instructions before youbegin maintenance and service procedures.

You must follow your company's maintenance and service guidelines.

You must use special tools, when required, to avoid seriouspersonal injury and damage to components.

Meritor uses the following notations to alert the user of possiblesafety issues and to provide information that will help to preventdamage to equipment and components.

WARNINGA WARNING indicates a procedure that you must followexactly to avoid serious personal injury.

CAUTIONA CAUTION indicates a procedure that you must followexactly to avoid damaging equipment or components.Serious personal injury can also occur.

NOTE: A note indicates an operational, procedure or instructionthat is important for proper service. A NOTE can also supplyinformation that will help to make service quicker and easier.

This symbol indicates that you must tighten fasteners to a specific torque.

Information contained in this publication was in effect at the time the publicationwas approved for printing and is subject to change without notice or liability.ArvinMeritor Commercial Vehicle Systems reserves the right to revise theinformation presented to discontinue the production of parts described at any time.

Access Information on ArvinMeritor's WebSiteAdditional maintenance and service information for ArvinMeritor'scommercial vehicle systems component lineup is also available atwww.arvinmeritor.com.

To access information, click on Products & Services/Tech LibraryIcon/HVS Publications. The screen will display an index ofpublications by type.

3ArvinMeritor Differential Carrier Series 7

4 ArvinMeritor Differential Carrier Series 7

Terms used in this manual

Manufacturer:ARVINMERITOR

Manual:Maintenance manual no. MM-0140

Device:Single Reduction Differential CarrierSeries 7 - MS15 - MS16 - MS17 - MR15

Technician:Qualified personnel working on differential maintenance andservicing.

Maintenance and servicing:Maintenance and servicing refer to periodical checks and/orreplacement of differential parts or components. It also refers tothe determining of the cause of a malfunction in order to restorethe initial operating conditions.

Operator:Any person who will use the differential as part of a morecomplex device..

WarrantyWarranty applies to the differential unit installed on vehicles forwhich it was designed. Warranty is void in the following cases:

• Improper use of the vehicle on which the differential is installed(usage conditions, overloading etc.)

• Tampering with vehicle components that may affect rear axleperformance.

• Use of non-original spare parts.

• Improper installation, adjustment, repair or modification.

• Poor or improper maintenance (including consumables otherthan those specified).

Further information on warranty conditions may be obtaineddirectly from the manufacturer or by referring to the ArvinMeritorweb site at www.arvinmeritor.com

5ArvinMeritor Differential Carrier Series 7

pg.

1

Introduction

06 Description06 Specifications and data 07 Single reduction differential carrier “standard” version

MS16-MS1708 Single reduction differential carrier “curvic” version

MS16-MS1709 Single reduction differential carrier “curvic” version

MS15-MR1510 Exploded view “standard” version MS16-MS1711 Parts list “standard” version MS16-MS1712 Exploded view “curvic” version MS16-MS1713 Parts list “curvic” version MS16-MS1714 Exploded view “curvic” version MS15-MR1515 Parts list “curvic” version MS15-MR15

6 ArvinMeritor Differential Carrier Series 7

1 Introduction

General descriptionThe differential unit is of the single-reduction type featuring ahypoid gear set. The bevel pinion is mounted on two taper rollerbearings (pinion unit) and a third straight roller bearing. The bevelpinion setting relative to the drive gear can be adjusted by varyingthe thickness of the shim pack located between the differentialcarrier and the pinion bearing cage. The differential gear case issupported on two taper roller bearings and is adjusted for endplay through two threaded ring nut adjusters.

Specifications and dataHypoid pinion bearings 2, taper roller (pinion-pac) and

1 straight roller bearing

Differential unitFinal drive hypoid MS16-MS17 Fine Pitch 2.80; 2.93; 3.07; 3.21; 3.42; 3.73gear ratio 4.1; 4.30; 4.56; 4.89; 5.13; 5.63; 6.14

MS16-MS17 Coarse Pitch 2.85; 3.08; 3.10; 3.36; 4.11; 4.63; 5.29

MR15-MS15 Coarse Pitch 2.43; 2.57; 2.83; 3.09; 3.40; 3.78; 4.134.50; 5.14; 5.67

Pinion to drive MS16-MS17 mm 0.26 - 0.50

gear backlash MR15-MS15 mm 0.20 - 0.45

Pinion to crown by adjusting ringsbacklash adjustment

Pinion to crown by shimsbacklash adjustment

Differential bearing cap divergence mm 0.15 - 0.33

Differential bearing cap divergence adjustment

by ring nut adjusters

Differential idle pinion and side Nm 68 maxgear assembly revolving torque Kgm 6.8 max

Thickness range for shims fitted between bevel pinion bearing mm 0.125 - 0.200 - 0.500cage and differential carrier

Drive gear rest face runout on case half mm 0.13 max

The Series 7 MS15 - MS16 - MS17 - MR15 differential unit isavailable in two models:

• without differential lock• with differential lock

both in the STANDARD version with longitudinal clutch andCURVIC version with frontal clutch.

7ArvinMeritor Differential Carrier Series 7

1 Introduction Section through “Standard” single reduction differential carrier unit - type MS16-MS17

Fig. 1

8 ArvinMeritor Differential Carrier Series 7

1 Introduction Section through “Curvic” single reduction differential carrier unit - type MS16-MS17

Fig. 2

9ArvinMeritor Differential Carrier Series 7

1 Introduction Section through “Curvic” single reduction differential carrier unit - type MS15-MR15

Fig. 3

Exploded view “Standard” version - Single reduction differential carrier - type MS16-MS17

508

932

4849

13

1011

12 28

31

45

7

467

1

22

25

3

65

3

4

56

25

25

24

34

3537

36

40

44

5251

54

555653

mod

el

with

out d

iffer

entia

l loc

k

42 4341

3938

1718

14

19

27 26

25

24

23 2526

29

2730

331620

15

19

21

21

47

Fig. 4

11ArvinMeritor Differential Carrier Series 7

Parts list

1234567891011121314151617181920212223242526272829

Ref Description

CarrierBearing cap L.H.PinBearing cap R.H.Bearing cap washerBearing cap capscrewIdentification platePinion bearing cageO-ring (pinion cage)Pinion cage shimPinion cage shimPinion cage shimPinion cage capscrewPlain half diff caseDiff bearing cup L.H.Diff bearing cone L.H.Diff bearing cup R.H.Diff bearing cone R.H.Adjusting ringDiff case screwCotter pinPlugDiff spiderDiff pinionDiff pinion thrust washerDiff side gearSide gear thrust washerDrive pinionDrive gear

303132333435363738394041424344454647484950

Ref.515253545556

Ref Description

Flange half diff casePinion spigot bearingDrive pinion nutDrive gear screwShift forkShift fork pinShift shaftShift shaft springPistonPiston O-ringCylinder end coverCylinder cover gasketCover capscrewCover capscrew washerPlugSensor switchLock-nut sensor switchCluth collarCompanion flangeDeflectorPinion-pac seal

model without differential lockEnd coverSensor switch hole blanking plugWasher plugEnd cover capscrewEnd cover capscrew washerEnd cover gasket

Exploded view “Curvic” version - Single reduction differential carrier - type MS16-MS17 MS16 - MS17

857

936

5556

13

1011

12 32

35

4950

7

23

2524

26

12

5

36

3

4

56

28

29

29

38

3941

4243

40

4547

464448

1718

14

31 30

33

30

28

31

29

2927

3734

1620

1519

21

192251

5453

52

5958

61

626360

mod

el

with

out d

iffer

entia

l loc

k

Fig. 5

13ArvinMeritor Differential Carrier Series 7

Parts list

123456789101112131415161718192021222324252627282930313233

Ref Description

CarrierBearing cap L.H.PinBearing cap R.H.Bearing cap washerBearing cap capscrewIdentification platePinion bearing cage (pinion-pac)O-ring (pinion cage)Pinion cage shimPinion cage shimPinion cage shimPinion cage capscrewPlane half diff caseDiff bearing cup L.H.Diff bearing cone L.H.Diff bearing cup R.H.Diff bearing cone R.H.Adjusting ringDiff case screwCotter pinPin spirolPlugThrust screwWear padThrust screw nutDiff spiderDiff pinionDiff pinion thrust washerDiff side gearSide gear thrust washerDrive pinionDrive gear

343536373839404142434445464748495051525354555657

Ref.585960616263

Ref Description

Flange half diff casePinion spigot bearingDrive pinion nutDrive gear screwShift forkShift fork pinShift shaftShift shaft springPistonPiston O-ringCylinder end coverCylinder cover gasketCover capscrewCover capscrew washerPlugSensor switchLock nut-sensor switchClutch collarFixed collarSpacerRetaining ringCompanion flangeDeflectorPinion pac-seal

model without differential lockEnd coverSensor switch hole blanking plugWasher plugEnd cover capscrewEnd cover capscrew washerEnd cover gasket

Exploded view “Curvic” version - snap ring version - Single reduction differential carrier type MS15 - MR15

Fig. 6

857

936

5556

13

1011

12 32

3564

4950

7

23

2524

26

12

5

36

3

4

56

28

29

29

38

3941

4243

40

4547

464448

1718

14

51

31 30

33

30

28

31

29

2927

3734

1620

1519

21

1954

5352

22

5958

61

626360

mod

el

with

out d

iffer

entia

l loc

k

snap

ring

spig

ot b

earin

g

15ArvinMeritor Differential Carrier Series 7

Parts list

123456789101112131415161718192021222324252627282930313233

Ref Description

CarrierBearing cap L.H.PinBearing cap R.H.Bearing cap washerBearing cap capscrewIdentification platePinion bearing cage (pinion-pac)O-ring (pinion cage)Pinion cage shimPinion cage shimPinion cage shimPinion cage capscrewPlane half diff caseDiff bearing cup L.H.Diff bearing cone L.H.Diff bearing cup R.H.Diff bearing cone R.H.Adjusting ringDiff case screwCotter pinPin spirolPlugThrust screwWear padThrust screw nutDiff spiderDiff pinionDiff pinion thrust washerDiff side gearSide gear thrust washerDrive pinionDrive gear

34353637383940414243444546474849505152535455565764

Ref.585960616263

Ref Description

Flange half diff casePinion spigot bearingDrive pinion nutDrive gear screwShift forkShift fork pinShift shaftShift shaft springPistonPiston O-ringCylinder end coverCylinder cover gasketCover capscrewCover capscrew washerPlugSensor switchLock nut-sensor switchClutch collarFixed collarSpacerRetaining ringCompanion flangeDeflectorPinion pac-sealSnap ring

model without differential lockEnd coverSensor switch hole blanking plugWasher plugEnd cover capscrewEnd cover capscrew washerEnd cover gasket

16 ArvinMeritor Differential Carrier Series 7

17ArvinMeritor Differential Carrier Series 7

pg.

2

Maintenance

18 Single reduction differential carrier:removal and installation

19 Repairing the single reduction differential carrier 27 Installing the one-piece spigot bearing on the drive

pinion with snap ring 29 Calculating thickness of shim pack 33 Hypoid gear set - tooth contact patterns 38 Lock nut sensor switch 39 Replacing pinion-pac seal 41 Torque chart

18 ArvinMeritor Differential Carrier Series 7

2 Maintenance

IntroductionIn order to ensure reliable and efficient differential unit operation,maintenance intervals, use of lubricants and correct proceduresspecified by the manufacturer should be strictly observed (refer toLubrication Maintenance Manual no. 1). For further informationcontact the manufacturer’s engineering department or refer to theArvinMeritor Web site at www.arvinmeritor.com (technical library –manuals).

Spare partsUse original Meritor spare parts only.

Differential removal and installation

Removal1. If the vehicle is loaded, unload the rear axle before removing

the differential.

2. Place the vehicle on level ground and chock the front wheels.

3. Rest the rear axle on two suitably strong stands (fig. 5).

4. Remove the drain plug from the rear axle bottom end anddrain lubricant.

5. Engage differential lock before air pressure falls below 2.8bars

6. Remove axle shaft mounting screws and washers.

7. Remove axle drive shafts.

8. Remove propeller shaft.

9. Disconnect compressed air lines and differential lock sensorswitch coupling.

10. Remove differential carrier to rear axle housing fasteningscrews (leave two screws in place to prevent the differentialfrom falling).

11. Safely support carrier assembly with suitable lifting tool to aidremoval. Remove plastic protective plugs (22) fitted to theextraction screw holes. Fit extractor screws (Service toolCT08) Remove final 2 carrier screws to withdraw carrierassembly.

Checking rear axle housingCheck rear axle alignment to prevent possible distortion fromcausing abnormal stress, noise and pneumatic consumption.

InstallationReverse the removal operation sequence and torque fasteningscrews and/or nuts to tabulated specifications. Clean mountingfaces and threads thoroughly, then coat the rear axle mountingface with alcohol-base lining silicone sealant Dow Corning 9071type.

CAUTION:Only original Meritor spare parts should be used. Use of non-original parts could seriously affect differentialunit performance. Use of non-recommended lubricants willadversely affect performance and service life.

WARNING: Waste oil disposal must be carried out inconformity with the legislation in force.

CAUTION:Differential carrier removal and handling should beperformed using the specified lifting and carryingequipment.

CAUTION: During dismantling/reassembly operations always engagedifferential lock to ensure alignment of the splined sectionsand prevent shift fork bending and spline damage.

Lift or rest area

Stands

Fig. 7

19ArvinMeritor Differential Carrier Series 7

2 Maintenance

Finally ensure that:

• There are no leakages from air lines.

• Lubricating oil meets manufacturer’s specifications.

• Differential lock cab warning lamp functions correctly.

Repairing the single reduction differentialcarrier

Disassembly1. Suitably secure the carrier unit to the work bench. (Fig. 9)

2. Remove switch (1)

3. Loosen screws (2) and remove cylinder end cover (3) andgasket (7);

4. Remove piston (4), shaft (5) and spring (6). (Fig.10)

5. Curvic Version :

Loosen thrust screw nut (1) using service tool CT09 andrelease thrust screw (2) (Fig. 11)

siliconesealant

Fig. 9Fig. 8

Fig. 10 Fig. 11

20 ArvinMeritor Differential Carrier Series 7

2 Maintenance

6. Remove shift fork (3) together with clutch collar (2).

7. Standard version: remove cotter pin (1)

Curvic version: remove pin spirol (4)

8. Remove cotter pin from collar’s opposite side. (Fig.12)

9. Undo bearing adjusting rings (1).

10. Use a suitable wrench to loosen and remove screws (2) withtheir washers; repeat the same operation on the oppositeside;

11. Remove bearing caps (3). (Fig. 13)

12. Using suitable lifting equipment (1) remove the gear case (2)with drive gear and bearing cups (3). (Fig. 14)

NOTE: Differential carrier removal and handling should beperformed using the specified lifting and carrying equipment.

13. With flange lock tool CT03 (2) block rotation of companionflange (1).

14. Using wrench and service tool CT 02 (3) and torquemultiplier (4) loosen bevel drive pinion nut (5), but do notremove. (Fig.15)

15. Remove and discard the capscrews (3) fastening the drivepinion bearing cage to the carrier (4).

Fig. 12

Fig. 13

Fig. 14 Fig. 15

21ArvinMeritor Differential Carrier Series 7

2 Maintenance

16. Fit eye hooks to the flange and take out the bearing cage (5)from the carrier; ensure alignment of the differential unitduring the removal operation by means of two stud boltsspecial tool CT08. Remove and discard drive pinion nut (1)and withdraw the companion flange (2) using a puller, ifnecessary. (Fig. 16)

17. Remove pinion to drive gear backlash adjustment shims (6)and measure the overall shim thickness by means of amicrometer gauge.

Remove differential bearings1. Use a suitable puller (1) to remove bearing (2). (Fig.17)

2. Turn the differential case assy upside down and removebearing cone (1).(Fig.18)

3. Prevent the differential case from turning by securing it to asuitable fixture (1).

4. Undo self-locking screws and discard (2) fastening the drivegear (3) to the flange half diff case.

5. Drive off the ring gear using either a bronze drift or a press.(Fig. 19)

Fig. 16

Fig. 17

Fig. 18 Fig. 19

22 ArvinMeritor Differential Carrier Series 7

6. Mark the two case halves (2 and 3) and the spider (4) forcorrect mating at reassembly.

7. Remove screws and discard (1) and raise the flange half diffcase. (Fig. 20)

Disassembly the drive pinion from bearing cage(pinion-pac) *1. If the pinion spigot bearing (1) shows traces of wear or damage

and needs to be replaced, use an appropriate puller to removeit from the bevel pinion (2). (Fig. 21)

* Curvic single reduction differential carrier - Snap ring version type MS15-MR15Remove the snap ring from the end of drive pinion with snapring pliers that expand. Remove the spigot bearing from thedrive pinion with a bearing puller.

CAUTION: To prevent serious eye injury caused by splinters, alwayswear protection goggles when performing the aboveremoval operation.

2. With use of a press to drive the bevel pinion (1) off the bearingcage using special tool CT04 - (Fig. 22)

3. Use a suitable tool (1) to remove bearing (2). (Fig. 23)

2 Maintenance

Fig. 20

Fig. 21

Fig. 22 Fig. 23

matchmarking

*

23ArvinMeritor Differential Carrier Series 7

Inspection of differential components1. Clean all differential components thoroughly.

2. Lubricate the bearings and rock the roller cage: rotationshould be smooth without any sign of binding.

3. Inspect the bevel drive gear mounting face and ensurecomplete mating contact with the case abutment.Misalignment or distortion of these faces can cause mountingscrew vibrations leading to premature failure of the unit.

4. Inspect the splined section of final drive pinion for signs ofexcessive wear; if so, replace bevel gear pair and companionflange.

Differential case assembly1. Place plain case half (3) on the work bench.

2. Arrange the side gear thrust washer (2) in the case half; thenfit the side gear (1). (Fig. 24)

CAUTIONIf the spider has not been replaced, check for correctalignment of match marks made at disassembly, to avoidexcessive runout at backface of drive gear.

3. Fit the spider (6) to the case half (3) together with diff pinions(5) and thrust washers (4).

4. Install the second side gear (2) with its thrust washer (1).(Fig. 25)

NOTE: Lubricate all components with rear axle filling oil.

5. Install flange case half (2). Ensure match markings made atdisassembly are correctly aligned. Fit new screws and tightenthem according to the following sequence:

2 Maintenance

Fig. 24

Fig. 25

24 ArvinMeritor Differential Carrier Series 7

2 Maintenance

Fig. 26

Fig. 27

Fig. 28

Tightening sequence to be observed in all fastenertightening operations:

1. tighten the first capscrew pair positioned at diametricallyopposite ends;

2. proceed as specified at no. 1 above with the secondcapscrew pair (perpendicular to the first one);

3. carry out the screw tightening operation following thesame pattern.

• Stage 1:Tighten to 100 Nm (10 kgm) torque with torque wrench (3)(Fig. 26)

• Stage 2:Lock screws to an angle of 110° to 120° by means of boxwrench (3). (Fig.27)

CAUTION:Wear safe clothing and gloves for protection from injurywhen working with the hot bearing.

6. Heat bearing (2) in an air oven to a temperature of 100° forabout 15 minutes and drive it in place using a suitable drift.(Fig. 28)

7. Heat the drive gear (1) in an air oven to a temperature of100°C to 150°C and install it on the flange case half. Ensure itis free to rotate, then fit four screws to ensure alignment offastener holes of drive gear and flange case half. Alternately,heat the drive gear in a tank of water to a temperature of 70°Cto 80°C for about 15 minutes before reassembly according tothe above procedure. Do not press a cold drive gear on theflange case half. A cold drive gear will damage the case halfbecause of the interference fit.

CAUTION:Wear safe clothing and gloves for protection from injurywhen working with the hot drive gear

25ArvinMeritor Differential Carrier Series 7

2 Maintenance

Fig. 29

Fig. 30

Fig. 31

Fig. 32

8. Wait for the drive gear to cool down and then turn the bearingcage upside down on the tool.

9. Fit screws (1) and tighten them according to the followingsequence:

• Stage 1: Tighten to 100 Nm (10 kgm) torque with torquewrench (2); (Fig. 29)

• Stage 2: Lock screws to an angle of 80° to 90° by means ofbox wrench (1). (Fig.30)

10. Heat bearing (2) in an air circulation oven to a temperature of100°C for 15 minutes and drive it in place using a suitabledrift. (Fig.30)

CAUTION:Wear safe clothing and gloves for protection from injurywhen working with the hot bearing.

Assembling drive bevel pinion on bearing cage1. Heat bearing (2) in an air circulation oven to a temperature of

100°C for 15 minutes and drive it on bevel pinion (1). Wait forthe bearing to cool down. (Fig. 31)

CAUTION:Wear safe clothing and gloves for protection from injurywhen working with the hot bearing.

2. Using service tool CT11 (1) to press the bearing cage (2) ontothe bevel pinion (3). (Fig.32)

26 ArvinMeritor Differential Carrier Series 7

2 Maintenance

3. Proceed as follows if a new pinion spigot bearing needs to beinstalled:

Heat the spigot bearing (1) in an air circulation oven to atemperature of 100°C for 15 minutes and drive it onto bevelpinion (2).(Fig.33)

CAUTION:Wear safe clothing and gloves for protection from injurywhen working with the hot bearing.

WARNING:When installing the spigot bearing, place the larger radiustoward the pinion head.

4. Stake the bevel pinion spigot at ten evenly spaced points, asshown using special tool CT06. If dents from previousoperations can still be noticed, make sure the number of fullindentation is no less than the number of pinion teeth (a ‘fullindentation’ is a mark that does not spread out into the millinghollow). (Fig. 34)

CAUTION:The indentation diameter must be between 3.40 and 4.10mm, corresponding to a depth of 0.30 to 0.44 mm under aload of 4000 kg and a ball 10 mm in diameter.

Fig. 33

Fig. 34

bevel pinion spigot

2,3

27ArvinMeritor Differential Carrier Series 7

2 Maintenance

Alternative bearing retension

Installing the one-piece spigot bearing onthe drive pinion with snap ring1. Place the drive pinion in a press, gear head (teeth) toward the

top.

2. Press the spigot bearing on the end of drive pinion until thebearing is flat against the gear head. Use special tool CT05against the bearing in race. (Fig. 35)

NOTE: When installing the spigot bearing, place the larger radiustoward the pinion head, as shown.

3. Install the snap ring (*) into groove in end of drive pinion withsnap ring pliers. (Fig. 36)

NOTE: (*) Some Meritor carriers do not have these describedparts.

Completing assembly operations

1. Position the drive input flange (1) complete with deflector (2)and drive it home with service tool CT11 the use of a press isrecommended. (Fig. 38)

2. Temporarily tighten the retaining nut.

Fig. 35

Fig. 36 Fig. 38Fig. 37

press

sleeve

spigot bearing

spigotbearing

snapring

snap ring spigotbearing

28 ArvinMeritor Differential Carrier Series 7

2 Maintenance

WARNING:Where the same pinion-drive gear assembly is used as wastaken off when dismantling, position the previouslymeasured shim pack (2) and the bevel pinion bearing cage(1) with the bearing cage o-ring, on the carrier (3), makingsure the oil passage groove is correctly lined up usingservice tool CT 08 for alignment. (Fig. 39)

Replace the o-ring if damaged to avoid oil leakage throughthe shims.

3. If the gearset is replaced with a new ring and pinion, thecorrect location of the pinion is critical and is established byreference of the markings on the pinion and drive gear.

1. Part number.

2. Tooth combination number.

3. Pinion-drive gear pair set number.

4. Variation number needed to determine the thickness of theshim pack to be interposed between pinion bearing cage anddifferential carrier (in the examples below, the number isidentified as P.C.).

5. Pinion-drive gear set manufacturing and testing date(month/year).

6. Pinion-drive gear set nominal backlash value.

Part and tooth combination numbers are stamped at the threadedend of all pinions. On drive gears these numbers are usuallystamped on the outer face. In any final drive set the drive gearwill always bear an even category number (example: 36786)while the mating pinion will bear an odd category number(example: 36787). The tooth combination number (example, 10-41) indicates that the pinion has 10 teeth and the drive gear 41,equal to a drive ratio of 4.10 : 1.

Fig. 39

Fig. 40

WARNING:Never use a pinion and drive gear set unless bothcomponents have the same match number

Every drive gear is marked with a variation number whichindicates the nominal assembly distance. Use this number tocalculate the thickness of the shim pack that is interposedbetween pinion bearing cage and differential carrier. Thisvariation number (example, PC + 0.1 or PC – 0.1 mm) isstamped on the drive gear outer face.

29ArvinMeritor Differential Carrier Series 7

2 Maintenance

Fig. 41

Adjusting the pinion cage shim packthickness1. Measure the thickness of the shim pack removed with the old

pinion-drive gear assembly. Use a micrometer or a gauge andtake a note of the reading.

2. Read the P.C. marked on the drive gear to be replaced.If it is a plus (+) number, subtract it from the value obtainedunder item 1. above.If it is a minus (-) number, add it to the value obtained underitem 1. above.

WARNINGThe value obtained at Example 2 will be used to calculatethe thickness of the shim pack to be interposed betweenpinion bearing cage and differential carrier for correct newfinal drive assembly. Spare shims to be interposed betweendifferential carrier and bevel pinion bearing cage areavailable in thicknesses of 0.125 – 0.200 – 0.500 mm.

Take note of the result.

3. Read the P.C. marked on the new drive gear. Either add orsubtract the resulting value depending on the variation sign (+ add, - subtract) from the measurement taken at item 2.above.The resulting value indicates the thickness of the new shimpack to be assembled.

Refer to the following examples which cover all the possiblecalculation combinations.

All final drive sets are stamped with a number indicating thenominal backlash between pinion and drive gear obtained whenmachining was finished. This backlash value is shown on thedrive gear outer diameter.

Example 1:Original shim pack thickness mm 0.75P.C. marked on old drive gear + 0.05 - 0.05Resulting value mm 0.70P.C. marked on new drive gear + 0.10 + 0.10Thickness for new shim pack mm 0.80

Example 2:Original shim pack thickness mm 0.65P.C. marked on old drive gear - 0,05 + 0.05Resulting value mm 0.70P.C. marked on new drive gear + 0,15 + 0.15Thickness for new shim pack mm 0.85

Example 3:Original shim pack thickness mm 0.70P.C. marked on old drive gear + 0,05 - 0.05Resulting value mm 0.65P.C. marked on new drive gear - 0,05 - 0.05Thickness for new shim pack mm 0.60

Example 4:Original shim pack thickness mm 0.85P.C. marked on old drive gear -0,10 + 0.10Resulting value mm 0.95P.C. marked on new drive gear - 0,15 - 0.15Thickness for new shim pack mm 0.80

10 = combination number+0.05 = P.C. (Pinion Cone)10/00 = manufacturing month/yearB/L 0.32 = pinion/drive gear assembly nominal backlash

value

30 ArvinMeritor Differential Carrier Series 7

2 Maintenance

Differential carrier general assembly1. Fit new screws (2) and tighten in two stages as follows:

• Stage 1:Tighten with torque wrench (1) to 100 Nm (10 kgm); (Fig. 42)

• Stage 2:Lock screws (2) with box wrench to an angle of 60° to 70° (1).

2. Turn the unit around by 90°.

3. Block companion flange rotation (3) by means of service toolCT 03 (5). Use socket (2), torque multiplier (4) and torquewrench (1) to tighten new drive pinion nut to the specifiedtorque (1350 to 1670 Nm). (Fig. 43)

Torque multiplier:Ensure the torque multiplier ratio is correct.

4. Position the caps taking care to align the locating dowels.Insert capscrews complete with washers and tighten using atorque wrench to 650 to 810 Nm.

5. Check that bearing cups (1) slide into their housings with lightpressure without sticking.

6. Unscrew the retaining screws with washers again and removethe caps.

Fig. 42

Fig. 43

Fig. 44

31ArvinMeritor Differential Carrier Series 7

2 Maintenance

7. Position bearing cups (3).

8. Use a suitable lifting device (1) to lift the previouslyassembled differential assembly (2) and position in carrier.(Fig. 45)

WARNING:Differential carrier removal and handling should beperformed using the specified lifting and carryingequipment.

9. Position the caps (2) making sure locating dowels arealigned.

10. Fit cap screws (3) with washers; use torque wrench (1) totighten capscrews without locking to specified torque.(Fig. 46)

11. Lubricate taper roller bearings (1) with axle oil; screw inadjusting rings (2) manually until they touch bearing cups;lock capscrew (3 fig. 46) to 650 to 810 Nm (65 to 81 kgm).(Fig. 47)

Adjusting preload of differential bearingsExpansion between bearing caps (leg spread) can be performed intwo methods:

• method 1 :

1. Use wrench service tool CT 12 (3, fig. 48) to tighten bearingadjusting rings (4) until pinion-to-drive gear end play andbacklash readings are zero; also check that the drive gear isnot jammed against the pinion.

Fig. 45

Fig. 46

Fig. 47

Fig. 48

32 ArvinMeritor Differential Carrier Series 7

2 Maintenance

2. With an appropriate micrometer positioned crossways atpoints X and Y (arrows, fig. 49), read and take a note ofdistance between caps.

3. Tighten adjusting rings (4, fig 48) until cap (2, fig. 48)divergence - measured on either axes X or Y, as described atpoint 2. above - reads between 0.15 and 0.33 mm,corresponding to a bearing preloading of 1.7 to 3.9 Nm (0.17 to 0.39 kgm).

• method 2 :

1. Place two magnetic-base dial gauges in central and crosswaysposition on the outer machined faces of caps (2, fig. 48), asshown in fig. 48;

2. Proceed as specified at 1.1 above.;

3. When backlash and end play are zero, continue tightening bothadjusting rings (4. fig. 48) until the cap divergence reading setsbetween 0.15 and 0.33 mm, which corresponds to the sum ofreadings on dial gauges (1).

Hypoid ring gear backlash adjustmentProceed as follows to adjust end play between teeth of pinion-drive gear assembly, which should be:

0.20 - 0.45 mm for MS15-MR150.26 - 0.50 mm for MS16-MS17:

a. stop bevel drive pinion rotation;

b. position a magnetic-base dial gauge (1) as shown in fig. 50;

c. use wrench service tool CT 12 (3) to slacken the adjustingring on drive gear side and tighten the adjusting ring on theopposite side (2) by the same amount (by doing so, thepreviously measured cap divergence reading remainsunchanged);

d. proceed as previously described to obtain the specified endplay value.

End play should be checked at four evenly spaced points.

Fig. 49

Fig. 50

33ArvinMeritor Differential Carrier Series 7

2 Maintenance

Adjusting preload of differential bearingsExpansion between bearing caps (leg spread) can be performed intwo methods:

Use a magnetic-base dial gauge (1) to measure drive gear (2)runout: it should not exceed 0.20 mm.

If not, dismantle the differential unit and trace the cause for thedefect. (Fig. 51)

Reassemble the unit and repeat the above adjusting operations.With a brush, apply a thin coat of Prussian blue to the drive gearteeth. Rotate the pinion and examine the contact marks left by thepinion teeth on the drive gear teeth. The following figures illustratethe possible types of contact and the methods for correcting anyerrors.

Tooth contact pattern of the gear set1. Coast (concave side)2. Toe3. Drive (convex side)4. Heel

DRIVE SIDE Central toward the toe over the face of the gear tooth and in thecentre on the tooth profile (page 35).

COAST SIDE Central toward the heel over the face of the gear tooth and in thecentre along the tooth profile (pag. 35).

Fig. 51

Fig. 52

Fig. 53

34 ArvinMeritor Differential Carrier Series 7

Excessive contact toward the top of the gear tooth.Conditions A-B. - (pag. 35)Indicates that pinion is located too far outward and needs furtheradjustment. For a more correct positioning, remove shims underits bearing cages required to ensure proper contact.

Condition A - (pag. 35)Remove shims and increase backlash toward maximum value.

Condition B - (pag. 35)Check backlash reading, remove shims and set to correct value.

Excessive contact toward bottom of drive gear tooth.Conditions C-D. - (pag. 35-36)Indicates that pinion is located too deep inward and needs furtheradjustment. For a more correct positioning, add shims under itsbearing cage as required to ensure proper contact.

Condition C - (pag. 35)Check backlash reading, add shims and set to correct value.

Condition D - (pag. 36)Add shims and decrease backlash toward minimum value.

Condition E - (pag. 36) Decrease backlashCondition F - (pag. 36) Increase backlash

WARNINGShould pinion spigot bearing interfere with drive gear whilethe shim pack is replaced, loosen the ring nut on the drivegear rest side and take note of its position; replace shimsand return the ring nut to its previously recorded position.

Fig. 54

Fig. 55

Fig. 56

2 Maintenance

Adjust backlash

2 Maintenance

Tooth contact patterns of hypoid gear setTheoretical contacts

DRIVE SIDE COAST SIDE

(drive gear convex side) (drive gear concave side)

TOP TOP

HEEL TOE HEEL

BOTTOM BOTTOM

• DRIVE: Central toward the toe over the face of the gear tooth and in the centre on the tooth profile.• COAST: Central toward the heel over the face of the gear tooth and in the centre along the tooth profile.

Condition “A”DRIVE SIDE COAST SIDE

TOP TOP

HEEL TOE HEEL

BOTTOM BOTTOM

• DRIVE-RELEASE: Excessive contact toward the top• DRIVE: Excessive contact toward the toe• COAST: Excessive contact toward the heel• REMEDY: Remove shims and increase backlash to maximum value

Condition “B”TOP TOP

HEEL TOE HEEL

BOTTOM BOTTOM

• DRIVE-COAST: Excessive contact toward the top• REMEDY: Take backlash reading, remove shims, set backlash to correct value

Condition “C”TOP TOP

HEEL TOE HEEL

BOTTOM BOTTOM

• DRIVE-COAST: Excessive contact toward the bottom.• REMEDY: Take backlash reading, add shims, set backlash to correct value

36 ArvinMeritor Differential Carrier Series 7

Condition “D”DRIVE SIDE COAST SIDE

TOP TOP

HEEL TOE HEEL

BOTTOM BOTTOM

• DRIVE-COAST: Excessive contact toward bottom.• DRIVE: Excessive contact toward heel.• COAST: Excessive contact toward toe.• REMEDY: Add shims and decrease backlash to minimum value.

Condition “E”TOP TOP

HEEL TOE HEEL

BOTTOM BOTTOM

• DRIVE: Excessive contact toward heel.• COAST: Excessive contact toward toe.• REMEDY: Decrease backlash.

Condition “F”TOP TOP

HEEL TOE HEEL

BOTTOM BOTTOM

• DRIVE: Excessive contact toward toe.• COAST: Excessive contact toward heel.• REMEDY: Increase backlash.

2 Maintenance

7. Standard version: Fit cotter pin (1) and bend it over. Repeatthe same operation on the opposite side.Curvic version: Fit cotter pin (1) to collar’s opposite side andbend it over.

8. Curvic version: Fit pin spirol (2) to collar’s opposite side.

9. Install shift fork (2) with collar (1).

10. Coat with Molikote Gn Plus grease the shift fork’s slantingface.

11. Position the shift fork and the collar together with spring usingservice tool CT07 (3) and shift shaft (4).

12. Fit the piston (5) with its 0-ring. Before assembling the pistoncoat the 0-ring seal with Molikote 44 Medium grease.

13. Fit the cylinder end cover (6) with gasket (8), insert screwswith washers and tighten with a torque wrench to 12 to 16Nm.

Curvic Version:

14. Fit the thrust screw (1) and nut (2); tighten screw to abutmentagainst the drive gear face until resistance is felt. Apply Loctite573 on the thread.

15. Undo thrust screw by 180° approximately (clearance shouldbe between 0.65 and 1.14 mm).

16. Tighten nut to a torque of 270 to 335 Nm. (Fig. 60)

37ArvinMeritor Differential Carrier Series 7

2 Maintenance

Standard version

Curvic version

Fig. 57

Fig. 58

Fig. 59

Fig. 60

38 ArvinMeritor Differential Carrier Series 7

Instructions to install and adjust differential lock sensor switch

2 Maintenance

Fig. 61

WARNINGCheck and adjustment of differential sensor switch is carriedout with rear axle installed on vehicle.

1. Before screwing in the switch, coat switch point with MolikoteGn Plus grease, screw the switch threads and apply sealantLoctite 573 on the threads.

2. Engage differential lock and tighten sensor switch until theswitch point touches the shift fork slightly; check that warninglamp illuminates on dashboard.

3. As soon as the warning lamp is switched on in cab, turn theswitch one additional revolution.

4. Tighten the lock nut from 35 to 45 Nm.

5. Check differential lock engagement by blowing in air (6 kg/cm2/6 bar approximately).

6. Release differential lock and ensure in this condition warninglamp in cab is off.

7. Repeat the above operations several times before running thevehicle on the road.

39ArvinMeritor Differential Carrier Series 7

2 Maintenance

Replacing pinion-pac sealThe following repair operation may be carried out with differentialunit installed on vehicle.

Disassembly1. Unscrew nuts (1) fastening propeller shaft to differential

companion flange.

2. Disconnect the propeller shaft (2) and secure it to the chassis.Fig. 62

3. Block the rotation of flange (1) by means of service tool CT03(2).

4. With wrench (3), torque multiplier (4) and service tool CT02slacken bevel pinion nut and withdraw flange (1) Fig. 63.

5. With a suitable tool raise the outer edge of metal inner ring (1)in two opposite points. Fig. 64

6. Pry with two levers (2) to withdraw inner ring (1). Fig. 65

7. Pry with the lever in the direction shown by the arrow toremove grommet (1). Fig. 66

Fig. 62

Fig. 63

Fig. 65

Fig. 64

40 ArvinMeritor Differential Carrier Series 7

2 Maintenance

Assembly1. Accurately clean the seal ring seat from any trace of dirt or oil.

2. Position a new seal ring (1). Fit service tool CT01 (2), screw ina guide nut machined out of the old drive pinion nut, and bedthe seal ring to stop.(Fig. 67)

3. Loosen the guide nut, remove installer (2), reassemble theflange and screw in a new nut; lock to the specified torqueusing torque wrench and multiplier. Reassemble the propellershaft and tighten fastening nuts to the specified torque.

Fig. 66

Fig. 67

41ArvinMeritor Differential Carrier Series 7

Torque chart

Fig. 68

3

8

2

1

6

7

5

4

Description TorqueNm ° Kgm

1 Stud nuts and/or capscrews carrier to housing stage 1 torque 100 10(M16x2 Durlock) stage 2 angle 80° - 90°

2 Diff. case screws stage 1 torque 100 10stage 2 angle 110°-120°

3 Drive gear screws stage 1 torque 100 10stage 2 angle 80°-90°

4 Drive pinion nut 1350-1670 135-1675 Pinion cage capscrews stage 1 torque 100 10

stage 2 angle 60°-70°6 Lock nut sensor switch 35-45 3.5-4.57 Cover capscrews 10-12 1.0-1.28 Thrust screw nut 270-335 27-33.5

Bearing cap capscrews (not showed) 650-810 65-81

42 ArvinMeritor Differential Carrier Series 7

43ArvinMeritor Differential Carrier Series 7

pg.

3

Troubleshooting

44 Troubleshooting

44 ArvinMeritor Differential Carrier Series 7

Fault1. Wheel hub noise andpossible overheating

2. Anomalous knocks from thedifferential during acceleration/ deceleration stages

3. Noise when travelling

4. Oil leakages

Possible causesThe oil used is not of the typespecified by the manufacturerLow oil levelIncorrect backlash between drivegear teethGears damagedBearings worn or maladjustedIncorrect use of retarder/exhaustbrake

Diff pinion thrust washers wornDiff pinion or diff spider wornDriving wheel loose on hubDifferential unit splined sectionsworn

Low oil level in axle housingTeeth and/or bearings worn ordamagedBearings maladjusted or damaged

Excessively high oil level in axlehousingBreather blockedSeal rings damagedScrews/nuts loose

Seal between axle housing anddifferential unit damaged

RemedyDrain oil from housing and fill with new oil of the specifiedtypeTop up oil level in housingRemove bevel drive gear pair. Trace cause for possible geardamage. Adjust as requiredReplace defective componentsReplace defective componentsCheck retarder/exhaust brake efficiency and setting. Look forpossible damage to bevel drive gear pair and bearings

Replace all thrust washersReplace worn componentsCheck wheel nuts at regular intervals and tighten, as requiredReplace worn components

Top up oil levelReplace damaged components

Adjust bearings and replace, as required

Check oil level

Clear/replace breatherReplace damaged seal ringsClean threads, coat with sealant if necessary, and tighten tothe specified torqueRemove differential unit, check and clean all sealing surfacesand coat parts concerned with sealant, as required

The following chart shows the most common faults occurring to a differential unit.

3 Troubleshooting

Meritor Heavy Vehicle Braking SystemsGrange Road, Cwmbran Published in Italy

South Wales NP44 3XU - U.K.

Tel.: +44 (0) 1633 834238 © Copyright 2002 Issued 4/2003

Fax: +44 (0) 1633 834191

www.arvinmeritor.com ArvinMeritor Inc. M-graph - MM0140