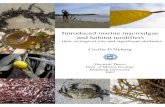

Macroalgae activities in Norway -

Transcript of Macroalgae activities in Norway -

Technology for a better society

20.09.2012, Nordic Algae Workshop,

Grenaa, Denmark

1

Jorunn Skjermo, SINTEF Fisheries and Aquaculture

Macroalgae activities in Norway

Technology for a better society

Macroalgae industry in Norway

2

Species Harvesting

(tons wet weight per

year)

Region Usage Company

"Stortare"

Laminaria hyperborea

130 000 – 180 000 Rogaland –

Sør Trøndelag

Alginate

(7000 tons)

FMC Biopolymer

"Grisetang"

Ascophyllum nodosum

10 000 – 20 000 Midt-Norge -

Troms

Seaweed

meal, extracts

(7000 tons)

Algea

Foto: Mentz Indergaard

Economic value: 1,2 billion NOK (0,16 billion €)

Technology for a better society

Why should Norway cultivate seaweeds?

• A biomass with great potentials – 3.generations bioenergy

– Food

– Feed

– Bioactive compounds, high-value chemicals

– Chemical building blocks

– Fertilizers

• Further, sustainable increase in use requires cultivated biomass, especially when large volumes are required (e.g. biofuels and feed)

3

Seaweed Energy Solutions

SINTEF

Technology for a better society

Seaweed biomass as 3rd generations biofuels

• Chemical composition suitable for conversion into biofuels (ethanol, buhtanol)

and biogas (methane): 60% carbohydrates (of dry weight)

• High biomass productivity (ca 2 kg C m-2 year-1)(Lüning 1990).

• CO2-consumption: 8-10 tons per ha per year

– (comparable to temperate woodlands (Chung et al. 2010)

• No use of valuable human food crops

• No use of productive land area

• No need for irrigation, pesticides or artificial fertilizers (NB! No phosphate)

4

Technology for a better society

BIOENERGY POTENTIAL in SEAWEEDS

5

Biomass outcome

• 100 tons biomass (wet weight) per ha per year (SINTEF)

• 20 tons dry weight per ha per year

Ethanol outcome (theoretical)

• 80% conversion: 0.281 L ethanol per kg seaweed (dry weight)(Wargacki et al., 2012)

• 5,620 L ethanol per ha per year

Potentials for increase:

• Higher biomass production (150-200 tons per ha)

- Breeding and species selection

- Improved cultivation technology and strategies

• 90% conversion: 2,500km2 gives 2 billion L (Kraan, 2010)

Technology for a better society

Norwegian advantages for macroalgae cultivation (i)

• Geography – Long coastline

– Large economic zone: 90.000 km2

• 480 macroalgae species • 205 red

• 175 brown

• 100 green

6

Technology for a better society

Norwegian advantages for macroalgae cultivation (ii)

• Knowledge and competence – Aquaculture (fish, mussels)

– Off-shore industry (fish, oil/gas)

– Biotechnology (phycocolloids)

• IMTA with salmon industry

7

Design: Mats Heide, SINTEF

Technology for a better society 8

Dissolved nutrients

(45% N)

(21% P)

Particulate

nutrients

(15% N)

(44% P)

Wang et al., 2012. Aquaculture and Environment Interactions, accepted for publication

Fish

(N40%)

(P35%)

1-5%

Feed

(100% N)

(100% P)

Nutrient mass-balance budget for Norwegian salmon aquaculture

Technology for a better society

Seaweed cultivation in IMTA - potentials in Norway

Photo: Mentz Indergård

Degree of

exploitation

Biomass outcome

Seaweed biomass : salmon biomass

10% of released N 1 : 1

20% of released N 2 : 1

Wang et al., 2012. Aquaculture and Environment Interactions, accepted for publication

Technology for a better society 10

Distribution of dissolved

N from a fish farm

• Color scale: The probability for ammonium

concentrations > 0.5 mmol m-3

• Simulation based on real feed consumtion

in september 2010.

Surface

22 m depth

MacroBiomass, Broch et al, subm.

Technology for a better society

Growth (length) of S. latissima in IMTA with Salmo salar

Reference Salmon farm

Handå et al. submitted

Aug-2 m

Aug Sep Oct Nov Dec Jan Feb Mar Apr May Jun Jul Aug Sep

Sp

oro

ph

yte

len

gth

(cm

)0

20

40

60

80

100

120

140

160

Salmon farm

Reference

R2=0.99

R2=0.99

Aug-5 m

Aug Sep Oct Nov Dec Jan Feb Mar Apr May Jun Jul Aug Sep

Sp

oro

ph

yte

len

gth

(cm

)

0

20

40

60

80

100

120

140

160

Salmon farm

Reference

R2=0.99

R2=0.98

Aug-8 m

Aug Sep Oct Nov Dec Jan Feb Mar Apr May Jun Jul Aug Sep

Sp

oro

ph

yte

len

gth

(cm

)

0

20

40

60

80

100

120

140

160

Salmon farm

Reference

R2=0.97

R2=0.94

* *

*

*

*

* **

**

*

*

*

*

C

B

A

MacroBiomass, Handå et al, subm.

Technology for a better society

Length of S. latissima in IMTA with Salmo salar

2 m depth 8 m depth

Handå et al. submitted

Aug-2 m

Aug Sep Oct Nov Dec Jan Feb Mar Apr May Jun Jul Aug Sep

Sp

oro

ph

yte

len

gth

(cm

)

0

20

40

60

80

100

120

140

160

Salmon farm

Reference

R2=0.99

R2=0.99

Aug-5 m

Aug Sep Oct Nov Dec Jan Feb Mar Apr May Jun Jul Aug Sep

Sp

oro

ph

yte

len

gth

(cm

)

0

20

40

60

80

100

120

140

160

Salmon farm

Reference

R2=0.99

R2=0.98

Aug-8 m

Aug Sep Oct Nov Dec Jan Feb Mar Apr May Jun Jul Aug Sep

Sp

oro

ph

yte

len

gth

(cm

)

0

20

40

60

80

100

120

140

160

Salmon farm

Reference

R2=0.97

R2=0.94

* *

*

*

*

* **

**

*

*

*

*

C

B

A

Aug-2 m

Aug Sep Oct Nov Dec Jan Feb Mar Apr May Jun Jul Aug Sep

Sp

oro

ph

yte

len

gth

(cm

)

0

20

40

60

80

100

120

140

160

Salmon farm

Reference

R2=0.99

R2=0.99

Aug-5 m

Aug Sep Oct Nov Dec Jan Feb Mar Apr May Jun Jul Aug Sep

Sp

oro

ph

yte

len

gth

(cm

)

0

20

40

60

80

100

120

140

160

Salmon farm

Reference

R2=0.99

R2=0.98

Aug-8 m

Aug Sep Oct Nov Dec Jan Feb Mar Apr May Jun Jul Aug Sep

Sp

oro

ph

yte

len

gth

(cm

)

0

20

40

60

80

100

120

140

160

Salmon farm

Reference

R2=0.97

R2=0.94

* *

*

*

*

* **

**

*

*

*

*

C

B

A

Technology for a better society

Seaweed species in Norway of special interest for industrial scale

farming – the large brown kelps.

13

Alaria esculenta

Biofuels

Feed

Food

Saccharina latissima

Biofuels

Food

Technology for a better society

Production of seedlings - upscaling

14

Spores or gametophytes are sprayed on thin ropes and incubated in 200 L's cylinders

(720 m pr cylinder).

MacroBiomass

Technology for a better society 16

Norwegian markets for cultivated macroalgae biomass

Product(-s) Company

Cultivation technology Seaweed Energy Solutions

Equipment Seaweed Energy Solutions, Aqualine

Biomass Seaweed Energy Solutions

Food Restaurants, Stokkøya Sjøsenter

Biofuels (liquid) Statoil

Biofuels (gas) Biokraft AS

Fish feed, animal feed Ewos, Skretting, Biomar, Felleskjøpet

Alginate FMC Biopolymer*

Food supplement Algea*

Extracts, high value products Algea*

Fertilizers Yara, Algea*

*in business, harvested biomass

Technology for a better society

Summary

• Only harvested biomass used

industrially

• R&D-activities on

– Cultivation technology (large scale)

– Processing (biofuels)

– Bioprospecting

– IMTA

• Seaweed Energy Solutions and Statoil

main drivers (biofuels)

17