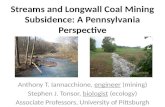

Longwall mining in Western Pennsylvania -

Transcript of Longwall mining in Western Pennsylvania -

Enlarged area

High-Quality

N

Waynesburg

1940

19

88

88

51

51

Enlow Fork

Shoemaker

Shoemaker

Balley

Eighty-four

Dilworth

Emerald

Blacksville #2

Cumberland

Washington

Bridgeville

W A S H I N G T O N

A L L E G H E N Y

G R E E N E

Gastonville

Bentleyville

Masontown

79

79

70 70

40

MapleCreek

High-Quality

Westland

Vesta

Gateway

Warwick

Humphrey #7

Blacksville #1

Canonsburg

Ground level

Mine floor

Pillarsof coal

Steel shields to protect the miners fromthe loose rocks aboveand behind.

Shearer

Conveyor belt

Raw coal

Machineoperator

“Panel” of coal to be mined using thelongwall technique.The area can range from 800 to 1,500 feetwide and up to 3 miles long.

Elevator/ventilation shaft(exhaust fan helps air flow)

Steve Thomas/Post-Gazette

Intake air

Ret

urn

air

Source: Consol

Longwall mining in Western Pennsylvania

Subsidence in which the overlying rock and other materialfalls into the void where coal has been removed resultsfrom longwall mining. As the longwall system advances,the mine roof caves in behind the steel shields.

G : graphic : Science : July2003 : Longwall Mining : “longwall_mining.FH9”

Pillars are in the “mains” developmentpart of the mine. The coal is removedthrough those passages and goodair/bad air is exchanged, also minerstravel through those passages.

Steel shields to protect the miners fromthe loose rocks aboveand behind.

Active and closed minesSubsidence

In longwall mining, a very large block or “panel” ofcoal is isolated by the development of entries andcrosscuts. Special mining and roof support equipmentis then set up along the working face. This working facecan be anywhere from 800 to 1,500 feet wide.

The coal is mined by a longwall mining machine thatmoves across the face. Mined coal is then hauled by achain conveyor along the length of the face. The roof issupported by special hydraulic supports called chocksand shields that are advanced as the mining progresses.

An ‘under’ view

Active Closed

RAG:• Cumberland Mine• Emerald Mine

Consol• Bailey Mine• Blacksville No. 1• Dilworth• Eighty-Four Mine• Enlow Fork Mine• Humphrey No. 7• Vesta:

Originally J&L Steel,then A.T. Massey Coal.

• Westland

Maple CreekMining, Inc.• High Quality Mine

Consol (WV)• Blacksville #2• Shoemaker

Duquesne Light Co.• Warwick No. 3

Gateway Coal Co.• Gateway

Coal

Mine floor

Ground level