Liquid Metal Reactor Design Technology Development ...

Transcript of Liquid Metal Reactor Design Technology Development ...

KR0000195

KAERI/RR-2026/99

M

Liquid Metal ReactorDesign Technology Development

Development of Mechanical StructureDesign Technology for LMR

A*

7|

Please be aware that all of the Missing Pages in this document wereoriginally blank pages

•=]

nf

2000. 5. 4.

: 0|

0|

C 3

AH

ofc—i

II.

i f"71

7^1 S

fe 150MWe

-, 1-10

^^ - 51

0.3g

31

m.

7]-.

7fl ^

7^^711(182711

- IHTS Ufl^ ofl til -

7} ^ £ 1 ^ SI

- % • • % • #

2.

7\.

(530°C/386°C

B(1^2H(SAC-C0RE)

. 7ff3E

4 ^ ( in .^^ ]^ l§ l ]^S^ : SAC- COREK-NONSTA)

IV.

fe ^ ?]] 7fl

in

7] ^ ofl U] 7V

V. 45

I&C, ^:

: IDEAS* 7]

w

S U M M A R Y

I . Project Title

Development of Mechanical Structure Design Technology of KALIMER

II. Objectives and Importance of the Project

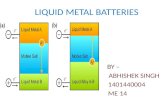

The main objectives of the project during the period of '97-'99 project

fiscal years are to develop a conceptual design and computer code systems

for mechanical structure design technology of 150MWe, pool type Liquid

Metal Reactor.

This project is essential since it provides the fundamental skeleton of

reactor system made by systematically implementing the complex interfaces

among core design, fluid system design, instrumentation & control design,

safety analysis and sodium technology.

Reactor structure design development consisting PHTS, containment

system, IHTS, and refueling system needs the design simplicity to meet the

various design requirements developed for the systems, structures and

components (SSC) with effective performance, easiness for inspection and

maintenance, prevention and mitigation of accidents.

Under the sodium operational environments in high temperature of 530°C,

low pressure range of 1 — 10 bars, high temperature structure design against

creep fatigue, ratcheting and thermal striping etc. should be developed for the

thin shell structure to keep sufficiently low thermal stress. On the other hand,

under design basis earthquake of 0.3g ground acceleration, an innovative

seismic design against buckling, seismic sloshing and safe shutdown of reactor

control rods should also be developed to keep the structural integrity for such

thin shell structures, introducing the seismic base isolation design which

remarkably reduces the earthquake loads on whole reactor systems to be more

economic and safer.

In developments of computer code schemes and analysis codes for

designs and analyses of reactor systems, structures, and components, following

four areas are needed;

1) Structural design code scheme for design, links of interfaces and

general arrangements of the 3-dimensional reactor structures

2) Structural analysis code system for the evaluation of structural

integrity of concept design developed

3) High temperature structural analysis codes for the evaluation of

nonlinear behavior of high temperature structures in the creep

fatigue, thermal striping and ratcheting conditions

4) Seismic analysis codes for the core seismic analysis, the

sloshing analysis of reactor vessel, and the buckling analysis of

thin vessels.

HI. Scope and Contents of the Project

1. Conceptual Design of Mechanical System

1) Main Systems, Components, Structures and Piping System of Reactor

System

- Preliminary Conceptual Design of Reactor System

- Structure Design Basis and Design Requirements

- Conceptual Design of Containment Vessel and Dome

- Conceptual Design of IHTS Piping

- Conceptual Design of Reactor Head

- Conceptual Design of Control Rod Drive Mechanism

- Conceptual Design of Refueling System

- Prevention and Minimization of Accidents and Faults Related to

Mechanical System

- Case Study of Reactor Vessel Slenderness and Buckling Analysis

VI

- Conceptual Design of Reactor Support Structure

- Conceptual Design of Support Structures of SG and EM Pump

2) Reactor Internal Structures

- Conceptual Design of Internal Structures

- Conceptual Design of Upper Internal Structure

- Functional Design of Shielding Structures

3) Seismic Isolation System

- Conceptual Design of Reactor Building

- Conceptual Design of Seismic Isolation System

- Conceptual Design of Piping Connection System

4) Preliminary Structure Analysis of Mechanical System

- Structure Analysis of Reactor Vessel

- Response Analysis of Reactor Vessel Sloshing

- Structure Analysis of Reactor Vessel Lower Head

- Preliminary Structure Analysis of IHTS Piping

- Thermal Stress Analysis of Internal Structures

- Structure Analysis of Upper Internal Structures

- Strength Evaluation of Weldments and Creep Fatigue Analysis

- Residual Stress Analysis of Weldments

- Floor Response Spectrum

2. Development of Computer Code Schemes for Mechanical System

1) Structural Design and Analysis Code

- Development of Structural Design Code Scheme

- Development of Structural Analysis Code Scheme

2) Seismic Analysis Code

- Development of Seismic Core Analysis Code

- Seismic Sloshing Analysis Code

- Setup of Small Capacity Structure Test Facility for Verification of

Analysis Results and Codes

- Seismic Isolation Design Guideline

VII

3) High Temperature Structure Analysis Code

- Creep Fatigue and High Temperature Ratcheting Analysis Code

- Setup of Ratcheting Test Facility

4) Code User's Manual

IV. Results of the Project

In this project, fundamentals for conceptual design of mechanical structure

system for LMR were independently established.

- Capability of conceptual design for SSC

- Design integration of interfaces

- Design consistency to keep functions and interfaces by developing

arrangement of reactor system and 3 dimensional concept drawings

- Development and revision of preliminary design requirements and

structural design basis

- Evaluation of structural integrity for SSC following structural design

criteria to check the conceptual design to be proper

- Development of high temperature structure design and analysis

technology and establishment of high temperature structural analysis

codes and scheme

- Development of seismic isolation design concept to reduce seismic

design loads to SSC and establishment of seismic analysis codes and

scheme

V. Proposal for Applications

Design technologies including computer code schemes and analysis codes

developed in this conceptual design for mechanical system for LMR can be

effectively applied for the establishment of concept design and basic design in

the next phases.

- System design to meet design requirements and structural design basis

Vll l

Design data to perform structural and stress analyses for SSC

Interface data for core design, fluid system and I/C, and safety

analysis

Maintenance and inspection design for reactor building and SSC, and

optimization of SSC to achieve economic design

Structural design code : production of 3-dimension mechanical system

drawings using IDEAS computer program.

Structural analysis code : evaluation of structural integrity against

normal and transient operational conditions

High temperature structure analysis code : mitigation of conservatism

in elastic analysis method for high temperature structures

Seismic analysis codes : generation of seismic load for SSC and

evaluation of seismic structural integrity

Small capacity structural test facility : verification of analysis model

and improvement of analysis codes

IX

Table of Contents

Summary i

Table of Contents xi

Chapter 1 Introduction 1

Chapter 2 States of the Arts 3

Section 1 Introduction 3

Section 2 Level of Technologies 10

Chapter 3 Conceptual Design of Mechanical System 17

Section 1 Introduction 17

Section 2 Main Systems, Components, Structures and Piping System

of Reactor System 21

1. Preliminary Conceptual Design of Reactor System 21

2. Structure Design Basis and Design Requirements 32

3. Conceptual Design of Containment Vessel and Dome 48

4. Conceptual Design of IHTS Piping 56

5. Conceptual Design of Reactor Head 64

6. Conceptual Design of Control Rod Drive Mechanism 85

7. Conceptual Design of Refueling System 89

8. Prevention and Minimization of Accident and Faults Related to

Mechanical System 99

9. Case Study of Reactor Vessel Slenderness and Buckling

Analysis 125

10. Conceptual Design of Reactor Support Structure 136

11. Conceptual Design of Support Structures of SG and

EM Pump 157

xi

Section 3 Reactor Internal Structures 160

1. Conceptual Design of Internal Structures 160

2. Conceptual Design of Upper Internal Structure 176

3. Functional Design of Shielding Structures 182

Section 4 Seismic Isolation System 185

1. Conceptual Design of Reactor Building 185

2. Conceptual Design of Seismic Isolation System 191

3. Conceptual Design of Piping Connection System 201

Section 5 Preliminary Structure Analysis of Mechanical System 208

1. Structure Analysis of Reactor Vessel 208

2. Sloshing Analysis of Reactor Vessel 264

3. Structure Analysis of Reactor Vessel Lower Head 271

4. Preliminary Structure Analysis of IHTS Piping 281

5. Thermal Stress Analysis of Internal Structures 288

6. Structure Analysis of Upper Internal Structure 311

7. Strength Evaluation of Weldments and Creep Fatigue Analysis 321

8. Residual Stress Analysis of Weldments 354

9. Floor Response Spectrum 367

Section 6 Conclusion 374

Chapter 4 Development of Computer Code Schemes for Mechanical

System 383

Section 1 Introduction 383

Section 2 Structural Design and Analysis Code 384

1. Development of Structural Design Code Scheme 384

2. Development of Structural Analysis Code Scheme 385

Section 3 Seismic Analysis Code 389

1. Seismic Core Analysis SAC-CORE Code 389

2. Seismic Sloshing Analysis Code 402

3. Setup of Small Structure Test Facility 404

xn

4. Seismic Isolation Design Guideline 415

Section 4 High Temperature Structure Analysis Code 420

1. Creep Fatigue and High Temperature Ratcheting Analysis Code 420

2. Setup of Ratcheting Test Facility 437

Section 5 Code User's Manual 452

1. SAC-CORE Code 452

2. NONSTA Code 464

Section 6 Conclusion 490

Chapter 5 Achievements and Contributions 493

Section 1 Achievements 493

Section 2 Contributions 498

Chapter 6 Proposals for Application 499

Chapter 7 References 501

xni

$& i

Summary v

Table of Contents xi

• xv

2 %• -ifl • 3 7]^?m ^ % 3

4 i ^ ^ ^ ^ - ^ 7]^?m « 3

*ll 2 7 ] ^ ^ ^ 10

3 ^ 7 l 7 i M l ^ 7 1 ) ^ ^ 7fl^- 17

^ 1 1 ^ 7i\& 17

4 2 ^^S7]]S- ^A7|7l, ^3:1- ^ Bfl^^lf 21

1. ^7,}S7Jl^ itl]7fl^7Jl 21

2. ^2:^^71 § ^ ^TflJl^i 32

3. 3tf-g-7] ^ ^ ^ ^ - ] t i ]7fl^^^ 48

4. IHTS afl^ 7fl^-i7fl 56

5. ^7^«llH. ^|al7fl^^7il 64

6. *\]°\% ^ ^ ^ 1 iHl7fl^^7il 85

7. «!]^S ^^-^741-f- <4|Hl7fl\i^7|| 89

8. 7] Til 2 : ^ ^ 4 J 1 ^ 3.^ ^Sl" -i^l ^ 99

9. ^^S.-g-7l ^Hl-ti} ^ 2f^3zj7} A>3^1^^ 1 2 5

10. ^7}S. 1 ^ 1 ^ S # ^7fl7l]^ - i ^ 136

11. ^ 7 1 ^ ^ 7 1 ^ ^ X > ^ ^ 1^1 -2 :# iHl^T]) 157

*ll 3 Qx}£. if l^-^-al- 160

i. ^flJf^ai- 7H^^7ii 160

2. W ^ ^ i - 3*}Q i«l7fl 7fl 176

XV

3. *}3^2:i- 7l i?H 182

4 4 ^^l^lf- i«l7fl^^7fl 185

1. Q*}£-^ 7H -M7]1 185

2. ^ A l ^ E 3 ) 7 f l ^^^ l 191

3. ^ ^ til^^l ^ ^ ^ l ^ a f l ^ ^ 1 ^ 3 ] 201

*ll 5 7l7fl7fl^ ofla] £ ^ 7 } 208

1. €^^-§-71 ^3,^7} 208

2. ^ ^ f S ^ - 7 l ^5L^ol «fl^ 264

3. Qz}S-&7] *}^niL ^ ^ 7 } 271

4. IHTS tiH^- «^«l^-2:3g7i. 281

5. iflJf^-S-i- t-g-^«l]^ 288

6. ^ ^ ^ S i - ^"2: 7> 311

7. - § - ^ 70V5L3|7}- ^J EL^A^- ^ A o ^ j 7 > 321

8. -g-^4 r^-g-^ ^7> 354

9. -g- - i^]S^ 367

^ 1 6 ^ 1 ^ 374

4 # 71^1^1^ ^ ^ ^ 1 ^ 1 71]^ 383

^1 1 7fl.&. 383

1 2 ^ - i 7 | 3 H ^ sfl^S^ ^I^l7fl# 384

1. ^ | 7 f l 3 H ^]^7fl^ 384

2. ^ l l ^ S H ^ ^ 7 i l ^ - 385

A 3 x]^l§1]A|iaH ?m 389

1. *1^^3.^-(SAC-CORE) 389

2. ^ l ^ l ^S -4 1 « f l ^ ^ ^ l ^ ^ 402

3. 3 ) - ^ ^ ^1^117fl - ^ ^ ^ ^ 2 : ^ 1 ^ 7 1 - 7 ^ 404

4. ^^^7^1^1^>H ^ ^ 415

1 4 H £ ^ 2 : * } H S J £ 7^ 420

1. EEL^S\S- ^ JL^-ef^l^ ^ ^ 3J71-SH 7im 420

2. Hf^]^ *1^#*1 ^ ^ 437

xvi

5 Q 7 | f2E Aj-g- l jA-1 452

1. ic^*l* l *fl*}-§- SAC-CORE 3 E 452

2. JL^^-Si ^Tflsfl^-g- NONSTA 2 H 464

6 *J 4.^ 490

7l^S. 493

^ ^ ^ ] ^ r g :^ 493

2 ^ tfl^l 7]<^£ 498

499

501

XVll

017]

tfl

717i01

014.

SI92\! 9

. 94\£

MDPi

GE, ANL ^ tfl74171

^) tfl

7] #

1

i f

FRAMATOME, AEAT, CRIEPI, JNC ^ IAEA CRP)

tfltb cfl*^

- 2 -

} f^ofl *} 4003$<H1

250

sl ii^l-o] 7fll£S|jL, 2 : ^ ^ ^ yo

-g- Pu

1990\l

, ^ 1 ^ ^ NERI

(Nuclear Energy Research Initiative) ^ ^ n ^ ^ r f-*}^ ^^- r*S

4 . °^^-^ ^ ^ S . DFBR 7 ^ ^ 7 1 1 * €:S.-3l-ji JAPC, JNC ^

Jl 91SL*\, 1 7 H ^-^=6.

IFR (Integral

- 3 -

Fast Reactor)4 PRISM(Power Reactor Innovative Small Module) 7]

4 4 7]

^-§-5)-

1. 1

1978^ ^^^F°i D0E7> i

^ FFTF(Fast Flux Test Facility)

d°fl ^ ° 1 f1^^ 975MWt ^ €

Reactor Plant)i tfl

T 3 1 ^ ^ A N L ^ l

^ 20MWe 3.7]^ EBR-II ^

°-#i$. uj- oj^- 400MWt ^-^

#<£ ^ * H $14. ^ tb 1983

CRBRP(Crinch River Breeder

4 oiji GE ^r^S 7fl

PRISMCPower Reactor Inherently Safe

Module)^ ALMR

IFRdntegral Fast

Reactor)

6.5. 1971 d ASME Boiler and Pressure Vessel

Code l Code Case 1331-ir *{•%• #!-u! Code Case 1592, 1974^^1 Code

Case N-47# 7]^^\ Code Case N-47-29S ^ ^ ^ $ 1 4 . n *

- 4 -

4 I N ASME Section III Subsection NHS.

DOE4 HTSD(High Temperature Structural Design) 31^4 WRC

(Welding Research Council) 31 PVRC(Pressure Vessel Research

Committee)^ < 3 ^ # ^ 4 *1€°.£- ^ ^ H & 4 .^A*> 7flS # ^ ^ 1 - &^}7] ^§1] DOE

^- 71-i-^ NSMH(Nuclear Systems Materials Handbook)!- # ! •

PRISM ASME-NH4

t}7] 1 . 500 °C

7im,

2. S^-i

Rapsodie^

1200MWe -

5.°] Phenix

Superphenix * 1986\1

Superphenixl-

^o] 4*> Phenix 5^

ol

C

, , °-S 1978\3 CEA, EdF ^ Novatome^l

(AFCEN)7l-

^Tfl ^ ^ ? ! : ^^1^ -^S ^-g- ^ ^ l S H ^ l RCC-MRi:

1985^ i

EFR(European Fast Reactor) 7l]

EFR ^^11- ^§1] -M l ? i ^ ^ 1 ^ ^ 7fliHr>7l ^*fl DCRC1- ^ ^

o]§fl EFR

1 1963\li

4 ojci Hfl^^-g- +s\\o] G C R o]^o^ pre-stressed concrete

^ ^ - ^ o.s ^-g-*> «}7r XI4. a t t 1973^^^ SSE 0.

^ ^ Koeberg(SSE, 0.3g) ^ CRUAS(SSE, 0.

$14. SL* Superphenix^l ^^f ^ ^ ^ ^ S ° J SPX2(1500MWe, SSE,

^ f ^ M SPX2 7^]^^

-fe EFR ^ ] ^ 1 S ^ ^ ^ 4 1

3.

- 6 -

JAPC^l ^ £ S ^ ^ S * l DFBR (Demonstration Fast Breeder Reactor) ^

Q*}£. =?^% - i ^ l * 3 $ W 7fl^^r ^*S«t ti} «IO.D] CRIEPI f-§-

f ^ A S MDP ?m ^o] o ^ ]

71 #^4 ^ ^ - ^ ^ ^ ,

- ^ 1971 \£ JOYCHf cfl^F^ M-Sf- 7]

JOYOi

A t 5lAS ^#sr)-JZ -o}^$\ Code Case 15921- ^-g-*}

*\°1 ^TflsH 711 51 ^ ^ . 4 j ^ O I ^ I - J L MONJU l JL

BDS S H I - ^-Aj^].^ A>-g-s]-$|4. BDS S H ^ Code

Case r

Code Case4

MONJU 2 >7flf- uH^o]

' ife JAPC1- ^43AS MONJUS 5 ^ 1999\! DFBR l zfl^^Tlll- ^S.t\ji JAPC,

JNC,

. JNC, CRIEPI f- - ^

BDS 2 S f 7flAi^- DDS S H I - *H3s]-7l o *V o £ ^ # ^ s j ^ o l r ^

] g t t ^ ] ^ 1 ^ € ^ > ^ Jl

- r

3: f^ ] &t)-. 125} JL CRIEPI

71 q- ^^flJE ^ ^ ^ofl olcf.

4.

1977\1 oleflS 1000 MWe - ^ EFRCEuropean Fast Reactor)^

7l]^-i- ^1*>^ CEC(Commission of European Communities)^ LMR

Coordinating Committee §H1 WGCS (Working Group Codes and

Standards)^ ^^1

o.^, =-«a^r 1973^^1 OIP] S ^ - ^ ^ Phenix^ 7 ^

SNR-3005] ? i ^^ ; A1^*> 4 OJ4^ o j ^ £ I955\li ^^fl^-^S.

DFR^ ^ I S ^ j i 1974 1 i ^ r AEA-TS] ^ ^>i 250 MWe

7fl A] ^ ^ # fe $1^ ^^1^-^S. 711

NNC ^-

i EFR

H<a R51- 7^SBK5} Interatom^ ^^-2-S ^ ^ S ^ J KNK-E

Ansaldo€ ^ ^ - ^ 1974\1 120 MWt

EFR £-£3134 ' i ^ l S H 7fliHl ^<*R> 4 o^_ E F R <g^.- 1 9 9 8

5.

BOR-60,

- r ^ ^ f °1 SiJi 1973\i3l- 1980^^1 AA ^y\ ^^^oHl ^m^l 130

MWe %%$\ %%/^^^^ BN-350(€^ ^ W ^ ^ f t &A)A # ^ 600

SX^- AJ"-g-S BN-8004 BN-1600

13 MWe^i ^ ^ ^ ^ FBTR^r *&A

# ^ 500 MWe

^<y CEFR 7fl^

IGCAR ^ ^ : f ^ ° _ S ^

RCC-MR

71

6.

El-

- 9 -

7]

- 1 0 -

1. 4^ 7 ] ^7\, ^\^9\ 7}

7] 3131 f-

713131 f-

" ^ ^ iiL "T-l jrL I E . " "^ ^TrJiL-^-] ^ ^1

- <5fl ] ] -g - -^^ . ^ 7 ] 1 ^ L H ^"M.

. ASME-NH, RCC-MR, BDS

4 ^ ^ i ^3l7l§- -M^#31- RV 4^1^(-"§' ^3 l7 l^s j - i- 713131*^31 Know-How Sj-iL

- ANSYS, ABAQUS, SYSTUS,CASTEM-2000, MARC, FINAS,NASTRAN, ADINA, COSMOS

'-^QIT^M^ *^

(SYSTUS ,CASTEM- 2000,FINAS)

° JL-&7^^ # ^ 4 tilo]El-Hflo]i ffl-^.

° °" "3" 3. "T2" 3i 7~\ - - 4 7l 'S' ^ # 31

° 31 •$• ^ 7fl 1 i^ \ 7ll W"/" -§" # 31

° 4'51 1'"§1 itS-'^ sfl'^71^' ^^#31° 'Ji'itS— ^ ^ 4 ^ 71^-^"^ #31

— viEfJ ~^>r Ti ^S--^\ ~T~ ^7. -^f ? i rs -^1 3 J~ y

- •S^l"5--§-7lJ ^^ -§ -7 ] ^ ^ 1

~~ ^c" V J 2 . 1 " 7?l ~^" Ull ji|- - ^ /^l

. ASME B&PV 2Ef -g -

. ASME SE.S1 4 t i l^ £ # ^ ^

- 713131- ^31 Know-How ail#31

- ANSYS, ABAQUS

- Jl^r Hl^Sfl-ij ^ S . ^ - ^ <3:TL7ll#

#31 (NONSTA 2E 7m :f^)

° 4 -?! *11 " s — 7H " 1 §•- Jn-^j4 -51*1]^3E7]] (SAC-CORE)

° J I ^ T ^ ^ 7ll'il 'il^31711 r <S~iL#3l

° - 1 -51 1"•§•/$• 3 ^ *fl'M7l^ l?l':rL#31

° -Ji'ilSS. 'n ir'M 1 S i L # 3 l

- 1 1 -

(1)

7EVC}.

IHTS

EM ^E.

- 1 2 -

71 Ef

^ o]n]

^7>7l#,

ol ^ ^ J ^ _

71 # ¥#

O 717|| Til-

- 1 3 -

CASTEM-2000 5LH.i Chaboche ^ i ^ S-Ht- 444-Si^l, Framasoft

7> 7H^^ --g-SH^l SYSTUS°11 Chaboche

1 Ohno-Wang £ | f ^

Alo] i f - 5 ] j l &*! ^ ^ ^ ^ o j j l <3j^^ j N C 7 l . yflm-^ji ol

FINAS 51 . 1 ^Si 7> 1

7]

(2)

7] ^TJl^f- ^ 3 : 7]]

44

- 1 4 -

51

I"

O

Know-How^

71 #5L^-1-

11 - # 5 . 71^1^-2: ^TflSIE.^ ^ ^ ^ I I ^ H nj^o^ ASME

Sec.III Subsection NH, Code Case 2014

DYWIDAG

LNG z\

7] 3]^>^ ^^l^T^l ^-§-^- 7^]^§}JI $14. t H - ^ r ^ T - i ^ UNISON

Super-Structurel-

371R

- 1 5 -

*fl^7]# 7fl

"(NONSTA-VP)-I- 7fl

0 1 ^ 014. rr*> ^ ^ ^ ^ S . ^ 71 Tfl A]

I-DEAS S H

SAC-CORE S H I -

7^1

- 1 6 -

71, 2) ^ 2 : # ^ «M^1^-, 3)

1 1 ^ 31 71-

4) o\}V}^-Et

KALIMER

IDEAS H §

31

L0CA<4 7^^ *}IL7} ^-^*M1 ^V r ^ i # ^ - ^ 7 > ^A*> A^ 31

Hf4. IHTS7]7l ^ ti]]^^^^ 1 #31 1*1 31^31

7171 f- - *l*l*Rr M ^ H ^ 31

- 1 7 -

ASME Section XI Division 3 # JI5]§}J1 KALIMER

^ A ^ 7 l - ^ ASME Code Section III,

Subsection

KALIMER

71-

Support), -^-•y^(Inlet Plenum), tfl^-^1^1 #(Support Barrel),

H(RV Liner), ^H] ^(Baffle Plate), £ e | ^(Separation Plate), o.z)5L

Guide), #^-tfl«-^-2:!-ol i ^ - s ) ^ , o) 6fl ufl *V ofl a] -i

1- IDEAS i ^ H ^ o ] ^

IHX

KALIMER

^ 2*1-31 £ ^ 7 1 1 5 } IDEAS

- 1 8 -

IDEAS s

KALIMER

^ ^ ^ KALIMER

^ ^ ^ 4 . tifl^ A£A 4^°fl^fe 480°C §1-90cmo] ^ ^ 2 : ^ ° 1 ] tfl

7l7fl7fl-fi cfl^ c jti]

7]-

^] ANSYS1-

KALIMER

spherical)

J 4 - IHTS

- 1 9 -

Chaboche

1000^5- ^Sj tf- ^ o H 1 ^ #^2:7iA] c^|til^7i]5l KALIMER

3

7H11"

0.3g <g^7]

^ 2.5cm

Tee-Junction^

ASME ^ H Section III Subsection N H *

0.3g

- 2 0 -

-8-7] 7],

1.

KALIMER

KALIMER

! ! I

M : !

^ ' / ' • t *''

(a) Arrangements of Duct Subassemblies (b) Detail Duct Assemblies

3.2.1-1 KALIMER Core Structures

- 2 1 -

3.2.1-2 Core Supports and UIS

- 2 2 -

•316SS SI

-PSDRS

3.2.1-3 Core Radiation Shield and Inlet Pipes

- 2 3 -

Station SXIXI

• o

« us

3.2.1-4 Support Barrel and Flow Guide

- 2 4 -

3.2.1-5 Separation and Baffle Plate

• 2 5 -

3.2.1-6 IHXs and EM Pumps

- 2 6 -

Overflow

3.^ 3.2.1-7 RV Liner and Insulation Plate

- 2 7 -

-316SS ME.5Cm, SOI 1855 Cm

- 2(1/4) Cr-liMo- ¥ 1 2 . 5 Cm, a 0| 1880 Cm

3.2.1-8 Assembled Reactor

- 2 8 -

3.2.1-9 Concept of Containment Structures

- 2 9 -

3.2.1-10 Preliminary Concept Design of KALIMER Reactor System

- 3 0 -

3.2.1-11 Seismically Isolated KALIMER Reactor Building

T 1

2.

7\.

KALIMER[3.2.2-1]

. o] 71$ £A-^ ^2:1-4 Tflf-, 7l7l

(1) ° ^ ^

(7f) 7] 7]

2010^

: -f-SS( 4 ) NSSS ^

( 4 ) Step ^ Ramp ^ - § } ^ «l-7Jl t f lcf l^^ NSSS

-t°i ^ £ ^ n^\°]o\ ^4.^ NSSS 7l7l ^ 4 4 1 " ^ ^ ^ ^ r ^ ^ 4^-2:?i(4^1, Missile

(4) -t4.

PSDRS7>

- 3 2 -

(2) ^_^}7)^^}^^$] JJTJ] (Relationships to Design Basis Events)

(3) ^r-n-iL^i (Classification Requirement)

(71-) °J^i^^-^^-(Safety Class)

^- 1, 2, 3

3.2.2-1 i 14EH- §14-

ic Category)

1).

© ^ ^ I

^ £ ^ 1, 2,

(2) Ml^^^r II

7]7l

7}

- 3 3 -

41- 5*

(4) aj-g_tf^(Code and Standard)

KALIMER ^ - S - i T f l ^ A>-g-

4^ 4 -o] ul^ifl^ %-g- 71- *1- 3HS}

- KS

(uf) Af-g- 7 1 - ^ ^ ^ ^ 4 ^ S . , fl-^(Code and Standard)

- ACI-349: American Concrete Institute, Code Requirements for Nuclear

Safety-Related Concrete Structures, 1980

- AISC: American Institute of Steel Construction, Specification for the

Design, Fabrication and Erection of Structural Steel for Buildings, 1978

- ASME B&PV Code, Section III, Rules for Construction of Nuclear

Power Plant Components, 1995

(4)

NRC4 4 ^ (Regulatory Guides)^ 4 ^ - 4

- 3 4 -

- 1.12, instrumentation for Earthquakes, Revision 1, April 1974.

- 1.59, Design Basis Floods for Nuclear Power Plants, Revision 2, August

1977.

- 1.60, Design Response Spectra for Seismic Design of Nuclear Power

Plants, Revision 1, December 1973.

- 1.61, Damping Values for Seismic Design of Nuclear Power1 Plants,

October 1973.

- 1.76, Design Basis Tornado for Nuclear Power Plants, April 1974.

- 1.92, Combining Modal Responses and Spatial Components in Seismic

Response Analysis, Revision 1, February 1976.

- 1.122, Development of Floor Design Response Spectra for Seismic Design

of Floor-Supported Equipment or Components, Revision 1, February 1978.

(5) *£A

^ ^ f l fl f ^ ^ ANSI 1

do] ^ ^ ^ ^-f n ^ n ^ ^ § } ^ 3 : ^ ^ 5L

^A(envelope)^ 4 ^ 4 - A^7fl^^,

^ ANSI A58.1-1982 - 4 ^ 4 .

Tornado

- 3 5 -

(4)

(5}) ulA><H(Missiles)

NRC 10CFR Part 100^

Sift

- 3 6 -

(4) *W*}^

L ^ 7};

^ ^ 1 * 1 ^ 1 - i ^ l l - ^*H 10CFR100

Appendix A # 1^5} ^ 7fl^ free-field ^1^1°^^ ^ ^ ] ^ ^ ^ :

NRC RG1.6(H

, 0

H ^ § } ^ - ^ ^ e j ^ ^ 2 : # ^ ] tflsflA-] ANSI/ACI 349^]

- 3 7 -

a 3.2.2-2^ 4 4 4 &4- 4 ^ 2 : ~t£ #51^1 ^ 3 H 7]

IS] ^ ^ ^S- i - ^ 3^2*h§- a 3.2.2-3< l

# a 3.2.2-4^ 4ll-f3f 7l7ll-£ ^^7l§Afjl§ol] cfl Sfl ^ ufl «>S] 7J- ?V

4 7]7l

thermal anchor movements^ i ^ - ^ }

(6) 7fl3-&-£l (Material Requirement)

(7})

(4)

(4)

(4) i

(4) -

(4) 03,4- s i i f l t ^ ^ ^ - ^ ^ ^ ^ ^ ° ^ ^ 4 4^H1 4 ^ 7fls.^^4

- 3 8 -

(7) 7}]#.3_£(I & C Requirement)

NRC RG1.12i

^71

| l ^ ] f ] ^ f l j l fl|} ANSI/ANS

2-2-1978^^

(8) ^7Jl^>^ ^(Design Methodology)

o>

(7J-) ASME Code *fl l-§-# Jf^- ^

ASME Code xfl 1^-g- Jff-^ 3Jj7}^ ASME ^ ^ ^ - 7 l Sec. Ill,

Subsection NBU 4 ^ ^ - ^ l ^ l f S t ^ Subsection NF# 4 ^ 4 ^7]-S. 4

IS. i t H ^ l ^ K g - 427 °C

371 °C V]T&)

- 3 9 -

a. NUREG-0800, Section 3.9.3, "ASME Code Class 1, 2, 3

Components, Component Supports."

J l £ ^ - # ( _ $ . i 3 l 4 0 l ^ ^£flo}3]i7ol-^ 427 °C O]AJ-3

371 °C o]Ai-)

a. ASME B&PV Code, Section III, Subsection NH, Class 1 component

in elevated temperature service (1995 Ed. Dec 31, 1995)

b. NUREG-0800, Section 3.9.3

2^-g- J f ^ £ Subsection NC, 4 3f-^ ^-f-^- Subsection ND, 2z$

Subsection NG# 4 ^ 4 - 1 4 ^ 4 W ^ l " 0 ] ovofl^ ^ A]

^ Section III, Code Case N-201-g- 4 4 AAA

(4) 4^1^^] ^ «

7H?} 4^^- i ^

(4)

^ 7^-f T^^1^2:1-Tfl^-(Seismic Isolation System)4

Isolated Structures), TJl-f ^ 7]7l, H E ] J 1

- 4 0 -

(9) ^ l ^ ^ f ^ ^(Testing and Qualification)

Vl

KALIMER

.2.2-4], ^^-§-71 [3.2.2-5], ^

[3.2.2-7], 2%} *AA"%^- ^-^-§-71 [3.2.2-8],

IHTS afl^ ^1f-[3.2.2-9],

[3.2.2-13], Qx}^ 4°]% T&QZ] [3.2.2-14], IHTS

[3.2.2-15] ^o\)

- 4 1 -

3. 3.2.2-1. Safety Classification and Seismic Classification

Safety ASME Code SeismicClass Section/Class Category

or Quality Group

I. REACTOR SYSTEM

Reactor CoreFuel assembliesRadial blanket assembliesRemovable radial shield assembliesControl assemblies

Reactivity Control and Shutdown

III/lIII/lHI/1III/l

Control rod drive assemblies

Reactor Internal StructuresSupport structure includingprimary sodium

Inlet Plenum and Core SupportSupport barrelFixed radiation shieldingReactor vessel liner andseparation platePrimary EM pump dischargemanifolds and sealsIHX seals and supportsCore assembly transfer stationHot pool thermal insulationInstrumentation supportsUpper internal structure

Reactor EnclosureReactor vesselReactor headContainment vessel

Primary Heat TransportPrimary EM pumpsIntermediate heat exchangers(IHX)EM pump coastdown equipment

1

1

111

1

11111

112

111

111/1(1)

QG-A

QG-AQG-AQG-A

QG-A

QG-AQG-AQG-AQG-AQG-A

HI/1III/lIII/l

III/lIII/l

QG-A

1

1

111

1

11111

111

111

- 4 2 -

5- 3.2.2-1 Safety Classification and Seismic Classification

SafetyClass

II. REACTOR PROTECTION SYSTEM

SensorsCableCabinets

112

III. REACTOR REFUELING SYSTEM

Reactor Fuel Handling SystemIn-vessel transfer machine(IVTM)Reactor fuel transfer portadapter and gate valve

Interim Transport System

31

ASME CodeSection/Classor Quality Group

QG-AQG-A

QG-B

QG-CHI/1

SeismicCategory

111

11

Fuel transfer casks 3

IV. AUXILIARY LIQUID METAL SYSTEM

Primary Sodium Processing SubsystemEM pump 3Cold trap module 3Sodium drain tank 3Sodium valves 2Piping 3

HI/3

111/3(1)HI/3HI/3

HI/3HI/3

V. INERT GAS RECEIVING AND PROCESSING SYSTEM

Reactor Helium Distribution SubsystemIsolation valvesPiping

III/lIII/l

- 4 3 -

3.2.2-1 Safety Classification and Seismic Classification

SafetyClass

VI. BUILDINGS AND STRUCTURES

Reactor BuildingHead access area enclosureElectrical and Instrument vaultsPrimary sodium processing and

sodium drain tank vaultsPSDRS inlet and outlet ducts,horizontal plenums, collectorcylinder, and shielding concrete

Seismic isolatorsRadioactive Waste BuildingGround floor and curbs

Mobile Refueling Enclosure

333

3

3

3

ASME CodeSection/Classor Quality Group

QG-CQG-CQG-C

QG-C

QG-C

QG-C

SeismicCategory

111

1

1

1

Wall and roof steel framing 3 QG-C 1

Bridge crane 3 QG-C 1

VI. ELECTRICAL POWER

Class IE dc subsystem 1 QG-C 1Class IE ac subsystem 1 QG-C 1Electromagnetic pump power supply 1 QG-C 1

(1) Portions which form primary boundary

- 4 4 -

I£ 3.2.2-2 Load Combinations for Reinforced Concrete

Seismic Category I Structures

For normal and severe environmental conditions the following load

combinations and allowables are satisfied:

1) U = 1.4D + 1.7L

2) U = 1.4D + 1.7L + 1.9Eo

3) U = 1.4D + 1.7L + 1.9W

If thermal stresses due to To and Ro are present the following combinations

are considered:

4) U = (0.75) (1.4D + 1.7L + 1.7To + 1.7Ro)

5) U = (0.75) (1.4D + 1.7L + 1.9Eo + 1.7To + 1.7Ro)

6) U = (0.75) (1.4D + 1.7L + 1.7W + 1.7To + 1.7Ro)

In addition, the following combinations are also considered:

7) U = 1.2 D + 1.9Eo

8) U - 1.2 D + 1.7W

For extreme environmental, abnormal, abnormal/severe environmental and

abnormal/ extreme environmental conditions, the following load combinations

and allowables are satisfied:

9) U = D + L + To + Ro + Es

10) U = D + L + To + Ro + Wt

11) U = D + L + Ta + Ra + 1.5Pa

12) U = D + L + Ta + Ra + 1.2Pa +1.0(Yr + Yj + Ym) + 1.25Eo I

13) U = D + L + Ta + Ra + Pa + 1.0 (Yr + Yj + Ym) + Es

-45-

£ 3.2.2-3 Load Combinations For Structural Steel

Seismic Category I Structures

For normal and severe environmental conditions, the following load

combinations and allowables are satisfied:

1) S = D + L

2) S = D + L + Eo

3) S = D + L + W

If thermal stresses due to To and Ro are present the following combinations

are also considered:

4) 1.5S = D + L + To + Ro

5) 1.5S = D + L + To + Ro + Eo

6) 1.5S = D + L + To + Ro + W

For extreme environmental, abnormal, abnormal/severe environmental and

abnormal/extreme environmental conditions, the following load combinations

and allowables are satisfied:

7) 1.6S = D + L + To + Ro + Es

8) 1.6S = D + L + To + Ro + Wt

9) 1.6S = D + L + Ta + Ra + Pa

10) 1.6S = D + L + Ta + Ra + Pa + 1.0 (Yr + Yj + Y m ) + Es

11) 1.7S = D + L + Ta + Ra + Pa + 1.0 (Yr + Yj + Y m ) + Es

- 4 6 -

3.2.2-4 Structural Stability

Load Combinations

Minimum of Factors of Safety

Overturning Sliding Flotation

1)

2)

3)

4)

5)

6)

D -

D -

D -

D -

D -

D H

h H + Eo

H H + W

f- H + Es

h H + Wt

H Fl

h F2

1.5

1.5

1.1

1.1

-

-

1.5

1.5

1.1

1.1

-

-

-

-

-

1.5

1.1

Notes: Symbol "H" lateral earth pressure

"Fl" buoyancy force due to maximum ground water level

"F2" buoyancy force due to maximum flood level

S. 3.2.2-5 Minimum Design Loading Combinations for Systems

and Equipment

Condition

Design

Level A

Level B

Level C

Level D

Design Loading Combinations

Design Pressure

PMAX + Dead weight + Thermal(Operating)

(a) PMAX + Dead weight + Thermal(Operating) + OBE + Trans ients(w/ OBE)

(b) PMAX + Dead weight + Thermal(Operating) + Transients(w/o OBE)

PMAX + Dead weight + Thermal(Operating) + Transients + DSL*

(a) PMAX + Dead weight + Thermal(Operating) + SSE + Transients(w/ SSE)

(b) PMAX + Dead weight + Thermal(Operating) + Transients(w/o SSE)

PMAX : Peak pressureDSL* : Dynamic system loading associated with sodium water reactions

- 4 7 -

3.

KALIMER 3 ^ £ lOCFRlOO^ ^ ^ ^ 4 Part50^ GDC16 ^ GDC50

LOCA A>JI ^ o ] ^_g_ ^ 7 4 1 > ^ HH ^ ^

LOCAS} 7EV^. A}JL7\ ^ - ^ * H ?>J1 i f -

Z 3 U

3.2.3-H

[3.2.3-1].

r ^Z] 7}x] 71^-1- ^"^tll[3.2.3-2]

PSDRS 7fl^-[3.2.

# PSDRS ^ 7 1 ^

- 4 8 -

. ii*144 &JL 500 °C,

250KMM 7 1 ^ - f M 4 ^ ^nna\ W - ^4^-§-7]4 ^ - M 4

^7l 7fl >i7fl ^ r ^ l ^ ^ H ^ 3.2.3-24 go) Qz\3.x

M. ^ ^ 7 H H ^^"-§-71 ^ - 4 ^ # € 4 4

ell[3.2.3-5] ^

# € 4 1 - ^ - J I ^ 3.2.3-2011 j i ^ 4 4

ASME Section IIH ufef ^TJlsflo]: ^ j - ^ QT}SL 7} 7}

Subsection NE[3.2.3-7]7> ^-# ^^-§-7]6fl tfl

2]^-^£fe 371 °C4^1 ^

-^-4 H ^[3.2.3-8] PSDRSi

2.25Cr-lMo 7j-6)| tflsfl ASME Subsection NE l ^-g-

3711:* ^^r 5L-&2] ^ 3 , 4 4 - 4 4 4 ^^-g-71 >i7flA] ASME

Subsection NH[3.2.3-8]!- 3-§-«fl°> 3]-7l nfi -«i Subsection NH ] 4^- ^7^]

°fl §1144^- Subsection NB[3.2.3-9]1- ^

500°C, 0.

3.2.3-2 ] 4 4 ^ 1 4 4 ^°1 4 ^ 7.37m, SV^-^Hl-

18.8m, ^ 2.5cm^]4.

4- *

\^z ^^l^rS. 45014 QA*^ 240KPai4

- 4 9 -

7 ^ ^ <g 7\

HVACI-

^ £ # ° J ^ ^ SIS.^ personnel air

IHTS

A}2}-

[3.2.3-13]^

3.2.3-301]

UIS, EM pump

- ^*V I -EE^I l7fl, ^ l ^ ^ ^ ^ ^ l ^ USS

(Ultimate Shutdown System)^- ^ *V ^sflxl 27fl# f-tfl J Z ^ 47fl^l ^ - ^ #

Aj-a-s-jzi. § f « - § ^ ^ ^ ^ J f - ^ f Torispherical ^ - S . o l ^ - ^ ^ ^ c f l Tori-

spherical ^-^-^ ASME Section III, Appendices, Article A-4000[3.2.3-14]<*f].*]

^ 1036.5m3ol

-^r 2.25Cr-lMo7j-AS.

& 3.2.3-34 ^ o ] ^ ^ 14m, £ o ] 8.4m,

KALIMER

- 5 0 -

7}

HAA

3.2.3-4^ 7EVo]

Support ringl- ^

Support ringo]

fe 7A

3.2.3-1 KALIMER

7^ a]

ifl^- ^-3]

^^-§-71

500 °C

250 KPa

737 cm

1880 cm

2.5 cm

2.25Cr-lMo

66.9 m3

450 °C

240 KPa

1400 cm

840 cm

2.5 cm

2.25Cr-lMo

1036.5 mJ

- 5 1 -

3.2.3-1 KALIMER

-52-

Bolts

CV Flange

1880cm

30cm 10cm

ContainmentRing

Reactor Support/Reac to rHeaAichorBoItn2i/

it

Bolt Seal

" Omega Seal

3.2.3-2 3,7]

- 5 3 -

3.2.3-3 3 t f 1/2

- 5 4 -

Insulation

Containment dometemperature ~40C

InsulationPlates (22)

Hot Pool Sodium

-53OC

Containment Boundary(fixed seal)

Containment Ring

Reactor Head

-230 C Normal

PSDSS

Air out temp- 100C

Air In temp ~ 40C

RV Liner Collector cylinder

3.2.3-4

- 5 5 -

4. IHTS fl H

7\. KALIMER ol

(1) IHTS ufl^Tfl

KALIMER[3.2.4-1] *I*1] *)^$] 1 ^ 7 } ] ^ H& 3.2.4-14

$14- ^ 3.2.4-1 A-] 4 TJ-O] IHTS^r IHX # ^ ^ £ 7 f 511

Jl ^ T ^ S - f e 339.7 °C^ IHXS] # . ° J ^ ^ - ^ 4 7 > 171.3

2.571 °g-^.S ^>gs]«H 9X1= JL^ ^<a-^ <

^Js i l^J IHTS4 ^ " ^ ^ ^ 3.2.4-2^1 A 4

KALIMER IHTS n^$] Hfl l [3.2.4-2,3]

3.2.4-3ofl ^ 1 ^ 5 ] ^ X14- ^ 3.2.4-3 ^ 6 1

^ 7fl S] IHXS-^-E] 4 - ^ JL^^-ol -^45.7^1- B3i H> 6flA-l Tee

^ 1 4 4 - ^ ^ 3.2.4-3^A-] Tee ^^•^-•y ^ ^ 5 4

f- 7fl n&^r 14"SCH40^

20"SCH40S] c ) l^^

^ * } ^ ^-S^lr^-ar 5 ,^4 . ^ ^ ^ ^ « m ^ ^ 1 : ^ ^ ° ! 53.34cm,

^ 76.2cmo]4. z | ufl^ ^ o} ^ j ^ ^ . s 3.2.4-1^], nefjL IHTS

4 i ^ ^ ^ - ^ i ? ] 4 ^ a 3.2.4-2i 4 4 4 9XA- IHTS tifl^ TJI^O]

^ =L& 3.2.4-4ofl ZLS]J1 s j ^ £ ^ r n ^ 3.2.4-5^ ^ A] S] O] 014.

(2) <

IHTS tifl^^Sl ^ A ^7]lA^o_S-ir ^*(|, IHX4

4 , fl IHTS ^

i t b 10m ojAj-^. ^ ^

IHX4 SG4 f1^

- 5 6 -

(3)

H ^ 3.2.4-2^

^-#^1 IHX ^ o .

(4) g-§-^

KALIMER IHTS ti^Tili^ ^ ^ - ^ ^ ^^f- ^ ^ ^ ] ^ i 7}^-

Jl, H 5 . - f S l - *]-%-f± ^^}7^o] ^ 4 . n ] ^ ^ PRISM[3.2.4-5]^ IHTS

Gimballed ^ S - f ^ l - fl-g-*V w}^ -fi-^5^ EFR[3.2.4-6]^

- KALIMER IHTS

^ i tfltbSZ-tr

(5)

§T] hanger x]x] ^ i f i ^ S 4-§-*>^4- KALMER51 IHTS

77fl l hanger x]*]^^*] ^ ^

- 5 7 -

(6) 71 Ef JlS|Af*J-

] fflTS

IHTS «M ^ ^ f e i # ¥ ^ 1 tflal^H catch1 ^*1 Aj-Jl a^oJlA^ IHTS

IHTS tiM^life ^^r ^a^lf- ^wM°l ^-^-Slfe v}

- 5 8 -

3.2.4-1 Design features of KALIMER IHTS

IHX

SG

IHTS EMP

Large bored piping

(Hot Leg/Cold Leg)

Small bored piping

(Hot Leg/Cold Leg)

O.D

IHX-IHX distance

NumberO.D

Height

No.O.D

Height

NumberO.D

Thickness

Pipe spec.

Radius of curvatureO.D

Thickness

Pipe spec.

Radius of curvature

Horizontal distance of IHX-SG

Design feature of KALIMER1.2 m

3.74m

4 EA2.8 m

18.8 m

2 EA1.32 m

5.44 m

2 EA50.8 cm

1.506 cm

20SCH40

76.2 cm35.56 cm

1.113 cm

14SCH40

53.34 cm

11.5 m

3.2.4-2 Design parameters of KALIMER IHTS

ParametersDesign pressure

Operating pressure

Faulted pressureDesign

temperatureOperating

temperature

Hot legCold leg

Hot leg

Cold leg

Design features2.5 MPa

0.35 MPa

15.5 MPa530 °C395 °C

511 °C

339 °C

- 5 9 -

CORE mx SG TBN

530°C

386.2°C

529.8°C 511°C 511°C

3SSPC 339.TC 339°C

EMPHeater

3.2.4-1 Normal Operation Condition of KALIMER

Contnmnt Dome(0D=14m)

2.64 m

RxWall(t = 0.9m)

D=35cm

SOSm

II 5m

2.4m

1.87

2.765.02m

IHTS

(OD= 1.32 m)

3.2.4-2 Plan View of KALIMER IHTS

- 6 0 -

Nodal coordinates

IHX: small pipe

: large pipe

IHX

3.2.4-3 Schematic Diagram of KALIMER

IHTS Piping System

Node

12345678910111213141516171819202122232425262728293031323334353637383940414243

000805805805000805805805960960115011501150115011501150115011501150115011501150115011501150115011501150115098098082082098098082082010201020

0000

186.7373.5373.5373.5373.50

186.7373.6186.716.716.7186.7186.7-13.3-13.3186.7186.7426.7426.7426.7426.7-249.3-249.30.70.7

-249.3-249.3-249.3-249.3-249.3-249.3-249.3-249.3-249.3-249.3-249.3-89.3-89.3186.7

0120300300300300300120012012012012012012012058058010201020146014601360-520-650920-400-400-150-140566111012201220920920620620300300300300300

Small pipe (14"SCH40)

:Do: 35.56cm, t=l. 113cm

p=53.34cm

Large pipe (20"SCH40)

:Do: 50.8cm, t=l.506cm

p=76.2cm

- 6 1 -

Co-axial

piping part

3.2.4-4 KALIMER IHTS Piping System

3.2.4-5 Plan View of IHTS

- 6 2 -

EM Pump

3.2.4-6 Intermediate Heat Transport System of KALIMER

- 6 3 -

5.

KALIMER Q } n ] i fl^ ^ [

-^^l ^ < M ^ a ] A S y ^ o H 1^3.2 .5-2]

^7} 3.7% 4 ^ ^ 4 . 71^5] ^^}S^1 *R-2 : ! - £ H ^ 3.2.5-H]A^

30 7 ^ o . S . 127H51 x j ^ i l l - o]^-t><^ ^l^l*l-fe i H H 8 n f . o] 6\]

^ [3.2.5-2]i^^r Z l ^ 3.2.5-2^1^5)-

0>*Vo_S 30cm <£%& T]X]$ 7 ^

.2.5-4].

^ - ^ KALIMER

(1)

-§-71

- IHX (4 7]])

(47fl)

I S (access port : 1)

- UIS (17U)

- IVTM (I7fl)

^ 7U> 71 71

- 6 4 -

RV

S. -

RV ifl S.^r ^ 2 #

^-(gas-tight seal)o]

^ £ 1 ^-^^r seal

membrane seal)0]

^. a 3.2.5-H

7.37mo]c}. KALIMER

n ^ 3.2.5-5^ ^-nf.

7]

^ ^-[3.2.5-2]i

(2)

KALIMER

16mm-?] 227^7}

45cm

85.8^6]]

3.2.5-6oll

(3) SflS.

, EMP,

EMP

^ 3.2.5-4

3.4m^ ^

. ^ y}5f

. 2) *} # ^

^ ^-(welded

- ^ ^ 30cm

3.2.5-1^]

-f-

3.2.5-9

- 6 5 -

ledge ^ °fl * H £ H ledge

3.2.5-8^1 5 ^ 1 S ^ l ^ M O1O.B] zi& 3.2.5-7

IHX riser!- ^-g-^H €^VS.^H 3 3 IHX f } £ ^ f-^*l 3 ofl

- °^7H ^}S«HH<>flfe 4 7 ^ IHX7> ^1^5]^c|l

, IHX Risers ^4^ 0.6m^cf. IHX v}^

A ^ 47l]7f -M 1 sq^ti l ° 1 ^ ^ A J - ^ ^ ^ 3.2.5-8^

, 3.2.5-11^1^ a . ^ ^JJII- ^ o ] xl^l ^ 3 ^ u l ( 5 l ^ l . l75m)i ^

i HAA(Head Access Area)S^l

^(thermal bow)-§- ^4:S}-^?14. ^^>5.?i#- fl HAA^]

^ 38 °CS ^^§VJ1,

ufl ^5L^r 52 °CS. -i

KALIMER^ ^ - f ^^11 ^ ^ 1 ^71171- 65cmS

4.

•& ^ ^ ^ ^ ^ KALIMER ^^fS-SflHS] ^A}^7\%: 5]^ ^ ^ 7fl ^

[3.2.5-1,3]

l, 3fl.EL°ll

- 6 6 -

o}6\)

(1) i^l * 1 ^ ^

o i ^ KALIMER

3.2.5-2

IHX ^ EMP7]- ^-^-slfe- ^ ^ ^ ^ ^ ] Ml^^ \.2mSL

20cm, 25cm, 30cm, 35cm ^ 40cm£1 ^-fofl tfltb

«} $I4[3.2.5-8]. x l ^ l ^ t ^ l ^ E ] - ^ ^ ;g-f [3.2.5-2,6]ofl

(2) ^

-S^H^l^ 7]7]*\ 7] 7]

;«*1#(PRISMS1 4^- : 5271]) ^ ^fl^

7l ^|§f^ ZL& 3.2.5-12^A^ go] IHX, EMP

ANSYS £ 1 ^ DL 3.2.5-125}1 ^ ^ : i ^ « M ^ 1 ^ ^ 1/4^^ S - l ^ ^ ^ 4 - TllS^l^-^A^ 6

, uy, uz, x, y, z)t- fe €

- 6 7 -

4 4 4 r # 20cm

, y)5] 3 4 ^ ^-

(3)

- ^ [3.2.5-7]

i£ 3.2.5-2ofl

H^ 3.2.5-125] s f l ^ l ^ j 5]^i

2]^i#5izi #eflxl Aj-o]] - a 3.2.5-2^^5}- 7EVol ^ J t ^ ; CRD, UIS,

IVTM ^ 7Jl#^-yl ^ ^ 68.611- o} ^

8009.4 (N)5] ^ ^ ^ } ^ o l -g-§1-711

4 ^ ^ i ^ r 3771.54 (N)4 4f^°l 4 ^ 4 ^ , 711 254^1 S ^ 5 ^ s]ol °lo] z> ^ ^ o i l ^ ^-^4711 4714.42

(N)4 4^°1 4-§-44 44-4 4 ^ - e ZL^ 3.2.5-125] 3~4^^^OH1^ %*}

^ i f - f- # 1013.57^.5]

4 ^ i ^ 59161.12(N)4

4 . § f l ^o^ CV7> 4 4 ^ ^ ^ 3.2.5-125] 5 ~ 6 < i ^ l ^ 88.51^-5] CV4

^0} ^^.gj.^cfl o] A1AO>OI 43^^ofl^ 5046.1(N)4

4-

(4)

7] 71

-68-

3.2.5-13^r

3.2.5-14^ CFX S^[3.2.5-

^ ^ 223 °C, *}•$.#•& 230 °C£ M-Ef^^cU o]

PRISM[3.2.5-9]5] ^^^Ef l ^ S ^ H ^1H^ ^ £ 7 ] - 100 °C

} } ^ }^ )} Slfe ^ ^ seal J f £

seal &43. *1*>< ^ ^ ^ 7 B ^ ^ ^ ^ j - J L $14

. KALIMER ^ ^ S . « f l H ^ ^:3£7> 200 °C O]AJ-^_

44 44\+

(5) -g-^sfl^ % - i ^ l ^ ] ^ ^ 4

KALIMER ^ S - S f l n f e ^ - ^ i ^ i ^ ^ £ ] S - S . ASME Section III NB1-

44 ^^1^4- s*> 4

# PRISM[3.2.5-10]

a°HAi ^i-g-^ 4 4 £°1 20cm, 25cm, 30cm, 35cm ^40cmS] ^-fofl cflt}^ -g-e^^-!- ^^^. ^ ^ ^ a 3.2.5-3^ ^ H ^ 4

[3 .2 .5 -8 ]^ ] H l «

-69-

3. 3.2.5-3^^ SLTT 4 4

Sfl

3.2.5-15^^^ go] ^T?\}7\ 30cm

^ 2 ] ^ ^ ] ^ ^ r 0.83mmS 6.35mmiL4

3.2.5-1 KALIMER

^ ^

*r# (EA)

*H

As.

7jo] (shell)

KALIMER J@ *|-3.3I1 H&

16.0 mm22.0 mm

22316SS

^^>S«11 .

45 cm

30 cm304SS

702 cm

5 cm17.6 m316SS

- 7 0 -

i t 3.2.5-2 Weight of Components and Systems for KALIMER Reactor

Structure

^ ^ I - S J Z L + C U I S + C R D )

EMP (1EA)

IHX (1EA)

RVifl ±^

-xl x] tifl Jnlet Plenum

^7\] ( S ) :35.61+(33)

20

25

25

85.8

88.51

165.89

421

426.68

5. 3.2.5-3 Analysis Results of KALIMER Reactor Head

(cm)

20

25

30

35

40

2.73

1.42

0.83

0.53

0.36

rDM1-

6.35

*] (mm)

9.84

5.10

2.99

1.90

1.29

46.08

40.8

28.7

21.3

16.5

38(5.8

. (MPa)

99.95

64.13

44.64

32.88

25.23

-71

Bolts

CV

1687 5cm

ContainmentRing

Flange \Reactor Support/

R e a c t o r H e a Anchor Bolt (12) /

th

30cm 10cm

3.2.5-1 Previous Concept of Reactor Support Structure

- 7 2 -

Insulation Support Ring

\

Containment Boundary(fixed seal)

Reactor Head

-120C Normal

HeInsulationPlates (22)

Hot Pool Sodium

-530C

Ar

RV CVRV Liner

PSDRSAir out temp ~ 100C

Air In temp ~ 40C

Collector cylinder

3.2.5-2 Current Concept of Reactor Support Structure

- 7 3 -

-12)11- Lubrite A[g-li?f SI g

-316SS¥ l 5 C m , i ' 0 l 1855 Cm

-2(1/4)Cr-lMo2.5 Cm, & 01 1880 Cm

3.2.5-3 KALIMER Reactor Structure

- 7 4 -

Support Rin00 767cm

UISOD 140cm

IHX (4)OD 120cm

Thermal LinerOD 687cm

Reactor VesselOD 702cm

Containment VesselOD 737cm

3.2.5-4 Plan View of KALIMER Reactor Head

3.2.5-5 Penetration in KALIMER Reactor Head

- 7 5 -

ROTATING PLUGFLANGE

PINS AK3 SPACERS

3.2.5-6 Construction of Insulation and Shield Plates

- 7 6 -

3.2.5-7 Arrangements of Insulation and Shield Plates

- 7 7 -

3.2.5-8 Components supported by Reactor Head

- 7 8 -

CANOPY SEAL(316CRES

0:25 WALL)

DYNAMIC SEAL(INFLATABLE

ELASTOMERICI

ROTATING PLUGTIE-DOWN BOLTS

BUFFERED STATIC SEAL(4 PLACES)

JACK ATTACHMENTAREA

TIGHT SLIP FIT TO PREVENTTORQUINC BELLOWS

SUPPORT CHOCK SPACE

FIXED CLOSURE FLANGE

12 in.

RING GEAR

TOP SEALRING FLANGE

ROTATING PLUGANTI-ROTATION

TAPERED THRF"" 1—

RP SUPPORTBEARING

PRIMARY SEAL(INFLATABLE

ELASTOMERIC)

MAINTENANCESEAL

ROTATABLEPLUG

3.2.5-9 Alignment of Reactor Head and Rotating Plug during Operation

- 7 9 -

IHX MOON TINGFLANGE

, RE. ACT OHDEC*

1

3.2.5-10 Supporting Concept of IHX

EMP Flange

Reactor Head

Pump penetration : 1.2m O.D

Support cylinder. (I >175m O.D)

Reactor Head

3.2.5-11 Supporting Concept EMP

- 8 0 -

7 ^6 jf +

3;-;-

|:

• i

2

Reactor Head -

AN^ ^ ^ g : ^ . ^ Supporting line

-itIt f iC7f«S : f l^sS-^^ '12 : Rotating plug

^ ^ ^ ^ ^ ^ S ^ - * 5-6-7-8: support ring

Ro]

_xrinc" IMP

type support Xlt-30em) ^ ^ ^

4 5

Fig. 3.2.5-12 Finite Element Model of Reactor Head

- 8 1 -

Containment Dome(Argon gas)

Reactor vesselCenter line

Reactor HeadInsulation

Upper Helium gas region

Insulation plate (22 plates, t=?16mm, gap=22mm)

Lower Helium gas region

Hot pool surface3.435m

3.51m

3.685m

Ar

Reactorvessel

' Thermal lirier

Containmentvessel

3.2.5-13 Configuration of Reactor Structure

- 8 2 -

3.2.5-14 Thermal Analysis Results along RV Axial Direction

Reactor Head - ring type support (t=30cm)

C&VG)

ANSYS 5.5.3APR 11 200011:33:25NODAL SOLUTIONSTEP=1SUB =1TIME=1UZRSYS=0PowerGraphicsEFACET=1AVRES=MatDMX -.01497SMN =-.832E-03^ -.832E-03S I -.740E-03fSB* -.6-37E-03

-.S55E-03-.462E-03-.370E-03-.277E-03-.18SE-Q3-.925E-040

CDmm

CD

3.2.5-15 Vertical Deflection of Reactor Head under Thermal and Dead

Weight Load

- 8 3 -

Z XReactor Head - ring type support (t-30cm)

ANSYS 5.5.3APR 7 200016:55:18ELEMENT SOLUTIONSTEP=1SUB -1TIME=1SINI (NOAVG)PowerGraph icsEFACET-1DMX =.01497SMN -55797

=.287E+0855797.324E+07.642E+07.960E+07.12BE+08.160E+08.191E+08.223E+08.255E+08.287E+Q8

SMX

CDE3E3enCD

3.2.5-16 Distribution of Stress Intensities for Reactor Head

- 8 4 -

6.

3.2.6-14

3.2.6-H7}

ension member)^

(armature)^-

44.

$14.SLB\

(driveline)

44

tube)

44

B4C#

4.

A

- 8 5 -

. A

A

USS(ultimate shutdown system)7>

USS^r ii-a ^

(SASS) 7 l ^ # ^o>4^ 7 ^ ^ - 33*l#*]oM [3.2.6-2],

B4CS- t > l - ^ ^ ^5^ 7flS]

icf[3.2.6-l].

4. f-*11S, ^ 5 ^ # ^ A ^ ^-g-§>^ ^ I f e ^4^°H £\^*\ B4C

. B4C

USS

USS

ULOF(unscrammed unprotected loss-of-flow), ULOHS (unprotected

loss-of-heat sink), BEfe- UTOP(unprotected transient overpower)

- 8 7 -

3. 3.2.6-1 (CRDM)

Housing

Shim motor

Drive shaft

Screw driver

Motor support level

Drive nut

Rod stop screw

Rod stop drive gear

Diameter

30/27 cm

6 cm (1.5/2.5cm)

10 cm

6cm

100cm from bottom

17.08/(12.5/10.5)cm

2.5cm

8. 5cm

Length

400cm

50cm(5.0/2. 0cm)

360cm(-150cm)

150cm

Thickness of 2cm

2.0/10cm

80cm

2.0cm

3.2.6-1

7.

18

(In-Vessel Transfer Machine)^!

(Fuel Transfer Station)* -f-Sfl

-§-71 (Fuel Transfer Cask)ofl ^o ] - ^ ^ A j ^ ^ O ] ^ A | ^ 1 4 . ^ 3.2.7-H>H

*\%*]-£•£:

(1)

3.2.7-2^

- 8 9 -

7} #& #7]

Q4-7], 7}°],

t}7) ^]*>

m 5. ^.o] <^±v] main tube 4 } ^

0.915

1^^1H ^ $14- ^ ^ 3.2.7-3 ^ ^ i ^

^ ^ 3 J ° 1 * A £\ r ^cfl -tl^Al 0.3048

0.9144

(2)

(gate) l i

4 - 5E*> ^

hoists

(3)

2.743 m

. o l .

3 . 2 . 7 - 5 ^ s ] ^ i 4

n ^ 3.2.7-60JI 4 4 4 5 1 4 .

- 9 0 -

#£iHTr ledge seaH

hold-down

tacometer^l 51 sfl ^ r #

^ encorder

(4)

^ 67fl^

cflsfl SB]

t> cover

67fl 51 carousel

(5)

(6)

71

13)

(7)

- 9 1 -

1- f-sfl

3.2.7-8i

Sflo^jg.

Reactor Building

Fuel Handling andStorage Building

at n

3.2.7-1

- 9 2 -

m t n )

Telescopic Tube Length

/ Telescoping coupling

Grapple Assembly

r~ EL. o

EL. 11800

150X150

& 3.2.7-2 Pantograph Type IVTM

- 9 3 -

36 in

Top of core

i

Retracted Position Extended P osition

3.2.7-3 IVTM S]

- 9 4 -

Center of Reactor Qgj$(RC)

. KALIMERCore OuterDia.: 3381 mm

Control Rod Drive

RP Jacking

Mechanism

Plug Drive

Ultimate Shutdown

Assembly (356 O.D)

Center of Rotating PJ gTCF)

2845

Rotating Plug

(2743 dj.a.)

OffsetfromR.C(211)

IVTM

(600 O.D)

FTS (600 O.D)

Support Cylinder

QZ13O.D)

3.2.7-4

- 9 5 -

Center of R.C

2845

Center of RP483 j

< f-915 T T

EL. 900

EL. 300

EL. 0

" EL. -300

280 211

2743

600

1371.5

3.2.7-5

- 9 6 -

RP Support

3.2.7-6 RP seals]

3.2.7-7 RP seals]

- 9 7 -

Rotating Plui

1681.0

1771.0

1846.0

1910.0

Insulation and

Shield Plates

Fuel Transfer

Station

EM Pump

IVTM

IVS

3.2.7-8

8. 7] 7 ^ 2 : # £ A>JL

7}. o f l ^ ^ ^ ^ £ = .

[3.2.8-1]. ^ ^ 1 ^ - ^ S . ^ ^ S ^ l ] ^ i f - ^ ^ z ^ f l S A>-g-§]-7l

(1)

7171S1 ^S] ^-^1 f-afl ^ ^ 1 ^ 1

^^14. J ^ I -g-

. 7]

(2)

4-S-,

-99-

3.2.8-H

4.

3.2.8-H 127}]

2:4

o]o]

$14.

3.2.8-1

Phenix

S P X

Fermi

EBR I I

D F R

P F R

KNK 1

SNR

BN 350

BN 600

Rapsodie

Monju

711

it10

5

2

4

1

11

3

2

2

4

1

1

46

9

1

1

2

8

2

2

2

2

29

[ ^

zii

2

1

4

i

i

3

5

714

1

1

1

1

2

1

1

8

Si2

2

1

4

1

2

1

13

2

2

1

7

1

1

1

15

2

1

1

4

-1 *1

i

2

1

4

•SJMf

3

1

4

714

3

1

1

1

6

10

5

2

4

1

11

3

2

2

4

1

1

46

- 1 0 0 -

4-

<HH "11-f ^ A § } 4 . oil- ^sfl 31*1-3

(In-Service Inspection ; ISI)7>

.2.8-5].

^^l^^S-Oi] cfl*> 7\^^7iA\ ^ . ^ ^ ASME B&PV Section XI

Division 3 i 4 4 fl-^€4[3.2.8-6]. Section XRr 7 } ^ ^ ^

^ ^ ^ 71 A\ ^ ^ 7JA|- ^711- 7)^t}5L $14. KALIMER

4 ^ ^ ^ ^ ^ - S . ^ ^ € Tfl-f-4 ^ ^ ^ ASME fl-^#

4- i^r^°J ^^11- ^o1]T= A S M E

31

*>r}. of i^^-^^o^ ^ A J ^ - j i ^ ^ r } ^ KALIMER^

- 1 0 1 -

(1) 7]-§

(71-) 3 4

oJj^^-^^L^ ^ m JjL -ofl cfl*V 7f^^7jA}^ f ^ o j ASME Sec.

XI, Div. 3£ 7 > ^ 3 4 ^71, 3 4 W «.=., T^AJ-ti *J 7JA)- ^ ^

3.2.8-2) 31 *>^ -£?fl ^ < H $1^4 ASME 7}^-^

KALIMER

ALARA

(M-) ^ 4

ASME 2£.«>|Alr 7 > ^ - ^ ^ A } ^«J ^ 7 ] S . S. 3.2.8-3 S ^ S 3.2.8-4

1 0 0 o / o

- 1 0 2 -

£ 0 1 -

5af

I-W1A -

--hi* 4ot

\5

-bk

•[Z.-8T£]-br$ IT

[fl #-12 ^:A uoijoss HWSV

IY ^ ^ -§-ir

g_ 3.2.8-2. ASME B&PV Code, Section XI, Division 3£]

B-A

B-B

B-C

B-E

B-F

B-G

B-H

B-J-l

B-J-2

B-K

B-M

B-N

Guard Vessels. i i J ] r

Guard Vessels. JiJLSl^l

?}&] 7 f i l-}] 7)1 7l 7l

t r - - o irj r - * •• ^ r ^n "^

Guard pipe EETT ^ r i S .

Guard pipe JE.^ ^ 3 - S .

<5)] ^]] -g- . ^ ^ y}| j ! j -

71 71

€45. -§- -

7lH} -§-71 -8-^^f

€45 ^\v\

7lE} -§-71

€45 %

€ 4 5 -§-71

?>til7l-^: lfl7fl yflE]-

^ ^ ^ * ^ ~

1 4 ^ "?1 - 1 •?•

^ 7 V "S ^1 7Jl -W-

^-o>^A]- VTM-2

Sr°}^^} VTM-2

x\] ^ ^ j Aj-

o t 7V A]

^#^A!

^-oV^Af VTM-3

7.]] ^ 2 j A}

^-o>^A]- VTM-2

^-oj-7^Af VTM-2

^V\ ^•^l^Aj- VTM-2

^-^V^Al- VTM-3

**} W

^1-S-^-T"^ 33%

^-g-^-T-5] 33%

^ • g - ^ ^ 100%

d ^ ^

-§-^3] 33%

7 Til 51 33%

-104-

g_ 3.2.8-3. A

34 71

2,f (7^)

3^} (13\l^]r)

4x} (17\£ V)

34 471

1 - 3

4 - 7

8 - 10

11 - 13

14 - 17

18 - 20

21 - 2324 - 27

28 - 30

31 - 33

34 - 37

38 - 40

*\± 34 #s*

100

33

100

16

40

66

1008

25

50

75

100

SJtfl 3A} ^g.ig

100

67

100

34

50

75

10016

34

67

100

3.2.8-4. B

3 4 ^7,

\x} (10^3-)

2*} (10\13:)

3x} (10\£3r)

4x\ (lO1^?!)

34 471

1 - 3

4 - 7

8 - 1011 - 13

14 - 17

18 - 2021 - 23

24 - 27

28 - 3031 - 33

34 - 37

38 - 40

Z± 34 # «16

50

10016

50

10016

50

10016

50

100

m 34 sae34

67

10034

67

10034

67

10034

100

- 1 0 5 -

°) 4.

44ol

A]

Sl-cf.

A ] ^ ^j] ofl X\?}JL O)

$14.

106-

ASME

ic Emission), S 5 ^ >H

n-Line Monitoring) f-o]

(2)

ASME Section XI, Div. KALIMER

3.2.8-1^

A}

-§-7]

RV4

150 °C ~ 200

- 1 0 7 -

oflo] o o 7]-^ ^ f ^ 3}*} 3- -§-7]4 2^-g-7l Afo]o^ 5^^ 7fl ofl

7 ^ ^ ^ -81 * H l«fl

7} ^

ASME

3.2.8-24

$14.

-71 ofl ^ 4 ^ 4 - ^ °l-g- S^ :^ ^14S SflH°fl $I r ISI

(4) ^

VTM-3

TVofl 1«]- VTM-3^4# " r ^ 4 ^ n r ^ ^ ^ * ^ 4 ? 5 : 4 . ( ^ ^ 3.2.8-2)

- 1 0 8 -

Reactor Vessel

VTM-2, CM, VI

Containment Vessel

VTM-3, ILRT, CM

Primary

VTM-2,

EM Pump

CM

Int. Heat Exchanger

VTM-2, CM

Reactor Internal

VTM-3, CM, VI

Reactor Head

CM

Rx Support Structure

VTM-3

VTM : Visual Testing Method-1,2,3

USV: UnderSodiumViewing

CM : Continuous Monitoring

VI : Volumetric Inspection {UT, ECT)

SI : Surface Inspection {PT, MT)

ILRT : Integral Leak Rate Test

LLRT : Local Leak Rate Test

Containment Dome

ILRT, LLRT

Residual Heat Removal

VTM-3, CM

Primary Cover Gas Sys

Int. Heat Transfer Sys

VTM-2, CM, SI or VI

Isolation Valve

ILRT, Performance test

Intermediate EM Pump

VTM-3, CM

Steam Generator

VI, CM

3.2.8-1 KALIMER

- 1 0 9 -

ISI Access

Port (12)Monitor

Reactor Head

15cm

Reactor Vessel

(SS316) 5cm

EMAT Sensor

Video Camera

Ultrasonic Equipment

A

Video Recorder

Containment Vessel

(2-1/4 Cr-Mo) 2.5 cm

3.2.8-2 -§-71 -§-71^

- 1 1 0 -

RV/CV

tfl^-5] ^ J l 71714

VTM-37]- A ^ i ) ^ ^ ^ } ^ ^ r # ^ ^ tfl

^ 2 # £ ] VTM-3 ^ - ^ ^ A l - ^ ^ l f l ^ - ^ 2 : # ^ 71

Tfl 3 ^ " 2 : ^ A o^- t ^A}§f^ 31 0 ^

. a]

514- TflolT;] ^ - 4 IVTM#

3.2.8-34

- 1 1 1 -

4- TW 1-Hfl ^ ^ 11 f ^ ^ r IHX

Ultrasonic Equipment Monitor

Manipulator

Ultrasonic Transducer

ISI Port

IVTM

3.2.8-3

-112-

HAAi

^ 71

6\)

4-

(«!-) ^ t i 47] A^- (PSDRS)

47] Tfl^S] -71 <a - ^ # ^ ^-S-4 -71 -fr^^r ^ ^4. Dll ^ ^ ^ ^^1^7144 OI^^L ^.^ PSDRS f-s., ^^-§-71

- 1 1 3 -

-g-

(Af) Tg^l Al^Efl

114-

IHTS flfl^, l*f i f-

10CFR50 Appendix J<*f|

# ^ ^ J l S 35]

bulletin^- ^ ^ A ] ^ O ] § | ] ^ ^

10

5 psi <5flA-] 6 p s i ^ ^

JBLS. ASME 3 £

IHTS

A] ojl ^ E l ^ H . 1 - T£JL IHTStfl^ ^ . g - 7>«fl l i

-115-

4- IHTS Bfl2}5] 7}^7^A}±- i f ^ S ] <g^7j-A]5f VTM-2

4-

. IHTS Hfl^s] i f - ^ r ^ ^ i f - tifl^s]- ^ . s . tifl^ A\O)

IHTS

if"

. A S M E 7 > ^ - ^ 7 J A f i ] ^ ^ ] l a H } > ^ } ^

trfl^-ofl ^ ^ A ] Sj-7.1] A } J L ^ 7 | . - ^ o]

*j-g-£j

i r remote field

. IHTS4 i l l

#J± ^ S . 7>4# l7-]*l- ^ remote field

4 4 10% ^ £ 4 ^ ^ - 1 - fl 7 A)-7R>

(SGACS)4 ^ 7J 4 ° l S ^ ^ ^ 4 ^ ^ TV -7

- 1 1 6 -

fe ^ -§-1^*1 ^-§ *1 (Active Acoustic Leak

Detection)^ ^ ^ -g-%Va-*] (Passive Acoustic Leak Detection)-^ ^ - ^ ^ - § -

§Vcf. ^ ^

(plugging)

(3)

(7)-)

71

^r -SL

S 4^51 °io> W - KALIMER l

^7-1 §1-71 ^ ^ ^-#

. ALARA7fl

- 1 1 7 -

al-g-

KALIMERS]

KALIMER^

oi

$14-

- 1 1 8 -

f- 3 T\]

KALIMER

Id

(4)

reventive Maintenance : PM)4

ive Maintenance

57^1

^ ^ i ^ ^ ( D i s c r e t i o n a r y PM) H^Jl

(Preventive Diagnostic Maintenance : PDM)S 4 T 1 4 -

°J

(4)

iJ-'S-i- 3. 3.2.8-44

- 1 1 9 -

(7\)

-8-71

(4)

v ^ ^ f £14-

3.2.8-4^ €7-1 S^ IJ .^ 7H^51# 4 4 ^ 4 -

U

- 1 2 0 -

(4)

7]6] ^

o]

-^ 71-

- 1 2 1 -

S. 3.2.8-4 KALIMER ^r_3.-^#^

-g-71 o-8-71 o

oi

A>-g.)

o A

o A

o A

o A

5] ^ f o A

Xi- o A

o A

- 1 2 2 -

3.2.8-4

• 1 2 3 -

(5)

- ASME fl-^ofl S]^- 7 1 - ^ 3 4

] ^ ^ oflia]

17] # ^ 7-1 Jf^Sl XU1- ^ ^

1 5 . rgJ

4^517-14

(6)

KALIMER $] JL^r ^-^ 3LB\f>\5L ASME Section XI Division 3

-§-71

- KALIMER5] 7fl^ ^ ^ 1

4.

124-

9.

} &4[3.2.9-l,3.2.9-2].

Okada f-ojj <q

) - ^ ^ } ^ s ^ ^ 7 } # ^«S^>J1 ASME

Code Section III, Subsection NH[3.2.9-3]°M

7}.

(1)

(3.2.9-1)

• 1 2 5 -

(3.2.9-2)

(3.2.9-3)

^(3.2.9-2), ( 3 . 2 . 9 - 3 ) ^

^ AA

, 0.2% ^l-

flS., ^ 304SS, 316SS

Ramberg-Osgood^ ^ - ^

rjc = Min[\.Q, 1.04tanh(0.98.707£ lcrccre)] (3.2.9-4)

Vs = M«[1.14tanh(rO7£/rc%), tanh(1.6ro.7£ Irscre)} (3.2.9-5)

yft =1.0 + 0.21sech(3.5o-07£/<rJ (3.2.9-6)

ys = M«[1.0 + 0.22sech(1.7ro7E/<J, 1.0 + 13.0sech(6.4r07E / rscrj] (3.2.9-7)

[3.2.9-5]^

(3.2.9-8)

(3.2.9-9)

( 3 . 2 . 9 . 1 0 )

(3.2.9-11)

- 1 2 6 -

[3.2.9-6J. J. Okada

= 0.66^-0.9,1+1.0 (3.2.9-12)

A~~T1 (3.2.9-13)

^ ^ # ^ §tf^fe 0.5< L/R < 5.0 nelJL 50.0 < M < 500.0^4.

(2)

sfl (Eigenvalue Buckling Analysis) yo

VlH-4 til^i^ 2)-i-«l]^ (Nonlinear

Buckling Analysis) yo

Vtt!ol

point)!-

(3.2.9-12)

j 1 (Stress stiffness

matrix), A fe- 2}-

^7}A]

- 1 2 7 -

Snap-through 2 f ^ ^

. KALIMER

(1) KALIMER

3.2.9-1^-

-fe- 316SS

KALIMER ^

a t H^Jl 7]7l

702cm, -Tfl 5cm, 1700cm

(2)

3.2.9-25]-

KALIMER

510°C(950°F)#

ASME Code Section III,

ANSYS version 5.5[3.2.9-7]l-

SHELL63

SHELL43 &.±^

£=160 GPa

Subsection

316SS

^ ^ ^-A]^(Isochronous)

510°C M ^ 3xlO5

3.2.9-3-1:

KALIMER

Qcr = 1200

Qcr = 31829 tons

- 1 2 8 -

: Qcr = 19252 tons (

: Qcr = 2000 tons

5)^71

KALIMER

KALIMER

3.2.9-5^ KALIMER

7}

3.2.9-6^ KALIMER

R/t7\ *}

§ H ^ ^ S ^ « t KALIMER

= 19252 tons°]v\ °}?e D.% 3.2.9-5^1.

- 1 2 9 -

Qbcr.e=20000 tons3\

2000 toS 0cr=12OO tons

3711 ^ ^ - $14- 3.2.9-7^

(3) ASME ^

III, Division 1-Subsection

Jl $14-

:71

4^-4ASME Code Section

j-g-ofl tfl *V

4-8-

Factor)

i 2:71 7 l 4 ^ [ ^ imperfection

(Time-Independent Buckling) °ll JLi^

^ 7 l 4 * H imperfection^l ^

Buckling)^ J l

imperfection^

- 1 3 0 -

l ^ ASME

(Normalizing)S. ^ ^

ASME Subsection

(3.2.9-13)

oil tfl fl ^7]1 ^ ^ ^ S ? l A, B^l tflsflAife 3.0, ^ ^ S ^ i C

2.5, ^ ^ ^ ^ 1 D i tfltflA-ife 1.5 ZLB\3L Al^£^ol l uflsflX-]

Shutdown Earthquake)^

^ £ ^ 1 DSL

KALIMER

KALIMER ^

^ - f 0.9g,

q-. 1 4 4 ^ KALIMER

tons, ^.^.AiA^ ^ - f ° H r 26=171.9

KALIMER

: Load Factor = 1.09 < 1.5 ( £ * I 2 : ^ D)

: Load Factor = 6.98 > 1.5 ( ^ S ^ D)

- 1 3 1 -

KALIMER ^ j ^ 1 ^ ^ f ] f^

EL7\]

_g.7]o^ yV^o] j ^ ^ ^ S . 2 } - ^ 7117}- ^-el

KALIMER ^14S.-§-7l^ til^^l^7^1^ ^-fofl ASME

- 1 3 2 -

3.2.9-1 Conceptually Designed KALIMER Reactor

Fixed B.C.

3.2.9-2 Finite Element Analysis Model-1/2

- 1 3 3 -

s.»w

£V)

(1) ASNIE Code Section ill, Subsection NH(2) Material = 316SS(3) Temp = 510°C(4) Service Time = 3x10s hr

0.00 0.25 0.50 0.75 1.00 1.25

Strain (%)

1.50 1.75 2.00

3.2.9-3 Stress-Strain Curve Used in Buckling Analysis

(a) Eigenvalue Analysis (b) Nonlinear Elastic Analysis (c) Nonlinear Elastic-Plastic Analysis

3.2.9-4 Buckling Model of KALIMER Reactor Vessel

- 1 3 4 -

40000

30000

C 20000

10000 -

0 -

Elastic BendingElastic ShearPlasticPlastic and Imperfection

Imperfection Q

Shear Buckling Bending Buckling

L/R

3.2.9-5 Slenderness Effects on Buckling Loads

a " 30000

\ v l \ \ • Thickness = 5.0 Cm

i —— R = 300 Cm— R = 400 Cm— R = SOO Cm—•— R = 600 Cm— R = 700 Cm

Nonlinear Elastic Analysis

Won linear Elastic-Plastic Analysis

O- O - O - 0 - - 0 - 0 - 0 - 0 0

30 AO 50

Displacement (Cm)

60 70 30

3.2.9-6 Plasticity Effects 3.2.9-7 Disp-Force Responses

1 3 5 -

10.

KALIMER[3.2.10-l]S]

o> .s. ^AJ^JL 44^1 ^HU-^Hl ^ ^ 7flM 3J71-1- ^f*l-$i

[3.2.10-3].

7\. KALIMER

KALIMER ^

3.2.10-H 3.91

CRDM, IVTM, EM ^ ^ , IHX

1-^121- ^ ^ l S . ^ 1 ^ - ^ 127fl2l

[3.2.10-2]. ^^«J-*j=6.S. 127H5]

§11H.^^^^(Head Access Area)^l

20cm

7}

- 1 3 6 -

KALIMER

7]

- PSDRS

3.2.10-2^1

230°C

H KALIMER^- 2 ^ 3.2.10-2ofl &91 7AA

Collector Cylinder^! tij-^r^-^-S. -^^f ^7] 7}

- 1 3 7 -

131 3 Collector Cylinder 4 z*^-%-7] A \ ° } % §fl ^ 3.

cfA] UBj-^q-7]-^ PSDRS(Passive Safety Decay Heat Removal System) Tfl-f-

[3.2.10-4]^ ^ l ^ l H t\7\ nfl ofl ^ ^ x l x ] ^ 2 : # i : *AA% nfl PSDRS

PSDRS TJl ^ ^ l i tp} ]1PSDRS ^717} £ £ 7 }

A]

6\]

(1)

KALIMER ^^1-S. ^1^1^3:1-^ ^ y] 7

Jl ^7^1 lfl?>O.S ^]A]«V < AJ 7}*]$] 7]

3.2.10-34

- 1 3 8 -

°H

?J

(uj-)

3.2.10-4^

7}

- 1 3 9 -

€*>£• 4™}^ ^

°H1

^ ZL^ 3.2.10-5O11 £3.0} ^ 4 7^0]

HAA

-140-

3.2.10-6^1

9X3.,

*.

67fl~127ll

^ . ^ HAA

K) . tflo> 5

H ^ 3.2.10 A}

^ 6-12711

1, o]

H 4 HAA

- 1 4 1 -

(4) ^ 1 4 ^ 1 H ^ f ^*f|*§ ^ ^Efl ^-2: - tH<£ 6

(Af) ^ ^ t f l o j . S.^sg7l- 1 4

431 £4 1

4444 71-

^j 3.2.10-84 - E ~ I s-c-^-i ^ix Nr i a-^-sT TLL"ar i i*

^(support ring)-

HAA

back weld ^ ? ^ M §-^7]- € T1 Si-5-HS ^^-§-7] -§-^^- 4 t t weld

buildup^ 4 4 ^ 4 ^ ^ S ^14*1 3 ^43.^1]IE.i ^ ^ 4 ^ yoVc?14 7EV

4 ^ ^ Sj *V ^ 4 4

4 ^4^ ^ M ?^s 44^4-

^r 6~127fl S-

- 1 4 2 -

7j

HAA

Si

i - i tflsfl ASME B&PV

Code Section XI[3.2.10-6]£| IMF-2500i

. KALIMER^ ^ ^ ^ 7 ^ 1 ^ 3 ^ 4 ^^--§-71

: 1 - ^ 7}^f^ 7 A|-7l- -§-ol^ ^ ^ . ^

PSDRS £*1 2 : ^ A]

€45.

1 4 3 -

HAA

#^4 HAA

KALIMER cfl

(2)

ANSYS

(71-) SL

2.25Cr-lMo70>o]4.

fe ^ 30cm

HAA

B&PV Code, Section III, Subsection NF[3.2.10-7]^l

370°C A>O]O1]A^ 184.5MPa<y ^

20cmol

HAA

12.7MPa

ASME

- 1 4 4 -

15%

<£ ^ O |

KALIMER

(SSE) 0.2gt- JlSl

61= 0.6g7l-

} ^ 3 ] o . S ^^1^1 #Bfl^l^ ^7)1 5cm, £°}7\ 60cm

^ 77.5cm,

5cm,

HAA

103MPa

60% 3 5 . ^7>%> ^ - f £ § ] - § - ^^]70 i -£ i - ^>^Alz] 7474

- 1 4 5 -

^ 4-8-8-^4

344 sfl r ^ ^ I t l t ^

(4) ^ ^ S ^ l ^ ^ f ^ ^ 1 % ^Efl ^ S - tflo]- 6

^} £ £ • - 11 30cm, s. 30cm£l

SHELL63 ^ . i - t ^f-§-^F^ 1/4

11, IHX, ^ EM Pump

.5q- ^ ^ 304

. HAA «

3.2.10-114 ^ v i ^ ^ - ^ 4

3.2.10-124 ^ 4 - 4 4 ^ 4 # 4 20cm7> HAA

4 EM Pump 4 ° H H ^

2|tfl 21MPaS. §!-§- ^^7 j -£ . 1.5Sm ^ 4 184.5MPa(200°C

^ - ^ ^ i ^ r n ^ 3.2.10-13 1 4 4

8.7MPa^4 ^ ^ ^ ^ -g-^^ 4^?-> M ^ ^ ^ $1

4- 41 *}5.315.2] ^ 4 ^ £ f e 4 200°C~ 230°C?14[3.2.10-9] o ] ^ o ] ^ «g

44 ^4 f-g- - ^^4°ls.4#

- 1 4 6 -

4.

KALIMER Qx}£, 4 4 ^ 1 " 3 ^ 4 44

-a.

°m 37M

^ B f l

4-

€4*

HAA

44^fe

tfl <

44

444

HAA

- 1 4 7 -

57

KALIMER

- 1 4 8 -

1687.5cm

737cm

30cm 30cm

3.2.10-1 KALIMER ] 7fl

-149-

SGACS

I

o

U

jooto

SteamGenerator-

RPST

R D s -

Sodium

Dump Tank-

Sodium

Catch P a n -

LowerBasemat-

&>•\"

I Cask

HAA

PSDRS Stacks

Cask&TransporterPit

EquipVaults

ReactorModule

ReactorSupport

SeismicIsolators

30cm

60ctn

1687.5cm

30cm30cm

3.2.10-3

- 1 5 1 -

y S l (HAA)

3.2.10-5

- 1 5 2 -

3.2.10-6(HAA

811E

(HAA)

3.2.10-7 t|]6].(5) -

- 1 5 3 -

Reactor Head Support Ring

Containment Boundary(fixed seal)

HAA

3.2.10-8

ANSY5 5 . 5 . 1

OCT 31 1999

10:58:10NODAL SOLUTION

STEP=1

SUB =1

TIME=1

SIHT IAVG)

PowerGraphics

AVRES=Mat

DMX =.473E-04

SMH =3 66785

SMX =.127E+08

I1F0RRFORPATHA =.105E+07

I =.12OE+O8

3.2.10-9

- 1 5 4 -

Support Structure - Axisyro case

ABSYS 5.5.1OCT 31 199913:29:39HODAL SOLCTIOHSTEP=1

SUB =1

TME=1SIHT [AVG)PowerGraphics

EFACET=1

AYRES=MatDMX =.001353SHN =.125E+07

SMX =.103E+09A =.6SlEi-07

3.2.10-10

Reactor Support-Head Support ring : Cold deck (t = 30cm)

ANSYS 5.6APR 24 200013:20:26DISPLACEMENTSTEP=1SUB =1TIME=1PowerGraphicsEFACET=1&VRES=MatDMX =.709E-04

DSCA=2809XV =0YV =.866025ZV =.5

*DIST=2.378*XF =2.196*YF =1.799*2F =-.057643Z-BUFFER

3.2.10-11

- 1 5 5 -

Reactor Support-Head Support ring : Cold deck: (t = 30cm)

ANSYS 5.6APR 24 200013:38:02ELEMENT SOLUTIONSTEP=1SUB =1TIME=1SX (NOAVG)RSYS=1PowerG raph i csEFACET-1DMK =.243E-C4SMN —.210E+08SMX =.210E+08A —.186E+08

=.186E+0S

3.2.10-12

Reac to r Support-Head Support r i n g : Cold deck ( t = 30cm)

ANSYS S.6APR 24 200013:38 :4SELEMENT SOLUTIONSTEP=1SUB =1TIME-1SY (NOAVG)RSYS=1PowerGraphicsEFACET=1DMK - .243E-04SMN =-.866E+07SMX =.B66E+07A =-.770E+07

-.770E+D7

3.2.10-13

• 1 5 6 -

11.

2*} ^-ff,

3*H7l7l<y ^

[3.2.11-3,4,5]^

71 #*ll

3.2.11-131-

support hanger*

EM Jg^fe-

Saddle angle plate

hinge joint*

-g-7l ^ a f l ^

snubberl-

9-l^-B.S. snubber support hangerS.

hinged support column -rl °11 ^l^l^l Saddle angle plate

1 - 67]], ^ > ^ S - 4711

^ £^U1 Hfl ^ ^-711-

3£ E. ^7-1 (support hanger)

47fl

157-

Air Flow

SGACS

| Steaml- Outlet

WaterInlet

A-A Section View

B-B Section View

3.2.11-1

- 1 5 8 -

Sodium Outlet

\\\ww\\\wwwwwww\ww\x

A-A Section View

B-B Section View

3.2.11-2

- 1 5 9 -

7}-. Design Description

(1) PURPOSE

The purpose of this document is to provide the design description for

KALIMER (150MWe) reactor internal structures with conceptual

drawings of each internal parts.

(2) SCOPE

The scope of this document includes the description of KALIMER

reactor internal structures except the upper internal structure.

(3) DESIGN DESCRIPTION of KALIMER REACTOR INTERNAL

STRUCTURES

(7» OVERALL DISCRIPTIONS

The KALIMER reactor internal structures are composed of the Core

Support Structure, the Inlet Plenum, the Support Barrel, the RV Liner, the

Baffle Plate, the Separation Plate, the Flow Guide, the EMP Nozzle, the Inlet

Pipe, and the Radiation Shield Structures. Table 3.3.1-1 is the design data of

the KALIMER reactor structures and Fig. 3.3.1-1 shows the elevation of the

reactor internal structures including the containment vessel, reactor vessel,

reactor internal structures, and components. Fig. 3.3.1-2 presents the part

names of the reactor internal structures.

KALIMER reactor internal structures have 3-main functions providing 1)

core support, 2) primary coolant flow path, and 3) component support.

Basically all reactor internal structures are designed to meet these functional

requirements as shown in iso-view drawing of Fig. 3.3.1-3. The design basis

-160-

of KALIMER reactor internal structures is described in next section.

From Fig. 3.3.1-1 and Table 3.3.1-1, KALIMER reactor vessel is 17.0m

height of side cylinder, 7.02m outer diameter, and 0.05m thickness. For the

material data of the reactor internal structures, 304 SS or 316 SS will be

used but these materials are studying to be replaced by 316 LN.

The general seismic design features of KALIMER reactor internal

structures are the horizontally coupled between the fixed structures and the

components at the baffle plate and the separation plate to remove the

disadvantage of a single-stand cantilever structural type as shown in Fig.

3.3.1-2 and Fig. 3.3.1-3.

The annulus type internal structure called as the baffle annulus, which is

composed of the RV liner, the support barrel, the baffle plate, and the

separation plate, is provided to mitigate the large thermal gradients generated

between hot and cold sodium boundaries. The temperature of stagnant sodium

in the baffle annulus is steadily stratified at all operating conditions and will

greatly reduce the thermal stresses of boundary regions of hot and cold

sodium.

Table 3.3.1-2 shows the calculated weights of KALIMER reactor structures

and Table 3.3.1-3 shows the calculated primary sodium volume and weights

contained in reactor vessel.

More detail descriptions of the reactor internal structures for each part are

written in following sections.

(M-) CORE SUPPORT STRUCTURE

The core support structure provides the restraint of the reactor core

assemblies necessary to maintain them in their prescribed geometry during all

modes of reactor operation.

The KLAIMER core support structure is the simple skirt type as shown in

Fig. 3.3.1-2 and Fig. 3.3.1-3. This structure has main function to support the

- 1 6 1 -

core assemblies and the fixed internal structures. This skirt type provides very

simple core support design and fabrication. End parts are welded to the

reactor vessel bottom head and the lower grid plate of the inlet plenum. The

skirt side provides the holes to access for the welding works and to fill the

primary sodium inside the skirt structure.

( 4 ) INLET PLENUM

The inlet plenum is composed of the lower grid plate, the upper grid

plate, the side cylinder, and six (TBD) small diameter structural sleeves. The

upper grid plate is connected to the lower grid plate through the six (TBD)

tie sleeves and the side cylinder that carry the pressure loads tending to

separate the plates. All of the vertical loads from the core assemblies are

carried, through the receptacles to the lower grid plate. The upper grid plate

has a function of accurately positioning the receptacles and also participates in

sealing the annulus around each of the receptacles.

The main functions of the inlet plenum are to receive primary sodium

from 4-inlet pipes and distribute it to the core via the nosepiece receptacles

and structurally to hold the receptacle body supporting the nosepiece of duct

assemblies.

The depth of the inlet plenum is established by the space required for the

inlet pipe nozzles forging welds and the radial flow area necessary to assure

uniform flow distribution to all the core assemblies.

The support structure of the core radiation shields that have functions to

protect the irradiation of the reactor vessel, containment vessel, and to limit

the activation of the impurities in the air flowing the PSDRS is welded to the

outer surface of the lower grid plate of the inlet plenum.

(2}) SUPPORT BARREL

The Support barrel is integrated single cylinder type extending vertically

- 1 6 2 -

upward from its attachment at the upper grid plate of the inlet plenum.

Therefore, no core shroud is provided. At the active core region, support

barrel has a function of core shroud.

The main functions of the support barrel are to provide the support

locations of internal structures such as baffle plate and separation plate and to

guide the flow path of hot sodium coming from core to IHX inlet holes.

Support functions provided by the support barrel are:

- Lateral support of the core former ring

- Lateral and vertical support of the flow guide including EMP nozzle

- Lateral and vertical support of the baffle plate and the separation plate

including the RV liner and the component support structures.

- Support of the IHX shielding materials

(*}) RV LINER

The RV liner is a cylindrical type located 2.5cm inside the reactor vessel

between elevation 210.0cm and 1130.0cm. It is provided with slots at its top

end that under normal operating conditions are always above the hot sodium

level.

The RV liner is designed to protect the reactor vessel from directly

contacting the hot sodium at steady state and transient thermal operating

conditions and form a portion of the pressure boundary between the hot and

the cold sodium regions within the reactor. Therefore, this structure isolates

the reactor vessel from rapid temperature changes in the hot pool sodium that

results from duty cycle events, thus minimizing the thermal loading on vessel,

its attachment to the closure head, and to the containment vessel.

RV liner is one important part consisting of the baffle annulus. The RV

liner provides support for the baffle plate and the separation plate, which

force thermal stratification inside of the baffle annulus and thus minimize heat

transfer between the hot and cold pools.

- 1 6 3 -

(wf) BAFFLE PLATE

The baffle plate is located at the top end of the support barrel and welded

between the RV liner and the support barrel. This has a number of circular

penetrations that allow the IHX and EM pump to pass through while

providing a lateral seismic support for these components. The main function is

to force thermal stratification in the upper volumes of the cold pool and thus

minimize heat transfer between the hot and cold pools.

(A» SEPARATION PLATE

The separation plate is located at the bottom of the RV liner where the

IHX discharge nozzles are attached. The separation plate is welded between