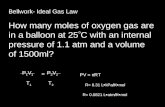

Lecture 3 - Diffusion

-

Upload

serge-low-jen-hahn -

Category

Documents

-

view

222 -

download

2

description

Transcript of Lecture 3 - Diffusion

-

1Diffusion

UNIVERSITI TUNKU ABDUL RAHMAN (UTAR)

-

2 Introduction Rate Reaction & Diffusion

Diffusion MechanismsVacancy diffusion

Interstitial diffusion

Steady State diffusion Ficks 1st Law

Non Steady State diffusion Ficks 2nd Law

Factors that influence diffusionDiffusion Species

Temperature

Diffusion

-

3 Many processes concerned with the rate at which atoms move in the solid state

Reactions occur in solid state resulting in more stable atomic arrangement.

Reacting atoms must have sufficient energy to overcome activation energy barrier.

At a given temperature, not all atoms have activation energy E*. It should be supplied to them.

E*

Er

EP

E*Activation Energy

Energy released

Due to reaction

Reaction Coordinate

Reactants

Products

Er = Energy of reactants

E* = Activation Energy Level

E* = Activation Energy

Ep = Energy of Products

Rate Process in Solids

-

4 As temperature increases, more and more atomsacquire activation energy level.

Probability of finding an atom/molecule with energy E*greater than average energy E of all atoms/ molecules

is given by

KTEEe /)*(

K = Boltzmans Constant = 1.38 x 10-23 J/(atom K)

T = Temperature in Kelvin.

Rate Process in Solids

Probability

-

5 Phenomenon of material (mass) transport by atomicmotion.

Atomic movement within the atomic structure arrangement.

Vary with temperature / kinetic energy. Phenomena of heattreatment.

Examples:

Movement of smoke particles in air : Very fast.

Movement of dye in water : Relatively slow.

Solid state reactions : Very restricted movement due

to bonding.

Diffusion

-

6Diffusion

Cu Ni

-

7Types of Diffusion

Two types of diffusion

Self diffusion Impurity diffusion

(Interdiffusion)

Diffusion of atoms of

one metal into another.

Atomic migration in

pure metals or of the

same type.

-

8Self diffusion

All atoms exchanging positions are of the same type.

Types of Diffusion

-

9Interdiffusion (Impurity Diffusion)

There is a net drift or transport of atoms from high to low concentration region.

Types of Diffusion

-

10

Diffusion Mechanisms

Atomic diffusion must meet two conditions:

1. There must be an empty adjacent site

2. The atom must have sufficient energy to

break bonds with its neighbour atoms and

then cause some lattice distortion during the

displacement

-

11

Diffusion Mechanisms

Two Mechanisms

Vacancy diffusion Interstitial diffusion

Interchange of an atom from a normal lattice position to an adjacent vacancy.

Involves atoms that migrate from an interstitial position to a neighboring interstitial site that is empty.

-

12

Diffusion Mechanisms

increasing elapsed time

Vacancy Diffusion ( Substitutional diffusion)

Degree of diffusion depends on the number ofvacancies that are present.

The motion of vacancies would be in the oppositedirection corresponds to the atomic diffusion.

-

13

Diffusion mechanisms

Interstitial Diffusion

More common with smaller size, such as hydrogen, carbon, nitrogen and oxygen (small atom fits into interstitial sites)

More rapidly and frequently than vacancy diffusion* Interstitial atoms are smaller, more mobile

* More empty interstitial position than vacancies

-

14

Diffusion flux mass M diffusing through and perpendicular to a unit cross-sectional area of material per unit time. (rate of mass transfer)

Where

A = cross section area which diffusion occur

t = diffusion time

The units for J is kg/m2s or atoms/m2s

Diffusion Flux

J = ---- ,MAt

J = --- ----1 dMA dt

Differential form

-

15

Steady-state Diffusion (Ficks First Law)

Diffusion flux does not change with time.

It is proportional to the concentration gradient.

Concentration gradient = ---- = ---- = -----------

Steady-state Diffusion

dCdx

Cx

CA - CBxA - xB

-

16

Steady-state Diffusion

Rate of diffusion is independent of time; the diffusion flux does not

change with time.

The concentration profile shows the concentration (C) vs the position

within the solid (x); the slope at a particular point is the concentration

gradient.

-

17

J = D(-----)

Where

D = diffusion coefficient (m2/s)

dC/dx = concentration gradient

Concentration gradient is the diving force for the diffusion reactions.

The magnitude of D indicates the diffusion rate.

Steady-state Diffusion

dCdx

Direction of diffusion

-

18

Nonsteady-state Diffusion

The diffusion flux and the concentration gradient at some particular point in a solid vary with time, with a net

accumulation or depletion of the diffusing species

resulting.

Nonsteady-state Diffusion

Involves most practical diffusion situations.

The figure on the right shows the concentration profiles for nonsteady-state diffusion taken at three different time t1 , t2 and t3.

-

19

Nonsteady-state diffusion

Ficks second law : if the diffusion coefficient is independent of composition, the time rate of

change of concentration is proportional to the

second derivative of concentration.

Nonsteady-state Diffusion

-

20

Where D is the diffusion coefficient (m2/s)

Solution to the expression is possible for a semi-infinite solid, in which none of the diffusing

atoms reaches the bar end during the time over

which diffusion takes place

----- = D(------)

Nonsteady-state Diffusion

d2Cdx2

dCdt

-

21

For a semi-infinite solid :

l > 10 Dt , where l is the length of the bar.

To obtain solution for the expression, the following assumptions are made ;

1. Before diffusion, any of the diffusing solute atoms in the solid are uniformly distributed with concentration of C0.

2. The value of x at the surface is zero and increases with distance into the solid.

3. The time is taken to be zero the instant before the diffusion process begins.

Nonsteady-state Diffusion

-

22

For a semi-infinite solid :

The boundary conditions are stated as follows :

For t= 0, C = C0 at 0 x

For t > 0, C = Cs (the constant surface concentration) at x = 0,

C = C0 at x =

Application of the boundary conditions to the expression yields

Where Cx represents the concentration at depth x after time t and erf()

is the Gaussian error function

Nonsteady-state Diffusion

-

23

Nonsteady-state Diffusion

Cx Co

Cs Co

Cs

Cx

Co

Co

nce

ntr

ati

on

, C

Distance from interface, x

-

24

Nonsteady-state Diffusion

For t= 0,

C = C0,

at 0 x

For t > 0,

C = Csat x = 0,

C = C0at x =

xCo

X = 0Cs

Co X =

X

-

25

Nonsteady-state Diffusion

t1 < t2 < t3

t1

t2

t3

Co

ncen

trati

on

of

dif

fusin

g s

pecie

s

Distance

-

26

The diffusing species as well as the hostmaterial influence the diffusion rate

Example : the diffusion coefficient at 500oC is greater in carbon- ironinterdiffusion (2.4 X 10-12 m2 /s) as compared to that of iron self-

diffusion (3.0 X 10-21 m2 /s)

The self-diffusion of iron occurs by a vacancy mechanism whereascarbon diffusion in iron is interstitial

The crystal structure of the host materialinfluence the diffusion rate of interdiffusion

Example : the diffusion coefficient at 900o C is greater in

carbon- iron (BCC) interdiffusion ( 1.7 X 10-10 m2 /s) as compared to

that of carbon- iron (FCC) interdiffusion ( 5.9 X 10-12 m 2/s)

Factors that Influence Diffusion

-

27

Factors that Influence Diffusion

-

28

Interstitial diffusion occurs more rapidly inBCC crystal structure as compared to FCC

crystal structure since there are more

interstitial spaces in crystal structure with a

lower atomic packing factor.

Type of crystal imperfection: More openstructures (grain boundaries) increases

diffusion.

Factors that Influence Diffusion

-

29

Increase in temperature would cause an increase in the diffusion coefficient and thus the

diffusion rate.

Example : the self-diffusion of Fe in Fe, the diffusion coefficient increases from 3.0 X 10-21 to

1.8 X 10-15 m2 /s in rising temperature from 500o

C to 900o C.

A large activation energy results in a small diffusion coefficient.

Factors that Influence Diffusion

-

30

Diffusion coefficient,

Where

D0 = a temperature-independent pre-exponential

(m2/s)

Qd = the activation energy, or the energy required to

produce the diffusive motion of one mol of

atoms (J/mol or eV/atom)

R = the gas constant , 8.31 J/mol.K

or 8.62 x 10-5 eV/atom.K

T = absolute temperature (K)

Temperature and Diffusion Rate

-

31

A technique by which both surfacehardness and fatigue life are

enhanced for steel alloys.

Can be accomplished by increasingthe surface concentration of carbon via

diffusion in a process termed

carburizing.

In carburizing, the steel piece isexposed, at an elevated temperature,

to an atmosphere rich in a

hydrocarbon gas, such as methane

(CH4).

Case Hardening

-

32

A plate of iron is exposed to a carburizing (carbon-rich) atmosphere on one

side and a decarburizing (carbon-deficient) at mosphere on th other side at

700oC (1300oF). If a condition of steady state is achieved, calculate the

diffusion flux of carbon through the plate if the concentrations of carbon at

positions of 5 and 10 mm (5 x 10-3 and 10-2 m) beneath the carburizing

surface are 1.2 and 0.8 kg/m3, respectively. Assume a diffusion coefficient of

3 x 10-11 m2/s at this temperature.

Solution

Ficks first law is utilized to determine the diffusion flux.

CA - CBxA - xB

J = D(----------) = (3 x 10-11 m2/s) -----------------------(1.2 0.8) kg/m3

(5 x 10-3 10-2) m

= 2.4 x 10-9 kg/m2s

Case Hardening

-

33

For some applications, it is necessary to harden the surface of a steel (or iron-carbon alloy) above that of its

interior. One way this may be accomplished is by increasing the surface concentration of carbon in a

process termed carburizing: the steel piece is exposed, at an elevated temperature, to an atmosphere rich in

a hydrocarbon gas such as methane (CH4).

Consider one such alloy that initially has a uniform carbon concentration of 0.25 wt% and is to be treated at

950oC (1750oF). If the concentration of carbon at the surface is suddenly brought to ad maintained at 1.20

wt%, how long will it take to achieve a carbon content of 0.80 wt% at a position 0.5 mm below the surface ?

The diffusion coefficient for carbon in iron at this temperature is 1.6 x 10-11 m2/s; assume that the steel piece

is semi-infinite.

Solution

Since this is a nonsteady-state diffusion problem in which the surface composition is held constant. Values

for all the parameters in this expression except time t are specified in the problem as follows :

Co = 0.25 wt% C

Cs = 1.20 wt% C

Cx = 0.80 wt% C

x = 0.50 mm = 5 x 10-4 m

D = 1.6 x 10-11 m2/s

Thus

Cx - Co

Cs - Co---------- = -------------------- = 1 erf (-------------------------------)

0.80 0.25

1.20 0.25

5 x 10-4 m

2(1.6 x 10-11 m2/s)(t)

0.4210 = erf (------------)62.5 s

t

Case Hardening

-

34

We must now determine the value of z for which the error function is 0.4210. An interpolation is

necessary, as

Z 0.35

0.40 0.35--------------- = -----------------------

0.4210 0.3794

0.4284 0.3794

Z = 0.392

(------------) = 0.39262.5 s

t

t = (------------)262.5 s

0.392

= 25,400s = 7.1h

z erf (z)

0.35 0.3794

z 0.4210

0.40 0.4284

Case Hardening