Large Eddy Simulation (LES) Applied to Advanced Engine ... · Large Eddy Simulation (LES) Applied...

Transcript of Large Eddy Simulation (LES) Applied to Advanced Engine ... · Large Eddy Simulation (LES) Applied...

Large Eddy Simulation (LES) Applied to Advanced Engine Combustion Research

Joseph C. Oefelein, Guilhem Lacaze, Layal Hakim

Combustion Research FacilitySandia National Laboratories, Livermore, CA 94551

Support Provided by the DOEOffice of Energy Efficiency and Renewable Energy

Vehicle Technologies Programis Gratefully Acknowledged

This presentation does not contain any proprietary, confidential, or otherwise restricted information

Project ID: ACE007Date: June 9, 2015

Overview

• Project provides fundamental research that supports advanced engine development

• Focused on next generation simulations and models using Large Eddy Simulation (LES)

• Goal is to combine unique code and resources, maximize benefits of DOE “leadership” computers

• Project scope, direction, and continuation evaluated annually

• Two sets of barriers addressed– Lack of fundamental knowledge of

advanced engine combustion regimes– LTC technologies (i.e., understanding

effects of fuel-injection, ignition-timing, heat-transfer, engine-geometry on fuel-air mixing, combustion, soot, emissions over broad operating ranges)

– Lack of predictive models for engine combustion design and control

– Efficient and routine use of new High-Performance-Computing (HPC) codes and architectures that facilitate “game changing” performance

• Total Project Funding− FY14 – $450K− FY15 – $450K

Timeline

Budget

Barriers

• CRF Engine Group (e.g., ECN)• Penn State, Michigan, Stanford,

CERFACS (e.g., DOE/NSF/FOA)• ≈ 50 collaborators and institutions• Project lead: Joe Oefelein

Partners

1

2

Relevance … need for advanced predictive models is well recognized

• Challenges … highly nonlinear, strongly coupled, multiscale/multiphysics phenomena

– High-Reynolds-number turbulence and scalar-mixing (Re > 100,000)

– High-pressure mixed-mode combustion– Compressible, acoustically active flow– Complex geometries, heat transfer– Complex fuels, multiphase flow

• Current codes and models are not predictive, model validation is problematic

– Simulations treat very limited ranges of scales– Experiments provide limited information– Many sources of uncertainty– Costs can be prohibitive

• A new generation of multiscale/multiphysics simulations and improved model development workflow is required

– Coupling with key experiments is imperative, but experimental data alone insufficient for validation

– Additional sources of data coupled with improved workflow can provide next level of precision

Diesel spray combustion imaging through transparent piston (Mark Musculus, Sandia)

Objective … provide science-base for advanced model development

Basic AppliedDOE Basic Energy Sciences Program

TNF Workshopwww.ca.sandia.gov/TNF

DOE Vehicle Technologies Program

Engine Combustion Networkwww.ca.sandia.gov/ECN

Detailed jet flame data for model development but low Reynolds number

and simple fuelsRe ≈ O(10,000)

Device relevant measurements but

limited due to complex geometry, flow, and fuels

Re > O(100,000)

• Use “high-fidelity” LES and “first-principles” models to complement data and insights gained from companion target experiments

– Match operating conditions, geometry, and detailed boundary conditions– Retain full system coupling, incorporate detailed physics– Validate benchmarks using available data, then extract additional information

• Data and insights not available from experiments alone• Perform data reduction aimed at affordable models for engineering

• Use full hierarchy of high-performance computing resources (both local and DOE platforms) while enabling next generation simulation capabilities

Unified Code Framework (RAPTOR)

Approach … application of first-principles LES framework

• Theoretical framework … (Comprehensive physics)

– Fully-coupled, compressible conservation equations

– Real-fluid equation of state (high-pressure phenomena)

– Detailed thermodynamics, transport and chemistry

– Multiphase flow, spray– Dynamic SGS modeling

(No Tuned Constants)– Advanced UQ methods for

error/sensitivity analysis

• Numerical framework … (High-quality numerics)

– Staggered finite-volume differencing (non-dissipative, discretely conservative)

– Dual-time stepping with generalized preconditioning (all-Mach-number formulation)

– Detailed treatment of geometry, wall phenomena, transient BC’s

• Advanced massively-parallel programming model• Strong/Weak scaling on ORNL CRAY XK7 (Titan)

– Test case – jet-in-cross-flow, 500-million cells– Strong scaling: 24,000 to 120,000 cores, > 90% efficiency– Weak scaling: 500-million-cells/24,000-cores to

2-billion-cells/120,000-cores, < 4% increase in CPU time

(RAPTOR)

Near linear scalability beyond 100,000 cores

11

Supporting resources … full hierarchy of advanced computer architectures

In-house VT/BESmidscale clusters (100 TF)

• OLCF (27 PF / Hybrid)– EERE-VT and SC-BES– ALCC, 75-million CPU-HRS

• ALCF (10 PF)– EERE-VT and SC-BES– Collaborations toward INCITE

• NERSC (2.4 PF)– Office of Science (SC) – BES– O(5 – 10-million) CPU-HRS

AEC research (this project) formed the basis for a successful ASCR Leadership Computing Challenge (ALCC) proposal- Title: High-Fidelity Multiphase Combustion Models for Advanced Engine Systems- Allocation: 75-million Titan Core-Hours, FY15

RAPTOR selected as one of 8 codes for early science on SUMMIT architecture

• Oak Ridge Leadership Computing Facility (OLCF), Center for Accelerated Application Readiness (CAAR), 2015 – 2018– Objective … port RAPTOR to new multicore/GPU

SUMMIT architecture– OLCF provides staff/postdoc (Sankaran et al.)– Matching effort at Sandia (Oefelein et al., BES)– Three-year Application Readiness Phase (2015-17)– Early Science “Grand-Challenge” Phase (2018)

• AEC research tasks proposed under this project in FY16 – FY18 are the major focal point– High-Reynolds-number reacting flow of ECN

dual-nozzle GDI configuration (FY16)– In-cylinder LES of LTGC optical engine with emphasis

on temperature stratification (FY17)– In-cylinder LES of LTGC optical engine including GDI

with emphasis on cycle-to-cycle variations (FY18)

• Will enable entirely new generation of multiscale/multiphysics simulations – Significant advances in speed and fidelity of physics– Assist in design of next generation design codes

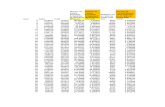

Feature Titan Summit

ApplicationPerformance Baseline 5-10x Titan

Number of Nodes 18,688 ~3,400

Node Performance 1.4 TF >40 TF

Peak Performance 27 PF >136 PF

Memory per Node 38GB(GDDR5+DDR3)

>512 GB (HBM + DDR4)

Processors AMD Opteron™NVIDIA Kepler™

IBM POWER9NVIDIA Volta™

File System 32 PB, 1 TB/s,Lustre®

120 PB, 1 TB/s, GPFS™

Peak power consumption 9 MW 10 MW

Comparison of TITAN versus SUMMIT

• Goal … maximize performance per node• Most codes currently well below 5% of peak

Milestones (FY14 – FY15)

FY 2014• Perform detailed comparisons between high-fidelity LES and available experimental data for

Spray-A in preparation for 3rd Engine Combustion Network (ECN) workshop (Q2, 03/31/14)

• Complete first fully-coupled first-principles LES of ECN Spray-A with emphasis on scalar-mixing and publish detailed analysis of transient flow field with emphasis on conditions leading to auto-ignition (Q4, 09/30/14)

FY 2015• Begin internal flow analysis of Spray-A injector to quantify the effects of geometric

anomalies, wall roughness, and heat transfer on nozzle exit conditions (Q1, 12/31/2014)

• Complete detailed analysis of reacting Spray-A case with emphasis on optimal tradeoffs between fidelity in chemistry, the combustion closure, and the coupled effects of turbulence-chemistry interactions on ignition predictions (Q2, 03/31/2015), Annual Milestone

• Establish initial series of first-principles LES calculations aimed at treatment of classical GDI spray phenomena with emphasis on ECN Spray G injector (Q3, 06/30/2015)

• Demonstrate progress toward first-principles LES of select optical engines (CRF LTGC, UM TCC) with progressively detailed treatment of both physics and geometry (Q4, 09/30/2015)

Effects of pressure on multiphase dynamics have been revealed

• R. N. Dahms and J. C. Oefelein. On the transition between two-phase and single-phase interface dynamics in multicomponent fluids at supercritical pressures. Physics of Fluids, 25: 092103, 2013.

• R. N. Dahms and J. C. Oefelein. Non-equilibrium gas-liquid interface dynamics in high-pressure liquid injection systems. Proceedings of the Combustion Institute, 35:1587–1594, 2015.

(n-Dodecane)

(Iso-Octane)

Real-fluid thermodynamics and transport dominate in this regionCurrent spray models do not account for these effects (e.g., dense-fluid or “miscible” mixing)

Using real-fluid model, we performed detailed analysis of Spray-A

Vorticity (Q-Criterion)

Liquid Core

Scalar Dissipation

• G. Lacaze, A. Misdariis, A. Ruiz, and J. C. Oefelein. Analysis of high-pressure diesel fuel injection processes using LES with real-fluid thermodynamics and transport. Proceedings of the Combustion Institute, 35:1603–1611, 2015.

• Model accounts for multicomponent thermodynamics and transport• Transient evolution of jet shows detailed structural flow interactions

Results reveal transient mixture state just prior to autoignition

Autoignition most likely to occur where• Ignition delay time• Scalar dissipation rate• Strain rate

are simultaneously minimized

Skeen et al., PCI, 2014

Cool-FlameIgnition

Hot Ignition

Flow just prior to autoigniton

Identification of flammable regions quantify conditions for chemical model

Sarathy et al., CF, 2011 (p = 60 bar)Pressure: 60±5 bar

Temperature, K (700 < T < 900)

Equivalence Ratio (0.5 < Φ < 4)

Envelope of conditions that selected chemical mechanisms need to work over:

Selection of candidate mechanisms presents interesting questions

• Sarathy et al., 2011– 2-methyl-alkanes and n-alkanes up to C12 (2755 species and 11173 reactions)– Validated for n-dodecane – air auto-ignition delay times …

• Against experimental data • Up to 20 bar from low to high temperatures (600 – 1500 K)

• Narayanaswami et al., 2013– Skeletal mechanism (255 species and 2289 reactions)– Reduced from Sarathy et al., 2011

• Directed relation graph with error propagation (DRGEP) and isomer lumping• Modification of some reaction rates based on recent theoretical and experimental analysis

– Validated for n-dodecane – air auto-ignition delay times• Against experimental data and detailed mechanism• Up to 20 bar from low to high temperatures (600 – 1500 K)

• Luo et al., 2014– Skeletal mechanism (105 species and 420 reactions)– Reduced from Sarathy et al., 2011

• DRG with expert knowledge (DRGX) and DRG-aided sensitivity analysis (DRGASA)– Validated for n-dodecane – air auto-ignition delay times

• Against experimental data and detailed mechanism• Up to 20 bar and from low to high temperatures (600 – 1500 K)

The dilemma … there is a wide range of variability between these mechanisms

n-Dodecane – Airϕ = 1, p = 20 bar

e.g., Predicted ignition delay time (even within designed ranges) exhibit notable differences, particularly in NTC region and at high temperatures

Consequence … large variations in ignition delay at Spray A conditions

ϕ = 1, p = 60 bar

ϕ = 1, P = 60 bar, Tinit = 1200 K

Deviations Between Mechanisms Can Be Large

p = 20 bar

p = 60 bar

Relativedeviation of 15.7%

Dependence on Pressure Not Fully Understood

Stoichiometric mixture of n-dodecane in the Spray A ambient gases (15% Oxygen)

UQ can be used to quantify variability and optimize “simple” mechanisms

• Objective– Design model around specified operating envelope (p, T, phi) using detailed reference

mechanism (e.g., Narayanaswami et al. 2013)– Capture characteristics of ignition, flame propagation, relevant species

• Approach:– Start with simplest mechanism; e.g., Westbrook et al. 1981, Misdariis et al. 2014– Use Bayesian inference to fit reference (pre-exponential factors, activation energies) – Calculate most probable surfaces, quantify uncertainties, add complexity as needed

ϕ = 1, p = 60 bar

We are currently testing a progression of mechanisms

Skeen et al., PCI, 2014

Cool-FlameIgnition

Hot Ignition

Flow just prior to autoigniton

314 μs

380 μs

260 μs

363 2600 K 1000 2000

We have begun detailed analysis of injector internal flow dynamics

Mac

h N

umbe

r [ -

]So

und

Spee

d [m

/s]

• Transient conditions at injector nozzle exit have significant effect on spatially evolving flow dynamics

• Real-fluid model facilitates seamless coupling between internal and external flow

Detailed studies using idealized nozzle with experimental data completed

Honeycombs

TurbulenceGenerator Plate

CeramicCombustionChamber

NitrogenShrouds

Pilot FlameNozzle

CH4/O2/N2

Nozzle and Composition VaryDepending on Case

High-fidelity LES reproduces parameter free boundary conditions (A. Ruiz, G. Lacaze, J. Oefelein)

Transient exit conditions reproduced with correct spectral fidelity

Good agreement with experimental data at nozzle exit obtained by simply changing turbulence generator plate position just as in experiment

Systematic treatment of GDI sprays in progress (Lagrangian-Eulerian method)

1. Primary atomization (sheet, filament and lattice formation)2. Secondary breakup (particle deformation and coalescence processes)3. Dilute spray dynamics

a. Drop dispersionb. Multicomponent drop vaporizationc. Two-way coupling between gas and dispersed liquid phase

− Turbulence modulation (damping of turbulence due to particle drag effects)− Turbulence generation (production of turbulence due to particle wakes)

4. Turbulent mixed-mode combustiona. Complex hydrocarbon chemistryb. High-pressure chemical kinetics

5. High-pressure supercritical phenomena (not shown)a. Real-fluid equations of state, detailed thermodynamics and transportb. Multicomponent mixtures, extreme property gradients, preferential transport

12

3

4

Photo courtesy C. F. Edwards, Stanford University

Dense Dilute

Foundation established via completed LDRD:

Development of High-Fidelity Models for Liquid Fuel Spray Atomization and Mixing Processes in

Transportation and Energy Systems

• Details published in SAND report

• Two publications to be submitted in FY15Q4

• Established system of Lagrangian models fully integrated into RAPTOR using new closure

Technology transfer and systematic treatment of optical LTGC engine

Optical LTGC engine, Dec et al.

Technology Transfer Mechanisms• Data and insights not

available from experiments• Verification, validation, UQ of

coupled sub-model framework• Portable layer of sub-models

(multicore/GPU architectures)• Next generation

multiscale/multiphysics simulation code

Response to previous year reviewer comments

• APPROACH … “using complex techniques to get accurate results then determining how the computationaltime can be reduced makes a lot of sense, …, the PI should clarify what the pathway to industry is”– RESPONSE: Technology transfer (previous slide) needs to be combined with optimal workflow (next slide).– “Will industry have access to the RAPTOR code” … Yes, will require right “Technology Readiness Level” and support model.

• TECHNICAL ACCOMPLISHMENTS … “while the technical accomplishments themselves are excellent, theproject loses points appreciably in addressing barriers directly related to designing better IC engines”– RESPONSE: Our goal is to complement what current commercial/industry design codes already do, not

reproduce more of the same. This involves providing data and insights not available from experiments,providing an improved understanding of model implementation requirements, and overcoming barriers fordevelopment of next generation massively-parallel codes.

– “How does the PI’s property evaluation scheme compared to others” … Our routines key off of NIST research, with broadtreatment of multicomponent mixtures (fuel/oxidizer/products) using both conventional and alternative fuels.

– “Is there a plan to compare model predictions with x-ray measurements” … Yes, as part of our internal nozzle flow calculations.– “Does the current modeling approach assist in the development of engineering-based Lagrangian-Eulerian models” … Yes, e.g.,

real-fluid model provides seamless connection between injector nozzle flow and external spray; regime maps highlight need toinclude transitional physics and when. We will implement Lagrangian-Eulerian spray modeling as part of FY16 tasks.

• COLLABORATION WITH OTHER INSTITUTIONS … “collaborations were mostly with other nationallaboratories, no industry collaboration was evident, …, ultimately to be the most useful, this work needs tobe related to the type of simulations the OEMs can run, …, there should be a continued linkage with theECN”– RESPONSE: We have a strong interest in working closely with all stakeholders (e.g., OEMs, national

laboratories, academia, ECN). The planned cases combined with better workflow will facilitate this.

• FUTURE RESEARCH AND RESOURCES … “proposed effort is excellent, …, priority should be put ondemonstrating highly-resolved, in-cylinder flow calculations, …, should continue to demonstrate comparisonof the high-resolution code with engineering codes to show benefit, …, a modest budget for this work effort”– RESPONSE: We agree and have aligned our future milestones with this advice. We have built the team up

over time. It will be important to maintain the planned level of resources required.– “Is there a plan to simulate the gasoline spray G test condition” … Yes, in FY16 and beyond.– “Can the modeling approach simulate flash boiling and cavitation” … Conceptually yes, this is also planned.

Remaining challenges and barriers include establishing optimal workflow

Professionally Supported Design Tool, Broad User Population• Fast solution turn-around, optimal

balance between cost and accuracy• Essential physics (cost vs. accuracy)• Robust resilient numerics• Minor parallelism and scalability

Specialized Research Code, Expert User/Developer• Maximum accuracy/fidelity, unique use

of leadership class platforms• Comprehensive physics (accuracy)• Optimal non-dissipative numerics• Massively-parallel and scalable

Basic Science

Experiments

First Principles LES

Engine Specific

Experiments

Engineering LES/RANS

Detailed DataIdealized Conditions

Re ≈ O(10,000)

Actual ConditionsLimited Data

Re ≈ O(100,000)

Joint Analysis of Common

Target Cases

Phenomenological Drivers• High-Reynolds-number turbulence• High-pressure mixed-mode combustion• Compressible, acoustically active flow• Complex geometry, heat transfer• Complex fuels, multiphase flow

GOALProvide data required for detailed

assessment of design codes

GOALExpand envelope of confidence and accuracy of design codes

Basic Research Engineering CFD

Predictive Models

Collaboration and coordination with other institutions … specific

• ORNL-OLCF, Center for Accelerated Application Readiness (CAAR)– CAAR Partnership in Turbulent Combustion using the RAPTOR Code

Framework: Application Readiness and Early Science on SUMMIT

• Penn State (Haworth), U Michigan (Sick), ORNL (Szybist)– Development and Validation of Predictive Models for In-Cylinder Radiation

and Wall Heat Transfer

• Penn State (Haworth), U Merced (Modest)– Turbulence-Radiation Interactions in Reacting Flows: Effects of Radiative

Heat Transfer on Turbulence

• Stanford (Ihme), U Michigan (Sick)– Development of a Dynamic Wall Layer Model for LES of Internal Combustion

Engines

• CERFACS (Poinsot et al.)– Numerical Benchmarks and comparisons of High-Pressure High-Reynolds-

Number Turbulent Reacting Flows using the AVBP and RAPTOR Codes

Collaboration and coordination with other institutions … general

• CRF Departments 8351, 8353, 8362, 8365 (Arienti, Barlow, Chen, Dahms, Debusschere, Frank, Lacaze, Miles, Musculus, Najm, Pickett, Shaddix, Templeton)

– 8351 Reacting Flow Research– 8353 Combustion Chemistry– 8362 Engine Combustion– 8365 Thermal/Fluid Science and Engineering

• Professor W. Anderson, Purdue• Professor J. -Y. Chen, UC Berkeley• Professor B. Cuenot, CERFACS, France• Professor R. Davis, UC Davis• Professor A. Dreizler, TU Darmstadt, Germany• Professor D. Haworth, The Pennsylvania State University*• Professor O. Haidn, TU Munich, Germany• Professor B. Helenbrook, Clarkson• Professor M. Ihme, Stanford*• Professor A. Kempf, Duisburg-Essen University, Germany• Professor M. Linne, Chalmers, Sweden• Professor T. Lieuwen, Georgia Institute of Technology• Professor S. Menon, Georgia Institute of Technology• Professor M. Modest, UC Merced*• Professor T. Poinsot, CERFACS, France• Professor S. Pope, Cornell• Professor C. Rutland, University of Wisconsin, Madison• Professor V. Sick, Michigan*• Professor J. Sutton, Ohio State• Professor V. Yang, Georgia Institute of Technology

• Dr. R. Balakrishnan, Argonne National Laboratory• Dr. A. Dord, General Electric Global Research• Dr. T. Drozda, NASA LaRC• Dr. S.-Y. Hsieh, General Electric Aviation• Dr. I. Leyva, Air Force Research Laboratory, EAFB• Dr. M. Oschwald, The German Aerospace Center (DLR), Germany• Dr. R. Sankaran, Oak Ridge National Laboratory• Dr. V. Sankaran, Air Force Research Laboratory, EAFB• Dr. S. Som, Argonne National Laboratory• Dr. K. Tucker, NASA MSFC• Dr. D. Talley, Air Force Research Laboratory, EAFB• Dr. D. Walker, General Electric Global Research

Postdoc’s and Students• J. Segura, Doctoral Committee, 2004 (Stanford); T. Drozda, Oct

2005 - Oct 2008 (NASA LaRC); V. Lee, Intern 2006, 2007 (California Polytechnic State University); V. Sankaran, Feb 2006 - Oct 2008 (UTRC); R. Knaus, Intern 2007, 2008 (UIUC); J. Smith, Doctoral Committee, 2007 (University of Adelaide, Australia); J. Doom, Jan 2009 - Aug 2010 (Minnesota State); B. Hu, Jan 2009 - Sep 2011 (Cummins); G. Lacaze, Aug 2009 - Nov 2012 (Sandia); V. Vuorinen, Doctoral Committee, 2009 (Helsinki University of Technology, Finland); R. Dahms, Jul 2010 - Dec 2012 (Sandia); R. Mari, Intern Apr 2011 - Sep 2011 (CERFACS, France); M. Masquelet, Doctoral Committee, 2012 (Georgia Institute of Technology); A. DeFilippo, Sep 2011 - Dec 2012 (UC Berkeley); J. Quinlan, Intern May 2013 -Jun 2013 (NASA LaRC); A. Misdariis, Intern Jun 2013 - Sep 2013 (CERFACS, France); A. Ruiz, June 2012 - Present (Sandia);

• L. Hakim, April 2014 - Present (Sandia) … DI Ignition/Combustion• F. Doisneau, April 2014 - Present (Sandia) … Primary Atomization

*NSF/DOE Advanced Combustion Engines Collaborations:Development of a Dynamic Wall Layer Model for LES of Internal Combustion EnginesRadiation Heat Transfer and Turbulent Fluctuations in IC Engines – Toward Predictive Models to Enable High Efficiency

Postdoctoral Appointees focused on DI Ignition and Combustion (this project) and development of advanced models for primary atomization (Sandia LDRD)

Proposed future work

• High-Reynolds-Number Reacting Flow LES of the Engine Combustion Network (ECN) Dual Nozzle Gasoline Direct Injection (GDI) Configuration using iso-Octane as Fuel (FY16)

• Detailed LES and Analysis of Ignition and Combustion in the ECN Spray-A Case, including Internal Flow, with Emphasis on Model Validation and Reduction (FY16)

• Detailed In-Cylinder LES of the Low Temperature Gasoline Combustion (LTGC) Engine Configuration with Emphasis on Temperature Stratification (FY17)

• In-Cylinder LES of the LTGC Engine Including Direct Injection and Combustion with Emphasis on Cycle-To-Cycle Variations (FY18)

Summary

• Project provides significant link between DOE Office of Science and EERE Vehicle Technologies program (basic → applied)– Addresses barriers related to both AEC research and development

of advanced simulation capabilities for engine design– Unique first principles solver for Large Eddy Simulation (LES)– Dedicated computational resources and facilities

• Primary focus … complement development of engineering models for RANS, LES at device relevant conditions– Direct coupling with key target experiments (anchor)– Application of science-based models at identical conditions– Joint analysis to understand model performance, limitations

• Critical trade-offs between cost and accuracy• Uncertainties as a function of fidelity and method• Implementation requirements as function of model

Obstacles for development of validated predictive models

• Accuracy of simulations is complicated by– Interdependence between different models– Model variability and numerical implementation– Competition between model and numerical errors

• Many uncertainties exist in addition to model accuracy– Error-prone numerical methods

• Narrow-band low wavenumbers for RANS (i.e., minimal requirements)• Broadband, non-dissipative, energy conservative for LES

– Poor grid quality and/or lack of appropriate spatial or temporal resolution– Incorrect and/or ill-posed boundary conditions or solution initialization

• Data available for validation does not provide fidelity required to draw “distinguishing” conclusions due to harsh environments

– Penetration, flame lift-off measurements necessary but not sufficient, instantaneous imaging is qualitative

– Progressive levels of model accuracy difficult to check (e.g., injection mixing combustion emissions)

• Combined uncertainties make it difficult to draw conclusions regarding both model performance and implementation requirements

Relation between structural/statistical flow dynamics must be understood

Scientific Achievement• Dynamics of turbulence, scalar-mixing in a JICF

predicted and analyzed using LES• First detailed map of turbulence scales from point

of injection to far field with direct correspondence to established experimental benchmark

Significance and Impact• Analysis demonstrates capabilities and

requirements for predicting complex turbulent flows• Understanding flow topologies facilitates

development of advanced predictive models• Established database now available for model

development and optimization

Research Details• Simulations predict results from the experiment of

Su and Mungal (JFM, 2004)• Subsequent analysis provides details and data on

instantaneous structural evolution of flow not available from experimental diagnostics

A. Ruiz, G. Lacaze and J. C. Oefelein. Flow topologies and turbulence scales in a jet-in-cross-flow. Physics of Fluids, 27, 045101, 2015.

Bayesian inference method

• Bayesian inference is a method of statistical inference in which Bayes rule is used to update the probability for a hypothesis as evidence is acquired

• Statistical inference is the process of deducing properties of an underlying distribution by analysis of data

• Here it provides a means to systematically compare models with the goal of identifying an optimal model, i.e.,

Reference data, y, are equal to model prediction, f(λ), with error, ελ are the input parameters of the model

• Bayes rule relates the odds of event A1 to the odds of event A2 before (prior to) and after (posterior to) conditioning on another event B

Gives joint PDF (posterior) on chosen parameters of interest (i.e., the probability of a hypothesis given the observed evidence)• Likelihood obtained by running ensemble of model

calculations while varying parameters• Prior indicates the previous estimate of probability that a

hypothesis is true before gaining the current evidence• Evidence is a normalizing constant in the present context