Kaplan Propeller Turbines&Generators

Transcript of Kaplan Propeller Turbines&Generators

VA TECH HYDRO

KAPLAN / PROPELLER TURBINES & GENERATORS

Water. Power. Kaplan.

www.vatech-hydro.com

sustainable solutions. for a better life.

We know how.We know how.

RZ_KAPLAN/PROP/TURB&GEN 2/12/04 02.12.2004 12:41 Uhr Seite 1

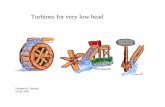

Up to approximately 30 m of head a con-crete spiral casing is possible whereas forhigher heads full steel plate spiral caseshave to be used.All types of regulation are possible today:since the Austrian Victor Kaplan has invent-ed this type of turbine in the beginning of the20th century, a full Kaplan turbine has ad-

justable blades and adjustable wicket gatesto better perform according to the changingwater discharge. A Propeller turbine hasfixed runner blades and only adjustablewicket gates for regulation and stopping themachine. This is comparable to a classicalFrancis turbine concept. A much wider range of regulation can beachieved by using adjustable blades andfixed wicket gates - thus the stopping of themachine has to be done by a gate. Whenhead and discharge are nearly constant over

2

KAPLAN /PROPELLER TURBINES & GENERATORS

General

Kaplan- and Propeller turbines are mostsuitable for low head applications in therange of 20 m to 70 m. The unit output to-day reaches the 200 MW range for thelargest applications. Runner diameters of10 m and more are also standard today.

The experience of VA TECH HYDRO regardingKaplan turbines is approx. 700 units and theoutput installed is more than 18,000 MWworldwide. Depending on the head rangethere are Kaplan runners with 3 to 8 bladesused today. Beside the very low head appli-cations of Bulb- and Pit turbines which havea horizontal setting the general arrangementof Kaplan- and Propeller turbines is a verti-cal shaft design. related unit discharge

rela

ted

effi

cien

cy

0.2 0.4 0.6 0.8 1 1.2 1.4

104

100

96

92

88

KAPLAN

PROPELLER

FIXED

BLADE REGULATION

RZ_KAPLAN/PROP/TURB&GEN 2/12/04 02.12.2004 12:41 Uhr Seite 2

3

the entire operating range, a concept withfixed wicket gates and fixed runner bladesis the most feasible solution.Today the development of Kaplan turbines isdone by numerical analysis (CFD) as well as finetuning by model testing.Within VA TECH HYDRO this will be done in the Hydraulic Laboratory in Linz, Austria. All components of large Kaplan turbines are designed using Unigraphics CAD-systemaccording to the latest design develop-ments. Stress analysis of each componentis done by FE-methods.

RZ_KAPLAN/PROP/TURB&GEN 2/12/04 02.12.2004 12:41 Uhr Seite 3

Generators driven by Kaplan turbines havetypically slow speeds resulting in large di-ameters. Stator bore diameters of morethan 10 meters are not unusual. Specialprecautions are necessary to guaranteestator roundness in cold and hot stage. Al-though the rated speed is slow, the run-away speed of these units is 3 times high-er and the rotors must safely withstandthis possible failure operation. Typicallylaminated yoke rims are used which usu-ally are based on friction to obtain a per-manent shape for reliable balance. For lowvibrations, rims do not float below load re-jection speed. Long lasting experiencewith tangential guidance provides low ec-centricities at runaway speed. Depending on the speed the generator hasone or two guide bearings. The thrust

VA TECH HYDRO generators are a syno-nym for state of the art design, high efficiency and long lifetime. VA TECHHYDRO has more than 110 years of ex-perience in design and manufacturingof all kinds of generators, from slowspeed to highest one, with air- or direct water cooling, from several kVAto more than 300 MVA. More than 33,000 MVA installed worldwide showthe impressive capability of VA TECHHYDRO with many references for vertical and horizontal hydro genera-tors including bulb type units and reversible speed motor-generators,for turbo generators and for specialapplications, like single phase machines.

For engineering of hydro generators themost advanced computer based designtechnologies like 3-D CAD, CFD for opti-misation of cooling air circuits or FEM formechanical calculations are used togeth-er with own developed programs, repre-senting the engineering experience accu-mulated in more than 110 years. Perma-nent improvement of the product is basedon own developments in cooperation withuniversities. The possibility of manufactur-ing a complete generator in one workshopallows shortest deliveries and grants highquality standards. Additionally VA TECHHYDRO has much experience in coopera-tion with local partners and subcontrac-tors. A sophisticated quality assurance isused to guarantee high reliability and longlife of the products. Modern tools are usedincluding 6-sigma methods for permanentquality improvement.

4

Generator

KAPLAN /PROPELLER TURBINES & GENERATORS

RZ_KAPLAN/PROP/TURB&GEN 2/12/04 02.12.2004 12:41 Uhr Seite 4

bearing, usually combined with a guidebearing, is of segmental type with pivotsupports. The bearings are usually of selflubricating type and motor driven pumpsare only used for high pressure oil relieveduring start up and shut down of the units.The core components of each generatorare stator core, stator winding and fieldpoles. The stator winding is insulated by aVPI (vacuum pressure impregnation) sys-tem of outstanding quality. It has an innerpotential grading and an outside coronaprotection including end potential grading. A modern elastic winding fitting (EWB)system is used to fix the winding firmly,safely and durably in the stator core. If re-quested, other proven methods can alsobe applied. The stator core is built up oflow loss electrical steel sheets, insulatedon both sides. Pressing bolts of high tensile steel allow high elongation values and permanent pressing of thecore. Pole winding coils are made ofstraight copper strips connected at thecorners by brazing. The coils are built upaccurately by use of a CNC automated device. All insulation materials are flameresistant and self extinguishing; thereforea fire fighting system is not necessary.

5

Highlights

1924 First Kaplan turbine supplied to Walden-burg in Germany with a runner diameter of 2,100 mm and an output of 750 kW

1928 First large Kaplan turbine with a runner diameter of 7 m and an output of 30,000 kW for Schwoerstadt, Germany

1947 Four Kaplan turbines supplied for Blondel(Mondragon) with an unit output of 51.5 MW

1950 First Kaplan turbines with a runnerdiameter of 7,200 mm suppliedfor Birsfelden in Switzerland

1951 First highhead Kaplan turbine for Barcis, Italy with a headof 63.5 m

1953 Fourteen Kaplan turbines supp-lied for The Dalles Dam in USAwith 92.2 MW output and7,112 mm runner diameter

1954 Five Kaplan turbines and genera-tors supplied for Ybbs-Persen-beug in Austria with an runner diameter of 7,400 mm and anoutput of 34.4 MW each. Firststator bore diameter of 10 m

1960 Kaplan turbines with a runnerdiameter 8,400 mm and an output of 73 MW and generatorswith a stator diameter of13,000 mm for Aschach, Austria

1961 Twenty five Kaplan turbinessupplied for John Day, LowerMonumental and Little Goose onthe Columbia River in the USA with a runner diameter of 7,925 mm and an output of 158.3 MW each

1974 Two Propeller turbines for Kainji, Nigeriawith 128.7 MW and 6,800 mm runner diameter

1998 Refurbishment of six large Kaplan turbinesof the Iron Gate with a runner diameter of9,500 mm and an output of 200 MW each

RZ_KAPLAN/PROP/TURB&GEN 2/12/04 02.12.2004 12:41 Uhr Seite 5

Later on the Nasser Dam upstream of theAswan Dam was constructed so that thetailwater reservoir of the Nasser Dam is theheadwater reservoir of the Aswan Dam. Due to that reason the design head of 32 mwill no longer be reached anymore and theAswan turbines will now be operated at ahead of approx. 22 m and a power outputof 38.6 MW.

6

For more than 7000 years the Egyptianshave tried to restrain the regular floods of the Nile and therefore several dams wereerected along the river. One of these damsis the Aswan Dam which was erected between 1898 – 1902. In 1948 Escher WyssZürich was awarded – by the Upper EgyptPower Authority – with the contract to supplythe turbines for the new hydropower stationwhich was erected next to the existing dam. The tailwater of the power station isconnected to the river behind the dam viatwo large tunnels.The power station is equipped with 7 vertical5 blade Kaplan turbines for the main powerproduction. Additionally two small auxiliarypowerhouse turbines are installed to enable a blackstart when the grid is downand no power from outside can be supplied.

KAPLAN /PROPELLER TURBINE& GENERATOR EXPERIENCE

Technical data:Output: 47.8 MWHead: 32 mSpeed: 100 rpmRunner diameter: 5,600 mm

AswanEgypt

The Nile which is one of the longestrivers in the world with an approximatetotal length of 6,825 km has the oldestand most extensive hydrological records.

RZ_KAPLAN/PROP/TURB&GEN 2/12/04 02.12.2004 12:41 Uhr Seite 6

With the building of this station, a 40 kmstretch of the Danube between Jochensteinand Aschach has been opened for powergeneration and navigation has been im-proved in this very narrow part of the rivervalley. Power generation efficiency isenhanced by the large head and the highwinter percentage of annual energy. Thepowerhouse is of the semi-outdoor type,equipped with a 220 t capacity gantry crane

7

AschachAustria

travelling on the crest across the wholestructure. Situated between the locks andweir, it is connected to the switchyard andoperational building by bridges above thetailwater. Four vertical shaft Kaplan turbineswith a rated output of 73 MW each are coupled to generators of 85 MVA.

The turbine runners are 8.4 m in diameter

and have been the largest in Western Europe

at the t ime of de l ivery in 1963 and are situated 3.50 m below mean tailwater level.Also the outerdiameter of the generator-stator with 13 m is the largest diameter of aVA TECH HYDRO generator. Beside turbinesand generators, the scope of supply in-cludes also the main transformers, every-thing designed, manufactured and commis-sioned by VA TECH HYDRO.

The Aschach Power Station was built assecond Austrian power station on theriver Danube in the years 1959 to 1964and is located in Aschach approx. 20 kmnorthwest from Linz in Upper Austria.

Technical data:Output: 73 MW / 85 MVAVoltage: 10.5 kVHead: 17 mSpeed: 68.2 rpmRunner diameter: 8,400 mmStator diameter: 13,000 mm

RZ_KAPLAN/PROP/TURB&GEN 2/12/04 02.12.2004 12:41 Uhr Seite 7

KAPLAN /PROPELLER TURBINE& GENERATOR EXPERIENCE

8

VA TECH HYDRO has supplied all togetherfor the three power plants John Day, LowerMonumental and Little Goose 25 units ofKaplan turbines of the same size and out-put. The turbines were manufactured byBaldwin-Lima-Hamilton from Philadelphiaat that time.

The project consists of a navigation lock,spillway, powerhouse and fish-passage facilities on both shores. Construction beganin 1958, the first of the 16 main units beganoperation in 1968, the last in 1971. Com-pletion of John Day Dam marked the final step in harnessing the waters of the Lower Columbia River. At peak productionthe powerhouse is capable of producing2,500 MW, enough to meet the electricalneeds of two cities the size of Seattle.

Technical data:Output: 158.3 MWHead: 28.7 mSpeed: 90 rpmRunner diameter: 7,925 mm

John Day, Lower Monu-mental, Little Goose/ USA

The John Day Dam is located at thehead of Lake Celilo, about 330 km up-stream from the mouth of the Columbiariver. The dam crosses the river near Rufus, Oregon about 40 km upstreamfrom The Dalles, just below the mouth ofthe John Day river.

RZ_KAPLAN/PROP/TURB&GEN 2/12/04 02.12.2004 12:41 Uhr Seite 8

9

The Power Station Jupia is located at the Parana river in the state of SaoPaulo in Brazil approximately 600 kmupstream of Itaipu. Jupia is operated bythe Companhia Energética de Sao Paulo(CESP) just like the Ilha Solteira PowerStation.

In the years 1963 to 1969 VA TECH HYDRO as a consortium partner delivered all Kaplan turbines which were equippedwith 5 blade runners. In total 14 turbinesare installed, each with 110.8 MW poweroutput. At that time it was one of the largesthydropower stations ever built.

In a Kaplan runner blade the concentrationof the stresses has its peak at the inter-section between blade and blade disc.To reduce these stress peaks, so calledundercuts are milled at these sections.The blades for Jupia were the first ones tobe designed and manufactured in this wayaccording to a global patent.

Today these undercuts are a worldwidestandard. Additionally these blades wereone of the first ones with anti cavitation lips.These anti cavitation lips are used to protectthe base material and to reduce cavitationat the hydraulic important surfaces.

Therefore, it can be stated that the turbineswere at that time not only within the largestof their type, they were also the first oneswhere the newest and most advanced tech-nology of VA TECH HYDRO was employed.

Technical data:Output: 110.8 MWHead: 23 mSpeed: 78.3 rpmRunner diameter: 8,400 mm

JupiaBrazil

RZ_KAPLAN/PROP/TURB&GEN 2/12/04 02.12.2004 12:41 Uhr Seite 9

10

KAPLAN /PROPELLER TURBINE& GENERATOR EXPERIENCE

Located approx. 45 km downstream ofLinz, the Wallsee Power Station was builtin an oxbow of the Danube, where the river crosses the border between Upper andLower Austria, in the years 1965 to 1968.

WallseeAustria

Technical data:Output: 37.9 MW / 42.5 MVAVoltage: 8 kVHead: 11 mSpeed: 65.2 rpmRunner diameter: 7,800 mmStator diameter: 12,250 mm

Upstream of Wallsee the Danube bendsextremely, featuring sand banks and blindcorners, which used to be a serious obsta-cle for shipping. The power plant was constructed with the so called “dry con-struction”-method in the dry area and a newriverbed was dug for the Danube. Thismethod was used for the first time in Austria. VA TECH HYDRO’s scope of supplyincludes 6 vertical shaft Kaplan turbines and 6 generators as well as the excitation &automation system.

RZ_KAPLAN/PROP/TURB&GEN 2/12/04 02.12.2004 12:41 Uhr Seite 10

11

90 MW units only, the new units had to fitin these narrow unit bays.Along with the six 95 MW turbines at Jebbaand the four 150 MW turbines at Shiroro, VA TECH HYDRO has supplied the turbinesfor more than 80% of Nigeria’s hydro elec-tric capacity.

Kainji Dam and Power Station are located onthe River Niger in Niger State, some 350 kmwest of the Nigerian capital Abuja. The reservoir has a width of up to 20 kilometersand stretches back some 180 kilometers,almost reaching the border of neighbouringcountry Niger. Construction work at Kainjistarted in 1964.In 1972, National Electric Power Authority(NEPA) awarded a contract to VOEST-ALPINE,one of the predecessors of VA TECHHYDRO, to design, manufacture and installtwo vertical Kaplan turbines of 108 MW ma-ximum output. Before these two units –number 11 and 12 - were commissioned in1974, NEPA ordered two more turbines –units 5 and 6. These two units of 128 MWoutput each are designed as fixed blade propeller turbines. The design challenge onall four turbines was the limitation in size: theexisting turbine blocks were designed for

Technical data: 5/6 PropellerOutput: 128.7 MWHead: 38.1 mSpeed: 107.1 rpmRunner diameter: 6,800 mm

Technical data: 11/12 KaplanOutput: 108.1 MWHead: 38.1 mSpeed: 115 rpmRunner diameter: 6,500 mm

KainjiNigeria

In 1962, the Federal Government of Nigeria decided to base the main supplyof electricity on hydropower technology.This led to the decision to constructKainji, the first large hydropower stationin Nigeria.

RZ_KAPLAN/PROP/TURB&GEN 2/12/04 02.12.2004 12:42 Uhr Seite 11

12

KAPLAN /PROPELLER TURBINE& GENERATOR EXPERIENCE

The Jebba Power Station is located atthe Niger in the center of Nigeriaapproximately a five hours drive westfrom the capital Abuja.

Due to the high manufacturing quality of thespiral case, with a diameter of more than 10 m, it was not required to press out thespiral case. The power station has no shutoff device. Therefore the turbine will only bestopped by closing the wicket gates.During commissioning in 1982 / 1983 Montreal Engineering and NEPA observedimmediately that the wicket gates were verytight since no noise from the leakage watercould be heard. This extreme tightness wasarchived with the conical machined pre-stressed wicket gates.

Technical data:Output: 102.7 MWHead: 29.3 mSpeed: 93.75 rpmRunner diameter: 7,100 mm

JebbaNigeria

In 1978 VA TECH HYDRO in Ravensburgwas awarded with the contract to sup-ply the 6 turbines for the power station bythe Nigeria Electric Power Authority (NEPA).Montreal Engineering from Canada was theconsulting company employed by the clientto supervise the works at the power station.The turbines were designed as 5 blade Propeller turbines and the speciality of theseturbines is, that the blades are clamped intothe hub and are not fixed with any kind ofscrew connection.

RZ_KAPLAN/PROP/TURB&GEN 2/12/04 02.12.2004 12:42 Uhr Seite 12

13

VA TECH HYDRO’s delivery includedthree vertical generators, the main trans-formers, generator switchgear and balanceof plant equipment (station service equip-ment including station service transformers,emergency Diesel, batteries, chargers andinverters, uninterrupted power supply andthe control system), fire fighting equipment,telecommunication and grounding system.

Technical data:Output: 45 MVAVoltage: 11 kVSpeed: 200 rpmStator diameter: 5,900 mm

KotapanjangIndonesia

Also included in the scope was the design,manufacturing, transportation, erection,commissioning as well as the training of the operation staff. All three units are in successful commercial operation sinceNovember 1998.

Located right at the equator in the Riauprovince in Central Sumatra / Indonesia,the Kotapanjang Power Plant was builtfor the client PT. PLN (Persero). The gen-erated power is required for the furtherindustrial development in the Pekanbaruarea. Since the crises in Southeast Asiathe Kotapanjang project is one of thekey projects in the grid system for theRiau and West Sumatra Areas.

RZ_KAPLAN/PROP/TURB&GEN 2/12/04 02.12.2004 12:42 Uhr Seite 13

14

KAPLAN /PROPELLER TURBINE& GENERATOR EXPERIENCE

Start of construction was in October 1994and four years later in January and April1998 the two Kaplan turbines were suc-cessfully commisioned and handed over to the client VODNE DIELO ZILINA (VDZ), a subsidiary company of the SlovakianEnergy Supp ly Company VODNE ELECTRARNE TRENCIN.

Technical data:Output: 38.1 MWHead: 25.8 mSpeed: 150 rpmRunner diameter: 4,800 mm

ZilinaSlovakia

Two vertical Kaplan turbines have been installed utilizing 320 m3/s of the river discharge. It was on 28th of October 1994 when the consortium of ABB-SAE-SADELMI and VA TECH HYDROsigned the contract for the design, fabrica-tion, supply and installation of the equipment. This included the following: - Two vertical shaft Kaplan turbines includ-

ing digital type governors - Hydromechanical steel structures includ-

ing three large radial spillway gates, sto-plogs, rakes and trashrach raking equip-ment

- Powerhouse crane - Generators and electrical equipment

(supplied by ABB).

The power plant of Zilina is located onthe river Vah approximately 200 kmnorth/east of Bratislava nearby the cityof Zilina in Slovakia. The plant will sup-ply the local grid with 173 GWh of elec-tricity and is regulated also for peakload production.

RZ_KAPLAN/PROP/TURB&GEN 2/12/04 02.12.2004 12:42 Uhr Seite 14

15

as well as the auxiliaries and all the engineering, design, manufacture, trans-port, erection and commissioning work of the plant.

The Candonga Power Station is locatedon the river Rio Doce in Minas Geraisnear Ponte Nova / Brazil and has a totalcapacity of 142 MW.

Technical data:Output: 47.6 MW / 53 MVAVoltage: 13.8 kVHead: 48.6 mSpeed: 225 rpmRunner diameter: 2,840 mmStator diameter: 6,500 mm

CandongaBrazil

Located in the municipalities of Ponte Nove,the turnkey engineering procurement andconstruction (EPC) contract was won by aconsortium VA TECH HYDRO BRASIL beinga part of it. Work on this project is sched-uled from 2001 till 2004 where the first ofthese three units was set into operation atthe end of 2003.For the private investors EPP and CVRD,VA TECH HYDRO supplied the completeelectromechanical equipment includingthree vertical Kaplan units, the hydro-mechanics, the three generators, substationand transmission line, main transformers,protection, excitation and control system

RZ_KAPLAN/PROP/TURB&GEN 2/12/04 02.12.2004 12:42 Uhr Seite 15

www.vatech-hydro.com

sustainable solutions. for a better life.

VA TECH HYDRO worldwide

Set-ups in Austria, Brazil, Canada, China, Colombia, France, Germany, Hungary, India, Indonesia, Iran, Italy, Malaysia, Mexico, Norway, Poland, Russia, South Africa, Spain, Switzerland, Thailand, Turkey,

United Kingdom, Ukraine, USA, Venezuela and Vietnam.

VA TECH HYDRO can point to more than 160 years of experience in hydraulic power generation and is a competent partner for sustainable solutions.

VA TECH HYDROe-mail: [email protected]

eHY

D.L

H.3

6.40

00.C

04

Lunzerstrasse 78A-4031 Linz, Austria

Phone: (+43/732) 6987 - 3451Fax: (+43/732) 6980 - 2554

Escher-Wyss-Strasse 25D-88212 Ravensburg, Germany

Phone: (+49/751) 83 - 2941Fax: (+49/751) 83 - 3280

Penzinger Strasse 76A-1141 Vienna, Austria

Phone: (+43/1) 89 100 - 2963Fax: (+43/1) 89 100 - 3821

RZ_KAPLAN/PROP/TURB&GEN 2/12/04 02.12.2004 12:42 Uhr Seite 16

![Research Article Dynamic Model of Kaplan Turbine Regulating … · 2019. 7. 31. · turbines in hydropower systems [, ]. ere is an urgent need to establish Kaplan turbine regulating](https://static.fdocuments.in/doc/165x107/610e2bfd8b398e4ac366bd42/research-article-dynamic-model-of-kaplan-turbine-regulating-2019-7-31-turbines.jpg)