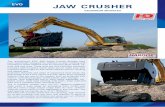

JW54 JAW CRUSHER

Transcript of JW54 JAW CRUSHER

Form 25898 A4 (10/12)

Terex® Minerals Processing SystemsJW54

JW54 JAW CRUSHER

STAndARd FEATURES

OPTiOnAl EqUiPMEnT

Hydraulic wedge jaw adjustment • Internally mounted hydraulicsHydraulic tension rodElectric/hydraulic adjust unitQuick change jaw die wedge system • Side access to stationary dieHigh strength frame • Four-piece bolted and dowelled construction • Cast steel front and rear sections • High strength structural steel side sections • Machined jaw die support facesThree-piece side cheek plates

Reversible corrugated jaw dies • Wrap around full height stationary jaw die • Lift slots cast into stationary jaw die • Extended jaw die frame protection Robust swing jaw design • Cast steel swing jaw body • Large spherical self-aligning roller bearings • Large drop forged steel shaftReplaceable jaw backing platesRight hand driveMid-mount bolt-on support feet

V-belt driveElectric motor

Effective Date: October 2012. Product specifications and prices are subject to change without notice or obligation. The photographs and/or drawings in this document are for illustrative purposes only. Refer to the appropriate Operator’s Manual for instructions on the proper use of this equipment. Failure to follow the appropriate Operator’s Manual when using our equipment or to otherwise act irresponsibly may result in serious injury or death. The only warranty applicable to our equipment is the standard written warranty applicable to the particular product and sale and Terex makes no other warranty, express or implied. Products and services listed may be trademarks, service marks or trade-names of Terex Corporation and/or its subsidiaries in the USA and other countries. All rights are reserved. Terex is a registered trademark of Terex Corporation in the USA and many other countries. © 2012 Terex Corporation.

Terex® Minerals Processing Systems • www.terexmps.comIndia +91 11 4361 0000 or +91 4344 302000 • Malaysia +60 3 5631 6199 • Thailand +66 38 214761Europe, Middle East, Africa +44 (0) 28 82 418 790 • Australia +61 3 8551 9300 • North & South America +1 989 288 3121

www.terexmps.com

Form 25898 A4 (10/12)

*Closed side setting measured from tip of fixed to bottom of moving jaws.

Terex® Minerals Processing SystemsJW54 Jaw Crusher

SPECiFiCATiOnS

SPECiFiCATiOnSModel Weight Horsepower RPM Jaw Opening *Closed Side Setting

JW54 52,000 lbs(23,550 kg)

200 HP(150 kW) 250 32" x 55"

(815 x 1400 mm)4.13" - 8.9"(105 - 225 mm)

JW54 Throughput - Typical Range (Limestone Application with Pre-Screen removing -75mm)

0

100

200

300

400

500

600

700

800

70 80 90 100 110 120 130 140 150 160 170 180 190 200 210 220 230 240 250

Closed Side Setting (mm)

To

nn

ag

e/H

r (M

etr

ic)

Lower Tolerance Upper Tolerance

JW54 Product Gradation

-20

0

20

40

60

80

100

300

1258063504031

.52522.420161412

.51086.3542.8210.50.25

0.125

0.063

Particle Size (mm)

% M

ass P

assin

g

Setting: 100mm CSS Setting: 150mm CSS Setting: 200mm CSS

Note: Tonnage and gradations shown are representative only. Actual tonnage and gradations will vary according to application conditions.

8'3"(2506 mm)

9'5" (2863 mm)

7" (172 mm)

5'8"(1713 mm)

7'1" (2160 mm)

4'8" (1420)Inside Liners

7'6" (2276 mm)

16.5"(420 mm)