Journal for the Certified Organic Associations of BC ... · Try building your very own drip winder....

Transcript of Journal for the Certified Organic Associations of BC ... · Try building your very own drip winder....

BC Organic Grower, Volume 14, Number 3, Summer 2011 Page 1

COABC, 202-3002 32 Ave, Vernon BC V1T 2L7 Canadian Publications Mail Agreement

#40047167

Official mark of the BC Certified Organic Program

British Columbia Certified Organic

Program Administrator:

Journal for the Certified Organic Associations of BC - Summer 2011Volume 14, Issue 3 ($5.00)

Page 2 BC Organic Grower, Volume 14, Number 3, Summer 2011

BC Organic Groweris received by all members of organizations belonging to the Certified Organic Association of British Columbia. BC Organic Grower is published quarterly by COABC. Subscribe online at:www.certifiedorganic.bc.ca

We welcome letters to the Edi-tor (300 words maximum) and articles (1000 words maximum). Letters to the Editor are pub-lished at the discretion of the editor, based on relevance and suitability.

Letters & submissions to:Andrea Langlois, [email protected]

Advertising (rates & copy) & non-member subscriptions ($20/year plus HST) to:

COABC 202-3002 32nd AveVernon, BC, V1T 2L7Phone: 250-260-4429Fax: 250-260-4436office@certifiedorganic.bc.cawww.certifiedorganic.bc.ca

For general information or to contact your local Certifying Body, call the office – or check our website:www.CertifiedOrganic.bc.ca

On the Cover: Risa Lin, Formo-sa Nursery Credit: Spring Gillard

Layout & Design: moss dance

Other photos property of COABC

or Creative Commons

Products advertised in BC Organic Grower are not necessarily ap-proved for use by organic farm-ers/processors. Please consult the permitted substance list CAN/32.3.11 for guidance.

President’s Letter ....................................Administrator’s Report .............................Editor’s Note ..........................................Footnotes from the Field ..........................Farmer Focus: Formosa Nursery ................People Points ..........................................Events and Announcements ......................COABC Order Form ..................................

3 4 5 1216293031

In This Issue

The Evolution of Marketing ........................Community Farms Part III .......................Cider Project & Workshop ..........................Aphid Control in Pea and Cole Crops ..........DIY Drip Winder ......................................Adding Value to your Farm Business ..........The Benefits of Compost ..........................

6121519222427

Features

Still growing strong at Formosa Nursery. Find out about farmer re-siliency on page 16.

Learn more about spent mush-room substrate in Footnotes from the Field on page 12.

Getting all tangled with your ir-rigation? Try building your very own drip winder. Instructions on page 22.

BC Organic Grower, Volume 14, Number 3, Summer 2011 Page 3

As you farm and process this season think seriously about direct marketing and selling at a farmers mar-ket. Consumers are hungry for organics and they are starving to meet the farmers.

I encourage each of you to take ownership of COABC. Remember the COABC is your associa-tion! The directors, along with staff, guide the as-sociation but is the membership that must lead. Your cooperation in promoting the COABC will benefit you and the rest of the BC Organic Community.

I look forward to the next months as we look for the beauty in storm and the rainbows in our dreams.

I’m “checking” my product are you?

Mary ForstbauerCOABC President & BioD rep(Photo: Carol Topalian and Edible Vancouver)

President’s Letter For the man sound in body and serene of mind there is no such thing as bad weather; every day has its beauty, and storms which whip the blood do but make it pulse more vigorously. George Gissing, “Winter,” The Private Papers of Henry Ryecroft, 1903

As I look out the living room window at the fall-

ing rain, I contemplate my life. A large part of it has been about farming and being ac-tively involved with COABC. The last three months I have thought a lot about what COABC has accomplished over the years. We have had many sunny days and we have weathered many storms.

The storms have strengthened us and made our blood pulse more vigorously and the sunshine has helped us grow.

The introduction of the Canadian Organic Standard has affected us all. We need to pay attention and be ready for June 30, 2011, when the Stream of Com-merce ends and the regulations begin to be fully en-forced.

In BC we have challenges as we weather the storm of having both regional and national certifiers. Under the national guidelines, we are not permitted to say “Certified Organic” but if we are regionally certified we can. We are blessed with sunshine as the phrase “Certified Organic” is incorporated into our check-mark logo. This logo is like an umbrella. As the rain falls and the weather does not cooperate, we have raised our umbrellas and started an active campaign to market the checkmark logo. Now is the time for everyone to CHECK! CHECK! CHECK! your products!

Watch for emails from the Promotions committee as we tell the BC organic story. The beauty of the storm is the sunshine that will follow as more consumers recognize the checkmark and start asking for BC Or-ganic.

Contact the promo-tions committee at [email protected] with ideas or if you would like to support our pro-gram to promote the checkmark in various publications.

Official mark of the BC Certified Organic Program

British Columbia Certified Organic

A leading manufacturer and distributor of organic andnatural products. An integral part of our mission is to support organic farmers.

Proud maker of:

Page 4 BC Organic Grower, Volume 14, Number 3, Summer 2011

The office and the board have been

working together to raise the profile of COABC over the last couple of months. We’ve initiated a check-mark promotion cam-paign that started with a half page ad in the Sum-mer edition of Edible Vancouver. COABC plans to continue the model of members purchasing ad space to help promote both their own businesses and the checkmark in subsequent publications.

We’ve also been raising the profile of the COABC within the government by collaborating with the Min-istry of Agriculture to build a case for the regulation of the word organic. With the CFIA decision to disal-low the use of the word “certified” to describe organic products, our ISO members have been put at a disad-vantage. We are working on many fronts to convince the government that regulating the word organic is a necessary measure.

Information sheets on Mandatory Organic and the need for extension have been sent to the Ministry and the BCAC and are now available on the web-site. These are documents that any member can take to their local MLA or MP to impress upon them the importance of these needs in the organic sector. By sending a consistent message, we will increase the awareness of these issues through the government.

As an individual member of the organic community you can help by displaying the BC Certified Organic logo and COABC promotional material where you sell your certified organic products. Because the check-mark logo, including the words BC Certified Organic, has been approved for use by the CFIA, our ISO op-erators can use it to promote their certified status even though they can no longer use the word “certified” in the remainder of the packaging.

Finally, please help us spread the word that the COABC conference will be held in Chilliwack this coming February. Make plans to attend the conference and bring a friend. If you are able to volunteer or have an idea for speakers, please let the office know.

Administrator’s Report by Jen Gamble

Achievements for last Quarter

√ Selected Chilliwack as the 2012 conference location

√ Finalized 1st Quarter financials √ The Accreditation Board met to re-

view the annual reports and make the renewal decisions

√ Sent thank you letter to all COABC operators

Husky Mohawk Community Rebate ProgramCOABC is involved with the Husky Mohawk Community Rebate Program in order to raise additional funds for the organisation. Husky forwards 2% of the loyalty card users’ purchases to COABC in the form of a rebate. All COABC members were sent a card in 2005 and a small amount of members have been using the card re-sulting in an average rebate of $30 per quarter. We still need more help to raise funds using this loyalty program.

If you would like to receive a card or additional cards, please con-tact the COABC office at (250) 260-4429 or email us at [email protected].

BC Organic Grower, Volume 14, Number 3, Summer 2011 Page 5

Welcome to the summer issue of the BC Or-

ganic Grower, although many of you may have been so busy this summer that you`re sit-ting down to read this in the fall!

A few words that come to mind for me when reading through the submissions for this issue were “best prac-tices.” While there are no ab-solutes in farming, there are a lot of opinions and everyone has a “tried and true” method – from the best way to weed to the best way to market. One thing that the farming community is never lacking is advice!

This issue presents a few of these – from a third ex-ample of a community farm structure to an excellent article about building your own drip winder, to make that pesky side of irrigation a little, well less tangled.

This issue also brings findings from the OSDP-funded pea and aphid control project, conducted by E.S. Cropconsult Ltd, which shows that the “industry standard” of using soap to control aphids just doesn’t pass the research test. It also presents some initial findings on that may be useful for farmers wanting to try a few new tricks to stop the bug brigade.

We also have our second article from Marjorie Harris in her BCOG series “Footnotes from the Field,” in which she sheds some light on the complex story of spent mushroom substrate, outlining how it`s made as well as offering tips for its use.

Dana Zaruba, author of an interesting new book on running a successful market stall joins us with the first of three articles that she will be contributing. Her first article comes just in time for the bounty of July (ie more zucchinis than anyone can handle!) with tips on how to offer value-added products as part of your farmers’ market or CSA gig. And, if you’re considering using new technologies to market your farm business, make sure you flip the pages and learn about how marketing has evolved, making advertis-ing more affordable.

We’re also pleased, as usual, to present the faces be-hind organic farms in BC with Spring Gillard’s Farmer Focus – in this issue we get to meet Ting and Risa Lin from Formosa Nursery.

As always, I’ll end with a plea for you to send us your thoughts. What would you like to learn about? Do you have a home-made solution to a common problem? Let us know, as sharing a great idea is always a won-derful thing.

Administrator’s Report by Jen Gamble Editor’s Note by Andrea Langlois

moss dance, layout

Andrea Langlois, editor

N.O.O.AB.C.'s certifi er of choice for small and medium

scale operations

• Simple application forms• Lowest Fees with Peer Review• Additional Services: Mentoring, Seminars, Farm Visits• Flexible, friendly organization

Farm Certification$370

Contact Cara: [email protected]

Discovery Organics

In business since 1999, Discovery Organics is an

independently owned Canadian distributor of

certified organic produce. We serve hundreds of

customers, including rural buying groups, natural

foods retailers, and wholesalers

across Western Canada.

www.discoveryorganics.ca T:604.299.1683 F:604.299.1673

Page 6 BC Organic Grower, Volume 14, Number 3, Summer 2011

By Sharmila Singh

T here are many definitions of marketing. Better definitions are focused on customer orientation

and the satisfaction of customer needs. Here are a few definitions of marketing:

• Marketing is the social process by which individuals and groups obtain what they need and want through creating and exchanging products and value with others. (Kotler)

• Marketing is the management process that identi-fies, anticipates and satisfies customer requirements profitably. (The Chartered Institute of Marketing)

So what does that mean?

Marketing is the study of human behavior and the thought process that makes people purchase a product or service. Once we understand human behavior and why people buy, then we can determine which medium is best suited to get their attention (gain awareness).

This is where most small to medium businesses would hit a roadblock. Traditionally marketing costs could be upwards of 20% of your annual sales. Yes we know “it costs money to make money.” So let’s say that is true... but how did the companies know that for every dollar they were spending they were making three?

Generally, marketing is attributed to advertising, which comes across a scary expense. Some market-ing mediums that can be costly are direct mail, TV, radio, newspaper & magazine advertising, billboard/signage, sponsorship, and the list goes on. Now if you’re a small or medium-sized business how are you supposed to afford these costs?

Today, marketing has evolved

In the later 90’s we embraced the internet – a medium that would affect the way people buy and the way people do business. The internet, in some ways, re-set the competitive landscape for everyone. Then in early 2000 we were handed web-based technologies to

help us mass email our customers/clients, social plat-forms to engage and interact with end users, and better search capabilities.

People now rarely use the phone book, plus mobile phones have built in applications that can do the same things as your computer. Who would have ever thought! So now that all these great technologies are available to everyone for little or no cost – how do you apply them to your business?

Using new technology as marketing tools Whether you’re a farm, a retail outfit, or a large cor-poration with a website, the fundamentals for using web-based technologies (such as newsletter programs) and social platforms (such as Facebook and Twitter) are the same. But as for all elements of business, it is important to make sure you are using an integrated ap-proach and that you have someone who is maintaining and managing them as well.

Web-based technologies are great to use when you want to send mass email newsletters and manage the content on your website.

Email newsletter software: Some easy-to-use inex-pensive solutions are Mail Chimp, Constant Contact and Infusion Soft. These allow you to use templates to create emails and help to manage large email lists.

Content management systems (CMS): CMSs are basically systems that allow for dynamic websites that can be maintained from any computer with minimal skills. One of the most valued open source CMSs is Wordpress because if its ease of use and compatibility with most plugins.

Social platforms: The introduction of social media has really put a tailspin on how people engage and interact with each other, enabling a type of narrow-casing that allows businesses to communicate directly to their audience of “friends” or “followers.” However if you don’t have someone managing this medium, it could work against you.

Share

leave a comment...

Business has Changed Marketing has Evolved...

BC Organic Grower, Volume 14, Number 3, Summer 2011 Page 7

There are two major social platforms that are most used today – Facebook and LinkedIn. For example if you sell produce, Facebook could be a tool that you use to let your clients know what’s ready at the farm each week. Now, if you sell cold storage to businesses you might use a business-to-businesses application, such as LinkedIn, so you could reach businesses fast-er. LinkedIn is the largest social networking site for business professionals looking to do more business. With LinkedIn you can see what others in your area are doing, dialogue with like-minded professionals worldwide, recruit professionals, and more.

And above all, these platforms are free!

Now that you know a bit more about the evolution of marketing remember one last thing… Don’t just follow the crowd, figure out what tools work best for your business and then stick to it!

Sharmila Singh is a branding & marketing expert who brings 10 years of agriculture, food & beverage and high tech industry experience.

Business has Changed Marketing has Evolved...

Bolivia’s Law of Mother Earth

Bolivia has enstated laws that recognize the rights of all species and ecologies as equal

to humans. The Law of Mother Earth establishes 11 rights of nature. They include:

• the right to life and to exist• the right to continue vital cycles and pro-

cesses free from human alteration• the right to maintain the integrity of life and

natural processes• the right to pure water • the right to clean air• the right to balance• the right to be free of toxic and radioactive

pollution• the right to not have cellular structure modi-

fied or genetically altered.• the right to not be affected by mega-infra-

structure and development projects that affect the balance of ecosystems and the local inhabitant communities

Encacted by Bolivia’s first Indigenous prime minister, Evo Morales, the law is inspired by Indigenous Andean values that recognize the earth deity Pachamama as the centre of all life. It represents a cultural revitalization that could inspire peoples across the world to stand up for Mother Earth.

Adapted by moss dance from John Vidal, guard-ian.co.uk, Sunday 10 April 2011 (http://www.guardian.co.uk/environment/2011/apr/10/boliv-ia-enshrines-natural-worlds-rights

Keep posted on our LinkedIn WorkshopsVisit us at www.goroute3.com RouteThree Marketing, Vancouver & Fraser Valley.

Facebook www.facebook.com/route3marketingLinkedIn www.linkedin.com/company/route-three-marketingTwitter @goroute3

Spiral image credit: Nevit Dilmen (talk)

Page 8 BC Organic Grower, Volume 14, Number 3, Summer 2011

By Heather Pritchard

The mid-seventies were an exciting and innovative time in the Vancouver area. Vancouver’s hosting of the United Na-

tions Habitat Conference on Human Settlements in 1976 cata-lyzed new thinking about housing, energy, and community.

That year, a small group of engaged citizens formed “Communi-ty Alternatives,” a non-profit society dedicated to putting some of these new ideas into practical form.

Soon after, the group took its first real risk, buying a 10-acre plot of land near Aldergrove, about one hour east of Vancouver. They formed Fraser Common Farm Cooperative (FCFC) and sold shares to purchase the land for food production.

Decision-making about the daily operations on this community farm is the responsibility of a member-based committee called Farmkeepers. Farmkeepers are mostly farm residents with some interested non-residents. They provide leadership on policy, conflict resolution and farm use, as well as managing finances, housing, and licenses. They act on behalf of the shareholders in

May pole parade. Credit: Michael Marrapese

Fraser Common Farm Cooperative & Glorious Organics Cooperative

Part 3 of a 4 part series on Community Farms

BC Organic Grower, Volume 14, Number 3, Summer 2011 Page 9

Gold

NEW

negotiating a license with Glorious Organics Coop-erative (GLO) to farm the land.

Land licenses, housing charges, and member contri-butions are the main sources of FCFC revenue. This revenue is used to meet ongoing costs of insurance, utilities, maintenance and the mortgage.

Glorious Organic Cooperative: the Farming Cooperative

In 1986, two FCFC members, Heather Pritchard and Herb Barbolet – secured a contract to provide salad for the Northwest Territory pavilion at Expo ’86 and incorporated a farming business: Glorious Garnish and Seasonal Salad Company. Shortly after, two other members, Susan Davidson and then Dave McCandless, joined “The Salad Company,” the busi-ness’s new nickname.

When Herb left in 1995 – to start FarmFolkCityFolk – the remaining members, all of which were rapidly approaching the average age for BC farmers, asked the question: “How can we attract the next genera-tion of farmers?”

Hiring a facilitator (paid mostly in produce) they con-ducted a series of consultations with their custom-

ers/chefs, coop members and other organic growers. They determined that to attract young farmers to join them, they would need to be willing to change and open their business to new ideas. Young people may come to learn to how to farm but unless they became owners, they would most likely to move on to actual-ize their own dreams.

Glorious Garnish and Seasonal Salad Co. decided to sell the company. The three owners invited Donna and David, the young farming couple who were working on the farm to form a cooperative with them – Glorious Organic Cooperative. The new co-op ne-gotiated the purchase of original company’s assets. A cooperative was clearly more congruent with their values and made ownership an easier transition for new farmers to buy into the business.

Glorious Organics continues to sell to restaurants but has added Farmer’s Markets and a 50-person Com-munity Shared Agriculture (CSA) program to their marketing plan.

The Whole Farm Plan

Like other community farms, FCFC, is multi-func-tional and complex. When FarmFolkCityFolk re-ceived funding to adapt their Whole Farm Plan Guide

Page 10 BC Organic Grower, Volume 14, Number 3, Summer 2011

to a cooperative farm, FCFC agreed to be the test farm.

Susan Davidson, who coordinated the process, reports: “Over the years, our farm has done a lot of visioning, goal-setting, conflict resolution, budgeting, and planning. Because the Whole Farm Plan is holistic, it has brought all of these into one place, along with a detailed in-ventory of all of our resources, policies, and agreements (land, buildings, leases). This improves accessibility and fairness for everyone.”

Community Engagement

For decades, FCFC members have been a major force in the movement for sus-tainable agriculture. They have helped develop, lead, and sustain numerous or-ganizations working for healthy food and land in BC: FarmFolkCityFolk, the BC Association for Regenerative Agriculture (BCARA), Glen Valley Organic Farm Co-operative, Vancouver Farmers Market, and Langley Farmers Market.

Fraser Common Farm Cooperative Profile

• Owns two adjacent 10-acre farm properties in LangleyTownshipclosetoAldergrove

• Licenses 5-6 acres to Glorious Organics Cooperative forfarming

• CertifiedorganicbyBCARA• Hometo13peopleaged5-76,inthreehouseholds• Includestwoshopsforwoodworkingandblacksmithing• Opentonewmembers

Above:Donnaharvestingrhubarb.Credit:MichaelMarrapese

Organic, naturally. For thirty five years, Horizon Distributors has supplied retailers with premium quality, organic, natural and gourmet products in the dry, chill and frozen categories. Our 5,000 SKUs provide healthy alternatives for your customers, whether they are long-time natural foods consumers, or those with special dietary needs searching for new options.A market leader in Western Canada for decades, Horizon is the parent company of a national network of Canadian businesses distributing organic and natural foods, health and beauty aids, supplements and household products.

The Horizon Group comprises the following well-established companies, which supply more than 20,000 SKUs to 4,000 outlets across Canada:Horizon Distributors, Burnaby, BCPSC Natural Foods, Victoria, BCChristmas Natural, Burnaby, BCTara Natural, Burnaby, BCOrganic Horizons, Guelph, ONCorwin Distribution, Concord, ONDirecta Distribution, Pointe-Claire, QC

www.horizondistributors.com604.524.6610 | 1.800.663.1838

BC Organic Grower, Volume 14, Number 3, Summer 2011 Page 11

For a community farm to succeed, two groups of people need to work closely together – one group that supports local food production by securing land to grow food and the other group that grows the food. In the case Fraser Common Farm and Glori-ous Organics both these groups are registered co-operatives.

Heather Pritchard is the Farm Program Manager of FarmFolkCityFolk Society, a member of Fraser Common Farm Cooperative, a founder of Glorious Organics Cooperative and sits on the Metro Van-couver Agricultural Advisory Committee.

Organic Certification Services

Growing Together Since 1990

Pro-Cert believes in: offering certification services that work

using qualified field inspectors and evaluators having real people at the end of your phone

providing affordable, cost effective certification programs providing clients with access to all international markets

We believe in Organic!

Canadian Family Owned & Operated International Recognition

All Inclusive Certification Quotations

For more information contact our Head Office T: (306) 382-1299 Email: [email protected]

www.pro-cert.org

For more information

Fraser Common Farm Cooperative and Glorious Organic Cooperative: www.gloriousorganics.com

FarmFolkCityFolk: www.farmfolkcityfolk.ca

Page 12 BC Organic Grower, Volume 14, Number 3, Summer 2011

By Marjorie Harris

Only a small percentage of the Spent Mushroom Substrate

(SMS) produced is certified organic in BC; overwhelmingly, the SMS is from conventional sources. SMS is a varied and complex mixture of agricultural materials with organic compliance, health and safety risks attached to its use.

Recently, Deb Kellogg, administrator for the Shuswap Thompson Organic Producers Association (STOPA) certi-fying body asked for an evaluation of conventionally sourced SMS for com-pliance within the Canadian and BC Organic Regimes.

Well, no sooner said than done; it was like SMS wanted its story told and told right now. The day after STOPA asked for the review of SMS, CBC radio news was full of news coverage about the five BC mushroom workers who

had been overcome by toxic fumes released in a pump house on Sept. 5, 2008. Three of the workers died and two others suffered severe brain inju-ries. One worker still remains in hos-pital no longer able to recognize his wife and daughters.

Work Safe BC finally finished its in-vestigation into this tragedy on May 18, 2010. Then on Aug. 30, 2010 the Crown laid 29 charges under the Workers’ Compensation Act and safe-ty related regulations on the owners and senior management of A-1 Mush-room Substratum Ltd.1

What went wrong, and what was the toxic gas emission?

The SMS story continued to unfold that very evening at the BC Institute of Agrology AGM banquet. The col-league seating next to me was Dr. Jas-bir Mann PhD, P.Ag., Regional Safety

Consultant with FARSHA (Farm and Ranch Safety and Health Association). Dr. Mann knew the answer – it was a release of hydrogen sulphide, (rotten egg) gas in an unventilated building that had caused harm and death to the workers.

The story was further revealed by Dr. Mann’s co-worker David Nguyen, Fraser Valley Agricultural Health and Safety Specialist, his best under-standing was that the ingredients of the Phase 1 mushroom substrate (of 3 production phases) of the production process had become anaerobic, and through a chain of events eventually exposed the workers to lethal hydro-gen sulphide gas.

As my investigation into SMS contin-ued in-earnest, I had a lot of questions.Was it in compliance with the organic regime and what are the potential risks to the farmer when handling it?

Putting the Spotlight on

Eraticus

BC Organic Grower, Volume 14, Number 3, Summer 2011 Page 13

The Irish Teagasc Mushroom Group made a presentation specifically on monitoring hydrogen sulphide gas emissions from SMS, farm worker safety when handling it, and docu-mented the death of a young Lithu-anian worker.

In the Teagasc guideline 9.4 the con-clusions clearly state that when SMS is taken out of mushroom production and allowed to stagnate in static piles or windrows, large or small, indoors or outdoors, for 20 weeks or more while turning into composted SMS, anaerobic digestion takes over and consistently produces hydrogen sul-phide gas (H2S) in concentrations between 20-80 ppm for indoor piles and a 3 fold greater H2S production in outdoor piles with 50-250 ppm! Mea-surements are also given for inside the tractor cab that reach up to 28 ppm!2

Dr. John Paul, Ph.D, P.Ag., owner of Transform Compost Products in Ab-botsford BC, concurred with the find-ings by the Irish Teagasc Mushroom Group’s studies. Transform Compost

Products composts a fair amount of organic SMS into soil conditioners and top dressing. Dr. Paul confirmed that the only way to prevent H2S gas generation and emissions from occur-ring was to keep the SMS in constant aerobic (oxygenated) digestion, turn-ing frequently for complete compost-ing until the pile is cured.

SMS must be handled by properly trained and skilled workers, who have on-site access to gas monitors, safety equipment and air respirators and fol-low Work Safe BC regulations. It is recommended to work with SMS in a well ventilated area or outside on a windy day with the tractor doors well sealed shut.

What kind of mushrooms are grown on SMS, and what is SMS composed of?

According to the Mushrooms Canada Association, Canada supports over 100 mushroom farms with 50% of the production in Ontario and 35% in British Columbia. Canada produces over 200 million pounds (91,000 tonnes) of mushrooms annually. Ex-ports to the USA account for 80 mil-lion lb. (36,300 tonnes) and imports from China as canned or processed mushroom are 45 million lb. (20,600 tonnes).

The mushroom species, Agaricus bisporus produces the popular White Button, Brown Crimini and Porto-bello mushrooms. Agaricus mush-rooms that are secondary saprophytes (decomposers) require a specialized growing media of which SMS is the end waste by-product. Until recently SMS was considered an industrial waste and the corporate mushroom industry has funded university and industry research demonstrating that

SMS can be used safely and be con-sidered a valuable agricultural input.

All Agaricus mushroom substrate for-mulas are based on the primary ingre-dients of either straw-bedded horse or poultry manure and require the addi-tion of nitrogen and gypsum supple-ments. Poultry manure has high levels of arsenic in it from dewormer com-pounds given to the chickens. High carbohydrate items such as corncobs, cottonseed hulls, or cocoa bean hulls are mixed together with gypsum (cal-cium sulphate).

Mushroom growing basics

In Phase 1, hay bales are soaked in ‘goody water’ and mixed with the ma-nure/gypsum material and composted on concrete aerated pads or placed in ‘rics.’ Phase 1 is a control-point for hydrogen sulphide gas production. (In the case mentioned above, Work Safe BC found hydrogen sulphide in improperly managed goody water.)

The process must remain hot, wet and aerobic to prevent “odours” from developing. The odorous emissions are a complex cocktail of chemical species and may contain ammonia, amines, mercaptens, hydrogen sul-phide, volatile organic compounds, bioaerosols and airborne biological agents.3 At the end of Phase 1 the mushroom substrate should ideally be dark brown, pliable, water holding and have a sharp ammonia odour.

In Phase 2, the mushroom substrate achieves natural pasteurization and conditioning by the activity of the microbes in a hot, moist and aerobic environment.

Now, in Phase 3 the spawn is added along with additional feed materials

SMS must be handled by properly trained and skilled workers, who have on-site ac-cess to gas monitors, safety equipment and air respirators and follow Work Safe BC regulations. It is rec-ommended to work with SMS in a well ven-tilated area or outside on a windy day with the tractor doors well sealed shut.

Page 14 BC Organic Grower, Volume 14, Number 3, Summer 2011

such as soybean meal or seed meal, then a ‘casing’ layer of sphagnum peat moss and ground limestone are applied over the top. During the crop cycle Organochloride pesticides are often used to control the Fungus Gnat, these pesticides persist in the com-post.4,5

When the mushroom substrate has finally become “spent,” evidenced by diminished mushroom harvest it is then removed from the mushroom house and considered to be the by-product. Fresh SMS is a control-point for hydrogen sulphide gas production, when the SMS is fumigated by chemi-cals or sterilized by steam it becomes vulnerable to anaerobic digestion and hydrogen sulphide gas production while stored in static piles of any size.

Characteristics of spent mushroom substrate

The typical composition of fresh SMS will vary slightly from source to source, since raw materials and other cultivation practices differ. Each load of fresh SMS has a slightly different content and mineral analysis.

The fresh substrate is high enough in dissolved salts to hinder plant growth, however, these salts decline during the final composting or “weathering” for 6 months over winter. Microbial activity changes the characteristics of the aged material. SMS can be sold “fresh” – with a higher hydrogen ul-phide emission risk – or “weathered more than 6 months.”

All SMS should arrive at the farm with a “Compost Analysis Test,” lab report (make sure it’s not a Manure Test). The analysis provides macro-nutrient content, carbon to nitrogen ratios, dry matter, pH and total salts. An additional test for nitrates and heavy metals maybe required. SMS tends to contain appreciable amounts of iron, manganese, zinc and boron. Both types of fresh SMS or aged SMS should smell earthy and not odorous and resemble soil in texture.

In summary, potential non-compli-ance points and safety concerns

• PSL: Requires documented soil test for boron levels. High boron levels can hinder plant growth in some soil conditions.

• PSL: Requires documented soil test for copper levels.

• PSL: Limestone must be from a nat-ural source.

• PSL: Sphagnum moss shall not have wetting agents.

• PSL: Use oilseed meals from organic sources, cannot be GMO.

• Prohibited 1.4.1 (b) Organochlo-rides-type pesticides to control the Fungus Gnat.

• Prohibited 1.4.1 (b) Fumigant to sterilize the fresh SMS

• Prohibited 1.4.1 (b) Straw bales and animal bedding must not come from sources treated with persistent herbi-cides.

• Compost obtained from off-farm source: “Compost obtained from off-farm sources shall meet the criteria

for composting feedstocks (i) and (ii) shall not cause a build-up of heavy metals in soil over repeated applica-tions. Poultry manure has high levels of arsenic from chicken dewormers.

• Keep SMS on a concrete pad to prevent ‘goody water’ and leachate from contaminating soils.

• When placed in static piles or wind-rows, large or small, indoors or out-doors, for 20 weeks or more, anaero-bic digestion consistently produces hydrogen sulphide gas (H2S). There is a 3-fold greater concentration in outdoor vs. indoor H2S emission generations.

• The only way to prevent H2S pro-duction is to keep the SMS in con-stant aerobic (oxygenated) digestion, turning frequently for complete com-posting until the pile is cured. SMS must be handled by properly trained and skilled workers, who have on-site access to gas monitors, safety equipment and air respirators and follow Work Safe BC regulations. It is recommended to work with SMS in a well-ventilated area or outside on a windy day with the tractor doors well sealed shut.

• Excess salt in fresh SMS may harms plants.

Marjorie Harris, BSc, IOIA Adv.V.O., A.Ag, lives in Armstrong, BC, and works locally and internationally. She can be reached at [email protected].

References1 Canadian Employment Law Today; Published by Canadian HR Reporter, a Thomson Reuters business www.employmentlawtoday.com/Arti-cleView.aspx?l=1&articleid=24782 Teagasc Mushroom Group, Ireland. www.hsa.ie/eng/Your_Industry/Agriculture/.../Hydrogen_Sulphide_gas.pdf3 “Mushroom substrate manufacturing process-es,” Department of the Environment; Process Guidance Note NIPG 6/30 (Version 2). www.doeni.gov.uk4 Stamets, Paul. (2005) Mycelium Running: How Mushrooms Can Help Save the World, 10 Speed Press, p 1665 Beyer, David M. “Spent Mushroom Substrate Fact Sheet,” http://mushroomspawn.cas.psu.edu/spent.htm6 Car, Jim & Munn, David A. “Agricultural Disposal method of Construction Site Gypsum Wallboard Waste.” Journal of Construction Edu-cation, Spring 2001, Vol. 6, no1, pp 28-33

Fig.1: Basic Procedures for Agaricus Mushroom Growing; (Penn State University)

BC Organic Grower, Volume 14, Number 3, Summer 2011 Page 15

By Brian Mennell

Cawston Cold Storage stores, packs and sells a full range of organic tree fruits produced by its share-

holders as well as 24 other organic growers located in the Similkameen and Okanagan Valleys. The com-pany handles and sells about 80% of all the organic tree fruits produced in British Columbia with annual sales of about $10 million.

Although there is a good market for organic cull ap-ples, on bad hail years there can be excess supply. This study (partially funded by the Organic Sector Devel-opment Fund) examined the potential for taking the culls and hail damaged apples of the varieties handled by the CCS and creating an organic cider business.

If an organic cider market were to be developed to process this oversupply of apples and hopefully create a demand for more, all commercial organic tree fruit producers in the Okanagan and Similkameen Valleys (est. 60 enterprises) would benefit as it would firm up the price for all the apples culls that are sold.

If this comes to fruition and is located in the Similka-meen Valley it will further enhance the "Organic Capi-tal of Canada" prestige, as well as complimenting the two organic fruit wineries and the other conventional wineries in the valley. If the potential returns are any-where near what people close to this area of business speculate, then those growers directly supplying the cull product will double or triple their current returns for their culls.

Two blends of varying degrees of dryness have been made from the 2010 crop. The first used 1/3 Mac, 1/3 Braeburn and 1/3 Pink Lady; the second used 50% Fuji and 50% equal share of Mac, Breaburn and Pink Lady. As well as creating a “garage test product,” other evaluation reports on conventional apple ciders produced 7 years ago by the Okanagan Similkameen Co-op in cooperation with wine evaluators at the Ag Canada Research Station in Summerland have also been acquired to help with the study.

CCS has involved Dwight Brown and Rhys Pender in the project, both of who bring a variety of cider-mak-

ing experience to the project, along with Rob Horrick who, along with his experience in organic fruit grow-ing, recently attended a workshop held by the North West Cider Society in Mount Vernon Washington.

If you are interested in learning more, please join us in July for our Organic Cider Workshop.

Organic Cider Workshop Cawston Hall, Main Street, Cawston1-4 PM, Sunday, July 24, 2011FREE

Agenda

• Rob Horrick – Report on the North West Cider Society workshop held last Oct. in Mount Ver-non Washington.

• Dwight Brown – Report on the design, source and cost of a plant equipment needed to pro-duce cider from 80 to 100 tons of apples.

• Rhys Pender – Report on the market potential for an organic cider in BC and Alberta, the le-gal and government requirements to establish a Cidery and the potential distribution channels available to market and distribute product in BC and Alberta.

• We will end the afternoon with some taste test-ing of product.

For more information contact Brian or Linda at 250-499-5303 or email [email protected] credit: dean diamond

Cawston Cold Storage COMMERCIAL CIDER PROJECT &

WORKSHOP

Page 16 BC Organic Grower, Volume 14, Number 3, Summer 2011

By Spring Gillard

In November 2006, I got involved in the fight to save Formosa Nursery, a forty-six acre organic blueberry

farm in Maple Ridge. Translink, BC’s transit authority, had decided to put a highway right through the farm, even though there was already a planned and gazetted road nearby, meaning it was legal and government sanctioned.

After a valiant struggle by the family, their friends, politicians and activists, our campaign called Hope lost the fight and the bulldozers moved in. It was heart-breaking for all of us. Golden Ears Way (originally called the Abernethy Connector) opened in June 2009.

I decided to pay owners Ting Wu and Risa Lin a visit, to hear how they were doing and how the highway had affected their farm. I had tried to get out to their farm by transit during the farm fight and when I did a trip plan on Translink’s website, ironically it came up as “No use.” That means you need at least three transfers and would have to walk more than half a kilometre from the last bus stop. That is still true despite the new highway.

Fortunately for this trip, I had a friend drive me. As we drove up to the farm, I noticed how different it felt. The area used to feel very rural, like farm country. Now there is a major intersection on their doorstep.

“Inthemorningwhentheywanttogotothefarm,theyhavetogetintheirvehicleanddriveacrossthehighwaytogetthere.”

Farmer Focus:

Photos by Spring Gillard

Formosa Nursery’s Hope Campaign attempted to stop Translink’s plan to put a highway through their farm.

BC Organic Grower, Volume 14, Number 3, Summer 2011 Page 17

As we sat in their kitchen chatting, we could hear the traffic roaring by. Ting and Risa told me the big trucks and the motorbikes are the worst. But the highway has brought a criminal element to their farm too. “They steal radiators, batteries, electrical wiring, aluminum fittings and they’ve even broken into the freezer,” says Ting.

The break-ins never used to happen when the farm was in one piece and the family was on-site throughout the night. Now their house, which sits on a five-acre section, is split off from the rest of the thirty-five or so acres. In the morning when they want to go to the farm, they have to get in their vehicle and drive across the highway to get there. Sometimes Risa takes the golf cart, which is illegal to drive on the road, but if she has a load of materials, it can’t be helped.

The highway took out the greenhouse, propa-gation buildings and their nursery area, where Risa used to grow and sell annuals – about five acres went to pavement. Ting had to recon-figure the farm, moving thousands of mature blueberry plants out of harm’s way. Translink

Farmer Focus:

An employee-owned company

Order online at Johnnyseeds.com

or call 1-877-564-6697Winslow, Maine U.S.A.

Over 350 organic products to meet yourcustomers’ demandsEnsure repeat business with unique varieties

and innovative products.

Selected for:lQuality lTaste lAppearance lPerformance

Page 18 BC Organic Grower, Volume 14, Number 3, Summer 2011

wanted to destroy them: in their opinion the plants wouldn’t survive transplanting.

We drove over in the golf cart to take a look. It looked to me like the farm was imprisoned by the chain link fence that now surrounds it. Too bad they couldn’t have dug them a tunnel at the same time, so that the farmers could have accessed their farm more easily.

A large new warehouse sits inside the locked gates; it will become the processing area. Armed guards would not look out of place there, perhaps the only way to keep vandals out now. Their new guard dog can guard the house, but not the farm. Remnants of the Hope campaign are tucked in a corner.

Despite the challenges, the farmers have persevered. They are looking at ways to diversify and make their operation more sustainable. They have added raspber-ries and strawberries to their repertoire. Risa would like to build waist high raised strawberry beds, to make it easier for seniors to pick the berries. Ting worries about the cost. They are both interested in the agritourism potential. Risa has visions of a healing garden, a destination place for the city-weary to come and revive.

“I just want to make people happy. To come, relax, let nature heal,” she says. Both of them could use some of nature’s healing themselves. All the hard work and stress of trying to save their farm took its toll. Ting still battles with the gout that began at that time. Risa has arthritis. They could use some extra helping hands; volunteers are welcome.

As we drive around the farm, it’s obvious much Ting and Risa love their land. And how committed they are to farming organically. They have retained their organ-ic status and are certified with Fraser Valley Organic Producers.

The biodiversity is rich and evident. They have a resident hawk, eagles fly over regularly, and coyotes roam. When I ask if there are any pest problems, Ting tells me the beaver that lives in the slough sometimes eats the trees, but that’s about it.

Back in the bustling kitchen, Ting and Risa’s kids Jessica, 18 and Jonathan, 13 wander in and out while we’re having a delicious farm fresh lunch of freshly picked greens and mushroom stuffed focaccia bread. The kids are doing very well in school.

And the transplanted blueberries – they’re thriving too.

Spring Gillard is a communications consultant, SFU sustainability instructor and author of Diary of a Compost Hotline Operator. She blogs at www.com-postdiaries.com.

Above: The new major intersection at Ting Wu and Risa Lin’s doorstep. Below: The blueberries are still triving at Formosa Nursery.

For more information, visit Formosa Nursery online:www.formosanursery.com

BC Organic Grower, Volume 14, Number 3, Summer 2011 Page 19

By Marjolaine Dessureault and Renee Prasad

Aphid control is one of the main challenges in organic

production. Heavy aphid infesta-tions cause severe economic losses for two main reasons: reduced crop yield and crop contamination for processing or fresh market.

Cabbage aphids (Brevicoryne bras-sicae) form large colonies, which often leads to weekly sprays of soap in organic cole crops. Howev-er, soap provides inconsistent con-trol due to poor product coverage on plants. Peas, another important crop for organic vegetable grow-ers, are attacked by pea aphids (Acyrthosiphon pisum). Although both types of aphids are attacked by many natural enemies, often these predators and parasitoids don’t attack early enough prevent production losses.

It’s clear that organic vegetable growers would benefit from more tools that could be used to control aphids, which is what led us to do this study. Funded jointly by the Organic Sector Development Pro-gram, the Certified Organic Asso-ciation of BC, Fraserland Organics,

and the Processing Vegetable Trust Fund, this study explored three dif-ferent methods of aphid control – biological, physical and chemical control – in a series of field experi-ments conducted in Delta, during the 2010 field season.

Biological control of pea aphids

For pea aphid control, we wanted to test the effectiveness of com-bining weekly introductions of the predatory midge Aphidoletes aphidimyza (Aphidoletes) with in-sectary plants that could provide the Aphidoletes with food (nectar) and help with establishment in the field.

Aphidoletes are very effective in greenhouses for aphid control. They were released weekly for three weeks once we started to see aphids on the peas, and the release rate was 3000 adult Aphidoletes/acre/week.

The insectary plants we used in-cluded alyssum, carrot, Phacelia, yarrow and dill; plants known to attract beneficial insects and pro-vide additional food sources such as pollen and nectar (Fig. 1). In

our trial the plants were planted into 5 gallon pots, and grown in the greenhouse for several weeks prior to setting out in the field. This ensured that plants were flowering when Aphidoletes were released. In our trial we did not observe any impact of Aphidoletes releases on pea aphids nor did we find any Aphidoletes larvae (released or native) on peas in the weeks fol-lowing release. Further, the insec-tary plants that were introduced in fields did not support increased activity of the released Aphidoletes or other naturally occurring en-emies (e.g. ladybugs, syrphids, parasitoid wasps).

Demonstrating effectiveness of biological control in the field is al-ways challenging. Given the size of our plots (1/4 to 1 acres) we may have seen better results with higher Aphidoletes release rates and high-er densities of insectary plants. For smaller plantings of peas, on mixed vegetable farms, planting insectary plants at the ends of beds could provide sufficient resources to en-courage native Aphidoletes.

However, if native populations of predators are not acting quickly

Stopping the Bug Brigade: Aphid control in organic pea and cole crop production

Figure 1. Flowering insectary plants were placed in fields at a density of 6/acre. Credit: M. Dessureault

Page 20 BC Organic Grower, Volume 14, Number 3, Summer 2011

enough to control aphids, growers may want to consider releases of Aphidoletes or other enemies. We encourage growers to experiment on their own in using insectary plants to support natural enemies, both naturally occurring and those that are released.

Physical control for cabbage

aphids

For cabbage aphids we evaluated the potential of two types of row covers: Agryl P17 (lightweight polypropylene fabric) and Pro-tecknet (high density polyethylene mesh, donated by Dubois Agrino-vation, www.duboisag.com). The idea was to protect cabbage and broccoli from cabbage aphids by preventing aphids from contacting the plants (Fig. 2).

We compared the row covers with the industry standard of using soap sprays and an untreated Control plot. This trial was repeated in the three different fields. We found that both types of row covers were equally effective at keeping aphids off of the crop. Overall, both row covers provided more consistent and longer dura-tion of aphid control than soap, which provided inconsistent con-

Interested in experimenting on your own farm?

Growers interested in experimenting with aphid control this season are encouraged to set up small trial areas so that they can evaluate a new control method against what they are currently using. Ideally, a Control treatment of not doing anything at all or spraying water should also be in-cluded. These trial areas should be checked frequently (at least once a week, but preferably more) to count the aphid and natural enemy activity.

Run the trial for multiple weeks, at least a month, and re-member to take good notes on what the starting aphid pop-ulation was in each plot before you made your treatments.

Although this type of on-farm evaluation is ideal, not all growers have the time to do this. But growers can still gain valuable information from a large scale approach - e.g. planting insectary plants on the whole farm or covering all of the cabbage transplants with row cover, by taking care-ful notes on aphid populations, natural enemy activity and comparing these notes to previous years.

One step that can make taking regular observations easier is to flag certain plants and to observe these plants regu-larly. Effective pest control is part art and part science and growers have to factor in their own tolerance for pest dam-age/activity versus costs (including labour) of a control technique.

Figure 2. Agryl P17 (left) and Protecknet (right) were tested for cabbage aphid control. Credit: M. Dessureault

BC Organic Grower, Volume 14, Number 3, Summer 2011 Page 21

trol. We also saw that the row cov-ers could be effective at excluding caterpillars from the crop as well. Finally, yield was significantly higher in Agryl P17 plots than the Control or soap plots in one of our three fields – i.e. the field with the earliest planting date.

To be used effectively, both types of row cover must be placed on to plants very early on, at transplant or seeding, before pests begin feeding. Covers must be securely buried and without holes because some pests can gain access to the crop via gaps.

In general the mesh-type row cov-ers are more durable and long lasting than the fabric covers and these mesh-type covers are very difficult to tear or make holes in. Some growers are able to re-use their mesh-type row covers for 10 or more years. This is an impor-tant consideration as row covers are much more expensive than the standard of insecticidal soap, and there is the added labour cost of installing and removing the covers.

Chemical control in both pea and cole crops

Finally, we also evaluated the ef-ficacy of three organic insecticides for aphid control in peas and cole crops. We tested three very differ-ent products: the first product was made from the fungus Beauveria bassiana a naturally-occurring pathogen of many insects includ-ing aphids; the second product was a paraffinic mineral oil; and the third product was a garlic extract.

Although none of these products are currently registered for use on field peas or cole crops, our goal was to determine which product(s) were effective and to have our data support the expansion of these products to field vegetables. These products were tested along with a water Control and the indus-try standard of insecticidal soap. In these trials plots were sprayed weekly for five weeks and aphids were counted weekly.In both pea and cole crops we ob-served good aphid control by the

mineral oil and the garlic extract when aphid populations were low at the first spray (i.e. < 30 aphids/plot in peas and < 10 aphids/plot in cole crops). Neither product was effective if starting aphid popula-tions were high.

It is important to note that perfor-mance of both the mineral oil and garlic extract was similar to insec-ticidal soap. Additionally, we also some effects of both the garlic ex-tract and mineral oil on caterpillars and this will be examined further in 2011 with a follow-up study.

Marjolaine Dessureault has a B. Sc. in Agronomy. She is passion-ate about all aspects of agriculture and specializes in Integrated Pest Management and coordinates or-ganic vegetable monitoring servic-es at E.S. Cropconsult. Ltd. Renee Prasad is the research coordinator with E.S. Cropconsult Ltd. Renee also teaches IPM classes at the Unthe University of the Fraser Val-ley (Chilliwack).

Submit your photos to the BCOG!TheBCOrganicGrowerisyourpublica-tion-andwewantittolooklikeyou!Do you have photos to share of yourfarm,crops,livestockandpeople?Youmightjustfindyourphotoonthecoverofthenextissue!

Wewelcomephotosfromfarmkids!

Please submit your high-resolutionphotos to moss at [email protected]

Photo: Helmut Lang

Page 22 BC Organic Grower, Volume 14, Number 3, Summer 2011

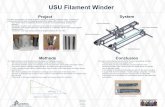

By Josh Volk

Spooling out new drip tape isn’t too bad with just a stick and

something to hold it up, but roll-ing it back up for storage is much easier with a winder. For larger farms there are PTO driven winders that take special plastic spools and will retrieve tape quickly, but these are expensive and require a tractor to power them.

A winder will spool out new or used drip tape, and it will roll it back up into compact, manageable bales for storage and reuse. I got this design from Mike Raymond when he was the manager of Holcomb Farm CSA in Connecticut. I’ve built a few dif-ferent versions for different farms and I’ll describe my most recent design here.

The winder is made from standard iron plumbing parts found at a good hardware store and two plywood rounds. It uses short pieces of PVC or ABS water pipe for spools. The winder can either sit on a simple stand made from scrap lumber, or

better, it can be mounted on a gar-den cart so that it can be easily wheeled around the farm and from bed to bed.

Building the winder

To build the roller itself you’ll need two 24” rounds of plywood – 1/2” is probably best but anything that’s not flimsy will work. Buy 1/2” black pipe nipples in the following lengths (galvanized will also work, but is unnecessary): one 24” and two 6”. You will also need two 1/2” elbows, a 1” x 12” nipple, two 1” flanges, eight pan head machine screws to fit through the flanges and the depth of your plywood thickness, and eight T nuts and star washers to match the screws. You’ll need a 1 1/2” long 1/4” bolt with a nut and split washer or a roll pin as well.

To assemble the winder slide the 1” nipple over the 12” long 1/2” nip-ple, center it and then drill through the center to tie them together either with the 1/4” bolt, or a roll pin. Next, take the plywood rounds

and drill a hole in the center large enough for the center of the flange to stick through. Drill four holes for the mounting screws and T nuts and mount the flanges so that the threads of the flange are extending into the center hole of the plywood. Screw the rounds to the 1” nipple and then an elbow to one end of the 24” nipple. Add a 6” nipple to the elbow, then the second elbow, and finally the last 6” nipple making a simple crank.

To make the winder work you’ll need a center for your spool and a stand to hold it up while you crank. I make the spools out of scraps of 2” or 3” PVC, whatever will slide over the center of the winder. Any stiff plastic pipe will work but don’t use cardboard. I made that mistake my first year and the next spring when I went to recover the spools the centers had dissolved from moisture left in the tape.

The spools need to be cut very square and to the exact length that will be captured firmly in the cen-ter of the roller. To determine this

BuildYourOwnDripWinder

Photos by Josh Volk

BC Organic Grower, Volume 14, Number 3, Summer 2011 Page 23

measurement tighten the rounds onto the 12” nipple and measure the distance between the rounds close to the flanges. Then loosen the rounds until there’s only about two or three threads holding them onto the nipple and measure again. You want a length between these numbers.

For a simple stand that works with a garden cart take two 2x4s that are 7” longer than the width of your garden cart and drill a 1” hole 3/4 of an inch from the edge at the center of the 2x4. Notch this out so that the winder axles can sit down in the notches. Cut two 17” lengths of 2x4. These are screwed to the opposite side from the notches in the long 2x4s to make a rectangle. This frame sits on top of the garden cart and the roller sits on top of the frame in the notches.

Using the winder

Drip tape comes in very compact rolls and it’s impossible to get it that compact when you wind it back up but for the sake of saving space, it’s important to wind the tape as tight and flat as possible.

To start, insert a new PVC spool in the center of the winder. Make sure that the tape in the bed is open at both ends to let water and air out and that it’s lifted and not held down by weeds. Make a full wrap around the spool and start winding with the crank while hold-ing a little tension on the tape and pinching it flat to exclude as much air and water as possible. Work the tape back and forth as you wind so that it fills the spool evenly – this is important! If you come to couplers remove them.

When you come to the end, start a new piece of tape by leaving about 12” of the old tape pulled tight and capture the new tape under it. As you start winding slowly, the old tape will capture the new, and as the old tape end is about to come

out of your hand, move it under the old tape to keep it from coming loose (this is a fancy way of doing this that makes unrolling easier).

The spool is full when you get to within an inch of the edge of the plywood round. At this point you need to tie up the spool and start a new one. Be very careful with this next part if you want to be able to reuse the tape without hours of tangled tape frustration.

Lift the winder out of the notches and place the winder crank-side down on the handle of the gar-den cart. Carefully unscrew the plywood round from the winder, exposing the roll of tape. Using poly twine (not natural twine which will rot), carefully drop the twine end down the inside of the spool and lift the bottom edge of the roll enough to pull the twine around and tie it tightly. Do this in three or spots around the spooled tape to make a tight bale. Handle these bales carefully and store them on their sides so that they do not come apart at the edges (which would signify disaster).

In the spring, you can just remount the bales on the winder, cut or untie the twine, and then roll the tape back out. For easiest use, if you have different lengths or types of tape, wind them on separate spools and label the spools clearly with something that won’t rot or fade.

I have used this system on miles of drip for more than 12 years now and it works really well, but it is not at all idiot proof so pay atten-tion to what you’re doing. The neater you are with the process the better it works.

Josh Volk grows vegetables at Slow Hand Farm just outside of Portland, Oregon and helps other farms improve their production in the US and Canada.

Step-by-Stepu

v

w

x

Page 24 BC Organic Grower, Volume 14, Number 3, Summer 2011

By Dana Zaruba

We are currently in the midst of a renaissance of artisanal

food production and it can only mean good things for organic farm-ers seeking to create a diversified income stream. You are at a perfect time to provide customers with high quality, organic, locally grown and processed value-added food prod-ucts.

One of the benefits of adding a line of specialty food products is that many can be made in the off-season, especially if you blanche, freeze or dehydrate ingredients until you have the time to process. Depend-ing on the size of your operation, selling value-added foods can gen-erate significant income throughout the market season and into the lu-crative Holiday fair season of No-vember and early December.

While some farm operations delve further into wholesaling to local

stores, there are many issues to con-sider, including careful cost analy-sis, cash flow and labeling require-ments, and large batch production issues. It’s a lot easier just to make and sell the products yourself on a smaller scale.

For many people, though, creating additional product lines is not just about the extra money. It’s about expressing one’s passions through sharing wonderful foods and reci-pes. For Deborah and Russ Fahl-man of Kilrenny farm in Cobble Hill, BC, adding preserves to their market stall initially came due to a change in market policy. Many markets now insist that vendors re-main at the market until the end of the day, even if they’ve completely sold out. The Fahlman’s needed something else to sell for the rest of the day, so they translated Debo-rah’s passion for cooking into sell-ing jams and pickles.

According to Deborah, “What has

happened as a result is that now our regular produce customers have started coming back for the jams and preserves and our zucchini relish has since become our most popular item.”

Deborah and Russ have been run-ning their nine acre farm for the past 23 years and supplemented their fresh food and frozen chicken sales by making pickles and jams in their home kitchen. They use their own produce for the pickles and purchase local berries from nearby farms for their jams. Still, the ex-

Be sure to check the guidelines and consult with your local health inspector before you make any investment in equipment or product development.

Adding Value

to your Farm Business

BC Organic Grower, Volume 14, Number 3, Summer 2011 Page 25

hausting years of market life has led to a new venture meant to em-brace more of Deborah’s passion for cooking.

Their recently completed commer-cial kitchen and farm store will be used to manufacture their new line of pasta and sauces as well as for holding cooking classes. While building a commercial kitchen is, for many, a dream scenario, the good news is that most of us are al-lowed to produce low risk foods in a home kitchen as long as you don’t plan on wholesaling your products through stores.

If you live in British Columbia visit your health authority’s website (on Vancouver Island it is www.viha.ca/mho/food) and search for the Guidelines for Temporary Food Markets. Recent changes to the guidelines mean that you may no longer have to have health author-ity approval to sell your products through local farmers’ markets.It is still important, though, to have certain products tested in a lab to be sure their pH and Aw (water activ-

ity) are within acceptable levels. Anything considered higher risk has the potential to develop deadly pathogens if they are not processed or stored correctly and will usu-ally need health authority approval prior to sale. Be sure to check the guidelines and consult with your local health inspector before you

make any investment in equipment or product development. Once you have an idea of any relevant food safety issues, product development is next.

The key to creating a financially vi-able product line is to know your customer base, appeal to the wid-

Adding Value

Clockwise from top left: Kilrenny Farm’s pasta sauce and chicken, Dana Zaru-ba’s book includes more tips about how to succeed at local markets, Deborah Falham in her commercial kitchen in Cowichan Bay, BC. Credit: Dana Zaruba

Page 26 BC Organic Grower, Volume 14, Number 3, Summer 2011

est range of tastes and be ready to adopt current trends. Each market attracts customers with different shopping habits and tastes so it’s essential to address all aspects of product design, including formula-tion and visual appeal.

While you may believe that custom-ers only care about what’s inside a package, you would essentially be cutting yourself off from potential customers by creating poor pack-aging and labels. Invest in good graphic design and then save by using stock labels and packaging. Either get labels printed inexpen-sively through places like Staples, or team up with a few other vendors using the same size labels and do combined print runs.

Producing small batches from home also means that it’s relatively easy

to add or change a product to adopt certain flavor trends as they come into the public awareness. You’ll know it when it happens, but it’s always a good idea to take a look at what’s happening in food trends in the US as well as Australia, and then plan to see those trends adopt-ed up to three years later in Canada. We’re a little slower to adopt trends here but research also allows you to plan ahead.

Be prepared to phase out recipes that don’t perform and try to add a new product to your line every year, if possible. This keeps things fresh and customers asking what’s new.

Consumers are hungry for home preserved foods. Try to use ingre-dients sourced at your own farm if at all possible and be sure to sample everything you make. Careful, con-

trolled sampling is one of the best ways of selling a value-added food product. Be sure to provide a flyer with recipes that incorporate your main market products and display photos of the dishes made up us-ing your ingredients and your value added food products. This has been, hands down, one of my most suc-cessful techniques for selling my own products.

Finally, try to create products that are complementary to what you’re already selling. If you sell salad greens, then making your own dressings or vinegars makes sense. If your family uses spice blends or sauces specific to your cultural background or family, then make up a batch and provide recipes that include the other products you sell. The key is to incorporate items into your regular product line that be-come a natural extension of your overall farm image so that it makes sense to your customers.

One final thought – when you ob-viously love what you’re selling, customers pick up on that and will trust you enough to try something new. They feed off your enthusiasm as much as your products and this, more than anything, determines a product’s success. Have fun with it, experiment, test out recipes on friends and customers but in the end, create something you enjoy and will be confident promoting at the market. Happy cooking!

Dana Zaruba is gourmet food man-ufacturer and author from Vancou-ver Island. She sells her exotic con-diments at markets on Vancouver Island and the lower mainland. Her new book, How to Run a Success-ful Market Stall: A Simple Guide for Food Producers and Crafters, is loaded with tips on how to develop and sell a product line. Visit her websites at www.overunitypress.com and www.hotchickspicecom-pany.com

Well known in Victoria for delicious jams, spreads & sauces, Rebecca’s Garden offers year-round local

delectables. Credit: Rebecca Jehn

BC Organic Grower, Volume 14, Number 3, Summer 2011 Page 27

By Marjorie Harris

Compost adds organic matter to the soil which helps to:

• Break up the soil, improving soil structure with hu-mus

• Let more air and water into the plant root zone• Improve soil development, preventing soil erosion • Reduce soil compaction providing good drainage

for roots• Make soil easier to work in for people and plants• Release nutrients slowly to plants as they need them• Provide a wide range of valuable micro-nutrients • Minimize weed growth when used as a mulch• Suppress some plant diseases• Reduce or eliminate the use of fertilizers• Hold water in the soil for plants so you water less

It is estimated that 40% of our garbage is made up of kitchen scraps and yard waste. By recycling this into garden soil through composting you can: • Feed the soil food web of beneficial bacteria, fungi

& insects

• Encourage earthworm activity in a good soil food web

• Hot composting suppresses weed seeds and patho-genic organisms

• Aerobic (oxygen breathing) compost reduces meth-ane emissions

• Mature compost tends to have a neutral pH; good for soil

Making Your Compost

• Choose a compost system for a sunny spot with good soil drainage

• Put in kitchen scraps and yard waste in layers as they arrive

• Cut up or smash down large corn cobs and woody material

• When composter is full, cover with earth or land-scape fabric to cook

• Water frequently; the beneficial organisms need wa-ter to live

• Turn often to keep air in it for the hard working fungi & bacteria

• Keep out meat or dairy products they tend to sour and attract rodents

• Leave to compost, it will smell like healthy earth when ready

• Screen out large chunks before applying to the gar-den

Compost produced on the farm

For Certified organic farms, compost produced on the farm must meet the criteria for composting feedstocks. If it is made from animal manures or other likely sourc-es of human pathogens, it shall reach a temperature of 55 C (130F) for a period of four consecutive days or more. The compost piles shall be mixed or managed to ensure that all of the feedstock heats to the required temperature for the minimum time.

Compost obtained from off-farm sources shall meet the criteria for composting feedstocks (i) and (ii) and shall not cause a build-up of heavy metals in soil over re-peated applications.

Marjorie Harris, BSc, IOIA Adv.V.O., A.Ag, lives in Armstrong, BC, and works locally and internationally. She can be reached at [email protected].

Compost Definition

The product of a carefully managed aerobic process by which non-synthetic materials are digested by micro-organisms. Organic materials for compost shall be managed appropriately to reach temperatures for the duration necessary to effectively stabilize nutrients and kill human pathogens.

The many benefits of Composting

Page 28 BC Organic Grower, Volume 14, Number 3, Summer 2011

.

BC Organic Grower, Volume 14, Number 3, Summer 2011 Page 29

By Karen Fenske

You might have the most reliable, trustworthy staff today but that could change. To grow an

operation with a high level of integrity and reliabili-ty, and to prevent disappointment, focus on transpar-ency and accountability. The following article lists a few simple tracking systems you can try.

The first common area for accountability is employ-ee hours. You want to make sure that you are paying the right amount for the hours worked. A simple sys-tem is to print numbered pages (Excel spreadsheets) on which employees can sign in and out and have you initial and date. This may seem awkward at first but many businesses have a similar procedure.

A major area for transparency is tracking sales and dealing with cash. If you have a farm gate or mar-ket operation you will want to track sales revenue with product volumes. It is efficient to have one page (Excel spreadsheet) to start the day or week with specific details such as beginning (the product you send) and ending inventory (the product that returns), the cash float start and end amounts, and places for employees to make notes of any extra spending or price changes, etc.

If you want more details and have the time, you can use numbered pages or a sales receipt book that employees input the sale data i.e. amount, price and total sale and have the customer sign. At the end of the day staple all the pages to the main page or they can be put into an envelope. Deal with any discrep-

ancies in cash at the end of the day, while everyone remembers. Either system allows you to track sales and volumes of products sold, gives you some sta-tistics to see how the season went, and helps keep everyone honest.

Another area which is a little more work is employ-ee efficiency and productivity – how much time should a task take? To determine this, you will need to do the task and then have someone who is new to do the task and take an average to set a baseline. Once you have the baseline (this could take a couple of seasons) you can determine if your employee is working hard or dawdling, and then you can discuss expectations with them.

You may experience resistance to the new systems from current employees as they may feel like they aren’t trusted. It is a good idea to validate that change can be challenging, however, the new system will help operations be more consistent for everyone. Allowing staff to give input can also help the transition. Your staff may have some ideas from their own experience or be able to provide insights on how to make the systems better.

Working together to foster a reliable, organized, honorable business is one of the keys to sustain-ability. Have a great season!

Karen Fenske is the President of StratPoint Solutions, www.stratpoint.ca.

People PointsIs everyone on the up-and-up?

Page 30 BC Organic Grower, Volume 14, Number 3, Summer 2011

Events and AnnouncementsThe 2011 6th Annual Or-ganic Okanagan Festi-val is on Sunday Septem-ber 18, 2011 from 11am to 5pm at Summerhill Pyramid Winery, 4870 Chute Lake Road, Kelowna and Center for Learning at Okanagan College, 1000 KLO Road, Kelowna. For more infor-mation: www.okanagan-greens.ca

Salt Spring Island’s 13th Annual Apple Festival – Let apples bring out the kid in everyone, it’s fun! Sun-day Oct 2, 2011 from 9am to 5pm. For more infor-mation: http://saltspring-market.com/apples

14th Annual Pacific Agri-culture Show, Tradex Ex-hibition Centre (Abbotsford Airport), Abbotsford, BC, January 26-28, 2012. For more in-formation www.agriculture-show.net

Organic Master Garden-er Course in Shawnigan Lake, September 13 to Oct 13, 2011. For more infor-mation http://gaiacollege.ca or email info@ gaiacol-lege.ca

The Organic Sector De-velopment Program Stra-tegic Initiative (OSDP) is a fund for the development of the BC organic sector. Applications are accepted for projects that match the objectives identified in the Organic Sector Strategic Plan 2009-2013. Any per-son or organisation with an interest in the organic sector may apply. Sector

participants may include primary producers, proces-sors, handlers, members of the educational community and government and pri-vate regulators. The next application deadline is Oc-tober 14, 2011. For more information visit www.certifiedorganic.bc.ca/pro-grams/osdp.php

“What is organic farm-ing?” BOOKLET IS NOW AVAILABLE ONLINE! Are you familiar with the COABC’s green “What is Organic Farming” booklet? The booklet is now available on our website as a down-loadable resource at http://certifiedorganic.bc.ca/mar-keting/docs/COABCbooklet.pdf

My Garden Footprint is an online community focused on the development of the local food movement. They are currently signing up local producers and busi-nesses and hope to be BC’s leading online community for the local and sustainable movement by summer of 2011. Joining the MGF com-munity is 100% free and could be the online mar-keting avenue that could grow your business within your local community. Go to MyGardenFootprint.com and sign your business up now for free!

Feast of Fields - a gour-met wandering harvest fes-tival - is FarmFolkCityFolk’s annual fundraising event. Feast of Fields highlights the connections between producer and chef, field and table, and farm folks and

city folks. Feast of Fields is a gastronomic journey to-wards a sustainable, local food system, with events in the Okanagan, Vancouver, and Victoria. www.feastof-fields.com

Midsummer Feast at Left Fields farm –On August 14 Crannóg Ales is hosting a Midsummer Feast at the farm and brewery in Sor-rento with noted local chef Geoffrey Couper. French meets fresh, in this inspired combination of local food and drink. www.cranno-gales.com/site/events.php

farms2chefs – Shuswap Chef Farmer Collaborative Farm2Chefs fundraiser on August 7. We take over a farm for the day, invite the public, and let our chefs show off the best of what our farmers/producers of-fer. http://tscfc.org/farm-2chefs/

C L A S S I F I E D S