Iron casting production - rustrade.cz casting.pdf · Success factors in detail ... production of...

-

Upload

trinhquynh -

Category

Documents

-

view

221 -

download

2

Transcript of Iron casting production - rustrade.cz casting.pdf · Success factors in detail ... production of...

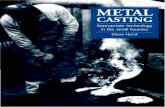

Iron casting production

2

Business of Autocomponents Division

Chassis and Power Train systems

Steering system

Brake system

Fuel system

Driving and non-driving axles

Suspension modules

Clutch

Wheel discs

Leaf springs

Control systems

Body armature

Stamped parts

Truck beds

Frame

Body

Success factors in detail

Tools and accessories

Dies and press-molds

Fasteners

(JV Bulten-GAZ)

Tooling

Joint ventures

Exhaust system

(JV Bosal-GAZ)

Iron casting

Forging

Aluminum and other

non-ferrous casting

Blanking production

Player №1 in the Russian iron castings market,

produces 8% of the total market volume.

The “iron casting” direction is one of

the Division’s key business lines,

which makes up 20% of the total revenue.

3

Product portfolio

1. High competence in design and production of various types of iron

castings

2. Application of Magmasoft automated end-to-end- design and casting

process preparation system 3. Competitive price

4. Up-to-date high-technology efficient equipment

Wide range of castings, the weight of which varies from 0.1 to 150 kg.:

Cast parts for vehicle engines: crankshafts, camshafts, cylinder blocks, cylinder heads,

inlet and outlet manifolds, etc.

Cast parts of vehicle suspension: brake discs, brake calipers, hubs, bearing caps, etc.

Cast parts for railway equipment: anchors, friction wedges, monoblocks, etc.

Cast parts for power-plant industry, manufacturers of special-purpose vehicles,

agricultural equipment, machine-tools, etc.

Competitiveness

Major products

4

Customer portfolio

Breakdown by customers

2012

факт

GAZ; 32%

Motor Plants of GAZ Group; 10%

Russian Railways; 35%

Sollers; 13%

Minsk Motor Plant; 2%

Knorr Bremse; 1% Other customers; 7% (incl. )

5

Production capacities and basic manufacturing technologies

Production

capacities

Basic

technologies

Production of a wide range of castings, the weight of which varies from 0.1 to

150 kg. with various sizes:

production of castings from grey cast iron (SCh) – 18, 24 (56 thou. t/y)

production of castings from high-strength iron (VCh)– 50, 60, 70 (56 thou. t/y)

production of castings for repairs from SCh and VCh

production of castings from heat-resistant and oxidation-resisting steels

production of castings from wear-resistant alloys

own production of casting tooling of any complexity

product yield – 108 thou. t/y

Magmasoft automated system of end-to-end- design and process

preparation

Induction melting and duplex-process

Automatic ladling

Equipment for core production according to cold-box and hot-box processes

Investment

projects

Creation of a new shop for production of castings from grey cast iron and

high-strength cast iron with capacity of 30 thou. t/y (under consideration,

planned for implementation)

22

thou. t/y

6

Iron casting production location

GAZ JSC

Foundry shop №2

Gray cast iron

Foundry shop №4

Gray cast iron

Foundry shop №7

VCh50, VCh70

Foundry shop №8

VCh50, VCh60, VCh70

Foundry shop №1

VCh50

Foundry shop №3

Gray cast iron

Pattern-shop

Space, m2

Foundry shop №1 35 181

Foundry shop №2 17 499

Foundry shop №3 17 720

Foundry shop №4 22 017

Foundry shop №7 20 525

Foundry shop №8 18 127

Pattern-shop 6 092

7

Foundry shop № 1

Casting type High-strength iron

VCh50

Installed

capacity 24 thou. t/y

Product mix

Wide range of castings weighting

from 0.01 to 35.0 kg. Anchor

Rear spring

Rear wheel hub etc.

Melting area Induction melting furnaces with

bath capacity – 31t.

Molding area Automatic molding lines (molding

box size: 1100х800х300/300)

Core-making area

Automatic core-making machines

Hot box & Cold box core-making

machines

Dressing section Rotoblast barrel

Equipment

8

Foundry shop № 2

Casting type Gray cast iron

Installed

capacity 22.4 thou. t/y

Product mix

Wide range of castings weighting

from 5 to 122 kg. Cylinder block

Brake drum

Friction wedge etc.

Melting area Cupola furnace

Electric arc furnaces with

bath capacity – 10t.

Molding area Automatic molding lines (molding box

size:1100х700х400/350)

Core-making area Core-making machines, «LAEMPE»

Mixing rubbing mill for “LAEMPE” core-

making machines

Castings’ painting Spray painting

Dressing section Three-turbine rotobalst chamber

Integrated mechanized line for cylinder

block deburring

Equipment

9

Foundry shop № 4

Casting type Gray cast iron

Installed

capacity 29 thou. t/y

Product mix

Wide range of castings weighting

from 0.3 to 45.5 kg.

Friction wedge

Manifold

Fly-wheel etc.

Melting area

Cupola furnace

Electric arc furnaces with bath

capacity – 3t.

Molding area Automatic molding lines (molding

box size:700х650х250/230)

Core-making area

Automatic core-making machines

Hot box & Cold box semi-

automatic core-making machines

Dressing section Rotoblast barrel

Equipment

10

Foundry shop № 7

Casting type VCh50, VCh70

Installed

capacity 13.5 thou. t/y

Product mix

Main product – crankshaft castings

with weight from 20 to 35 kg.

Crankshaft

Connecting piece and other

Melting area Induction furnaces with bath

capacity – 12t.

Molding area

Automatic molding lines

(molding box size:

1200х1000х250/250)

Core-making area

Core-making automatic

machines using chemical curable

components (BelNIILIT JSC)

Dressing section Rotoblast barrel

Six-turbine rotobalst chamber

Equipment

11

Foundry shop № 8

Casting type VCh50, VCh60, VCh70

Installed

capacity 23.3 thou. t/y

Product mix

Wide range of castings weighting

from 0.2 kg to 150 kg. Satellite gear case

Bearing cap and other

Melting area

Medium frequency crucible

furnaces (bath capacity – 13.5 t),

ladling devices of АВР company

production

Molding area Automatic molding lines (molding

box size: 1100х800х 250/250

Core-making area Hot box & Cold box core-making machines

Dressing section Rotoblast barrel

Equipment

12

Pattern-shop

Equipment for making

models

Milling machines

Turning machines

Drilling machines

Grinding machines

Special-purpose machines

Woodworking machines

Machines with numerical control

Wooden casting patterns Core boxes Casting-boxes

Metal casting patterns

13 13

Quality

Certification

Iron Casting Production

ISO-9001

Compliance with international standards

Выполнение требований потребителей достигается за счет приведения процессов производства

Дивизиона Автокомпоненты в соответствие со стандартами ISO 9001 и ISO/TS 16949

Company success at the market

Product competitiveness

Rise of the company prestige and status

Build-up of the personnel motivation

Certification plan

Iron Casting Production 2015

ISO/TS 16949

ISO 14001:2004

BS OHSAS 18001:2007

Certification

GAZ OJSC

14

THANK YOU

FOR

ATTENTION! Lenina Avenue 88, Nizhny Novgorod,

Russia 603004, Tel. +7 (831) 299 09 90,

fax: +7 (831) 290 81 89

Epshteyn Kirill – Director of Autocomponents Division

e-mail: [email protected]

Alexey Zaytsev– Director for Development

Autocomponents Division

e-mail: [email protected]

Nikolay Raytsyn - Director for Sales,

Autocomponents Division

e-mail: [email protected]

www.gaz.ru