Inverters Catalogue

-

date post

11-Sep-2014 -

Category

Technology

-

view

1.773 -

download

9

description

Transcript of Inverters Catalogue

6.8 WIND SYSTEMS 6.9 BATTERIES AND INVERTERS6.9 BATTERIES AND INVERTERS ENERGY usE213

Batteries and InvertersBatteries and inverters store renewable energy turning it into useable electricity. A complete renewable energy system has a number of components, as discussed in this fact sheet.

Grid connected systems require an inverter and metering system. Battery banks can be installed if back up supply is required.

Grid connected system.

Stand-alone systems include a battery bank, inverter, battery charger and a fuel generator set (genset) if required.

Stand alone system.

Each system will require a specific regulator/controller.

A complete system will include the necessary switches, circuit breakers and fuses to ensure that the system is electrically safe and to allow for major items of equipment to be isolated for maintenance purposes.

Battery banks and inverters are required whether the charging source is photovoltaics, wind, or micro hydro.

The exact layout will vary depending on the equipment configuration and space available.

BAttery BAnks

Battery types

Lead-acid batteries are used most often in renewable energy systems. Less common are nickel-cadmium batteries which last longer but are much more expensive.

Most batteries are composed of a number of cells. For example a car battery is 12 volt, but is supplied as one unit (monoblock), that comprises 6 x 2 volt cells. In stand-alone power systems the battery banks are supplied as either 12V, 24V, 48V or 120V. These batteries could be supplied as monoblock (12V or 6V) batteries but are generally supplied as individual 2V cells. A 12V battery bank will consist of 6 x 2V cells, and so on.

Battery banks can be designed to provide many days energy requirement with no input from the charging source.

Lead-acid batteries can be supplied as either wet batteries, as used in cars, or valve regulated batteries commonly called ‘sealed’ or ‘gel’ batteries. Wet batteries are most commonly used in renewable electricity systems.

The life of a battery bank is affected by how regularly it is discharged, and its use. This is referred to as the average daily depth of discharge. If the battery bank capacity is large enough to keep the depth of discharge low, the

battery life should be at least ten years. Battery manufacturers will provide information on the cycle life of the battery. Your installer will adjust your system to comply with relevant standards and maximise battery life.

Battery installation

Batteries emit a corrosive and explosive mixture of hydrogen and oxygen gas during the final stages of charging. This can ignite if exposed to a flame or spark.

Batteries must be installed in a well-ventilated environment, preferably in an appropriately designed structure away from the house.

Because the gases rise, ventilation design must permit air to enter below the batteries and exit the room at the highest point.

Ventilation can be achieved naturally or by installing fans and electrical vents. The amount of ventilation required depends on the number of battery cells and the charging current. A large battery bank using large charging currents needs more ventilation.

Your installer will design an appropriate battery storage facility in accordance with relevant standards.

Batteries should be mounted on stands to keep them clear of the ground. If the batteries are ground mounted they should be thermally insulated from the ground temperature. They should not be installed directly onto concrete,

Grid connectinverter

Switchboard

Electricitymeter

Grid connected system

Wind turbine

PV arrayRegulator

Batteries

Inverter

Generator

Stand alone power system (SAPS)

Geoff Stapleton

A battery bank.

)

6.9 BATTERIES AND INVERTERSENERGY usE 6.9 BATTERIES AND INVERTERS214 6.9 BATTERIES AND INVERTERS

as concrete will cool to ground temperature, causing the electrolyte to stratify. This is detrimental to a battery’s long-term life and performance. Low electrolyte temperatures also reduce the capacity of a battery.

Batteries must not be installed where they will be exposed to direct sunlight, as high temperatures may cause electrodes to buckle.

The typical area required for the installation of a battery bank is:

12V 1.4m x 0.3m or 0.7m x 0.6m

24V 1.4m x 0.6m

48V 2.8m x 0.6m

The batteries can be as high as 700mm, and if installed in a box it must have a removable lid or at least 500mm clearance above them to allow access for a hygrometer to check the charge level.

Access to the battery room or container should be limited to responsible people trained in system maintenance and shut down procedures.

Safety signs are required in accordance with Australian Standards.

The installation must include a switch/fuse near the batteries to enable the bank to be electrically isolated from the rest of the system.

Battery maintenance

Battery maintenance includes keeping terminals clean and tight and ensuring the electrolyte is kept above minimum levels. Use only distilled water when topping up the electrolyte level.

Batteries are dangerous items and must be treated cautiously. There are three main dangers with batteries:

> Explosion or fire from the battery gases.

> Short-circuiting the terminals.

> Acid burns from wet, lead-acid batteries.

Ensure that when working with batteries you do not short across the battery terminals. Under Australian Standards the terminals must be covered (shrouded) to prevent accidental shorting.

Wet, lead-acid batteries hold a fluid electrolyte that contains sulphuric acid. This can cause serious burns to the skin and eyes. Always wear protective clothing and eye protection. If ‘acid’ is spilt on the floor or equipment, it must be diluted with water and neutralised with sodium bi-carbonate. These should be readily accessible and stored near the battery bank.

Batteries need specific charge regimes that include equalisation charging. The system designer will explain this process. The equalisation charge will either be controlled by the system or require the owner to connect a generator and battery charger. Specific gravity readings are the best method to determine the charge level. A safe method for performing this will be explained by the system designer.

System owners should read and fully understand the manufacturer’s manual for their battery bank.

Battery disposal

Batteries contain lead and acid that are harmful to the environment. When a battery bank is being replaced the old batteries should be disposed of at a battery recycling station or other suitable site.

Inverter InstAllAtIon

Inverters are commonly a part of battery based stand alone and grid connected systems.

Inverters convert DC power from batteries or solar modules into useable AC, normally 240V AC (single phase) or 415V AC (three phase) power. Inverters are complex electronic devices and must be installed in dust free environments.

Inverters can be either wall or shelf mounted. They are heavy – a 5kW unit could measure 0.6m x 0.6 x 0.4m and weigh 60kg.

Inverters become very warm or hot when operating at large power outputs and need suitable ventilation and cooling air-flow. Insects often like to nest in the heat dissipation vents. To prevent this, inverters should be carefully sited and regularly checked.

Inverters must not be installed in direct sunlight.

Inverters should be readily accessible in case they need to be electrically isolated in an emergency.

Lightning can damage inverters. The risk should be assessed by the designer and appropriate protection installed if required.

Only a suitably trained and qualified person may undertake AC hard wiring to an inverter.

Grid connected systems

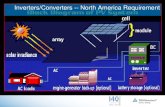

Grid connected inverters convert power from solar modules, wind or micro hydro into AC power that feeds into the grid.

On the DC side, the grid inverter is connected directly to the renewable charging source – generally PV.

The AC output of the inverter interconnects with the building switchboard in accordance with regulations.

The inverter can be installed in any suitable location between the renewable energy source and the switchboard.

Battery based systems

The DC currents in the battery leads between the inverter and battery can be very large. To avoid problems due to overheating and voltage drop, these must be sized accordingly and should be kept to a minimum length. Situate the inverter as close as possible to the battery bank.

The battery charger can be a separate unit or be incorporated within a combined inverter/charger. The inverter supplies 240V AC power from the battery bank. When the generator starts, the inverter passes the load to the generator and becomes a battery charger.

Each battery charging source requires a regulator/ controller to prevent overcharging the batteries. These can be manual or automatic. In automatic controls the generator is started when the batteries reach a low charge level or the load is greater than the maximum power output of the inverter. In manual controls the state of battery charge must be regularly monitored.

6.9 BATTERIES AND INVERTERS 6.9 BATTERIES AND INVERTERS6.9 BATTERIES AND INVERTERS ENERGY usE215

Battery charger installation

If the stand alone power system installation includes a separate battery charger, it should be treated in a similar manner to the inverter. Chargers are generally no larger than 0.4m x 0.4 x 0.6m and weigh up to 40kg.

The charger must be installed close to the batteries and can be floor or shelf mounted. The input power to the charger must be a generator-only power point.

GenerAtor InstAllAtIon

The generator should be installed in a separate room or enclosure. If installed in the same room as the rest of the system it should be located as far away from other components as possible. This helps prevent excessive heating and contamination from a malfunctioning exhaust.

Sufficient space should be allowed around the generator for maintenance.

Generators can be noisy, so locate and design the enclosure to minimise noise.

The generator fuel must be kept in an approved container in a safe location.

AdditionAl REAdinG

Contact your State / Territory government or local council for further information on renewable energy, including what rebates are available. www.gov.au

ReNew, Batteries Buyers Guide, Issue 98 and Inverters Buyers Guide, Issue 87. www.renew.org.au

Principal authors: Geoff Stapleton Geoff Milne

Contributing author: Chris Riedy

10th Edition • Solar Electric Products Catalog • March 2003

While an inverter can account for a good portion of the cost ofa PV system, it is really a sub-system that requires a number ofadditional components. To make a safe, reliable, code compliantinstallation one should provide the following:

Inverter to battery cablingBecause of the high current required on low voltage circuits,this cable is large, commonly #2 to 4/0 in size. Smallerconductors than required are unsafe and will not allow theinverter to perform to its full rating.

DC input disconnect and overcurrentprotectionIt is important to have safe installation with a properly sized DC rated, UL listed disconnect. Typically the disconnect works inconjunction with an overcurrent protection device such as afuse or circuit breaker. These components are usually installedin an enclosure which can also house shunts and additionalequipment or circuit breakers.

ShuntsUsed to read the amperage flowing between the battery andinverter, this device is installed in the negative conductor. It caneasily be housed in the disconnect or its own enclosure.

AC output disconnect and overcurrentprotectionIf the breaker panel, which is fed from the inverter, is adjacent tothe inverter, then the main breaker will serve as the inverteroutput disconnect and overcurrent protection.If, however, this panel is not grouped with the inverter, then aseparate unit should be installed. This also holds true for ACcircuits coming into the inverter from a generator or utilitysource. A second breaker may be needed if these breakers arenot grouped.

INVERTERSThe inverter is a basic component of PV systems and it converts DC power from the batteries or in the case of grid-tie, directly from the PVarray into high voltage AC power as needed. Inverters of the past were inefficient and unreliable while today’s generation of inverters arevery efficient (85 to 94%) and reliable.

Today, the majority, if not all of the loads in a typical remote home operate at 120 VAC from the inverter. Most stand-alone invertersproduce only 120 VAC, not 120/240 VAC as in the typical utility-connected home. The reason being, once electrical heating appliances arereplaced with gas appliances, there is little need for 240 VAC power. Exceptions include good-sized submersible pumps and shop toolswhich can either be powered by a generator, step-up transformer, or possibly justify the cost of adding a second inverter. Several utilityline-tie inverters do produce 240 VAC.

Two types of stand-alone inverters predominate the market – modified sine and sine wave inverters. Modified sine wave units are lessexpensive per watt of power and do a good job of operating all but the most delicate appliances. Sine wave units produce power which isalmost identical to the utility grid, will operate any appliance within their power range, and cost more per watt of output.

Utility-tie systems / sine wave inverters for utility interactive photovoltaic applications, provide direct conversion of solar electric energy toutility power with or without a battery storage system. These systems are designed to meet or exceed utility power company requirementsand can be paralleled for any power level requirement. They are listed to UL 1741 for photovoltaic power systems.

Inverter ComponentChecklist

Batteries in Vented Enclosure

Inverter with Built-inBattery Charger

InverterBreaker

GeneratorBreaker

To ACHousePanel

FromGenerator

Inverter Sub-System Checklist

_____ Inverter to battery cabling_____ DC disconnect and overcurrent device_____ Inverter conduit boxes_____ Inverter output breaker box_____ Generator input breaker box_____ Shunt(s) if required for monitoring

See the Sizing Tables in theAppendix D for cable and

overcurrent device sizing forthe inverter you select.

I N V E R T E R S

I N V E R T E R S

Most largerinverters canoperate as batterychargers as well.This is easily andeconomicallyaccomplished

because of the design of most inverters. Inverters step up lowvoltage DC power and change it to 120VAC power. Batterychargers do the reverse of this.

Transfer switches are also incorporated into these Inverter /Chargers so that the AC loads can be powered directly from thegenerator when the battery charger is operating.

From a reliability, performance, and economical standpoint,built-in battery chargers are the way to go.

Comparing InvertersInverters are compared by three factors:

• Continuous wattage rating. Hour after hour, what amount of power in watts can the inverter deliver.

• Surge Power. How much power and for howlong can an inverter deliver the power neededto start motors and other loads.

• Efficiency. How efficient is the inverter at low,medium and high power draws. How much power is used at idle.

A typical 12-voltlead-acid batterymust be taken toapproximately14.2-14.6 VDCbefore it is fullycharged. (For 24

volt systems double these figures for 48 volt, multiply by four.) Iftaken to a lesser voltage level, some of the sulfate deposits thatform during discharge will remain on the battery’s lead plates.Over time, these deposits will cause a 200 amp-hour battery toact more like a 100 amp-hour battery, and battery life will beshortened considerably. Once fully charged, batteries should beheld at a lower float voltage to maintain their charge – typically13.2 to 13.4 volts. Higher voltage levels will "gas" the batteryand boil off electrolyte, requiring more frequent maintenance.

Most automotive battery charger designs cannot deal with theconflicting voltage requirements of the initial “bulk charge” andsubsequent “float” or maintenance stage. These designs canaccommodate only one charge voltage, and therefore must usea compromise setting – typically 13.8 volts. The result is a slowincomplete charge, sulfate deposit build-up, excessive gassingand reduced battery life.

The charger available in our inverters automatically cyclesbatteries through a proper three stage sequence (bulk,absorption and float) to assure a rapid and complete chargewithout excessive gassing.

Factory battery charger settings on most inverter-chargercombinations are optimal for a lead acid (liquid electrolyte)battery bank of 250-300 amp hours in a 70°F environment. Ifyour installation varies from these conditions, you will obtainbetter performance from your batteries if you adjust the controlsettings.

The Maximum Charge Rate in amps should be set to 20-25% ofthe total amp-hour rating of a liquid electrolyte battery bank.For example, a 400 amp-hour bank should be charged at nomore than an 80 -100 amp rate. Excessive charge rates candamage batteries and create a safety hazard.

The Bulk Charge Voltage of typical liquid electrolyte lead acidbatteries should be about 14.6 VDC. There is no one correctvoltage for all types of batteries. Incorrect voltages will limitbattery performance and useful life. Check the batterymanufacturer’s recommendations.

The Float Voltage setting should hold the batteries at a levelhigh enough to maintain a full charge, but not so high as tocause excessive "gassing" which will "boil off" electrolyte. For a12-volt liquid electrolyte battery at rest, a float voltage of 13.2-13.4 is normally appropriate; gel cells are typically maintainedbetween 13.5 and 13.8. If the batteries are being used while inthe float stage, slightly higher settings may be required.

Charge voltage guidelines used here are based on ambienttemperatures of 70°F. If your batteries are not in a 70°Fenvironment, the guidelines are not valid. TemperatureCompensation automatically adjusts the voltage settings tocompensate for the differences between ambient temperatureand the 70°F baseline. Temperature compensation is importantfor all battery types, but particularly gel cell, valve-regulatedtypes which are more sensitive to temperature.

Built-In BatteryChargers

Multi-StageBattery Charging

Safety Information

IMPORTANT Read all the Cautions and Warnings before installing and using the power inverter. The

inverter must be properly installed.

IMPORTANT If you are not familiar with 12 volt high current wiring, it is recommended that you have a

professional automotive installer install the inverter.

CAUTION The power inverter generates 115 VAC power from your 12 volt car battery. Treat the 115

VAC output just like you treat the 115 VAC in your house. Keep children away from the unit.

Do not connect the unit to AC distribution wiring. Keep the unit away from water. Do not allow water to drip or splash on to the power inverter. Keep the unit in cool environments. Ambient air temperature should be between 32 degrees and

75 degrees F. Keep out of direct sunlight and away from heating vents. Keep the unit away from flammable material or in any location which may accumulate flammable

fumes or gases, such as the battery compartment of your car, boat, RV or truck. With heavy use, the unit will become warm and possibly hot. So keep it away from any heat

sensitive materials. Make sure the opening to the fan and vent holes are not blocked. Do not open the unit. High voltages are inside. Use proper size wiring. High power inverters can draw many amps from the 12 volt source and

can melt wires if not fused and sized properly.

IMPORTANT Sima Products Corporation does not authorize any products to be used in life support

devices or systems. Serial # ____________________________ Date Purchased ___________

page 2

Table of Contents

Safety Information ...................................................................................................2 Introduction..............................................................................................................4 Key Features ............................................................................................................4 Package Includes......................................................................................................4 Needed for Installation (not included) .....................................................................4 Overview of the Power Inverter...............................................................................5 Installation ...............................................................................................................6

Installation Overview ....................................................................................................................6 Step #1: Mounting the Inverter .....................................................................................................6 Step #2: Wiring Inverter to 12 volt Power ....................................................................................7

Permanent Installation...............................................................................................................8 Wiring Steps..............................................................................................................................8 Advanced Installation................................................................................................................9

Step #3: Testing the Power Inverter ..............................................................................................9 Operation .................................................................................................................9

Equipment Power Usage ...............................................................................................................9 Battery Life .................................................................................................................................10 Lights and Alarms .......................................................................................................................11

How the Inverter Works.........................................................................................12 Troubleshooting .....................................................................................................13 Product Specifications ...........................................................................................14 Warranty ................................................................................................................15

page 3

Introduction Congratulations on your purchase of a Sima Products Corporation power inverter. It provides 115 VAC anywhere you have 12 DC volts in your car, truck, RV or boat. It is designed to be easy to use and provide years of dependable service.

Key Features High-efficiency operation to provide the most output with the least battery power. Advanced protection

• Thermal Protection shuts the unit off to guard against the unit getting too hot • Overload Protection protects the unit from excessive loads • Under Voltage Protection turns the unit off to protect the battery from being over

discharged The STP-1000T power inverter produces a modified sine wave output that is suitable for most AC loads. This includes lights, appliances, motors, TVs and most electronics.

Caution: A few battery chargers are not compatible with modified sine wave operation. These are typically small, rechargeable, battery operated devices like razors and flashlights that can be plugged directly into an AC receptacle to recharge. Some chargers for battery packs used in power tools also should not be used with an inverter. These chargers typically have a warning label indicating that dangerous voltages are present at the battery terminals. Only a true sine wave inverter should be used with these types of appliances. Damage to the device could result if you attempt to use them with any type of modified sine wave inverter. Do not use this power inverter with the above devices.

Package Includes Inverter (STP-1000T) Cables This manual

Needed for Installation (not included) Mounting hardware for the inverter 12 volt DC power wiring, fuse block and connectors Tools – Drill and drill bit, small socket set, wire crimpers, volt meter Optional: wiring kit from Sima Model SK-200

page 4

Overview of the Power Inverter The STP-1000T power inverters are electronic devices that convert the low voltage 12 VOLTS DC from a battery or other power source to 115 VAC to run standard household appliances. See the section on How it Works to learn more about the technology used in these power inverters.

DC Side (12 VOLTS Input) AC Side (115 VAC Output) STP-1000

Figure #1, DC and AC Sides of the STP-1000T Inverter

page 5

Installation

Installation Overview There are three basic steps you need to follow when installing the power inverter. 1) Mounting: Mount the inverter securely 2) Wiring: Wire the inverter to a 12 VOLT source 3) Testing: Test for proper operation

Step #1: Mounting the Inverter The power inverter should be secured to a solid flat surface capable of handling the weight of the unit. It is very important that the unit be secured using the proper size mounting hardware (not included) to keep the unit from moving around or becoming loose in emergency situations. The power inverter should be placed with space around the unit for proper ventilation. Do not block the air entrance to the fan or block the exhaust holes located on the side or bottom of the unit. The unit must be mounted in a dry, cool area. Do not allow water to drip or splash onto the inverter. The ambient air temperature should be between 32 deg F and 75 deg F. The unit must not be mounted in an area with batteries or in any area capable of storing flammable liquids such as gasoline. To minimize cable lengths, the unit should be mounted as close as possible to the battery, but not in the same compartment. If you have a choice, it is better to run longer AC wires than DC cables.

Caution: The power inverter must be mounted securely in any type of moving vehicle. In an emergency situation, if the power inverter is not securely mounted, it could cause bodily injury

Figure 2, Mounting the power inverter

page 6

Step #2: Wiring Inverter to 12 volt Power The power inverter requires connection to a standard 12 volt DC power source as found in most cars, trucks, RVs and boats. The power source must provide between 11 and 15 volts DC. The power source must be able to provide sufficient current to power the load. See the chart below that shows minimal wire sizing and current draw at full load.

Inverter Model Current at rated power

Suggested User Installed 12 volt Fuse Size

Suggested Wire gauge, less than-10’

Suggested Wire gauge, 10’ to 25’

STP-1000T 94 Amps 100A 2 AWG 0 AWG

Wire Size Chart Always connect the positive, red (+) terminal to the positive connection and the negative, black (-) terminal to the negative or ground side of the power system.

WARNING Failure to connect the correct polarity may cause damage to the power inverter

and/or your electrical system and is not covered by the warranty.

Installation Tip To minimize electrical interference, keep the DC power cables as short as possible

and twist them with 1 to 3 twists per foot. This minimizes radiated interference from the cables.

page 7

Permanent Installation Figure 3, Wiring the STP-1000T power inverter

Caution: Always use adequate wire size and fusing for any installation

Wiring Steps • Disconnect the positive battery terminal before doing any wiring to the inverter. • Using proper sized copper wire and proper terminations, wire the inverter to the electrical

system and fuse block. See your local RV dealer or automotive shop for wire, connectors, fuse block and other wiring parts. Tighten all connections firmly, but do not over tighten. Remember to recheck all connections every few months of operation.

WARNING Do not operate the power inverter without a fuse installed.

page 8

• Double check all wiring for proper polarity. • Install the fuse and reconnect the wire to the battery. Note, a slight spark and beep from the

inverter is normal when the unit is first connected to 12 volt power.

Advanced Installation Large inverters can draw high currents from your battery and charging system especially when used with appliances and tools that use a lot of power. In these applications, you may need to increase the capacity of your 12 volt system. There are several ways to do this.

High Capacity Batteries You can purchase high capacity batteries that are specially designed for deep discharge operation. Contact your automotive or RV specialist for more information. Multiple Batteries In systems with more than one battery, you typically wire the system with the batteries in parallel (negative to negative and positive to positive) with a battery isolator between the positive terminals. The isolator allows a single alternator to charge all batteries but lets the inverter only use the second battery so the vehicle’s battery is not discharged during operation. Contact your automotive or RV specialist for more information about battery isolators and wiring. Larger Alternator Typical automotive alternators may not be able to supply the power required for continuous operation of the inverter at high power usage. Contact your automotive or RV specialist for more information about larger output alternators.

Step #3: Testing the Power Inverter After you make sure the 12 volt power is wired properly to the power inverter, with nothing plugged into the 115 VAC outlets, turn the power switch on the power inverter to On. The green POWER light will light. Note: If the inverter does not operate properly and the POWER light does not illuminate, turn the power switch off and check your wiring and external fuse. With the inverter turned off, plug the appliance you want to use into the 115 VAC power outlet on the unit. Turn the power switch on the power inverter on so the green POWER light is illuminated. Turn on the appliance. The appliance should now be operational. Check the Troubleshooting section if you have any difficulties.

Operation

Equipment Power Usage It is important to use only products that draw less than the power rating of the power inverter. Use of products greater than the rated power rating may either cause the protection circuitry of the power

page 9

inverter to shut down or the fuse to blow. Repeated use of excessive power draw can cause failure of the power inverter. How to calculate power usage. Most products have a power rating on them such as 45 watts. Others may be marked with their current draw, such as .9 amps. To convert the current to watts multiply the current by 115. (Example: .9 amps x 115 = 104 watts)

Typical Power Usage Chart Typical Appliance Current Draw TV/VCR combo 120 watts 19” TV 160 watts Blender 650 watts Small power drill 3/8” 500 watts Toaster 850 watts Vacuum 900

Some products draw a high surge current to start up. If the appliance does not operate and the inverter turns off, you may need a larger inverter. Also, check that the battery and the 12 volt wiring to the inverter is large enough to handle the current draw and that the battery is fully charged.

Important: The power inverters may not operate some appliances designed to produce heat such as hair dryers, heaters, toasters and coffee makers. Always check the power rating before using these kinds of products to be sure they do not exceed the power capability of the inverter.

Battery Life Important: The power inverter can draw lots of amps from your car’s battery when operating. If you are using it for extended periods of time, you will want to operate your car occasionally to maintain the charge in your car’s battery. In addition, the power inverter will also draw a small current, less than 0.1 amp, when turned off and not operating. Therefore, it should be disconnected from your car’s battery if your vehicle will not be used for more than a day. The following chart shows typical operation time for typical car batteries with the engine not running for various loads. Check the size of your battery.

page 10

Battery Life Chart Power Usage

Approximate 12 volt Current

Typical operation time with 50 amp-hour car battery

Typical operation time with 100 amp-hour car battery

100 watt 9 Amps 5.5 hours 11 hours 200 watt 19 Amps 2.6 hours 5.2 hours 500 watt 47 Amps 1 hour 2 hours

Actual Current Draw Approximate 12 volt current draw is the load in watts divided by 10. Thus a 60 watt light bulb plugged into the inverter will cause the inverter to draw 6 amps (60 / 10 = 6) from the 12 volt supply. Batteries are rated in several different ways:

Peak cranking amps - This has little to do with how long an inverter can supply power, so it is not a useful number for inverter operation.

Battery reserve capacity - This number shows how long a battery can supply a given current, typically 25 amps, before the battery voltage reaches a low voltage. Therefore, a battery rated at 200 minutes reserve can deliver 25 amps for 200 minutes before it is discharged.

Ampere-hour capacity - This rating indicates how many amps a battery can deliver over a period of time, typically 20 hours. Therefore, a 100 amp-hour battery can deliver 5 amps for 20 hours (5 x 20 = 100).

Actual operating time from a battery will depend upon the current draw from the battery. A

battery will deliver less total power (energy) as you draw higher amps. A 100 amp-hour battery can deliver 5 amps for 20 hours (100 amp-hours) but it will only deliver 50 amps for 1 ½ hours (50 x 1.5 = 75) or 75 amp-hours at the higher rate.

Also remember, battery life is decreased if the battery is discharged fully. Lead acid batteries have the longest life, if they are kept fully charged.

Lights and Alarms POWER Indicator (Green) This light will illuminate when the inverter is turned on and is operating normally. If this light goes out the 12 volt power is missing (possible blown fuse). These fault conditions include output overload, output short circuit, low input voltage and over temperature of the unit. This can happen if a device has a large turn on surge, if an appliance (like a drill or saw) is stalled or if the inverter does not have a supply of cool air.

Fault Indicator (Red) Fault conditions include output overload, output short circuit, low input voltage and over temperature of the unit. This can happen if a device has a large turn on surge, if an appliance (like a drill or saw) is stalled or if the inverter does not have a supply of cool air.

Fuse Replacement If you overload the power inverter, it is possible that the external fuse might blow. Always determine the cause of the fuse blowing and remedy the problem before using the power inverter again.

page 11

How the Inverter Works

The Sima Products Corporation power inverter has two electronic sections. The first section converts 12 volts DC to approximately 160 volts DC using modern high frequency conversion techniques that uses small lightweight efficient transformers. The second section converts the 160 volts DC to 115 VAC using high efficiency power MOSFET transistor devices. The inverters generate a modified sine wave that works with almost every product on the market.

CAUTION: Do not use the following products with an inverter with a modified sine wave output.

Small battery operated devices like razors, flashlights and night lights that can be plugged directly into an AC outlet to recharge

A few battery chargers for power tool battery packs that have warnings about high voltage present on the battery terminals.

Smooth Start The Smooth Start feature of the STP line of power inverters is designed to handle the power surge that is created when some appliances are turned on. This feature helps protect both the appliance and the inverter from excessive power draws and surges. When the power switch is turned on, the STP inverter smoothly brings up the AC power. This circuitry also activates under excessive loads, even short circuits, to quickly turn off power to protect the device and the inverter. The STP inverter then attempts to smoothly bring up the AC power, unless it detects an excessive load.

page 12

Troubleshooting

Problem Cause Solution Unit does not operate Input voltage is below

10 volts Attach to proper supply

Fuse blown Determine cause for fuse blowing and then replace fuse feeding inverter.

Unit operates for a short period and then turns off

Load is trying to draw too much current

Be sure load is less than rated watts of inverter. Remove excessive load. Turn inverter off and back on to reset.

Unit operates for a while and gets warm

Inverter is in thermal shutdown mode

Allow inverter to cool down. Turn inverter off and back on to reset.

Low battery alarm is on

Input voltage is below 10.2 volts

Make sure car engine is running. Check condition of wiring. Battery may be low and needs

recharging. Television and stereo

interference RF interference from

power inverter Position the power inverter and

wiring as far as possible from electronic equipment, antenna and cables and reorient as necessary.

115 VAC Output

voltage reads incorrectly

Modified sine wave output can cause incorrect reading on a typical multimeter

Use a true RMS meter like a Fluke 8060A or Triplett 4200 to measure correct voltage.

Light Status Chart

Power Switch

Power Light

Beeper Fan Fault Light Mode

Off Off Off Off Off Unit is off On On Off On Off Normal Operation On On On On Off Low input voltage, 10.2 to 9.7 volts On On On On On Low input voltage, less than 9.7 volts On On Off On On High Input voltage, greater than 15V On On Off On On Unit over temperature or overloaded On Off Off Off Off No 12 VOLTS input to inverter

page 13

Product Specifications

Key Features STP-1000T Input 12 - 15 volts DC Input no-load current < .6 A Output type modified sine wave Output, Watts, 10 minutes continuous

1,000W 800W

Output, peak 2,000W Frequency, +/- 1% 60 Hz Efficiency 85 - 90% Outlets 2 Protection

Thermal Low battery alarm (10.2v) Low battery shutdown (9.7v) Output short circuit Over voltage (15V)

yes yes yes yes yes

Size (inches) 3” x 4.75” x 13” Weight: unit/gross 7.1/11 lb Package Includes: User Manual Cables with ring terminals

yes

yes (2.5’)

page 14

Limited Warranty Sima Products Corporation (“Company”) warrants that if the accompanying product proves to be defective to the original purchaser in material or workmanship within 90 days from the original retail purchase, the Company will, at the Company’s option, either repair or replace same without charge (but no cash refund will be made). If the product is returned within three (3) years from the original date of purchase, the Company will repair or replace the unit, however, a standardized labor-only fee will be charged. The Company will not charge a fee for any parts used in the repair. The Company will notify you of any fees to be assessed prior to servicing the unit. What you must do to enforce the Warranty: You must deliver, mail or ship the product, together with the original bill of sale, this limited Warranty statement as proof of warranty coverage to: Sima Products Corporation Attn: Customer Service 140 Pennsylvania Ave., Bldg. #5, Oakmont, PA 15139 Call customer service (800-345-7462) before sending the unit in for service.

Limitation of Liability and Remedies

Sima Products Corporation shall have no liability for any damages due to lost profits, loss of use or anticipated benefits, or other incidental, consequential, special or punitive damages arising from the use of, or the inability to use, this product, whether arising out of contract, negligence, tort or under any warranty, even if Sima Products Corporation has been advised of the possibility of such damages. Sima Products Corporation’s liability for damages in no event shall exceed the amount paid for this product. Sima Products Corporation neither assumes nor authorizes anyone to assume for it any other liabilities. Sima Products Corporation 140 Pennsylvania Ave Bldg #5 Oakmont, PA 15139 USA

800-345-7462 Sima Products Corporation ©2003 P/N #21687

page 15

Index

TN/TS-1500 Instruction ManualInverter

1. Safety Guidelines 1

1

2

2

3

3

5

9

12

14

17

17

12

13

4

3

4

5

6

8

9

9

10

12

2. Introduction

3. User Interface

4. Explanation of Operating Logic

5. Initial Setup of TN/TS-1500

6. Protection

7. Installation & Wiring

8. Failure Correction Notes

9. Warranty

2.1 Features

3.2 LED Indicator on Front Panel

3.1 Front Panel

2.2 Main Specification

2.3 System Block Diagram

3.3 Functional Indication andAlarm

3.4 Rear Panel

4.1 Explanation of UPS Mode Control Logic

4.2 Explanation of Energy Saving Mode Control Logic

5.1 Initia l State

5.2 Initia l Set Point for Transition Voltages

5.3 Procedure of Setting Operating Mode, Output Voltage,

5.4 Remote Monitoring Software

Frequency, and Saving Mode

6.1 Input Protection

6.2 Output Protection

...............................................................................

........................................................................................

........................................................................................

........................................................................

..................................................................

......................................................................................

....................................................................................

......................................................

................................................

....................................................................................

..................................................................................

...............................................................

......................................................

.......................................................

...........................................................................................

...........................................................................

........................................................................

..........................................................................

...................................................................

.............................................................................................

.....................................

........................................................

....................................

...................

Feb. 2013 Version 13

Inverter InverterInverter Inverter

1

Don'tdisassemble

Away frommoistu re

Away from fire orh igh temperature

Don't stack onthe inverter

Keep goodventilation

1.Safety Guidelines (Please read through this manual before assembling

TN/TS-1500)

‧Risk of electrical shock and energy hazard. All failures should be examined bythe qualified technician. Please do not remove the case of the inverter by

‧After connecting the AC input of the inverter to the utility, the AC out let of the

‧It is highly recommended to mount the unit hor izontally.

‧Please do not install the inverter in places with high moisture or near water.

‧Please do not instal l the inverter in places with high ambient temperature or

‧Please only connect batteries with the same brand and model number in one

‧Never allow a spark or f lame in the vicinity of the batteries because they may

‧Make sure the air flow from the fan is not obstructed at both sides (front and

‧Please do not stack any object on the inverter.

‧Fully digital controlled by an advanced CPU, TN-1500 is a true sine wave

‧TS-1500 series only possess the inverter function. It uses batteries as the input

‧TN-1500 is capable of drawing energy from solar panel thus provide

yourself!

inverter will have AC output even if the power switch on the front panel is in the

OFF position .

under direct sunlight.

battery bank. Using batteries from different manufacturers or different capacity

generate explosive gases during normal operation.

back) of the inverter. (Please allow at least 15cm of space)

inverter equipped with an AC charger and solar charger. It can also operate

source and converts the energy intoAC output.

uninterrupted power (UPS mode). Besides providing uninterrupted power, i t

also has user adjustable energy saving mode. The main purposes of energy

reduction and building an independent sub power stat ion are realized. We can

say tha t TN-1500 se r ies is a mult i - funct iona l and designed to be

environmentally friendly.

under UPS and Energy saving modes. (Descriptions which are high lighted

represents functions only for the TN-1500 series)

is str ictly prohibited!

2.Introduction

WARNING:It is suggested to execute regular battery maintenance

Batteries will have aging problem after years of operation.

(e.g. every year). Once aged, the batteries should be changed

by professional technician, or the failed batteries may cause

fire or other hazards.

2.2 Main Specification

2.1 Features

‧True sine wave output (THD<3%)

‧Selectable UPS or Energy saving mode

‧1500W rated output

‧High effic iency up to 90%

‧Complete LED indication for operating status

‧Battery low alarm and indicator

‧Surge power capability up to 3000W

‧Output vo ltage / frequency selectable

‧Fully digi tal controlled

‧Compliance to UL458 / FCC / E / CE13

‧Can be used for most of electronic products with AC input

‧3 year global warranty

‧Solar charging current 30A max

‧Fast transfer time 10ms (Typ.)

1500W max. continuously, 1750W max. for 180 seconds, 1875Wmax. for 10 seconds,3000W for 30 cycle

INPUT

CHARGER

BAT. VOLTAGE

DC CURRENT

EFFICIENCY

OFF MODECURRENTDRAW

PROTECTION

CHARGEVOLTAGEAC CHARGECURRENTSOLAR OPENCIRCUITVOLTAGE

CHARGESOLAR

10.5 ~ 15.0V

150A

87%

14.5V

5.5A 0.5A±

25Vmax

30A max.

Under 1.0mA at power switch OFF

21.0 ~ 30.0V

75A

89%

29.0V

2.7A 0.4A±

45Vmax

42.0 ~ 60.0V

37.5A

58.0V

1.35A 0.2A±

75Vmax

10.5 ~ 15.0V

150A

88%

14.5V

5.5A 0.5A±

25Vmax

21.0 ~ 30.0V

75A

90%

29.0V

2.7A 0.4A±

45Vmax

42.0 ~ 60.0V

37.5A

91%

58.0V

1.35A 0.2A±

75Vmax

MODEL

Ratedpower

Output vol tage

Frequency

SurgeCurrentFactoryset ting

WAVEFORM

OUTPUT

PROTECTION

112 124 148 212 224 248

110V 60Hz

100 / 110 / 115 / 120V

True s ine wave (THD <3.0%)

AC short Overload Over Temperature、 、

230V 50Hz

200 / 220 / 230 / 240V

Over current battery polarity reverse by fuse battery low shutdown battery low alarm、 、 、

CURRENT

2

‧TN-1500 series will automatically detect the input sources (whether AC main or

‧With pure sine wave output, TN/TS-1500 can provide 1500W cont inuously,

solar panels exist) and then adjust its internal setting. Users can also set up the

operating mode, output voltage, frequency, and saving mode by themselves

based on their special needs, geographic area, and environmental conditions.

1750W for 3 minutes, or 20~40A of peak current for all kinds of load such as

inductive, capacitive, or resistive. General applications include PC, ITE,

vehicles, yachts , home appliances, motors, power tools, industrial control

equipments, AV system, and etc.. .

89%

60 0.1Hz± 50 0.1Hz±

3

2.3 System Block Diagram

Figure 2.1 System Block Diagram

TN-1500 Inverter

ACInput

ACOutput

AC charger

Solar charger

Battery

Fuse

Fuse

12V/24V/48VDC/DC

Converter

Solar Panel

EMIfi l ter

200V DC

CPUControll er

Polari tydetect

DC/ACInverte r

LOAD

120V/230V

Circui tBreaker

50Hz/60Hz/400VDC

LEDDisplay

A

B

C

D

E

F

G

3.1 Front Panel

POWER on/off switch: The inverter will turn OFF if the switch is in the OFF

AC output outlet: To satisfy application demand of d ifferent geographic areas

No Fuse Breaker; Reset: Under "Bypass Mode", when the AC output is

Ventilation holes: The inverter requires suitable ventilation to work properly.

Function Setting: Operating Mode, Output vo ltage, frequency, and saving

LED Indicating Panel: Operating status, load condit ion, and all types of

Communication Port: For remote monitoring purpose, the unit can be

position.

all over the world, there are many optional AC outlets to choose from.

shorted or the load current exceeds the rated current of the No Fuse Breaker,

Please make sure there is good ventilat ion and the l ifespan of the inverter can

mode can be set through this button.

warnings will be displayed on this panel.

connected to a PC through this communication port by using the optional cable

and monitoring software.

preserved.

the No Fuse Breaker wi ll open and that stops bypassing energy from the utility

getting to prevent poss ible danger. When the abnormal operating condit ion is

removed, user can press down on the Reset button to resume operation.

3.User interface

4

3.2 LED Indicator on Front Panel

3.3 Function Indication and Alarm

LED 1 ON

LED 1 ON

LED 1~ 2 ON

LED 1~ 2 ON

LED 1 ~ 3 ON

LED 1 ~ 3 ON

LED 1 ~ 4 ON

LED 1 ~ 4 ON

BatteryCapacity

BatteryCapacity

LED Display

LED Display

0 ~ 25% 26 ~ 50% 51 ~ 75% 76 ~ 100%

AC OUTPUTSOLAR CHARGE

AC CHARGE

B F

A

C

BATTERY100

0

1 00

0

Saving

Ba t Low

On

Se ttin gLOA D

INV ERTER

BY PAS SAC I N

E

G

Figure 3.1: Front Panel (TN-1500)

D

ON

OFF

Remoteport

0 ~ 30% 30 ~ 50% 50 ~ 75% 75 ~ 100%

Battery Capacity Indicator: represents the remaining capacity of external

◎On : The inverter started up and output is normal.

◎ Bat Low : Voltage of external batteries is too low. The inverter will send out

◎ Saving : The inverter is operating under the "Saving Mode" and there's no

a "Beep" sound to warn the users.

AC output.

batteries.

Load Condition Ind icator: represents the magnitude of output loads.

◎AC CHARGE : The built- in AC charger is charging external batteries.

◎ SOLAR CHARGE : The external solar panels are provid ing energy to the

◎ AC IN: The status of utility is normal.

◎ BYPASS: The unit is working under "Bypass Mode". The AC electricity

◎ INVERTER: The unit is working under "Inverter Mode" The AC electricity

◎BATTERY: Display the remain ing capacity of external batteries.

◎LOAD: Display the output load status.

external batteries through the built-in solar charger.

consumed by the loads is provided by the utility instead of the inverter.

consumed by the loads is converted from the batteries .

3.4 Rear Panel

Battery input (+), (-) .

Uti lity / AC inlet (IEC320).

Solar panel input terminal.

Frame ground (FG).

A

B

C

D

Fig 3.2: Rear Panel (TN-1500)

5

4.Explanation of Operating Logic

TN-1500 (CPU control led inverter) is des igned to achieve the goal of energy

saving and possesses both UPS and Energy saving modes. These 2 modes are

user adjustable. The unit will be factory set in the UPS mode. Depending on

weather and util ity conditions, users can manually adjust or use the monitoring

software to switch to the Energy sav ing mode.

The main difference between UPS and Energy saving mode is the amount of

energy conserved. Under the UPS mode, the unit will remain in the Bypass mode

as long as utili ty is available. Thus less energy is conserved (refer to Fig. 4.1 for

UPS mode control logic). Under the Energy saving mode, the priority of input

source chosen is solar panel AC main battery. If available, the CPU will select

external solar panels as its first priority in order to conserve energy. In case of

insufficient solar power and uti lity failure, battery power will be drawn as the last

resort. When the capacity of batteries is around 10~20%, the CPU will remind

end users by continuously sending out warning siren unt il the system shuts down.

BA

D

C

AC INPUT

Chassis

Ground

Reverse PolarityWill Damage The

Uni t.

Solar Input(30A max)

NEG POS

DC

INPUT

Cat .No.(1GG1HS-212 )Wire Ran ge(10-4AWG StrCu So ldered Wires )Torque ( 17.7 -26.5 in lb)

6

4.1 Explanation of UPS Mode Control Logic

ON

28.5V

26.5V

28.5V 28.5V

ON

OFF

ONON

By passmode

InverterMode

Batteryvoltage

ON

OFF

Solar chargerstate

AC chargerstate

ON

OFF

ON

OFF

OFF

26.5V

28.5V

OFF

ON

29.0V

ON

OFF

OFF

ON

Power-On Re-power-on

21V(Shut-down)

t

t

t

t

t

UtilityPower

ON

OFF

22.5V(Alarm)

ON

OFF

OFF

OFF

ON

OFF

ON

OFF

25.4V

t1 t2 t3 t4 t5 t6 t8 t9 t10 t11 t12t7

26.5V

Figure 4.1: Diagram of UPS Mode Control Logic

t1: To ensure the battery is at full capacity, when the TN-1500 is turned on, the

t2: When the batteries are full (battery voltage around 28.5V), both the AC and

CPU will execute the "Bypass Mode" automatically connecting the AC main to

the load. In the meantime, it will activate both the AC charger and solar

solar charger will be turned off by the CPU to prevent overcharging and

reducing the battery lifetime. In the meantime, the system will remain in the

"Bypass Mode" and AC electricity provided to the loads is coming from public

utility.

charger to simultaneously charge the batteries.

7

t3: At this time period, TN-1500 is still in the Bypass mode. The battery voltage

t4: If the energy provided by the charger is larger than what is consumed by the

t5: Since the chargers are in the OFF mode, the battery voltage will gradually

t6: Once utility recovers, the CPU will switch back to the bypass mode.

t7: When battery voltage drops to below 26.5V, the battery charger will be

t8: Same as t4.

t9: Due to lack of utility, TN-1500 will switch to the inverter mode. AC charging

t10: As the battery discharges to below 26.5V and ut ility remains unavai lable.

t11: Same as Energy Saving mode.

t12: When solar charger is providing current of larger than 3A, the vo ltage level of

level will decrease gradually due to standby power dissipation. When the

batteries are consumed to around 75% of their capacity (battery voltage

around 26.5V) the CPU will restart the charger. The CPU will use charging

current of 3A as a guide point. When the provided charging current is under

3A, the AC charger wil l be turned ON (e.g. Night time or cloudy day). As for

load, voltage of battery bank will increase gradual ly until 28.5V is reached

then the CPU will be shut off the charger to prevent overcharging. At this

decrease to the range of 26.5~28.5V (floating voltage level). If utility were to

fail at this moment, the CPU will automatically switch (<10ms) to the inverter

mode insuring uninterrupted power.

activated to charge the battery bank (refer to t3 for detailed description).

function wi ll be turned off. Since AC output relies purely on battery power, the

Only the solar charger is turned ON. The battery bank could be depleted

rather quickly.

the battery bank will r ise slowly. Once the battery vol tage reaches inverter

mode reactivation level, the inverter wi ll be revived.

battery bank wi ll be depleted rather quickly.

charging current of over 3A, the solar charger wi ll be turned ON instead.

point, output load is stil l supplied by utili ty.

4.2 Explanation of Energy Saving Mode Control Logic

ON

OFF

28.5V

26.5V

28.5V

22V

28.5V

ON

OFF

ONON

OFF

Bypassmode

Invertermode

Batteryvoltage

ON

OFF

Solar chargerstate

ON

26.5V

ON ON

OFF

OFF

26.5V

28.5V

OFF

ON

ON

OFFOFF

ON

21.0V (Sh ut-down)

t

t

t

t

Uti lityPower

Power-On

ON

OFF

22.5V(Alarm) 22.5V

(Alarm)

AC chargerstate

t1 t2 t3 t4 t5 t6 t7 t8

OFF OFFt

F igure 4.2 Diagram of Energy Saving Mode Control Logic

8

t1 : When the TN-1500 is turned on, CPU will execute the "Bypass Mode"

t2 : When the batteries are ful l (battery voltage around 28.5V), both the AC and

t3: When the batteries are depleted to around 75% of their capacity (battery

t4: If the energy provided by the solar panels is larger than the load requirement,

automatically connecting the AC main to the load. In the mean time, it will

activate both the AC charger and solar charger to simultaneously charge the

solar charger will be turned off to prevent overcharging and reducing the

battery lifetime. In the meantime, the system wil l switch to the "Inverter Mode"

and the AC electric ity provided to the loads will be coming from the batteries.

voltage around 26.5V), CPU will restart the solar charger but not the AC

voltage of battery bank will increase gradually unt il reaching 90% capacity

(battery vo ltage around 28.5V) and then the solar charger will be shut off to

charger to achieve the purpose of energy-saving.

prevent the batteries from overcharg ing.

batteries.

9

Factory Setting

AC ChargerTransit ion Voltage

AC ChargerStart Up Voltage

Solar ChargerStart Up Voltage

112 212 124 224 148 248

14.3V

11V

13.3V

28.5V

22V

26.5V

57V

44V

53V

Solar ChargerShut Down Voltage

Inver terShut Down

14.3V

10.5V

28.5V

21V

57V

42V

t5: When the capacity of batteries go down to about 75% (battery voltage around

t6: If the energy provided by the solar panels is lower than consumed by the loads,

t7: If the power consumption of the loads does not decrease and the AC main is

t8: When lacking AC main, the CPU will shut down the whole system if the capacity

26.5V), solar charger will restart and begin charg ing.

the users to take proper act ion.

"Solar Charger" charge the batteries to achieve the goal of energy-saving.

the CPU will provide LED indication to the user know why the inverter has shut

off .

requiring powering the inverter OFF and ON.

voltage of battery bank will decrease gradually to 20% of its capacity

(battery voltage around 22V), the built-in buzzer will be activated and inform

normal, CPU will detect this and the unit will be transferred to "Bypass Mode".

The ut ility will provide energy to the loads and charge the battery bank at the

same time in order to prevent the unit from shutting off. If the solar current is

higher than 3A, the CPU will not activate the "AC charger" and just let the

of external battery bank is less than 10% (battery voltage around 21V)

in order to prevent over-discharging and reducing its lifetime. After shut down,

5. Initial Setup of TN/TS-1500 (Operating Mode, Output Voltage, Frequency,

and Saving Mode)

TN/TS-1500

5.1 Initial State

5.2 Initial Set Point for Transition Voltages

The ini tial state of TN/TS-1500 is 120Vac/60Hz or 230Vac/50Hz and both the

"UPS mode" and "Saving Mode" is activated. If the users need to revise it for

certain application, it can be done through the setting button on the front panel

(Please refer to section 5.3). The unit will start up automatically after the

setting procedure is finished and the new sett ings will be executed. These

new settings will be kept even if AC, battery, and solar is disconnected or

occurrence of fault conditions leading to failure of output voltage thus

Energy Saving

Mode

UPS Mode

Bat Low

Bat Low

Saving

Saving

On

On

● Light

○ Dark

★ Flashing

●

★

★

★

★

○

Table 5.1 Operating Mode

Figure 5.1: Adjustment of Output Mode, Output Voltage,

Frequency, and Saving Mode

Use an insulated stick to

press th is setting button

ON

AC OUTPUTSOLAR CHARGE

AC CHARGE

OFFBATTERY

100

0

10 0

0

Saving

Bat Low

On

Settin gLOAD

INVERTER

BY PASSAC IN

Remoteport

10

5.3 Procedure of Setting Operating Mode, Output Voltage, Frequency, and

Saving Mode

Note: TS-1500 does not have Step 3~5.

STEP 1: The inverter should be turned off while resetting. Input batteries

STEP 2: Use an insulated stick to press the setting button and then turn on the

STEP 3: Please refer to Table 5.1 and check the LED status to see if the

STEP 4: The LEDs will change state by pressing the setting button for 1

STEP 5: After selecting the Operat ing Mode, press the setting button for 3~5

STEP 6: Please refer to Table 5.2 and check whether the combination of

should be connected, AC main can either be connected or

power switch. After pressing for 5 seconds, the inverter will send out

Operating Mode is the one you need. If yes, please skip to STEP 5.

second and then release. Operating Mode can be adjusted as

seconds and the inverter will send out a "Beep" sound. The button

output vol tage and frequency is the one you need. If yes, please skip

to STEP 8. If change is required, please follow STEP 7~11.

can be released and you can go on to the setting section of

"Voltage/frequency."

required.

If change is required, please follow STEP 4~11.

a "Beep" sound. Users can release the button and go into the setting

procedure.

disconnected, and the loads should be removed.

Bat Low

Bat Low

Saving

Saving

On

On

Table 5.3 LED Indication for Saving Mode ON/OFF

● Light

○ Dark

★ Flashing

●

★

★

★

★

○

Figure 5.2: State Circu lation Diagram of Output Voltage and Frequency

Table 5.2 : LED Indication of Output Voltage / Frequency Combination

50Hz

60Hz

100Vac 110Vac 115Vac 120Vac

(200Vac)

●On

On

●

●

●

●

●

●● Light

●○ Dark

●●●●

○Bat Low

Bat Low

○

○Saving

Saving

○

★ ★ Flashing★★★

○ ○

○ ○

(220Vac) (230Vac) (240Vac)

OutputVoltage

Frequency

100Vac(200Vac)50Hz

110Vac(220Vac)50Hz

115Vac(230Vac)50Hz

100Vac(200Vac)60Hz

120Vac(240Vac)50Hz

120Vac(240Vac)60Hz 110Vac

(220Vac)60Hz115Vac(230Vac)60Hz

Sav ing Mode

ON

Saving Mode

OFF

11

STEP 7: The LEDs will change state by pressing the setting button for 1

second and then release (refer to Figure 5.2). Please select the

combination of output voltage and frequency you need.

STEP 8: After selecting the output vol tage and frequency, press the setting

STEP 9: Please refer to Table 5.3 and check whether the "Saving Mode" is set

button for 3~5 seconds and the inverter will send out a "Beep"

as required. I f yes, please skip to STEP 11. If change is required,

please fol low STEP 10~11.

sound. The button can be released and it wi ll go into the setting

section for "Saving Mode."

12

STEP 10: The LEDs will change state by pressing the setting button for 1

STEP 11: After activat ing or canceling the "Saving Mode", press the setting

second and then release. You can activate or cancel the "Saving

button for around 5 seconds and the inverter will send out a "Beep"

sound. The button can be released and al l the sett ings are finished.

The inverter will automatically store all the settings and then start

to operate.

Mode" function by this adjustment.

5.4 Remote Monitoring Software

6.1 Input Protection

(A)Battery Polarity Protection: If the battery input is connected in reverse

(B)Battery Under Voltage Protection: When the battery vol tage is lower than

(C)Battery Over Voltage Protection: When the battery voltage is too high,

(D)Solar Charger Over Current Protection: The maximum charging current

Please choose suitable batteries that is within the rated input DC

voltage of TN/TS-1500 (refer to the SPEC). If the input DC voltage is

too low (ex. using 12Vdc battery bank for 24Vdc input models), TN/TS-

1500 can't be started up properly. If the input DC voltage is too high

(ex. using 48Vdc battery bank for 24Vdc input models), TN/TS-1500

WARNING:

will be damaged!

polarity, the internal fuse will blow and the inverter should be send back to

the preset value, the inverter will automatically terminate the output and

inverter will automatical ly terminate the output and the built- in buzzer will

of the built-in solar charger is 30A. I f the charging current is too high, the

internal fuse will blow and the inverter should be send back to MEAN WELL

for repair.

activate to inform the users. Please refer to Table 6.1 for more detail about

the failure signals displayed through the "Load Meter."

"Battery Low" signal on the front panel will light up. Please refer to Table 6.1

for more detail about the failure signals d isplayed through the "Load Meter."

MEAN WELL for repair.

(A)Users can also make Operating Mode, voltage/frequency, saving mode,

(B)DB9-USB conversion cable should not be used because it wi ll not be

and transition voltage adjustments by using this software. Software update

compatible with the monitor ing software.

can be downloaded from the MW website. Please contact us or our

distributor if you have any questions.

6. Protection

13

100

0

0

LOAD

100 10 0

100

100

0 0

0

LOAD LOA D

LO AD

LOAD

Table 6.1: Failure Messages On Front Panel

10 0

100

100

100

0

0

0

0

LOAD

LOAD

LOAD

LOAD

(>1875W)

OutputOverload

OutputOverload

(1500W~1750W)

Failure

Message

OutputOverload

Over

Temperature

(1750W~1875W)

LED

Indicator

LED

Indicator

AC Output

Short Circuit

Failure

Message

AbnormalAC OutputVoltage

AbnormalBatteryVoltage

6.2 Output Protection

(A)Bypass Mode: Uses "No Fuse Breaker" as automatic over current

(B)Inverter Mode: Under the "Inverter Mode", if any abnormal situation

(1)Over Temperature Protection: When the internal temperature is h igher

(2)AC Output Abnormal Protection: When the AC output voltage of the

(3)AC Output Short Circuit Protection: When a short circuit situation

(4)Battery Voltage Abnormal Protection: When the battery voltage is too

(5)Output Overload Protection: When output is overloaded between 1500W

protect ion. When over current occurs, the button of the circuit breaker on

occurs, the front panel will send out fai lure messages through the "Load

than the limit value, the "Over Temperature Protect ion" will be activated.

inverter is too high or too low, the unit will turn off and should be restarted

occurs at the output side of the inverter or the load increase greatly in a

high or too low, this protection will be activated. The inverter will auto-

~ 1750W, the inverter can continuously provide power for 3 minutes. After

that, if the overload condition is not removed, the overload protection will

be activated. When the load is higher than 1875W, the overload protection

wil l act ivate instant ly. For these overload protections, once activated, you

should reset the unit.

recover once the battery voltage go back to a safe level and users do not

need to restart it.

short period of time, the unit will turn off and should be restarted again.

again.

The unit will automatically turn off and should be restarted again.

Meter" (Please refer to Table 6.1).

the front panel will pop up and the inverter wil l shut down. At this time,

users should remove the loads, restart the inverter and press down on the

button of the circuit breaker and the AC output can now be provided

normal ly.

14

(B)Suggested Battery Type and Capacity

5A ~ 25A

Battery Type

BatteryCapacity

Lead-acid

12V / 120Ah ~ 24V / 60Ah ~ 48V / 30Ah ~

12V / 400Ah 24V / 200Ah 48V / 100Ah

112 212 124 224 148 248

TN/TS-1500

10A ~ 13A 1.25

1.5

2.5

4

6

10

16

25

35

50

16 Choosing suitable

wires based on therating of solar panels

and distance from

the inverter

14

12

10

8

6 Models us ing 48Vbatteries

Models us ing 24Vbatteries

Models us ing 12Vbatteries

4

2

1

0

13A ~ 16A

16A ~ 25A

25A ~ 32A

32A ~ 40A

40A ~ 63A

63A ~ 80A

80A ~ 100A

100A ~ 125A

≧125A

Cross-section ofLead (mm )

2Rated Current ofEquipment (Amp)

Table 7.1: Suggestion for Wire Selection

Input Current

from Solar Panel

(A)Wiring for Batteries: Wire connections should be as short as possible and

less than 1.5 meter is highly recommended. Make sure that suitable wires are

chosen based on Safety requirement and rating of current. Too small cross-

section wil l result in lower efficiency, less output power, and the wires may

also become overheated and cause danger. Please refer to Table 7.1 and

consult our local distributor if you have any questions.

7. Installation & Wiring

(C)Requirement of Installation:

The unit should be mounted on a flat surface or holding rack with suitable

strength. In order to ensure the lifespan of the unit , you should refrain from

operating the unit in environment of high dust or mois ture. This is a power

supply with bui lt-in DC fan. Please make sure the ventilation is not blocked.

We recommend that there should be no barriers with in 15cm of the ventilating

holes.

15

Solar Panel

LOAD

TN/TS-1500

Inverter

AC O/P

AC I/P DC I/P

- +

Chassis

Solar I/P

Wall or system FG

+ -

Battery

(D)Example of System Diagram

Figure 7.1: Example of Installation

>15cm

Inverter Air

>15cm

Air

As short as possible

Larger

Larger

than

than

15cm

15cm

Should less than 1.5m

Based on the actual length of wiring and

choose suitable cross-section of the leads

Where, the DC I/P and chassis f ix manner as following :

16

Chassis

0 10 20 30 40 50 60 70

20

40

60

80

100

21VDC 23VDC 30VDC (HORIZONTAL)

20

40

60

80

100

(E)Derating

Battery Input Voltage (V) - 24V ModelAmbient Temperature ( )℃

Figure 7.2: Output Derating Curve Figure 7.3: Input Derating Curve

1. Company Name : Mean Well Enterprises Co Ltd

2. Model Name : 1GG1HS-191

3. Rating : 150A

4. Torque : 106.2 Ib.in max.

5. Suitable Wire : Copper wire (temp rating : 75C )

6. Intended for termination onto a Listed ring tongue connector

7. To Be Sold Only With Installation Instructions

8. Amounting screw that is first inserted through the tang and is threaded

into the connector to secure the connector to the tang shall be torqued

to 32 in-lbs minimum

9. Mounting Screws - Plated Steel . Two provided, size M4

Cat.No.(1GG1HS-212)

Wire Range (10-4AWG

Str Cu Soldered Wires)

Torque (17.7-26.5 in lb)

(F) Notes on Output Loads:

TN/TS-1500 Series can power most of equipments that need an AC

source of 1500W. But for certain specific type of load, the unit may not

work properly.

(1)Since inductive loads or motor based equipments need a large start up

(2)When the output are capacit ive or rectified equipments (such as switching

current (6~10 times of i ts rated current), please make sure this start up

power supply), we suggest operating these equipment at no load or light

load condition. Increase the loads slight ly only after the TN/TS-1500 has

started up to ensure proper operation.

current is less than the maximum current capability of the inverter.

Malfunct ion of the charger

(no charging voltage)

Repair required. Please send it back

to us or any of our distributors

Clog with foreign objects Remove the foreign objectsFan doesnot sp in Malfunct ion of the fan

Repair required. Please send it backto us or any of our distributors

Short circuit protectionMake sure the output is not

overloaded or short circui t

Batteries are aging or broken Replace the batteriesDischargingperiod ofbatter ies istoo short

Battery capacity is too smallReconfirm the specification and enlarge

the battery capac ity as suggested

Status Possible Reasons Ways to Eliminate

Abnormal input

Check the AC or DC input sources.

Make sure the voltage is within the

required range.

No input (battery, AC main,or solar energy)

Make sure the wiring and polarityis correct.

Over temperatureprotection

Make sure that the ventila tion is not

b locked or whether the ambienttemperature is too high. Pleasederate output usage or reduce the

ambient temperature.

Overload protect ion

Make sure the output load does not

exceed the rated value or theinstantaneous start up current is not

too high (for inductive or capacitiveloads).

No AC outputvoltage

17

TN/TS-1500 should serviced by a professional technician. Improper usage or

modification may damage the unit or result in shock hazard. If you are not able to

clear the failure condition, please contact Mean WELL or any of our dis tributors

for repair service.

8. Failure Correction Notes

Three years of global warranty is provided for TN/TS-1500 under normal

operating conditions. Please do not change components or modify the unit

by yourself or MEAN WELL may reserve the right not to provide the complete

warranty.

9.Warranty

Owner’s Manual

Quiet Mobile PowerCongratulations! You’ve purchased the most advanced, feature-rich Inverter/Charger designed for recreational vehicle applications. Tripp Lite

RV Inverter/Chargers are the quiet alternative to gas generators—with no fumes, fuel or noise to deal with! You get AC electricity anywhere

and anytime you need it: rolling down the highway, dry camping in majestic back country or parked overnight at a money-saving non-electric

site. RV Inverter/Chargers provide your equipment with utility- or generator-supplied AC electricity (filtered through premium ISOBAR® surge pro-

tection) whenever available. In addition, your RV Inverter/Charger automatically powers your RV’s 12V system and recharges your connected battery

bank—doing what traditional RV converter/chargers do. Whenever power blackouts, brownouts or high voltages occur, your RV Inverter/Charger imme-

diately and automatically switches over to inverting battery output to power connected AC equipment.

Better for Your Equipment Premium Protection Levels

• Built-In ISOBAR® Surge Protection

• Automatic Overload Protection

Ideal Output for All Loads (including computers)

• Frequency-Controlled Output