Semiconductors for Micro and Nanotechnology--Introduction Fo

Introduction to metrology for micro- and nanotechnology · PDF fileCHAPTER 1 Introduction to...

-

Upload

trinhkhuong -

Category

Documents

-

view

224 -

download

0

Transcript of Introduction to metrology for micro- and nanotechnology · PDF fileCHAPTER 1 Introduction to...

CHAPTER 1

Introduction to metrology formicro- and nanotechnology

There are many stories of wonderful new machines and changes in life-

style that will be brought about by the commercial exploitation of micro-

and nanotechnology (MNT) (see, for example, references 1-3). However,

despite significant increases in funding for research into MNT across the

globe, the commercial success to date has not been as high as has been

predicted. At the smaller of the two scales, most work in nanotechnology is

still very much at the research stage. However, in the more mature world

of microsystems technology (MST) there is already a significant industry in

its own right. In fact, the MST industry has now matured to such an

extent that it is undergoing dramatic change and restructuring, along the

lines followed previously by conventional engineering and macro-scale

technology. Despite overall steady growth in the total market, particular

sectors and individual companies are experiencing difficult times; acqui-

sitions, mergers and even bankruptcies are becoming commonplace. It is

asserted that what the MNT industry needs is a standards infrastructure

that will allow fabrication plants to interchange parts, packaging and

design rules; effectively the MNT equivalent of macro-scale nuts and bolts

or house bricks. This will not stifle innovation; on the contrary, it will

allow designers and inventors to have more time to consider the innovative

aspects of their work, rather than having to waste time ‘re-inventing the

wheel’.

The results of recent government reviews [3] and surveys in Europe [4]

and the USA [5] clearly indicate that standardization is the major issue that

is hampering commercial success of the MST industry. This book considers

a subset of the metrology that will be required in the near future to support

a standards infrastructure for MNT. If interchangeability of parts is to

become a reality, then fabrication plants need to move away from ‘in-house’

or ‘gold’ standards, and move towards measurement standards and

Fundamental Principles of Engineering Nanometrology

Copyright � 2010 by Elsevier Inc. All rights reserved.

CONTENTS

What is engineeringnanometrology?

The contents of thisbook

References

1

techniques that are traceable to national or international realisations of the

measurement units [6].

Progress in MNT is not just of interest at the academic level. There is

a considerable advantage in being able to reach a sufficient number of markets

with new devices and materials to be able to recover development costs. There

is consequently much effort devoted not only to development of MNT devices

and materials, but also to maximising market uptake and transfer of tech-

nology from the research stage, through production, out to the commercial

marketplace. In many cases, examination of the barriers preventing successful

uptake of new technology reveals some areas of metrology where there needs

to be more research than is carried out at the moment. Also, metrology does

not just allow control of production but can allow legal, ethical and safety

issues [7] to be settled in a quantitative and informative manner.

There is a major thrust in standardization for MNT activities in many

national and regional committees. The International Organization for

Standardization (ISO) has recently set up ISO technical committee (TC) 229.

The IEC has also established TC 113 to complement electrical activities.

Recognising that there is an intersection between matter and radiation at the

MNT level, several of the working groups are collaborations between ISO and

IEC. The Joint Working Groups (JWGs) are divided into terminology and

nomenclature (JWG1), measurement and characterization (JWG2) and two

sole ISO WGs on health, safety and environment (WG3) and product spec-

ifications and performance (WG4). The main work of the committees so far

has been to define common definitions for nanotechnology and to issue

reviews of handling engineered nanomaterials in the workplace. Measure-

ment and characterization standards are currently being developed especially

for carbon nanotube analysis. This work is also being complemented by

activities in Europe that are coordinated by CEN TC 352. There are also

many well-established and related ISO committees that are not exclusively

MNT but cover aspects of engineering nanometrology; for example, ISO TC

213, which covers surface texture standards, and ISO TC 201, which covers

many of the standardization issues for scanning probe microscopes, and ISO

TC 209 (cleanroom technologies) is also forming a working group (WG10) on

nanotechnology considerations.

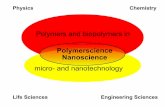

1.1 What is engineering nanometrology?

The field of engineering metrology relates to the measurement and stan-

dardization requirements for manufacturing. In the past, engineering

metrology mainly covered dimensional metrology, i.e. the science and

CHAPTER 1 : Introduction to metrology for micro- and nanotechnology2

technology of length measurement (see [8,9]). Modern engineering metrology

usually encompasses dimensional plus mass and related quantity metrology.

Some authors have also incorporated materials metrology into the fold [10]

and this is an important inclusion. However, this book will concentrate on

the more traditional dimensional and mass areas. This choice is partly to

keep the scope of the book at a manageable level and partly because those are

the areas of research that the author has been active in.

So, engineering nanometrology is traditional engineering metrology at the

MNTscale. Note that whilst nanotechnology is the science and technology of

structures varying in size from around 0.1 nm to 100 nm, nanometrology

does not only cover this size range. Nanometrology relates to measurements

with accuracies or uncertainties in this size range (and smaller!). For

example, one may be measuring the form of a 1 m telescope mirror segment

to an accuracy of 10 nm.

It is important to realise that there are many areas of MNT measurement

that are equally as important as dimensional and mass measurements. Other

areas not included in this book are measurements of electrical, chemical and

biological quantities, and the wealth of measurements for material proper-

ties, including the properties of particles. There are also areas of metrology

that could well be considered engineering nanometrology but have not been

covered by this book. These include the measurement of roundness [11], thin

films (primarily thickness) [12,13], the dynamic measurement of vibrating

structures [14] and tomography measurements (primarily x-ray computed

tomography [15] and optical coherence tomography [16]). Once again, the

choice of contents has been dubiously justified above!

1.2 The contents of this book

This book is divided into ten chapters. Chapter 2 gives an introduction to

measurement, including short histories of, and the current unit definitions

for, length, angle, mass and force. Basic metrological terminology is intro-

duced, including the highly important topic of measurement uncertainty.

The laser is presented in chapter 2, as it is a very significant element of many

of the instruments described in this book.

Chapter 3 reviews the most important concepts needed when designing

or analysing precision instruments. Chapter 4 covers the measurement of

length using optical interferometry, and discusses the concepts behind

interferometry, including many error sources. Chapter 5 reviews the area of

displacement measurement and presents most modern forms of displace-

ment sensor. The field of surface texture measurement is covered in the next

The contents of this book 3

three chapters, as it is a very large and significant topic. Chapter 6 covers

stylus and optical surface measuring instruments, and chapter 7 covers

scanning probe and particle beam instruments. Both chapters 6 and 7 include

instrument descriptions, limitations and calibration methods. Chapter 8

presents methods for characterizing surfaces, including both profile and areal

techniques. Chapter 9 introduces the area of coordinate metrology and

reviews the latest developments with micro-coordinate measuring machines.

Lastly, chapter 10 presents a review of the latest advances in low mass and

force metrology.

1.3 References

[1] Storrs Hall J 2005 Nanofuture: what’s next for nanotechnology (PromethiusBooks)

[2] Mulhall D 2002 Our molecular future: how nanotechnology, robotics,genetics and artificial intelligence will transform our future (PromethiusBooks)

[3] 2004 Nanoscience and nanotechnologies: opportunities and uncertainties(Royal Society and Royal Academy of Engineering)

[4] Singleton L, Leach R K, Cui Z 2003 Analysis of the MEMSTAND survey onstandardisation for microsystems technology Proc. Int. Seminar MEM-STAND, Barcelona, Spain, 24-26 Feb. 11–31

[5] MEMS Industry Group Report: ‘‘Focus on Fabrication,’’ Feb. 2003

[6] Postek M T, Lyons K 2007 Instrumentation, metrology and standards:key elements for the future of nanotechnology Proc. SPIE 6648 664802

[7] Hunt G, Mehta M 2008 Nanotechnology: risk, ethics and law (EarthscanLtd)

[8] Hume K J 1967 Engineering metrology (Macdonald & Co.) 2nd edition

[9] Thomas G G 1974 Engineering metrology (Newnes-Butterworth: London)

[10] Anthony D M 1986 Engineering metrology (materials engineering practice)(Pergamon)

[11] Smith G T 2002 Industrial metrology: surfaces and roundness (Springer)

[12] Tompkins H G, Eugene A I 2004 Handbook of ellipsometry (Springer)

[13] Yacoot A, Leach R K 2007 Review of x-ray and optical thin film measurementmethods and transfer artefacts NPL Report DEPC-EM 13

[14] Lobontiu N 2007 Dynamics of microelectromechanical systems (Springer)

[15] Withers P J 2007 X-ray nanotomography Materials Today 10 26–34

[16] Brezinski M E 2006 Optical coherence tomography: principles and appli-cations (Academic Press)

CHAPTER 1 : Introduction to metrology for micro- and nanotechnology4