integrated solutions in filament winding - 2017 r3 · for filament winding are e.g. drive and...

Transcript of integrated solutions in filament winding - 2017 r3 · for filament winding are e.g. drive and...

What can we do for you?

●

● Product development support

● Prototyping & small series

● Concept engineering

● High quality modular equipment

● Full production line integration

● System integration

● Turn-key project management

Feasibility studies

Autonational Composites BV designs and supplies innovative production solutions for leading manufacturers of composite parts in the aerospace, automotive and infrastructure markets.

Autonational Composites can integrate, automate, expand and upgrade any filament winding production process for high volume production; but also for low volumes that require high accuracy and reproducibility. Our solutions are based on our standard modular winder program or on a dedicated winding solution as per your specifications.

We are able to upscale & improve production capacity, efficiency (e.g. reduction of scrap), reliability and reproducibility. We offer advanced solutions for resin mixing and dosing, handling materials, mandrels & products, Track & Trace (e.g. RFID), throughput ovens and machining & test equipment.

As a competent development partner and system integrator we can cooperate in every step of your project, from feasibility study and concept design to turn-key delivery. We are able to offer prototyping activities and supply small series of products for validation. In addition, we design, integrate and supply vital test and rework/machining equipment.

Output, efficiency, quality, reliability and reproducibility are critical issues for many industries in order to reduce costs and increase competitiveness. Our turn-key approach makes it possible!

INTEGRATED SOLUTIONS IN FILAMENT WINDING“Autonational Composites, your “one-stop-shop” for filament winding automation''

AerospaceManufacturers increasingly incorporate advanced (thermoplastic) composite materialsto save weight and increase fuel efficiency. Aerospace (but also Space and Defence) products ideal for filament winding are e.g. struds, fuel pipes, actuator (drive) shafts, tanks, cones and all other cylindrical shapes.

AutomotiveComposites provide strength and reduce weight. Automotive products mainly usedfor filament winding are e.g. drive and transmission shafts, high-speed fly wheels, LNG/Hydrogen vessels, wheel rims, magnetic retention sleeves and other cylindrical shapes.

InfrastructureInfrastructure products suitable for filament winding are e.g. pipes, tanks, special couplings, elbows, poles, power pylons, tees and flanges and other cylindrical shapes. Especially used for products typically made from glass-fibre reinforced epoxy (GRE) and glassfibre reinforced polyester (GRP).

IndustryFinally, more and more composites can be found in a wide variety of industrial applications because of their customizable characteristics. Industrial products manufactured for filament winding are e.g. pipes, slide bearings, pressure vessels, tanks, insulators, sealings and other cylindrical shapes.

Our Markets

Autonational Composites BVDe Finne 2, NL-8651CW IJlst, NetherlandsPhone +31 515532325 Fax +31 [email protected]

This brochure only serves general information purposes, it may be subject to change at any time without prior notice. © Autonational Group 2016 r2

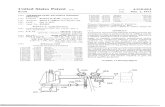

This turn-key project covers 3 fully automated composite production lines. Each line include a dedicated 2-spindle winding machine based on a robust CNC-platform. These lines integrate many functionalities like automated raw material handling & resin dosing, double winding process, curing, extraction, slitting, testing, mandrel preparation/cleaning & storage. Our equipment is designed for 24/7 reliable & maintenance-free operation, resulting in the lowest possible Total Cost of Ownership (TCO).

Our Automated Production Lines