Installing Cable Railings - torontodeckbuilder.com Cable Railings mounting, plus a cap rail that...

Transcript of Installing Cable Railings - torontodeckbuilder.com Cable Railings mounting, plus a cap rail that...

1 Professional Deck Builder • March/April 2007

InstallingCable Railings

Two specialty tools and a few techniquesexpand your design options

2 Professional Deck Builder • March/April 2007

Cable railing is much easier toinstall than many deck builders

think. Horizontal cables are runthrough holes drilled in railing postsand tightened with turnbuckles orstuds (connectors that grab the cableand tighten by way of a nut) untilthey “sing.”

Open and airy, cable railing virtuallydisappears, offering the client an unob-structed view and a clean, contempo-rary look. Stainless steel cable railing islow maintenance, long lasting, andfairly easy to install. With a little know-how, you can turn a nice profit.

Cable and PostsCable comes in 1⁄8-inch to 1⁄2-inch dia-meters, in 1⁄16-inch increments. Thesizes most often used for residentialapplications are 1⁄8 inch, 3⁄16 inch, and1⁄4 inch. When using very large posts,

such as 10-inch-diameter logs, youneed to balance the look of the railingby using the larger 1⁄4-inch to 1⁄2-inchcable. For commercial applications,3⁄16 inch is the smallest size allowed,but 1⁄4 inch is recommended.

To give you an idea of price, 3⁄16-inchcable runs around $.80 per foot whenpurchased in 100-foot rolls (it costsmore when purchased by the foot).

Posts can be made of a variety ofmaterials, such as wood, powder-coated steel, or powder-coated alu-minum (Figure 1). Cables should bespaced 31⁄2 inches or less apart, so a 4-inch sphere can’t pass between them(code requirement). This means thereare at least 9 cables on a 36-inch-highrailing, and since each cable exertsroughly 300 lb. of tension, the postsneed to withstand a minimum of2,700 lb. of pull. Posts require stout

Figure 1. Posts andrails can be a varietyof materials. Althoughwood is most com-mon, powder-coatedsteel or aluminum isa clean-looking alter-native. Componentscan be had from specialty vendors, orlocally sourced from a metal shop.

by Kim and Linda Katwijk

RA

ND

Y VA

RG

A

3 Professional Deck Builder • March/April 2007

Installing Cable Railings

mounting, plus a cap rail that spreadsthe load out from the anchor posts tothe intermediate posts (Figure 2).

Most wood 4x4 posts can withstandthese pressures. Because cedar is sosoft, however, you must use widerwashers at cable terminations to pre-vent the cable from pulling through —and you should consider using largerposts, such as 4x6s or 6x6s.

Steel posts can be 1-inch-by-3-inchflat bar, 2-inch-by-2-inch-by-3⁄8-inchangle, schedule-80 pipe, or 1⁄ 4-inchwalled tubing. With all steel posts, youneed to use sleeves of rubber, nylon, orstainless steel to separate the cablefrom the steel to prevent wear. Alumi-num posts of the same dimensions canbe used, except that 2-inch-by-2-inchangle must be beefed up to 1⁄2-inchthickness.

Do not attempt cable railing withsolid composite posts, as they will warpwhen the cables are tightened. Com-posite or plastic sleeves that fit over awood post, though, are fine.

Basic Framework

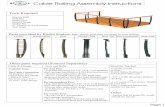

Stays are attached to deck and top railing

Corner post securely fastenedto deck and cap

Intermediate post to support cap, top railing

Cable spacingmax. 31⁄ 2"

Housewall

End post securely fastened to deck and cap

Min. 3" for attaching and tightening cables

Cap is run continuously

Top rail installed between posts

Max. cable spans to minimize cable deflection1⁄ 8" cable: 3'3⁄ 16" cable: 3'6"1⁄ 4" and larger: 4' Figure 2. Cable railings function as a system. Because the cables

exert a tremendous tension on the end posts, it’s critical to mountthe posts firmly to the framing, and brace between them with asubrail that’s capable of withstanding the pressure.

STAINLESS STEEL CABLE CONFIGURATION

Different configurations of stain-less steel cable vary in flexibility.

For example, semi-flexible 7x7 cablehas seven cords, each with sevenindividual wires, and it’s used forstraight runs and corners wherecable runs between multiple posts.The smooth cable preferred by mostcustomers is 1x19 rope, made bytwisting 18 wires around one centerwire. It’s semi-rigid, so 1x19 is usedfor straight runs and gentle turns.

Stainless steel is an alloy of iron

and carbon that contains between 12percent and 30 percent chromium.The chromium forms an oxide film onthe surface, which provides stainlesssteel its superior corrosion resis-tance. Good as it is, stainless steelin contact with chloride salts or sul-fides can discolor or rust.

Stainless steel comes in severalgrades. Type 303 contains sulphur toenhance its machinability. Typicalapplications include bolts, bushings,nuts, and shafts. The stainless most

widely used for aesthetic pur-poses is type 304, a low-carbon,general-purpose alloy. The mostcorrosion-resistant stainless steelcommonly available, type 316,contains more nickel and molyb-denum, and is used in marine en-vironments. This is the type mostoften used for cable railing.

7x7 cable 1x19 cable

4 Professional Deck Builder • March/April 2007

Installing Cable Railings

Post ConfigurationYou can use single-posted (Figure 3)or double-posted (Figure 4) corners.Post spacing should be determinedaccording to the strength of the toprail, which needs to withstand 200 lb.of pressure in any direction to meetcode (that’s in addition to being ableto help spread out the tension fromthe cables to the other posts). Mostrailing materials are limited to 6 feetor less, though with engineering, steelrailings can exceed 6 feet.

In most cases, the rail can span agreater distance than the cables. Thesmaller the cable, the closer the posts— no more than 36 inches betweenposts for 1⁄ 8-inch cable, 42 inches for 3⁄16-inch cable, and 48 inches for1⁄4-inch-diameter and larger cables. Ifyou want a more open look, you canavoid placing full-sized posts mid-span by substituting “stays” — thinnerpieces of steel, aluminum, fiberglass,or wood. The cables run through holesdrilled in the stays, which keeps thecables from spreading.

Because longer runs are harder totension, I try to avoid straight runs ofcable more than 80 feet long. For runs

Figure 3. When a cable has to turn a corner at a single post (left), one methodis to drill a curved hole through the post (A). Because there’s a lot of tensionon the inside corner of these posts, hardwood such as ipe is recommendedover soft cedar or pine. The second way around a single-post corner is fortwo cables to terminate at that post (B). For the cables to run at the samelevel, the hole for one cable stud must be angled to miss the other stud (C).

Single Post Single Post Double End

Figure 4. Double-post corners offer options. Set the posts within 4 inchesof each other, and the cable can terminate here, leaving an open spacebetween the posts (left). Alternatively, the cable can run through the poststo create a decorative corner (right).

Double Corner Posts with Pass ThroughDouble Corner End Posts

A B C

RA

ND

Y V

AR

GA

that have one or two 90-degree cor-ners or up to four 45-degree corners,40 feet or less is the rule of thumb.End posts need to be spaced awayfrom the building (Figure 5) to allowfor tightening the cable. When the faceof an end post is exposed, the ends ofthe studs are covered with a cap thatcan be removed for subsequent tight-ening (Figure 6).

When using post and rail materialsthat can be field cut, such as wood, I order all the railing componentsbefore building the deck. If I’m usinga welded steel or aluminum framewhose dimensions can’t be easilychanged, I order the frame after thedeck is built. I like having the flexibil-ity to make changes in the deck fram-ing without worrying about therailing being exactly right.

Cable ConnectionsTo lower costs, I have a local machineshop make my cable studs, and get mycable from a local supplier. The studsI use are 4-inch-long pieces of 1⁄ 4-inch303 stainless rod. The machine shopdrills a 1⁄ 8-inch hole down the centerof one end to a depth of 11⁄ 4 inch.The shop threads the other end for21⁄ 2 inches to take a 1⁄ 4x20 nut. Thestud slides over the cable and isswaged, or crimped, with an H.K.Porter swaging tool ($110; 919/362-1709, www.cooperhandtools.com).Swaging makes a permanent connec-tion (Figure 7).

Alternatively, the Atlantis Rail Sys-tem uses a mechanical swaging that isan integral part of its universal turn-buckle (Figure 8, page 6). Its balljoint and flange mount allows it to beused for straight runs, turns, or stairs.Tightening a cap nut secures thecable — no swaging tool needed, just awrench. The turnbuckle screws to theinside of the post, so it can be in-stalled tight to the building. Thescrew attachment also saves the time

5

Installing Cable Railings

Figure 5. Space end postsfrom the house to leaveroom for a wrench totighten the cables.

Figure 7. A swaging tool and a cable cutter are the onlyspecial tools required. A cable cutter cleanly snips multi-ple steel strands, and a swaging tool crimps connectorsonto cables for a connection that won’t pull free.

Cover plate5⁄ 8"x11⁄ 2" hole

Nut

Washer

1⁄ 4" hole

Cable stud

Cable

Figure 6. A removable cap protects peoplefrom the ends of the cable hardware whileallowing for maintenance tightening.

Single Post

Professional Deck Builder • March/April 2007

6 Professional Deck Builder • March/April 2007

Installing Cable Railings

spent on drilling the end posts. Atabout $14 each, it is the only commer-cial stud I’ve ever considered.

The cable end that doesn’t receive astud is anchored with a swaged cablestop and a washer that go on the farside of the last post (Figure 9). Cablestops are 1⁄ 2-inch-by-1⁄ 2-inch alumi-num tubes with a hole sized to fit thecable. If the posts are ACQ-treated lum-ber, use a stainless steel cable stop.

Preparing Posts for CableThe first step in installing a cable rail-ing is locating the posts, making surethey’re spaced to support both theupper railing and the cable. The postlocations dictate how to drill the posts.For example, single-post corners getholes that curve, while double-postedcorners are drilled straight through.Posts at stairs will need angled holes.

Most posts I’ll drill straight through,using a bit that’s 1⁄16 inch larger thanthe cable size and guided by a jig. Now,a jig sounds complicated, but this oneis nothing more than a piece of 1x4 the height of the posts, with holesdrilled where I want the cables to be. Iuse a Milwaukee Pathfinder bit to drillthe curved holes in single-post cor-ners; I start these holes from each side,and join them in the middle. Mil-waukee no longer makes Pathfinderbits, but Bad Dog Tools (800/252-1330, www.baddogtools.com) has sim-ilar ones (Figure 10). Single posts on45-degree corners are mounted at 22degrees and drilled straight through.

End posts need to be drilled to fit a cable stud, washer, and nut. Use a 5⁄8-inch Forstner bit to drill a holeabout 2 inches deep for the washer andnut (Figure 11). Center a 1⁄4-inch bit inthe 5⁄8-inch hole, and drill the rest ofthe way through for the cable stud. TheForstner bit makes an indentation inthe center so you can line up the 1⁄4-inch bit more easily. It’s importantfor the larger and smaller holes to line

Figure 8. The author’s favorite commercial cable stud is made by

Atlantis Rail Systems. A cap nutand bushing eliminates the

need for a swaging tool, andthe flange mount allows

this stud to work at avariety of angles.

Figure 10. Curving holes are made pos-sible with Rover bits by Bad Dog Tools.

Figure 11. A two-step holemakes room for a socketwrench. The cable and studenter the opposite side of thepost through a smaller hole,and the nut used to tension the cable is buried inside a 5⁄ 8-inch-diameter hole that also accommodates the socket.

Figure 9. Studs and stops end the cable runs. Stops are simplealuminum rings that are swaged onto one end of the cable. Usedin conjunction with a washer, they resist the tension applied by thestud. The author has studs made locally from stainless steel rod.They’re swaged to the cable, and tightened with a nut.

up, because there is little room for a9⁄16-inch washer and the cable stud toalign. On short runs of 20 feet or less,only one end needs a stud to tensionthe cable. That end doesn’t need a holeas deep as 5⁄8 inch; this smaller holeshould be the same as all the othercable holes.

Stairs require the posts to be drilledat an angle. I find the angle with a 6-foot level, a Speed Square, and a tor-pedo level (Figure 12). I cut a smallblock of wood at that angle for guid-ing the drill bit. I use a 6-inch-longdrill bit, which helps to get the holehalfway through the post. Then Iremove the guide and continue todrill a hole following the path thathas already been drilled out.

If the stair post is going to be used as an end post, it will need to have a5⁄8-inch two-step hole drilled into it toaccommodate a cable stud or stop.This is done using the same block ofwood and a Forstner bit with a drillstop mounted 2 inches back from thecutting head (Figure 13). This can be atricky hole to drill. Start drilling withthe bit vertical and then gently tip it tomeet the guide block. Continue to drilluntil the hole is 11⁄2 inch deep.

Capping and CablingAfter all the posts are installed, thetop rail is fitted between the posts toresist the tension when the cables aretightened. The decorative cap is theninstalled continuously over the toprail and the posts.

Cable comes on a large spool, which Imount on a spindle so that it feeds eas-ily from post to post. It’s usually best toset up the spool so that it feeds straightinto the end post — generally the endpost that is not against the house.Before threading the cable, I wrap theend with tape to keep it from frayingon its journey through the holes. A $24 HIT Tools 22WRC75 cable cutter(909/974-0369, www.hittools.com)

7 Professional Deck Builder • March/April 2007

Installing Cable Railings

Figure 13. Use the angleobtained with the speedsquare to make anangled block to guidethe drill on stair newels.The block is cut on amiter saw. Here, the car-penter is preparing todrill the large diameterside of a two-step holefor a cable stud.

Figure 12. Tools you probably already own determine the angle for drillingthe stair posts. A long level on the tread noses establishes the stair pitch,and a Speed Square, held level, measures the angle.

BUYING COMPONENTS

number of good companies supply complete cable railing sys-tems. It’s easier to order everything from one source, but you pay

more for that convenience. Each supplier has better prices on somecomponents than others, so if you are willing to work with several sup-pliers, you can make a better profit. In addition to the listed suppliers,local marine supply houses often sell cable and other components.

Sources:Atlantis Rail Systems (800/541-6829, www.atlantisrail.com) Ultra-tec (800/851-2961, www.ultra-tec.com) Cable Railing by Feeney (800/888-2418, www.cablerail.com)Carl Stahl DécorCable (800/444-6271, www.decorcable.com)

A

cuts the cable cleanly. Once the cableis fed through all the posts, I swage acable stud or a stop to its end.

The next step is pretensioning, orstretching the cable tight before put-ting on the end stud (Figure 14). Ifyou skip this step and rely on only thestuds for tightening, it’s possible torun out of thread on the stud beforethe cable is tight enough. Then,you’ve got to cut off that stud, whichis now expensive scrap, and swage onanother.

Pretensioning is done with lockingpliers, pieces of wood or compositedecking slit to fit over the cable, andwedges. Working back from the firstend post, pull the cable hand taut andslip a piece of wood over the cable onthe pull side of the post. With the lock-ing pliers, gently grip the cable rightbehind the block. Then, drive thewedges between the block and the postto tighten the cable.

Leaving the pliers and wedges inplace, jump ahead three or four postsand do it again. Pretension at everycorner. Using four or five pairs of lock-ing pliers eases the job.

With the cable taut at the last post,cut it to fit in the stud so that justenough threads to engage a nut pro-trude past the bearing surface in thepost. Swage the cable stud, slip it intothe end post, and put a washer andnut on it. Install the rest of the cablesin the same way.

Once pretensioning all the cables iscomplete, it is time to fully tensioneach cable. There is a correct sequenceto this, starting with the center cable,followed by tightening the remainingcables, alternating above and below the

center cable (Figure 15). You need totake out any sag, and get the cables to auniform tension. Each cable shouldsound the same note when strummed.

The final step is to cover the holesin the end posts. I use a 1⁄ 4-inch-thick strip of the same material asthe post. Screw it on so that it can beremoved easily in case the cables needtightening. ❖

Kim Katwijk is a NADRA board memberwho builds decks in Olympia, Wash. His wife,Linda Katwijk, helps Kim write about them.

8 Professional Deck Builder • March/April 2007

Installing Cable Railings

Tightening Sequence

10

8

6

4

2

1

3

5

7

9

Figure 15. Because the topand bottom of the posts arebraced, tightening starts inthe flexible middle. Tightenthe center cable enough toremove sags, then tightenthe cables that are directlyabove and below, and soon. All should sound thesame note when properlytensioned.

Figure 14. Snug up the cablebefore final tightening. Lockingpliers gently closed on the cableprovide the grip. Wedges providethe force to stretch the cable.Stretch from several spots alongthe run, particularly at corners.