Inspection Solutions for Splash Zone & Subsea Assets · PDF fileCaissons Pipeline Ship Hull...

Transcript of Inspection Solutions for Splash Zone & Subsea Assets · PDF fileCaissons Pipeline Ship Hull...

© Copyright Innospection Ltd. 2017

GENERAL OVERVIEW

Inspection Solutions for

Splash Zone & Subsea Assets

ANDREAS BOENISCH

© Copyright Innospection Ltd. 2017

KEY INSPECTION SERVICE AREAS

TOP SIDE FlexIQSplash Zone

(standard)Subsea

UWILD

Insp.

Internal

Pipeline

Equipment

SalesR&D

Heat

Exchangers

Flexible

RisersCaissons Pipeline Ship Hull

(2017)

Tethered pig

(non pig-

able pipes )

Floor

Scanners

Application

Developm.

Storage

Tanks

Mooring

LinesConductors Flowlines

SemiSub

Ponton(2017)

Free

swimming

Pig

(intelligent) (2019)

Pipe

Scanners

Perman.

Inst.

Sensors (2018-19)

Top Side

PipesUmbilical Risers Manifolds

Drill

Risers (2017)Accessories

Principle

NDT

Pressure

Vessel (NII)Structures Others Others

CUI (PECT)

(Under development)

© Copyright Innospection Ltd. 2017

Top Side

Splash Zone

Subsea

Offshore Inspection & Integrity Support

OFFSHORE INSPECTION & INTEGRITY SUPPORT

© Copyright Innospection Ltd. 2017

Magnetisation Level MFL

Magnetisation Level MEC

Advanced NDE Technology

Principle MEC™ (Magnetic Field controlled High Frequency Eddy Current)

Principle Controlled Magnetic field Online Recording

Defect C-Scan Map Individual defect assessment Asset Modelling

MEC TECHNOLOGY

© Copyright Innospection Ltd. 2017

Riser & Caisson Scanning

WT range : up to 30mm

trough coating up to 15mm

Pipe Scanning

WT range : up to 1”

Vessel Scanning

WT range : up to 33mm

Tank Scanning

WT range : up to 30mm

through coating up to 10mm

Amonium Chloride

Salt Corrosion

Micro Biological

Corrosion

(MIC/SRB)

General Corrosion

/ C02 Corrosion

Corrosion /

Cracking

MEC (Magnetic Eddy Current )

Focus for Corrosion Detection / Mapping : fast scanning , high POD for isolated pits /

general corrosion (e.g. MIC), inspection through coatings, low prep. required

MEC™ - TYPICAL INSPECTION APPLICATIONS

© Copyright Innospection Ltd. 2017

Splash Zone Inspection & Assesment Support

- Riser

- Caisson

- Conductor

- Structures

Sp

lash

Zo

ne

SPLASH ZONE INSPECTION & INTEGRITY SUPPORT

© Copyright Innospection Ltd. 2017

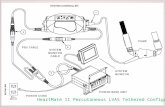

External Scanning of Risers, Conductors, Caissons

External MEC-Combi Tools

deployed by ROV, diver, from top side

- Inspecting wall thickness of 1” (1½ “)

- external & internal localised wall loss detection

- inspecting coated or cladded risers

- general marine growth removal

(ROV/diver/ integrated cleaning)

- inspection top side, splash zone & subsea

- Corrosion Mapping

Online Reporting Scan Map

To

p S

ide

Ca

iss

on

Dep

loym

en

t

SPLASH ZONE INSPECTION

© Copyright Innospection Ltd. 2017

External and internal corrosion detection. Isolated defects, areas........

Current activities parting Conductor in 3 sections. Activities 1-2 shifts per conductor

Well Conductor Inspection - Integrity Assessment

SPLASH ZONE INSPECTION

© Copyright Innospection Ltd. 2017

EXTERNAL SPLASH ZONE SCANNING

WITH INTEGRATED CLEANING SYSTEMS

M-PS200+ including Cleaning head

SPLASH ZONE INSPECTION

M-PS200+ including HP Jetting Array

© Copyright Innospection Ltd. 2017

Inspecting through coatings

OD 20” x WT, Neoprene ½”

External & internal local spherical defect detection results with MEC M-PS200+ scanner

SPLASH ZONE INSPECTION

© Copyright Innospection Ltd. 2017

Subsea Inspection & Assesment Support

- Risers

- Flexible Riser

- Umbilical

- Mooring Lines

- Subsea Pipelines / Flowlines

Su

bsea

SUBSEA INSPECTION & INTEGRITY SUPPORT

© Copyright Innospection Ltd. 2017

MEC – Combi Crawler

ROV / diver deployed

Scanning with

MEC & Ultrasonic

Sensor arrays

SUBSEA MEC COMBI CRAWLER

MEC Scan vs UT Array Scan

© Copyright Innospection Ltd. 2017

MEC-FIT™

Magnetic Eddy

Current Flexible Riser

Inspection Tool

FLEXIBLE RISER FROM INSPECTION TO ASSESMENT

- External scan, detection in 2 (up to 3) layers

• corrosion (pitting/general ), cracking , wire misalignment

- Scanning in axial & circumferential direction

- Fast external scanning

- No couplant required

© Copyright Innospection Ltd. 2017

Subsea Flexible Pipe Flowline scanning in upheaval buckling area

Detection target wire misalignment & local pitting/cracking 1st & 2nd annular wire

Operation at a 4” Flexible Riser scanning with top side deployment tool MEC - Hug

Detection target Pitting detection 1st & 2nd annular wire

MEC-FIT™ Flexible Riser Cases

© Copyright Innospection Ltd. 2017

North Sea Case : Wire Crack Detection of 55 degree Wire Flexible Riser

Flexible Riser set up: armour wire SCC verification tests

MEC-FIT™ Flexible Riser Cases

Target of the technique verification to detect tight

cracking in single wire with expected orientation of 45°

and 90°to the wire cross section.

Cracking to be detected on the inner wire & outer wire

layer.

Self crawling MEC – Combi Scanner top site deployed

© Copyright Innospection Ltd. 2017

SUBSEA PIPELINE INSPECTION

MEC Subsea Pipeline Scanning

– on coatings up to 15mm

– fast scanning

– high sensitivity for corrosion detection (pitting or general

corrosion areas

– ROV or diver deploying

PEC Subsea Pipeline Scanning– on coatings up to 200mm

– Static measurement

– footprint measurement – averaging of area wall loss

– ROV or diver deploying

© Copyright Innospection Ltd. 2017

MEC-Combi Crawler for Subsea PipeScan

Self crawling systems with Inspection technology

adaptations : MEC , UT, Visual, Laser, PEC

SUBSEA PIPELINE INSPECTION

© Copyright Innospection Ltd. 2017

MEC and UT inspection report, Subsea Pipeline Section

SUBSEA PIPELINE INSPECTION

© Copyright Innospection Ltd. 2017

Subsea PEC Deployment

The SUBSEA PEC is a static measurement with capability to inspect through up to

200mm stand off (coating). Two sensors are guided to scan circumferentially and

axially along the pipe. Pipe Diameter Range 8” – 36 “

Subsea Pipeline Inspection

Generation 2 Sensor Units

R&D

Generation 12 Sensor

Units - increasing Scan

speed 6 x

© Copyright Innospection Ltd. 2017

- MEC Combi Crawler Robot Hull Cleaning & Inspection Robot with top side deployment

R&D and Equipment Production

- Top side deployed Crawler Inspection system with integrated thrusters, replace ROV /

diver requirement

- Splash Zone cleaning & inspection system with automatic operation (avoid RAT

requirements : therefore less weather dependent & clamp/guide passing

© Copyright Innospection Ltd. 2017

Innospection Limited

Howemoss Avenue

Kirkhill Industrial Estate

Dyce - Aberdeen - AB21 0GP

United Kingdom

P +44 (0) 1224 724 744

F +44 (0) 1224 774 087

Web: www.innospection.com

THANK YOU FOR YOUR ATTENTION