Industrial attachment of naz bangladesh ltd

-

Upload

mazadul-hasan -

Category

Engineering

-

view

1.910 -

download

30

Transcript of Industrial attachment of naz bangladesh ltd

SOUTHEAST UNIVERSITYDepartment of Textile Engineering

INDUSTRIAL ATTACHMENTN. A. Z Bangladesh Ltd

AcknowledgementA number of people have made significant contributions in preparing this report.Their insights, advice and suggestions helped me a lot. I would like to pay specialthanks to Prof. Syed Fakhrul Hassan, C-Text. ATI, the Head of the departmentof Textile Engineering, Southeast University, for continuously guiding us about thedevelopment and preparation of the report. He has enriched us with necessary ideasand concepts for incessant improvement of the report.I would also like to expressour heartfelt thanks to Md. Fazley Elahi, Assistant Professor, Department of TextileEngineering, Southeast University for all necessary information for preparing this report.

I would like to express our sincere gratitude to Mr. Monju, General Manager, N.A. Z Bangladesh Ltd, who has allowed us to work in his organization within acongenial atmosphere during the industrial training period.

I recognize Mr. Nipu, Manager (Dyeing) and Md. Shifon AGM (knitting) N. A. ZBangladesh Ltd. for providing sincere help in all administrative and technical matterswhile working in the organization.

I express my heartiest thanks to Deputy Manager & Assistant Manager, Knitting,Dyeing & Fishing, Garment and Accessories for enriching our knowledge on variousfabric manufacturing and finishing processes with their excellent professionalknowledge.

My sincere appreciation goes to the entire N. A. Z Bangladesh Ltd. team forextending their hands of cooperation through out the training period.

1

Name:N. A. Z Bangladesh Ltd.

2

1 CHAPTER : PROJECT DESCRIPTION

1

1.1. Introduction:

Every one knows that learning is the best part of thinking possibility. In human lifeeducation is the primary source of learning process. We need to learn for particular pointsof theoretical parts it should be some lack of looking this function such a fabric making ona circular machine and dyeing and finishing process in practical. It should be looking andknows about the functions, running of this machine, Uses material, and manufacturingmaterials. It must be need for good practical knowledge and proper handling of themachine.

Internship is making this opportunity. Because we have known theoretical knowledge butwe have lack of industrial knowledge. It has to fill up for industrial attachment. N.A.ZBangladesh Ltd. has getting this opportunity for me.

NAZ Bangladesh Ltd is a knit composite industry. It is a 100% export oriented industry inBangladesh. The factory is making about knitting, knit dyeing & finishing and knitgarments. Due to the change in environment, the textile sector is facing a great challenge.But NAZ BD Ltd fully prepared to face this situation. The goal of NAZ BD Ltd is tobecome the preferred partner for sourcing high quality fabrics and clothing fromBangladesh. N.A.Z has highly develop advanced technology and an emphasis ondeveloping local human resources, the Textile Division has the potential to make animportant contribution to the nation's growing ready made garments export sector.

The rational behind the existing structure and future expansion of the Textile & fiberDivision is to capture value-added at each stage of the textile manufacturing process.Despite Bangladesh's lack of indigenous cotton production capability, N.A.Z. hasleveraged Bangladesh's labor cost advantage and export competitiveness to the maximum.

This factory is fully complained and very much concern about the labor law andcompliance. This factory also concerned about environmental issue as they have wellestablished Effluent Treatment Plant (ETP). In NAZ Bangladesh Ltd., I have completed 2months (8 weeks) long industrial training in knitting, dyeing, finishing and garments.During the training period we faced a lot of technical problem, which we solve byconsulting with the related persons. Whatever knowledge we have gain during my trainingperiod, it will help us to build up our career as a Textile Technologist.

Project Description

2

1.2. Layout of N.A.Z Bangladesh Ltd.

ANSER CAMP

Gat

e

Dormitory

POND

Fabric storeACCESSORIESUNITE

ETP

POND

CH

EMIff

CfA

LST

OR

E

UNDERCONSTRUCTION

3 STD OFFICE ANDGARMENTS

Prin

ting

KNITTINGSECTION Utility Building

Chemicalstore

WORKSHOP

GA

TE

N E

SW

Project Profile

Industrial Training 3 | P a g e

1.3.Project Profile

Type : 100% Export Oriented Composite Knit Industry.

Legal Form of Company : Private Limited Company.

Year of Incorporation : 1987

Commencement of Operations : 1987

Project cost : 250 crore

Name of the Bank : Exim Bank

Company name N. A. Z. BANGLADESH LIMITED.

Head Office House #21 , Road # 13, Baridhara, Gulshan, Dhaka-1212

Tel No 880-2-9861831, 9860445, 8854101 Extn: 128 / 156

Fax 880-2-9889078

E-mail [email protected], [email protected]; [email protected];

URL www.nazbd.com

Factory 5, Bishuya Kuribari Bari, Mirzapur, Rajendrapur, Gazipur-1700

Tel No 880-2-9289054-6

Fax No 880-2-9289053

Location45~50 minutes drive from HSJI Airport to towards North(Mymansingh)

Contacted persons

Mr. Nasir Uddin Ahmed (Managing Director)

Contact Phone :+88 01711 814 912

Mr. Salauddin Jakir (Merchandising Manger)

Contact Phone: +8801714302133

Mr. Shamim Khan ( Sr. Merchandiser – Marketing &Merchandising )

Contact Phone: +88 01711 465 336

Project Profile

Industrial Training 4 | P a g e

Main Production : T-Shirt, Polo Shirt, Tank tock, Jacket, Trousers,

Bottoms, etc. and all kinds of Knit fabric & garments.

Factory space : 9, 07,200 sq.ft.

Total Employees : 3350 persons

No. Of employees : 350 persons

No. Of workers : 3000 persons

Working Period : 3 (Three) Shift Per Day

Production Capacity

Knitting : 20 Tons/Day

Dyeing & Finishing : 16 Tons/Day

Garments : 55,000 Pcs/Day

PC Printing : 25,000 Pcs/ Day

Embroidery : 50,000,000 Stitches/Day

Garments Wash : 25000 Pcs/Day

1.4.Yearly Turn Over

Serial No Year Turn Over (Per Year)01 1996 US $ 7.02 Million02 1997 US $ 8.20 Million03 1998 US $ 9.65 Million04 1999 US $ 10.56 Million05 2000 US $ 12.76 Million06 2001 US $ 15.86 Million07 2002 US $ 17.65 Million08 2003 US $ 20.00 Million9 2004 US $ 22.00 Million10 2005 US $ 25.00 Million11 2006 US $ 25.00 Million12 2007 US $ 26.00 Million13 2008 US $ 28.00 Million

Project Profile

Industrial Training 5 | P a g e

1.5.Different Dipertment:

Different sections of N.A.Z. Bangladesh Ltd.

A. Knit section

Knitting Inspection

B. Dyeing section

Batch section Dye house Dyeing lab Quality control Finishing

C. Garments section

Merchandising Sample Cutting section Sewing section Finishing section

D. Sewing Thread DyeingE. Printing UnitF. Embroidery UnitG. Accessories UnitH. Maintenance section

Electrical Mechanical

I. Utility: Electricity Gas Water Boiler ETP

J. Store section

K. Administration section

L. Security section

M. Marketing section

N. Production planning &control

O. Human Resource & Development

section

Differentsections

Project Profile

Industrial Training 6 | P a g e

Supporting Department

Personnel AdministrationProcurementMarketingHRDFinance & AccountingMIS (Management Information System)Work StudyComplience & Safety

Companies of N.A.Z. Group

N.A.Z. Bangladesh Ltd.

N.A.Z. Bangladesh Ltd. (Accessories Unit)

CA Knitwear Ltd.

Needle Touch Garments Ltd.

Certifications:

ISO

Oeko Tex-100

Main Buyers of N.A.Z. Bangladesh LTD:

SL BUYER COUNTRY

01 TARGET USA

02 TESCO UK

03 H&M SWEDEN

04 WAL MART USA, CANADA, MEXICO

05 PUNTORAMA SPAIN

06 TRR ITALY

Project Profile

Industrial Training 7 | P a g e

1.6.History of the project development

After successful operation in N.A.Z. Group, the owner had decided to start a fully

information & technology based along with the social accountability and quality controlled

modern readymade composite knit garments industry in large scale. It is situated at 5,

Bishuya Kuribari, Mirzapur, Gazipur-1700, Bangladesh. In the year 1987 to manufacture

knitwear garments for the international market. Right from inception the policy of the

company has been to provide total customer satisfaction by offering quality knitwear in time.

To meet the commitments of quality and prompt delivery, N.A.Z. Group Decided to

integrate the manufacturing process in a planned manner. Over the years the entire process

has been integrated by importing sophisticated machinery from world-renowned

manufacturers.

1.7.Vision & mission of the project:

The mission and vision of N.A.Z. Group is to manufacture and deliver high quality

readymade garments (RMG) to its customers. The core objective is to attain and enhance

customer satisfaction by providing on time delivery of desired quality readymade garments

and also to increase efficiency of workforce.

To attain these objectives, the management of N.A.Z. Group has decided to adopt the

following-

To increase awareness regarding customers requirements throughout the

organization.

By providing training to develop efficiency of the employee.

To collect customer’s feedback regularly to know about their conception about

their company and to take timely appropriate action.

To reduce the percentage of wastage / rejection minimum by 2% per annum’s

implement and monitor ISO 9001:2000 quality management system within the

organization.

Man Power Management

Industrial Training 8 | P a g e

2 CHAPTER : MAN POWER MANAGEMENT

Man Power Management

Industrial Training 9 | P a g e

2.1.Manpower Organ gram

Manpower organ gram of N. A. Z Bangladesh is as follows -

Finishing & Q.C Manager

Shift In-charge

Q.C Technician

Knitting Manager

Managing Director

Executive Director

GM (Marketing) GM (Production)

Asist. Manager

Sr. Production Officer

Shift In-charge

Production Officer

Assist. Production Officer

Sr. Operator

Operator

Dyeing Manager

Shift In-charge

Production Officer

Asist. Manager

Deputy Manager

Sr. Production Officer

Assist. Production Officer

Sr. Operator

Operator

Man Power Management

Industrial Training 10 | P a g e

2.2.Management system

Buyer sample is send to G.M or merchandising manager. Matching is done under lab manager. Sample is prepared by asst. dyeing manager. Sample is send to the buyer for approval. Approved sample is returned and taken as STD. sample for bulk production. Dyeing manager gives responsibilities to asst. dyeing manager. Then shift in-charge with the supervisors start bulk production. On line and off line quality check is done by lab in-charge and asst. dyeing manager. After dyeing asst. manager (finishing) controls the finishing process with the

supervision of shift in-charge. Finally G.M checks the result with dyeing manager and decision is taken for delivery.

Shifting:

In N. A. Z Bangladesh Ltd. The whole day production time is divided into 3 shift.Per shift 8 hours.

Shift Duration

Shift A 6:00 am- 2:00 pm

Shift B 2:00pm – 10:00 pm

Shift C 10:00 pm- 6:00 am

2.3.Duties & Responsibilities of Different Post

General Manager

To deal with the buyer and merchandiser. To set up price for the product. To plan apply and control all administrative functions. To follow up the instruction of managing director and chairman.

Manager

To supervise the personal working under him. To plan the sequence of production. To arrange necessary raw materials for the production problems. To find out the possible reasons which are responsible for less production? To follow up the instruction of Managing Director and Executive Director as well.

Man Power Management

Industrial Training 11 | P a g e

Deputy General Manager (DGM) production

Overall supervision of dyeing and finishing section. Check the sensitive parameters of different machines for smooth dyeing. Check the different log books in different areas and report to management. Check the plan to control the best output To trained and motive the subordinates how to improve the quality production. Control the supervisor, operator, asst. operator and helper of dyeing machine. Any other work as and when required.

Senior Production Officer

Overall supervision of dyeing and finishing section. Batch preparation and pH check. Dyes and chemicals requisition issue and check Write loading/unloading time from machine. Program making, sample checking color measurement. Control the supervisor, operator, asst. operator and helper of dyeing machine. Any other work as and when required.

Production officer

To collect the necessary information and infrastructure from the previous shift for thesmooth running of the section.

To match production sample with target shade. To match production sample lot sample matching next production. To observed dyed fabric during finishing running and also after finishing process. To identify disputed fabrics and report to PM/GM for necessary action. To discuss with PM about overall production if necessary. T sign the store requisition and delivery challenge in the absence of PM. To execute the overall floor work. To maintain loading/unloading paper.

Shift In charge

To follow the workers movement. Should discuss with the production Officer about what is happening. To maintain the production sequence. To check the sample at certain time interval.

Raw Materials

Industrial Training 12 | P a g e

3 CHAPTER: RAW MATERIALS

Raw Materials

Industrial Training 13 | P a g e

3.1.Raw Materials

Table 3. 1: Source of yarn for knitting

Lycra: CREORA

Made in Korea

Type # H-100 (20D, 40D)

Square Spinning mill Basher spinning mill

Kamal spinning mill Prime Spinning mill

Aman spinning mill RK Spinning mill

Fariha spinning mill JK Spinning mill

Shohagpur spinning mill AKIJ Spinning mill

Amber cotton mill Pahartoli Spinning mill

Rising spinning mill Youth Spinning mill

Shirin spinning mill Kader Spinning mill

NZ spinning mill Silver Spinning mill

Karim spinning mill Shemem Spinning mill

Knitting Section

14 | P a g e

3.2.Types of yarn used and their count:

Table 3. 2: Types of yarns used in N.A.Z. Bangladesh Ltd

Type of yarn Count

Cotton 20S ,24S, 26S, 28S, 30S, 32S, 34S, 36S ,40S, 45S

Polyester 70D,100D,150D

Spandex yarn 20D,40D,70D

Grey Mélange (C-90% V-10%) 24S, 26S

Ecru Mélange (C-85% V-15%) 24S, 26S, 28S

Cotton Mélange (100%) 24S, 26S, 28S

PC (65%Polyester & 35% cotton) 24S, 26S, 28S, 30S

CVC(60% Polyester & 40% Cotton) 24S, 26S, 28S, 30S

3.3.Cost of Raw Materials:

Table 3.3: Cost of yarn

Yarn Count Combed Yarn Carded Yarn

40/1 3.65 $/Kg 2.65-2.7$/Kg36/1 3.00 $/Kg 2.5-2.6 $/Kg

32/1 2.90 $/Kg 2.30 $/Kg

30/1 2.70 $/Kg 2.30 $/Kg

28/1 2.65 $/kg 2.25 $/Kg

26/1 2.60 $/Kg 2.25 $/Kg

24/1 2.55 $/Kg 2.20 $/Kg

20/1 2.50 $/Kg 2.15-2.2$/Kg

Knitting Section

15 | P a g e

Lycra Yarn:

20 den - 12.70 $/Kg

40 den - 8.40 $/Kg

70 den - 7.50 $/Kg

Cost of knitting

Table 3.4: Cost of knitting for different fabrices

Fabrics Taka/kg

Rib (1x1) 12-13

Rib (2x2) 14-15

Interlock 15-16

Single Jersey 7-8

Lacost 8-9

Pique 8-9

Terry fleece 14-15

Remarks: As the yarn consumption totally depends on production and production depends

on order of buyer, so recommendation of yarn type, source, price, requirements may vary.

Knitting Section

16 | P a g e

4 CHAPTER : KNITTING UNIT

Knitting Section

17 | P a g e

4.1.Organ gram of Knitting Department

ShiftA-4

ShiftB-4

ShiftC-4

Knitting Master

Asst.Master

Sr.Fitter

Servicing -5

Production

Floor In charge

Asst.Manager

Sr.Production Officer

Shift A

Production Officer

Shift B

Production Officer Production Officer

Shift C

Shift In Charge

APO

Operator-40

Shift In Charge

APO

Operator-40

Shift In Charge

APO

Operator-40

Asst. Manager

R& D sample

Supervisor

Asst.Operator-2

Y/D

In charge

Supervisor

QC- 3 QC- 3

Sub ContractOut Scorching

Manager

Sub ContractInside

Manager

Asst.Manager

GM

AGM

Manager

Knitting Section

18 | P a g e

4.2. Layout of Knitting Department

Fabric StoreOffice Room AGM

RoomMai

nten

ance

Roo

m

Gate

Knitting Section

19 | P a g e

4.3.Knitting:

Knitting is the method of making fabric by transforming continuous strands of yarn into aseries of interlooping loops, each row of such loops forms the one immediately preceding it.

Types of weft knitting m/c:

The N.A.Z Bangladesh Ltd. is a self- sufficient modern company. Its knitting section isdivided into two sections-

1. Flat Knitting Section2. Circular Knitting Section

4.4.Circular knitting section:

Main parts of circular knitting m/c:

1. Yarn feed guide2. Latch needle3. Holding down sinker4. Needle cylinder5. Needle retaining spring6. Needle operating cams7. Cylinder driving wheel8. Cylinder driving gear9. Cylinder driving pinion attached to the main shaft10. Sinker cam top11. Cam box12. Cam plate13. Creel: Creel is used to place the cone.

14. Feeder: Feeder is used to feed the yarn.

15. Tensioning device: Tensioning device is used to give proper tension to the yarn.

16. VDQ pulley: VDQ pulley is used to control the GSM by controlling the stitch length.

17. Guide: Guide is used to guide the yarn.

18. Sensor: Sensor is used to seen & the m/c stops when any problem occurs.

Fire Extinguisher

Hose Pipe

Fabric Rack

Floor MarkingFabric inspectionm/c

V-Bedknitting m/c

Circularknitting m/c

Knitting Section

20 | P a g e

19. Spreader: Spreader is used to spread the knitted fabric before take up roller.

20. Take up roller: Take up roller is used to take up the fabric

4.5.Basic knitting element:

1. Needle.2. Sinker.

3. Cam.

Needle:Function of needles: Needle is used to clear the old loop from the hook & to receive the newloop above it on the needle steam.Types of needle:In general there are three types of needles.

a. Bearded needle.b. Latch needle.c. Compound needle.

Figure 4.1: Latch Needle

CAM:

Cams are the devices which convert the rotary m/c drive into a suitable reciprocating action

for the needles or other elements.

Types of cam: Two type of cam

1. Engineering cam Knit cam

2. Knitting cam Miss cam

Tuck cam

LatchSteam

Hook

Rivet

Butt

Knitting Section

21 | P a g e

Function of CAM

The functions of cam are as follows:

Produce motion to needles. Loop formation. Holding down. Knocking over

Sinker:This is secondary primary knitting element. It is a thin metal plate with an individual andcollective action approximate at right angles from the hook side between adjoining needles.

Function of sinker:It may one or more of the following functions dependent upon the machines knitting actionand consequent sinker shape and movement.

Others Equipments Used In Knitting Section:

GSM cutter Electronic balance Inspection m/c

4.6.Terms and definition of knitting:

Course – A horizontal row of loops formed by the needles during one knitting cycle.

Wales – A vertical column of loops formed by a single needle.

Loop - It is a basic unit consisting of a loop of yarn meshed at its base with previously basicunit. Knitted loops are arranged in rows and columns roughly equivalent to the warp and weftof woven structures termed “Wales” and “courses” respectively

Stitch - The smallest dimensionally stable unit of all knitted fabric is stitch. It consists of ayarn loop which is held together by being intermeshed with another stitch or other loop.

Stitch length - Stitch length is a length of yarn which includes the needles of the needle loop& half of the sinker loop on either side of it. Generally the larger stitch length, the moreextensible & lighter the fabric & the poorer the cover, capacity & bursting strength.

Steps should be taken to change stitch length.

- Check the S.L of the m/c prevailing.- Change the diameter of V. DLQ pulley.- Set of the position of carriage.- Set the speed of take- up roller

Knitting Section

22 | P a g e

- Maintain the optimum yarn tension.

Yarn count:

Yarn count is the numerical system of expressing length per unit weight or weight per unit

length. Count express fineness or coarseness of yarn.

Yarn count can be calculated in two systems:

Direct system:

In direct system, yarn count is directly related to the yarn fineness. So, lower the count finner

the yarn and higher the count and coarser the yarn. This system is used for Polyester and Ly-

cra and other synthetic fibers.

W lDirect Countw L

Where, W=weight of the sample

L=length of the sample

w=unit weight of the system

l=unit length of the system

Table 4-1: Yarn Count in Direct system

System Unit weight Unit length Uses

Tex Grams 1,000m Polyester

Denier Grams 9,000m Lycra

D-Tex Grams 10,000m Lycra

Pounds/Spyndle Pounds 14400yds Jute

Knitting Section

23 | P a g e

Indirect system:

In indirect system, yarn count is inversely related to the yarn fineness. So, higher the count

finner the yarn and lower the count and coarser the yarn. This system is used for cotton,

worsted & woolen.

w LIndirect CountW l

Where, W=weight of the sample

L=length of the sample

w=unit weight of the system

l=unit length of the system

Table 4-2: Yarn Count in Indirect system

System Unit weight Unit length UsesEnglish (Ne) 1 lb 840 yds Cotton yarnMetric (Nm) 1 kg 1 km Cotton yarnWorsted 1 lb 560 yds Worsted yarn

Woolen 1 lb 256 yds Woolen yarn

Stitch Density - Courses per inch (CPI) × Wales per inch (WPI)

M/C Gauge - A number of needles per unit length in the knitting m/c, measured as thenumber of needles in one inch. This measure determines the number of Wales per unit lengthin the knitted fabric.

4.7.Flat Knitting Section

Flat knitting section consists of Flat knitting machines. Its main production is Collar & Cuff.Different types of designed collar & Cuff is produced here matching with the body of thegarments.

Flat knitting machine is used to make collar and cuff with the required shape. Collar and cuffis usually with heavier gsm and thus multiple ply of yarn is used per feeder. No of yarn plyused will also depend on the yarn count. Lycra is also used when required.

Knitting Section

24 | P a g e

Table 4-3: No. of yarn ply according to yarn count for collar & cuff

Yarn count (Ne) No. of yarn ply20 322 324 426 430 4-534 6

Size of collar according to size of garments:

Boy’s collar :Length 29 to 36 cm x width 8cm Boy’s cuff : Length 31 cm x width 3cm Man’s:

Table 4-4: Collar & Cuff measurements

Size Collar measurement (cm) Cuff measurement (cm)S 40 x 9 40 x 3.5M 42 x 9 40 x 3.5L 44 x 9 40 x 3.5

XL 46 x 9 40 x 3.5XXL 48 x 9 44 x 3.5

XXXL 50 x 9 44 x 3.5

Collar and cuff which is made with V-bed knitting machine has 3 edge and need not to cut.Those fabrics have following 4 parts:

1. Tube2. Tube end3. Body4. Separation

Knitting Section

25 | P a g e

Sequence of operations in knitting section:

Sample fabric

Design analysis

Sample fabric production

Setting the machine for the specificdesign

If Yes

If NoBuyer approval

Bulk Production

QC

Send to Batching section

Knitting Section

26 | P a g e

Table 4-5:Main Product - Fabrics :-

Single Jersey

- Single Jersey:- Single Jersey (Lycra)- Single Jersey (Auto Stripe)- Single Jersey (Singed)- Single Jersey (Pigment Dye)- Single Jersey (Sueded / Ultra Soft)

Pique

- Pique- Pique (Auto Stripe)- Pique (Sueded / Ultra Soft)- Pique (Mercerized)- Pique (Ultra soft)

Interlock

- Interlock- Interlock (Ultra soft)- Interlock (Pigment Dye)- Interlock D/N (Cotton)- Interlock D/N (Polyester)

Rib

- Rib: Any Drop Needle- Rib (Pigment Dye)- Rib (Ultra soft)- Rib Elastane- Flat Back Rib- Variegated Rib

Jacquard - Semi Jacquard

Mesh - Mesh

Fleece

- Fleece- Fleece (Inside Brush)- Fleece (Both Side Brush)- Terry Fleece- Polar Fleece- Terry Fleece (Pigment Dye)

Lacoste- Lacoste- Lacoste (Auto Stripe)- Lacoste (Pigment Dye)

Waffle - WaffleValor - Valor

Knitting Section

27 | P a g e

Table 4.6: Analysis of structure, looping diagram, cam arrangement and needle arrangement of knit fabric

Single Jersey Single jersey fabric vertical Wales’s line is shown on the face side of the fabric. On the back side sinker loops are produced. Thisfabric is produced by the needles of only one set needle. This fabric has curling effect on the edge after cut in relax state towardsthe back at the sides and towards the front at the top and bottom.End use: basic T-shirt, men’s vest, fine cardigans, ladies hosiery, full-fashioned knitwear etc.

Face Side Back Side

Looping diagram Cam Arrangement

K K K K

NeedleArrangement

1x1 Rib Rib fabric shows the face loop on the both sides of the fabric. Rib requires two sets of needles operating in-between each other sothat walse of face stitches and wales of back stitches are knitted on each side of the fabric. This fabric has good elasticity and has nocurling effect.End use: waist bands, cuffs and collars and typical applications, skirt belt, various types of fancy borders, sweaters etc.

Face Side Back Side

Looping diagram Cam Arrangement

K M K MM K M KK M K MM K M K

NeedleArrangement

D

C

Knitting Section

28 | P a g e

Interlock Interlock has same appearance on both sides, like face of plane, but its smooth surface cannot be stretched. Interlock processtwo sets of needles (short and long) in both cylinder and dial and at least two feeders. This fabric cannot be un roved fromeither sides and has no curling effect.End use: under wear, trouser, sportswear, t- shirts, polo shirts etc.

Face Side Back Side

Looping diagram Cam Arrangement

M KK MM KK M

NeedleArrangement

Single Lacost Single lacost is a knit-tuck single jersey structure. Face and back side of the fabric is different & produced withcylinder needle only. The prominence of the design appears on the back of the structure. The repeat of this structurecompletes on four courses.

Face Side Back Side

Looping diagram Cam Arrangement

K T K KK K K T

NeedleArrangement

D

C

Knitting Section

29 | P a g e

Double Lacost Double lacost is a knit-tuck single jersey structure. Face and back side of the fabric is different & produced with cylinderneedle only. The prominence of the design near to the single lacost design. The repeat of this structure completes on sixcourses. Benzene structure is shown on back side of the fabric.

Face Side Back Side

Looping diagram Cam Arrangement

K K K K T TK T T K K K

NeedleArrangement

Single Pique Single pique is a knit-tuck single jersey structure and produced with cylinder needle only. The prominence of the designappears on the back side of the fabric. Face side of this fabric is like face of s/j and benzene ring is produced on the backside of the fabric. The repeat of this structure completes on two courses.

Face side Back side

Looping diagram Cam Arrangement

K TT K

NeedleArrangement

Knitting Section

30 | P a g e

Double pique Double pique is a knit-tuck single jersey structure and produced with cylinder needle only. The prominence of the designappears on the back side of the fabric. Face side of this fabric is like face of s/j and benzene ring is produced on the back sideof the fabric. The repeat of this structure completes on four courses.

Face side Back side

Looping diagram Cam Arrangement

K K T TT T K K

NeedleArrangement

Fleece Fleece fabric is produced with the combination of knit, tuck and miss loops and this is s/j structure. Face side of thefabric is like face of s/j and miss loop will appear on the back side. If back side is brushed then called fleece fabric.

Face side Face side

Looping diagram Cam Arrangement

K T K MK M K MK M K T

NeedleArrangement

Knitting Section

Industrial Attachment 31 | P a g e

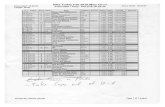

4.8.Specifications of knitting machines used in N. A. Z Bangladesh Ltd.

Table 4.7. 1Single Jersey

SL/NO.

M/CTYPE

MC/DIA

M/CGAUGE

FEEDER

QTY BRAND ORIGIN FABRIC’STYPE

PRO.CAP/KGS

REMARKS

1 S/J 19 24 57 1 ORIZIO ITALY S/J, Pique 200

2 S/J 20 24 60 1 ORIZIO ITALY S/J, Pique 225

3 S/J 21 24 63 2 ORIZIO ITALY S/J, Pique 450

4 S/J 22 24 66 2 ORIZIO ITALY S/J, Pique 500

5 S/J 23 24 69 3 ORIZIO ITALY S/J, Pique 750

6 S/J 22 24 66 2 ORIZIO ITALY S/J, Pique 500

7 S/J 23 24 69 3 ORIZIO ITALY S/J, Pique 750

8 S/J 25 24 75 1 ORIZIO ITALY S/J, Pique 300 LycraAttachment

9 S/J 24 24 72 2 ORIZIO ITALY S/J, Pique 550 LycraAttachment

10 S/J 25 24 75 1 ORIZIO ITALY S/J, Pique 300 LycraAttachment

11 S/J 26 24 114 1 MAYER & CIE GERMANY S/J, Pique 500 Lycra

Knitting Section

Industrial Attachment 32 | P a g e

Attachment

12 S/J 28 24 123 1 MAYER & CIE GERMANY S/J, Pique 500 LycraAttachment

13 S/J 26 24 114 1 MAYER & CIE GERMANY S/J, Pique 500 LycraAttachment

Total 21 6025

Table 4-7. 2 Fleece + 2 Thread Fleece + 3 Thread Fleece

SL/NO.

M/CTYPE

MC/DIA

M/CGAUGE

FEEDER QTY BRAND ORIGIN FABRIC’STYPE

PRODCAP/KGS

REMARKS

1 Fleece 28 20,24 90 1 MAYER & CIE GERMANY

S/J ,Fleece 400 LycraAttachment

2 Fleece 30 20,24 96 1 MAYER & CIE GERMANY

S/J ,Fleece 400 LycraAttachment

3 Fleece 32 20,24 102 1 MAYER & CIE GERMANY

S/J ,Fleece 450 LycraAttachment

4 Fleece 34 20,24 108 1 MAYER & CIE GERMANY

S/J ,Fleece 500 LycraAttachment

5 Fleece 32 20,24,28 96 1 Fukahama TAIWAN S/J ,Fleece 350 Lycra

Knitting Section

Industrial Attachment 33 | P a g e

Attachment

6 Fleece 34 20,24,28 102 1 Fukahama TAIWAN S/J ,Fleece 400 LycraAttachment

Total 6 2500

Table 4-7. 3 Rib + Interlock + Flat Back Rib + Drop Needle

SL/No.

M/C TYPE MC/DIA

M/CGAUGE

Feeder

QTY

BRAND ORIGIN FABRIC’STYPE

Prodcap/kg

REMARKS

1 Rib+Interlock 30 14,18 62 1 MAYER & CIE GERMANY Rib+I/L+F/Rib 300 Lycra Attachment

2 Rib+Interlock 34 14,19 70 3 MAYER & CIE GERMANY Rib+I/L+F/Rib 350 Lycra Attachment

3 Rib+Interlock 36 14,20 74 1 MAYER & CIE GERMANY Rib+I/L+F/Rib 400 Lycra Attachment

4 Rib +Interlock 36 14,20 74 1 MAYER & CIE GERMANY Rib+I/L+F/Rib 400 Lycra Attachment

5 Rib +Interlock 38 14,21 78 1 MAYER & CIE GERMANY Rib+I/L+F/Rib 500 Lycra Attachment

6 Rib +Interlock 36 16,22 72 1 Fukahama TAIWAN Rib+I/L+F/Rib 350 Lycra Attachment

7 Rib +Interlock 38 16,23 76 1 Fukahama TAIWAN Rib+I/L+F/Rib 400 Lycra Attachment

8 Rib +Interlock 40 18,22 84 3 Juinn Long TAIWAN Rib+I/L+F/Rib 400 Lycra Attachment

Knitting Section

Industrial Attachment 34 | P a g e

9 Rib 40 16 80 1 Juinn Long TAIWAN Rib +F/Rib 800 F/Look lycra Attach

10 Rib 42 18 84 4 Juinn Long TAIWAN Rib +F/Rib 400 F/Look lycra Attach

11 Interlock 38 24 114 1 Juinn Long TAIWAN INTERLOCK 400 Lycra Attachment

12 Interlock 40 24 120 1 Juinn Long TAIWAN INTERLOCK 400 Lycra Attachment

13 Interlock 42 24 126 1 Juinn Long TAIWAN INTERLOCK 400 Lycra Attachment

14 RIB 34 15 24 1 Juinn Long TAIWAN RIB 200 Lycra Attachment

Total 21 5700

Table 4.7.1 Terry = S/J + Terry / Terry Fleece + Velor + Polar Fleece etc.

M/CTYPE

MC/DIA

M/CGAUGE

FEEDER QTY BRAND ORIGIN FABRIC’S TYPE

PRODCAP/KGS

REMARKS

1 Terry 42 20 68 2 MAYER & CIE Germany Terry 1000 Lycra Attachment

Total 2 1000

Knitting Section

Industrial Attachment 35 | P a g e

Table 4.7. 4 Auto Stripe + Feeder Stripe (S/J + Pique + Lacoste + Other Design)

SL/NO.

M/C TYPE MC/DIA

M/CGAUGE

FEEDER

QTY

BRAND ORIGIN FABRICTYPE

PRODCAP/KGS

REMARKS

1Auto Stripe 34 24 48 4 Fukahama JAPAN Auto Stripe 300 Lycra Attachment

2 Auto Stripe 36 24 48 4 Fukahama JAPAN Auto Stripe 350 Lycra Attachment

3 Auto Stripe 38 24 48 2 Fukahama JAPAN Auto Stripe 400 Lycra Attachment

Total 8 1050

Table 4.7. 5: V-bed knitting m/c

SL/NO.

M/C TYPE MC/DIA

M/CGAUGE

FEEDER QTY

BRAND ORIGIN FABRICTYPE

PRODCAP/KGS

REMARKS

1 Flat Knit 0 14 8 6 Snima Seiki Japan Collar/Cuff 1400 Lycra Attachment

2 Flat Knit 0 14 12 1 Stoll Germany Collar/Cuff 700 Lycra Attachment

Total 7 2100

Knitting Section

Industrial Attachment 36 | P a g e

4.9.Quality Standard:

N. A. Z Bangladesh Ltd. follows the four point grading system to inspect the body& rib fabric, by this four point system, the faults arc found by the inspection and points aregiven against the faults. Following table shows the four point grading system followed byinspection at N. A. Z Bangladesh Ltd.

Table 4.8: four point system for knit fabric

Four Point Grading System

Size Of Defects Penalty

3 inches or less 1 point

Over 3 inch but not over 6 inch 2 point

Over 6 inch but not over 9 inch 3 point

Over 9 inch 4 point

Any Hole 4 Point

Typical knitting calculations:

The calculations which are frequently used in the knitting section are discussed below:

Gauge (G): Number of needles per inch.

Total needles: Machine diameter× Gauge×3.416

Feeders of Single Jersey: Machine diameter×3

Feeders of Double Jersey: Machine diameter×2

Relation between yarn count and fabric Gsm

For single jersey fabric:

4320Yarn CountFabric Gsm

For Double jersey fabric:

Knitting Section

Industrial Attachment 37 | P a g e

6000Yarn CountFabric Gsm

Relation between fabrics finished Gsm, stitch length, fabric gsm, yarn count:

For Single Jersey fabric:

590 KsStitch LengthYarn Count Finished Gsm

Where,

For s/j, Ks=19.6

For 1x1 rib, Ks=26

For Interlock, Ks=38

Fabric Thickness:

Fabric thickness = 4D

Here, D= yarn dia (in relaxed state)

Tightness Factor:

TexTightness FactorStitch Length , here stitch length is in mm

Production per shift:

. 60 8Pr1000 840 ( ) 36 2.2028

D G S L F RPM efficiencyoduction per shift Kgyarncount Ne

Where,

D= Machine dia G= Machine gauge S.L.=Stitch length F= No. of feeder

4.10. Remarks:

knitting section is equipped with a large number of machines. But some modern knittingmachine should purchased including engineering stripe machine with Lycra attachmentfacility.

Lab Section

Industrial Attachment 38 | P a g e

5 CHAPTER : BATCH SECTION

Lab Section

Industrial Attachment 39 | P a g e

5.1. Batching:

Primarily batching is done by batching section which is supervised by dyeing manager.

The main function of batching section is to prepare the batch for dyeing according to

machine capacity, order and emergency. This section receive the grey fabric from knitting

section and make batch according to order for particular shade. Then this batch delivers to

dyeing section for dyeing.

Function or purpose of Batch section:

To receive the grey fabric roll form knitting or other source.

Turn the gray fabric if require.

Prepare the batch for dyeing according to the following criteria:

Order sheet (Received from buyer)

Dyeing shade ( light or dark, color or white)

Machine capacity.

Type of fabric ( 100% Cotton, CVC, Stripe fabric)

Emergency order.

Fabric construction (Single jersey, Rib, Lycra Rib, Lacost, PK etc.)

To send the grey fabric to the dyeing floor with batch card.

To keep record.

Proper Batching Criteria:

To use maximum capacity of existing dyeing machine.

To minimize preparation time & machine stoppage time.

To use a particular machine for dyeing same shade.

5.2.Calculations related to batch section:

( )100

Dia cm GSMGrams per linear meter

1000kg per ChamberMeters Per ChemberGrms per linear meter

Now, when a gram per linear meter is low then meters per chamber will be more. Thus,fabric loading should be reduced to avoid jamming in the winch. In this case 80-85% fabric

Lab Section

Industrial Attachment 40 | P a g e

loading is given. But when gram per linear meter is more then rope length will reduce andin this case up to 90% fabric loading can be given.

Preparing the fabric ropes

The fabric ropes for each chamber should be prepared in batching section. The fabric rollsare correctly sewn together. This will minimize the time required to load the machine, andavoid the risk of rope entanglement.

Fabric loading in the m/c will vary with the type of fabric and the width of the fabric andthe amount is not less than 50% of the machine nominal load.

5.3.Calculating the chamber loading

In the following table are listed general recommendations covering rope cycle times andspeeds for a wide range of fabrics:

Fabric Rope cycle times in minutes Rope circulation speed m/min

Knit fabric

PES unfixed 1 250

PES heat set 1-1.5 200

PC 1-2 250Co - reactive 2-3 225-275

For calculation the following diagram shows the weight per running metre of a fabric ingrams, and the corresponding rope weight and length. e.g. a fabric of 200 gm/runningmetrewith rope length of 800 metres will have a dry weight of 160 kg.

Lab Section

Industrial Attachment 41 | P a g e

Kg

0200 400 800600 1000

01200

20

40

60

80

100

120

200

140

160

180

220

260

280

300

320

340

360

240

100g

125g

150g

175g

200g

225g50

0g

400g

350g

300g

275g

250g

550g

Grms/running meter

Rope length(m)

Lab Section

Industrial Attachment 42 | P a g e

Figure 5-1: Rope length (m) and fabric wt loading on m/c depending on the grams perrunning meter of fabric

Turn over time

The following diagram shows the relationship between winch speed and rope lengthnecessary to reach a required turn over time.

Figure 5-2: Rope length depending on winch speed

It is also possible to reverse the procedure and calculate the maximum rope length with afabric of a particular weight, having determined the winch speed and circulation time.

For example: 100% Cotton, Reactive dyeing:

Circulation time = 3 minutes

Winch speed = 250 m/min

Rope length = 3 mins x 250 m

0 200 400 600 800 1000 1200

100

200

300

400

500

m/min600

Win

ch sp

eed

m/m

in

Rope length(m)

3

1

2

45

6

Lab Section

Industrial Attachment 43 | P a g e

= 750 meters

If the rope is shorter, so that the same rope circulation time and nozzle contacts aremaintained during the cycle, the winch speed should be reduced.

Rope length 690 m

Circulation time 3 mins = 230 m/min (winch speed)

Calculation of the the rope length

If Rope weight is 105 kg

(weightper running metre) 200 kg/rm = 525 m (rope length)

Calculation of the winch speed

If Rope length is 540 m

Cycle time 3 mins

Then Winch speed = 180 m/min

Number of nozzle passages

(Process time) 360 mins

(Cycle time) 3 mins = 120 (nozzle passages)

5.4.Batch management

Primarily batching is done by dyeing manager taking the above criteria underconsideration. Batch section in charge receives this primary batch plan from dyeingmanager. Some time planning is adjusted according to m/c condition or emergency

Machines in Batch section:

Fabric turning m/c:

Machine Name : Air turning m/cBrand Name : TaidaOrigin : ChinaM/c Speed : 300-500m/minModel : DF 200Company : Shandong Taida Dyeing & Finishing Machinery Co. Ltd.

Lab Section

Industrial Attachment 44 | P a g e

5.5.Process flow chart of Batch preparation:

Deliver the Fabric to dyeing section

Receive the order sheet from in-charge

Make the batch card on the priority of shipment date

Take the Batch card which order have to deliver first

Check the availability of the fabric

Turn off the fabric (if necessary)

Distribute the collar/cuff or Rib in each rope equally ensuring equallength.

Take collar/cuff as per size and keep the total weight

Take require quantity of body fabric from the store

Stitch the fabric

Write down weight against roll no. in the back side of the Batch card

Write the total weight in the batch card

Fill up the Production report form

Lab Section

Industrial Attachment 45 | P a g e

Precautions during batch making

Check whether count variation is occured or not

Check whether lot variation is occured or not

Check whether rib fabric is included or not

Be sure about the packing instruction , whether it is

Solid color solid size

Solid color assorted size

Assorted color assorted size

Assorted color solid size

Lab Section

Industrial Attachment 46 | P a g e

6 CHAPTER : LAB SECTION

Lab Section

Industrial Attachment 47 | P a g e

6.1. Lab dip:

Lab dip is a process by which buyers supplied swatch is matched with the varying dyespercentage in the laboratory with or without help of “DATA COLOR”

Lab dip plays an important role in shade matching & and detaching the characteristics ofthe dyes and chemicals are to be used in the large scale of production so this is animportant task before bulk production.

Objective of Lab dip:

The main objectives in lab are as follows:

To calculate the recipe for sample dyeing. To compare dyed sample with swatch by light Box or spectrophotometer. To calculate revise recipe for sample dyeing. Finally approved lab dip (Grade: ABC)

Table 6-1: Amount salt and soda used depending on the shade %

Shade % Salt (g/l) Soda (g/l)

0.001-0.01 15 4

0.01-0.1 20 5

0.1-0.5 30 7

0.5-1.0 40 10

1.0-1.5 50 12

1.5-2 60 15

2-3 70 18

3 to above 80 20

Lab Section

Industrial Attachment 48 | P a g e

6.2.Instrumental Color matching Process:

Spectrophotometer flow Chart

Triangle shade

Initial recipe

Laboratory dyeing

Use L*, a*, b* to match

OK

Production dyeing

Use L*, a*, b* to match

Recipe correction

Not matched

Production correction

Not matched

Input database

History of the lab

Recipe Prediction calculated by CCM

Or calculated by smart shade library

Finished

OK

Lab Section

Industrial Attachment 49 | P a g e

6.3. Dyes and chemicals measuring formula for laboratory:

◘ The amount of dye solution (ml) is calculated as follow –

Fabric weight x Shade %

Amount of dye soln (ml) = -----------------------------------------------

Concentration of stock dye soln %

Example –

In recipe, Fabric wt. = 5gm

Shade % = 2%

[If used 0. 5 % stock soln of dyes] then,

5 x 2

Amount of dye soln (ml) = ----------- = 20ml.

0.5

◘ The amount of chemical soln (ml) is measured as follow –

Fabric wt. x M: L x g/l

Amount of chemical soln (ml) = --------------------------------------

1000 x Conc. of stock soln %

Example –

In recipe, The Fabric wt. = 5 gm

Salt = 20 g/l

M: L = 10

[If taken 25 % stock soln. of salt] then,

5 x 10 x 20

Amount of chemical soln (ml) = --------------------- = 4 ml

1000 x 0.25

Lab Section

Industrial Attachment 50 | P a g e

6.4. Stock solution preparation:

SHADE % STOCK SOLUTION %

0.0001-0.009 0.1

0.10-0.99 0.5

1-1.99 1

2-3.99 2

4 ( or above) 4

6.5.Procedure of lab dip formation:

A. For 100% cotton fabric:

Fabric weight measured by electric balance 5 gm sample is taken. Calculate the recipe. Make solution of required dyes and chemicals. Then required amount of dyes, water, salt, soda and other chemicals are taken to

the pot by digital pipette.(M:L=1:7) Wet the fabric with water. Keep the fabric in the pot and immerse well with tong. Cover the pot well and set to the m/c holder. Start the program for dyeing. The dyeing time and temperature depend on types of dyes being used.

Program – 1: For light shade

Fixed temp = 60

Time = 60 min.

Program – 2: For dark shade

Fixed temp = 80

Circulation Time = 60 min.

After finished the dyeing time then cold wash two times.Acid wash for neutralization with 1g/l acetic acid.Then soaping by required soap solution for 10 min. at 950CCold wash then drying the lab dip and compare with the standard.

Lab Section

Industrial Attachment 51 | P a g e

B. For cotton/ blend fabric (all in one method):

Fabric weight measured by electric balance 5 gm sample is taken. Calculate the recipe for polyester part. 1 to April 1 Make solution of required dyes and chemicals. Then required amount of dyes, water, dispersing agent, acetic acid and sodium ace-

tate are taken to the pot by digital pipette.Wet the fabric with water. Keep the fabric in the pot and immerse well with tong. Cover the pot well and set to the m/c holder. Start the program for dyeing. The dyeing time and temperature are carried out for 30 min. at 1300C After finished the dyeing time then cold wash two times. Then reduction clearing by hydrose, caustic & detergent for 20 min at 700C Cold wash then drying and match with the standard sample.

Again,

Dye the cotton part with cotton dyeing procedure.

6.6.Self shade formation:

Dyeing lab in-charge will produce self shade for new dyes stored in the dye store. Selfshade should be ok with the previous self shade of the dye or if any deviation is obtainedthen necessary steps should be taken.

Development of self shade:

Reactive Black B:

0.5%,30/8 1%,40/10 1.5%,40/10

2%,50/12 2.5%,50/12

3%,60/15

3.5%,60/15

4%,70/18 4.5%,80/20

5%,80/20 6%,80/20

Lab Section

Industrial Attachment 52 | P a g e

Reactive Yellow 4GL:

Ciba Red FNR:

Reactive Yellow RR:

Reactive Blue:

0.05%,0/6 0.1%,20/6 0.5%,30/8 0.8%,38/8 2%,60/15 3.5%,60/15

0.1%,20/6 0.5%,30/8 0.8%,30/8 2%,60/15 3.5%,60/15

5%,80/20

2%, 60/15 3.5%, 68/150.5%, 30/8 0.8%, 30/8 1%,48/10

0.05%,20/6 0.1%,20/6 0.5% 20/6 0.8%,20/6 2%,60/15 3.5%,60/15

Lab Section

Industrial Attachment 53 | P a g e

Ciba Orange FNK:

Ciba Yellow FN2R:

Ciba Red FNR:

2%, 50/12 3%, 80/20 4%, 80/20 5.5%, 80/20

0.05%,20/6 0.1%, 20/6 0.25%,30/8 0.5%,30/8 1%,40/10 1.5%,40/10

1.0%,30/8 2.5%,80/20 3.5%,80/20 5.0%,80/20

5%,80/203.5%,80/200.1%,30/8 0.5%,30/8 1%,30/8 2.5%,80/20

Lab Section

Industrial Attachment 54 | P a g e

Dimarine Scarlet HF3G:

Dimarine Turquoise CIB:

0.005%, 20/6 0.01%,20/6 0.05%,20/6 0.1% 20/6 0.5%,30/8 0.8%,30/8

1%, 40/10 2%, 60/15 3.5%,60/15 5%,60/15

0.005%, 20/6 0.01%,30/6 0.05%,20/6 0.1%,20/6 0.5%,30/8 0.8%,30/8

1%, 40/10 2%, 40/10 3.5%,70/15 5%, 80/20 5.5%,80/20

Lab Section

Industrial Attachment 55 | P a g e

Reactive Super Black RGB:

Sola Blue RSPL:

0.005%,20/6 0.01%,20/6 0.05%,20/6 0.1%,20/6 0.5%,30/8 0.8%,30/8

1%,40/10 2%,60/15 3.5%,60/15 4%,70/18

0.1 %, 20/6 0.5 %, 38/8 1%, 40/10 1.5%, 48/10 2.5%, 58/12 3.5%, 60/15

4%, 78/18 4.5%, 80/20 5%, 80/20 5.5%, 80/20 7%, 80/20 8.5%, 80/20

Lab Section

Industrial Attachment 56 | P a g e

6.7.Machine Specification of Dyeing Lab:

Machine No : 01

Machine Name : Power drum

Manufacturer : Samsung

Machine type : Fully automatic washingmachine

Machine No : 02

Manufacturer : Sharp

Country of origin : Japan

Machine type : Washing machine

Machine No : 03

Machine Name :Labdyeing machine(Polyester dye)

Manufacturer : Irdyer

Machine No : 04

Machine Name :Electrolux washcotar

Model : FOM71MP-lab

Function :Dimensional stability(Shrinkage)

Machine No : 05

Machine Name : Rota wash

Function : colorfastness towash

Machine No : 06

Machine Name : Lab dyeing machine(Cotton dye)

Manufacturer : IRDYER

Machine No : 07

Machine Name : Dimensionalstability to wash

Manufacturer : LG

Machine No : 08

Machine Name : Tumble dryer

Manufacturer : Indesit

Machine No : 09

Machine Name : Color fastness tolight

Manufacturer : SDL international

Machine No : 10

Machine Name : ICI pilling tester

Manufacturer : SDL international

Country of origin : England

Machine No : 11 Machine Name : 12

Lab Section

Industrial Attachment 57 | P a g e

Machine Name : Gray Scale

Manufacturer : SDL international

Country of origin : England

Machine Name : Incubator

Manufacturer : SDL international

Function : Colorfastness towater

Machine No : 13

Machine Name : Crockmeter

Manufacturer : James H. Heal &Co. Ltd.

Country of origin : England

Machine No : 14

Machine Name : Spectrophotometer

Brand : Color-eye 7000A

Manufacturer : SDL international

Country of origin : England

Machine No : 15

Machine Name : Light box

Manufacturer : Verivide (CAC 120)

Machine No : 16

Machine Name : Overlock sewingmachine

Dyeing Section

Industrial Attachment 58 | P a g e

7 CHAPTER : DYEING SECTION

Dyeing Section

Industrial Attachment 59 | P a g e

7.1.Layout of Dyeing Department

Hydro Extractor M/c

Fabric Inspection M/c

1 to 12- Dilmenler Dyeing M/c (Except 10 & 11)

10-bangla Dyeing m/c, 30 kg capacity

11-bangla Dyeing m/c, 50 kg capacity

BWM Bangla Washing M/c

CMC- Color Matching Cabinet

FTM-Fabric Turning M/c

8 7 6 5 4 3 2 11050

kg

700

kg525kg

1400kg

350kg

175kg

50kg

50kg

TumbleDryer

TumbleDryer

TumbleDryer

TumbleDryer

FTM

FTMBacksewingm/c

TubeCompactor

Relax Dryer

Tubesqueezer

CMC

Office Room

Dyeing lab

(1st floor)

OpenCompactor

Bruckner StenterOpenSqueezer

1400 kg

12

10kg

9

1110

BWM

BW M

Dyeing Section

Industrial Attachment 60 | P a g e

7.2.Orgn gram of Dyeing Department:

Chairman

Managing Director

General ManagerOperation

Manager Dyeing

Supervisor

ProductionOfficer

Worker

Finishing In-Charge

QualityController

QA In-Charge

Worker

AssistantManager QA

ManagerDyeing

Asst. Manager

Dyeing

Sr. ProductionOfficer/In-Charge

A.P.O

ProductionOfficer

Supervisor &Worker

Supervisor

Officer R&D

Worker

AssistantManager R&D

Dyeing Section

Industrial Attachment 61 | P a g e

7.3.Textile Dyeing:

Dyeing is a coloration process of textile which is invariable carried out in an aqueousmedium.

In the other hand, dyeing can be define as a process by which a yarn, fabric, garments andany other materials that come to contact of dye by presence of auxiliaries that create thecondition of dyeing environment

Table 7. 1Classes of dyes on the basis of suitability of dyeing different fibers:

Sl. no Name of dyes Suitable for Fibers

01 Acid dyes Wool, silk and Nylon

02 Basic dyes Nylon, Acrylic, Acetate Rayon, Silk, Wool and Jute

03 Direct dyes Cotton, Viscose Rayon, Linen, Nylon, Wool and Silk

04 Azoic dyes Cotton, Viscose and Linen.

05 Vat dyes Cotton, Viscose and Linen.

06 Sulpher dyers Cotton, Viscose and Linen.

07 Reactive dyes Cotton, Viscose, Linen, Wool, Silk and Nylon.

08 Disperse dyes Polyester, Nylon, Acrylic, Acetate Rayon and TriacetateRayon.

Cotton:

The repeating unit in the cotton polymer is cellobiose, which consists of two glucose units.The most important chemical grouping on the cotton polymer is the hydroxyl groups or -OHgroups. As a result

Cotton is a natural Cellulose has an empirical formula of (C6H10O5)n.

Figure 7.1: Cellulose, the polymer of cotton

Dyeing Section

Industrial Attachment 62 | P a g e

Chemical Composition of Cotton:

Table 7. 2: Chemical composition of raw cotton:

Component Main location Relative amountCellulose Secondary wall 86.8 %Oil and Wax Cuticle 0.70 %Pectins Primary cell wall 1.0 %Carbohydrates Primary cell wall 0.50 %Protein Lumen 1.2 %Salts Lumen 1.0 %Water Whole 6.8 %

Others 2.0 %

7.4. Reactive dye:

Reactive dyes are so called because their molecules react chemically with the fibre polymersof some fibres to form a covalent bond between the dye molecule and fibre polymer. Thefibre most readily coloured with reactive dyes are the man-made and natural cellulose fibres,synthetic nylon, and natural protein fibres.

History: In 1955, Rattee and Stephen, working for ICI in England, developed a procedure fordyeing cotton with fiber-reactive dyes containing dichlorotriazine groups. They establishedthat dyeing cotton with these dyes under mild alkaline conditions resulted in a reactivechlorine atom on the triazine ring being substituted by an oxygen atom from a cellulosehydroxyl group This is shown below:

Where Cell–OH is the cellulose with a reactive hydroxyl group, Dye–Cl- is the dye with itsreactive chlorine atom, and Cell–O–Dye the dye linked to the cellulose by a covalent bond.The role of the alkali is to cause acidic dissociation of some of the hydroxyl groups in thecellulose, and it is the cellulosate ion (Cell–O-) that reacts with the dye.

2Cell OH HO Cell O H OCell O Dye Cl Cell O Dye Cl

Dyeing Section

Industrial Attachment 63 | P a g e

Classification of Reactive dyes on the basis of functional group

Mono-functional

Multi-functional

Bi-functional

Homo-bifunctional

Hetero-bifunctional

Tri-functional

Tetra-functional

Penta- functional

Bi-and poly-functional reactive dyes can be divided into four groups. If the two reactivegroups in the dyestuff molecule are the same, they are known as homobifunctional dyes, andif they are different, they are known as heterobifunctional types.

Figure 7.2: Bifunctional reactive dye (Remazol Black B, DyStar)

Dyeing machine:

The machine which is used to dyeing or coloring of materials like yarn, fabric, garments orany other materials is called dyeing machine.

Dyeing Section

Industrial Attachment 64 | P a g e

7.5.Winch Dyeing Machine:

The winch or beck dyeing machine is quite simple and serves for all scouring,bleaching, dyeing, washing-off and softening processes. The machine contains a length offabric with the ends sewn together, which is compressed to form a continuous rope. This ropepasses from the dye bath over two elevated reels and then falls back into the bath. The firstroller is free-running (jockey or fly roller). The second (winch reel) is driven and controls therate of rope transport and the extent of pleating where the rope accumulates below and behindthe winch. Both reels extend the full length of the machine and accommodate several fabricropes running side by side. The fabric rope is held on the winch by friction and its ownweight. Covering the winch with polypropylene or polyester tape increases the friction.

Figure 7. 3: Dilmenlar Winch Dyeing m/c

7.6.Principle of winch dyeing machine

The basic principle of all winch dyeing machines is to have a number of loops orropes of the fabric in the dye bath, these ropes are of equal length, which are mostlyimmersed in the liquor in the bath.

The upper part of each rope runs over two reels which are mounted over dye bath. Atthe front of the machine, above the top of the dye liquor, is a smaller reel, which iscalled jockey or fly roller. The fly roller remains freewheeling along with fabric rope.

At the back of winch tank is the winch wheel, which pulls the fabric rope from the dyebath over the jockey reel for dropping in the dye bath for immersion.

From the dropped location, the fabric rope travels back. To be lifted and fed to winchwheel.

Dyeing Section

Industrial Attachment 65 | P a g e

The dyeing process on winch dyeing machines is based on higher M: L as comparedwith other dyeing machines.

The process is conducted with very little tension. The total dyeing time is lengthier as compared to other machines.

Table 7. 3: Production Parameters :

Process Temp(▫C) pH Time minM : Lratio

Scouring -

Bleaching98 10-11 30 1:8

Enzyme Wash 55 4.5-5 30 1:8

Reactive Dyeing

(Light Shade)60 10-11 60 1:8

Reactive Dyeing

(Dark Shade)60 11-12 60 1:8

White Shade 98 10.5-11.5 30 1:8

Turquish color dyeing 80-90 11-12 60 1:8

Polyester dyeing 130 4-4.5 45 1:8

7.7.Specification of Dyeing Machine used in N.A.Z Bangladesh LTD:

Machine No # 01

Manufacturer Dilmenler

Capacity 50 kg

No of nozzle 01

Website www.dilmenler.com.tr

Machine No # 02Manufacturer Dilmenler

Dyeing Section

Industrial Attachment 66 | P a g e

Capacity 50 kgNo of nozzle 01

Website www.dilmenler.com.tr

Machine No # 03

Manufacturer Dilmenler

Capacity 1050 kg

No of nozzle 06

Website www.dilmenler.com.tr

Machine No # 04

Manufacturer Dilmenler

Capacity 175 kg

No of nozzle 02

Website www.dilmenler.com.tr

Machine No # 05

Manufacturer Dilmenler

Capacity 350 kg

No of nozzle 02

Website www.dilmenler.com.tr

Machine No # 06

Manufacturer Dilmenler

Dyeing Section

Industrial Attachment 67 | P a g e

Capacity 1400 kg

No of nozzle 08

Website www.dilmenler.com.tr

Machine No # 07

Manufacturer Dilmenler

Capacity 525 kg

No of nozzle 03

Website www.dilmenler.com.tr

Machine No # 08

Manufacturer Dilmenler

Capacity 700 kg

No of nozzle 03

Website www.dilmenler.com.tr

Machine No # 09

Manufacturer Dilmenler

Capacity 10 kg

No of nozzle 01

Website www.dilmenler.com.tr

Machine No # 10

Capacity 30 kg

Dyeing Section

Industrial Attachment 68 | P a g e

Machine No # 11

Capacity 70 kg

Machine No # 12

Manufacturer Dilmenler

Capacity 1400 kg

No of nozzle 08

Website www.dilmenler.com.tr

Calculation realted to dyeing floor:

39.37 1000.

Machine CapacityWinch speedGSM fabric width no of Nozzle Cycle Timt

39.37 10000.

Machine CapacityCycle TimeFabric GSM Fabric width No of Nozzle Winch speed

Re ( ) %quired Dye kg Shade Fabric weight in Kg

/Re1000

g l required Total liquorquired Chemicals

Dyeing Section

Industrial Attachment 69 | P a g e

Figure 7. 4: Cross sectional view of Dilmenler Dyeing m/c

1-Minimum fabric tension withlow level main Winch

2-Adjustable patented nozzlesystem

3-Horizontal type cylindricalfilter with large filteringsurface

4-Teflon lined J-BOX bottom

5-J-BOX system which providenon-tangle even for sensitivefabric

6-Large inspection port withplatform with three combinedsecurity system

7-Halogen inner lighting

8-Elliptical fabric pipe

9-Rapid machine cleaningsystem

10-HAT-PRO 100% hot waterpreparation tank

11-Proportional heating &cooling valves

12-Heat exchanger with70C/min heating gradient

INLETINLET

DyeDosin

gTank

Chemical

DosingTank

65

4

32

7

21 8 9

10

11

12

13

14

WaterInlet

Dyeing Section

Industrial Attachment 70 | P a g e

Figure 7. 5: Different valves used in Dilmenler winch Dyeing m/c

Cold Soft WaterInlet

Steam Inlet

Hot Soft WaterInletCondensate Return Line

Cooling WaterReturn Line

DN

80 D

N 8

0

DN 20

AdditionTank

(Auxiliaries)

AdditionTank

(Dye)

DN 25

DN 80

DN 80

DN 80

DN 50

Hea

t Exc

hang

er

DN 125

DN 125

DMS140

DMS140

DN80

DN80

DMS140

DMS140

DN 125

8

Dyeing Section

Industrial Attachment 71 | P a g e

Controlling Points:

Air min 6 bar to max 7 bar

Steam supply min 6 bar to max 8 bar

Water supply min 2 bar to max 5 bar

Valve fig. Description

Steam valve

Steam valve

Swing check valve

Strainer

Manual valve

Flow scope

Pressure Gauge

½” muff and dummy plug

7.8. Important parts of Dilmenler Winch Dyeing m/c:

Winch:

Winch is an important part of dyeing machine and used for moving the fabric through thewhole dyeing machine. Winch is rotated with the help of motor. Fabric is passed over thewinch and fabric dwell time depends on the winch speed. Winch speed will depend on therope length and gsm of the fabric to be dyed. There is opening on the machine for winch toremove tangled fabric from winch. No. of nozzle per winch is normally 1 or 2 and total no. ofwinch per machine will depend on machine capacity.

Figure 7.6: winch

Dyeing Section

Industrial Attachment 72 | P a g e

Addition Motor:

Addition motor is used to dissolve salt, soda dye and other chemicals. This motor ensuresuniform dispersion of chemicals. This motor is used in the dosing tank and tiere is an agitatorconnected to the motor for addition.

Dosing tank:

Dosing tank is used for the application of dyes and chemicals to the dye bath in solutionform. Steam line is connected to the dosing tank. This tank ensures dissolved chemicals anddyes to the dyeing machine to ensure fault free dyeing.

Nozzle:

Nozzle is the part of winch dyeing machine where dye pick up of the fabric is maximum.After the winch the fabric is passed through the nozzle. Main motor is connected to thenozzle and continuously circulate dyeing liquor to the machine via nozzle. Fabric passed withthe pressure of water and used for controlling the speed of dye liquor. There is opening in thenozzle which can be controlled as required.

Heat Exchanger:

Heat exchanger is used for heating and cooling the dye bath liquor. Heat exchange process isachieved by passing steam or water through the coiled pipe line present in the heat exchanger.When heat is increased then steam valve is opened and passed through the coiled pipe lineand dyeing liquor is passed through the heat exchanger. During the passage, heat increase ofdyeing liquor. For reducing heat, water valve will opened and heat will reduce.

J-Box:

J-box of the machine is where fabric will stored after falling from the nozzle. J-shape helpsthe smooth passage of fabric. This box contains a deposition tube line attached to the fabricguide. This box is perforated and ensures easy circulation of dyeing liquor to the machine.

Main motor:

Centrifugal pump is used for circulating the liquor through the dyeing machine. Its capacitywill depend on the capacity of the machine.

Valves:

Different types of valves are used in dyeing machine. Such as steam valve, water valve,pneumatic valve etc.

Dyeing Section

Industrial Attachment 73 | P a g e

Viewing light:

Viewing light is given in the dyeing machine to see how the dyeing of the fabric is advancingin the dyeing machine from outside of the dyeing machine as it is impossible to look into thedyeing machine due to high steam temperature.

Filter Tube:

Filter tube is used inside the circulating line and drain line through which dyeing liquor ispassed to filter impurities. If the filter is jammed then removed from line and cleaned.

Drain line:

Drain line is used for extracting the liquor out of the dyeing automatically.

7.9.Machine Setup On The Basis Of Fabric Type & GSM

Fabric Type GSM Pump Speed % Reel Speed(MPM)

Single Jersey Up to 140 80 250

140 – 180 85 230

180 – above 90 210

Polo Pique, Back Pique

& Bubble Knit

Up to 160 85 280

160 – 200 90 260

220 – above 90 240

Interlock Up to 180 85 260

180 – 220 90 240

220 – above 90 220

Dyeing Section

Industrial Attachment 74 | P a g e

7.10. Stock Solution for Production:

S.L no. SHADE % SALT SODA WATER

1 0.0001-0.01 7 5 1:8

2 0.01-0.08 10 6

3 0.08-0.15 12 7

1:7

4 0.15-0.8 15 8

5 0.8-1.5 18 9

6 1.5-2 20 10

7 2-2.5 30 13

8 2.5-3 40 15

9 3-3.5 50 16

10 3.5-4 60 18

11 4-4.5 70 20 1:6

12 4.5 and over 80 20

7.11. Water level for different dyeing m/c on the basis of shade %:

Machine No Light Shade

≤ 0.49 %

Medium Shade

0.5 – 1.99 %

Deep Shade

≥ 2.0 %

DM – 01 4200 Litter 3800 Litter 3600 Litter

DM – 02 3000 Litter 2800 Litter 2600 Litter

DM – 03 3000 Litter 2800 Litter 2600 Litter

Dyeing Section

Industrial Attachment 75 | P a g e

DM – 04 1900 Litter 1750 Litter 1600 Litter

DM – 05 6200 Litter 5800 Litter 5600 Litter

DM – 06 4200 Litter 3800 Litter 3600 Litter

DM – 07 3200 Litter 3000 Litter 2800 Litter

SM – 01 180 Litter 150 Litter 120 Litter

SM – 02 300 Litter 250 Litter 230 Litter

SM – 03 180 Litter 150 Litter 120 Litter

SM – 04 160 Litter 140 Litter 120 Litter

SM – 05 160 Litter 140 Litter 120 Litter

SM – 06 160 Litter 140 Litter 120 Litter

7.12. Amount of Salt & Alkali on the basis of Shade%

Shade % ( owf ) Glauber salt ( g/l ) Soda ash ( g/l )

0.0010 – 0.2 20 5

0.2 – 1 40 10

1 – 2.5 60 15

2.5 – 4 70 20

4 – 8 80 20

Above 8 100 20

Dyeing Section

Industrial Attachment 76 | P a g e

7.13. Raw Material Used for Dyeing:Gray fabricsDyesChemicals

Table 7.4: Dyes, Chemicals & Cuxiliaries Use in N.A.Z:

Basic Chemicals Suppliers name Country of OrigineBasic acitic acid SINTEX &

CHEM.PTV.LTDChina

Basic common salt Osman Enterprise Local

Basic gluber salt chemical SINTEX &CHEM.PTV.LTD

China

Basic caustic soda SINTEX &CHEM.PTV.LTD

China

Basic hydrogen per oxide ASM CHEMICALS Bangladesh

Basic soda ash light SINTEX &CHEM.PTV.LTD

China

AuxiliariesPeroxide killer geizyme OEM SM COLOR CHEM USA

Peroxide tesbilizerSR/Stopa-52 chemical SM COLOR CHEM USA

Polyester leveling Melevel -lpf MATEX BANGLADESHLTD

Bangladesh

Sequestering austol AUSTEX SPAIN

Soaping asugal-ALBI AUSTEX SPAIN

Wetting agent –proder-SCPC/LF AUSTEX SPAIN

White softener gensoft AUSTEX SPAIN

Fixing ecofix DR/SR Ecochem/AUTEX Sri-lanka

Leveling drimegen E2R/ Texotech FORTUNE TOP INC Taiwan

Anticrease-Pac(8460)Jintex ECO GD CONE FORTUNE TOP INC Taiwan

Gintex ECO GS CONE FORTUNE TOP INC Taiwan

Genifoam NS FORTUNE TOP INC TaiwanSpecial ChemicalsBrightener Leuco phor BSB Clariant INDONESEIA

Brightener sun white SUN RISE CHEM. Taiwan

Enzyme producto _EAPS-A/Genincor-Bf-1600/3500

GENENCOR Singapore

Dyebath Enzyme Techzymr-p 1600 GENENCOR Singapore

Dyeing Section

Industrial Attachment 77 | P a g e

Silicon softener Gensoft-SA 852 FORTUNE TOP INC TaiwanOthersOthers Sodium Hydrose Chemicals Alif Chemicals ChinaDyesCiba blue FNR Dyes Swiss color Switzerland

Ciba brill Blue FNG FyesFGFN Swiss color Switzerland

Ciba red FN3G Dyes Swiss color Switzerland

Ciba red FNR Dyes Swiss color Switzerland

Ciba red WB Dyes Swiss color Switzerland

Ciba Navy SG Swiss color Switzerland

Ciba Red C2BL Swiss color Switzerland

Ciba Navy WB Swiss color Switzerland

Ciba yellow CRG Dyes Swiss color Switzerland

Ciba yellow S3R Swiss color Switzerland

Ciba yellow H2G Swiss color Switzerland

Ciba Navy FNB Swiss color Switzerland

Ciba Yellow F4G Dyes Swiss color Switzerland

Ciba Yellow DN2R Dyes Swiss color Switzerland

Ciba Orange FNR Dyes Swiss color Switzerland

Ciba Orange W3R Dyes Swiss color Switzerland

Dianix black CCR Dyes DyStar Switzerland

Dianix Blue SSB Dyes DyStar Switzerland

Dianix Navy CC Dyes DyStar Singapore

Dianix Yellow SEG Dyes DyStar Singapore

Drimarine Blue HFRL Dyes Clariant China/Pakistan

Drimarine BlueCLBRDyes Clariant China/Pakistan

Drimarine Red CL5B Dyes Clariant China/Pakistan

Drimarine Red RH3b Dyes Clariant China/Pakistan

Drimarine Scariate HF3G Dyes Clariant China/Pakistan

Drimarine Tarquise CLB Dyes Clariant China/Pakistan

Drimarine Yellow CL2R Dyes Clariant China/Pakistan

Drimarine Yellow HFR Dyes Clariant China/Pakistan

Reactive G. Yellow 3RS/MERL Kiri Dyes & Chemicals INDIA

Reactive black B Dyes /AB/5 Kiri Dyes & Chemicals INDIA

Reactive Red ME4BL Dyes Kiri Dyes & Chemicals INDIA

Reactive Yellow H4GL Dyes Kiri Dyes & Chemicals INDIA

Reactive Super black G Dyes/AG Kiri Dyes & Chemicals INDIA

Reactobond yellow HW Dyes/AEY Kiri Dyes & Chemicals INDIA

Dyeing Section

Industrial Attachment 78 | P a g e

Reactobond Red Hw Dyes Kiri Dyes & Chemicals INDIA

Reactive Navy WB Kiri Dyes & Chemicals INDIA

Reattofex orange ME2RL Kiri Dyes & Chemicals INDIA

Remazol Navy RGB Dyes DyStar Singapore

Remazol Red RGB Dyes DyStar Singapore

Remazol Blue RSPL Dyes DyStar Singapore

Remazol RED RR Dyes DyStar Singapore

Remazol Blue RR Dyes DyStar Singapore

Remazol Yellow RR Dyes DyStar Singapore

Synozol Black DR Kyung-in-SyntheticCorporation

Korea

Synozol Red HF 6BN Kyung-in-SyntheticCorporation

Korea

Synozol Yellow H F2GR Kyung-in-SyntheticCorporation

Korea

Synozol brilliant blue KRL Kyung-in-SyntheticCorporation

Korea

Solacion red HE Solarfine Chemicals China

Reactive Turkish Blue Kiri Dyes & Chemicals INDIA

7.14. Amount of Salt & Alkali (mixed) on the basis of Shade%

Shade% (owf) Glauber salt (g/l) Soda ash (g/l) Caustic (g/l)

Red ≤ 4 80 5 1.2

Navy ≤ 4 80 5 1.2

Black ≤ 4 100 5 1.2

Dyeing Section

Industrial Attachment 79 | P a g e

7.15.Process Flow Chart for Knit Dyeing: For Pink color

Fabric : Single Jersey Quantity : 1310 kg

GSM : 180 M: L=1:7 (During Pretreatment)

1.8 (During Dyeing)Color : Pink Water - 9200 lit (Pretreatment)

10500 lit (During Dyeing)

Recipe:

No. Commercial name of Dyes & Chemicals Amount(g/l or %)

Total amount

Pretreatment:1. Wetting Agent-Proder_SCPC/LD/NO-LF 0.5 4.48 kg2. Gintex ECO GS CONE (S.A) 0.1 896gm3 Peroxide Stabilizer SR/Stabilizer A/Stopa-52 0.4 3.584kg4 Anticrease-AULIT-PAC(8460) 0.8 7.360 kg5 Caustic soda 3.0 27.6 kg6 H2O2 2.75 25.3 kg7 Peroxide Killer Geizyme OEM/Cetatex PC 0.5 4.6 kg8 Acetic Acid 1.0 9.2 kg

Dye Bath Chemical:9 Acetic Acid 0.2 2.1 kg10 Gintex ECO GS CONE (S.A) 0.2 2.1 kg11 Anticrease-AULIT-PAC(8460) 0.8 8.4 kg12 Leveling Drimegen E2R/Secho IND/Jinleve 1.0 10.50 kg

Dyeing13 Rea yellow HW 0.01% 0.131 kg14 Rea. Orange-MEZRL 0.07% 0.917 kg15 Syno. Red-HF6BN 0.80% 10.48 kg16 Salt 30 314.4 kg17 Soda ash 8 83.84 kg

After treatment:18 Acetic Acid 1.0 9.2 kg19 Soaping Asugal-ALBI 0.6 5.520 kg20 Colour Softener Gensoft-100/150/ASUMIN B 0.7% 9.170 kg

Dyeing Section

Industrial Attachment 80 | P a g e

Dyeing Flow Chart:

Pretreatment:

Fabric loading in the machine and magnet is attached to the fabric rope to ensure cutting ofthe fabric from the specific place.

Filling the bath with the required water & run the fabric for 10 min

Raise the temp. to 50°C @1.5°C/min and inject wetting agent, sequestering agent, H2O2

stabilizer & Anti creasing agent and run for 10 min at 500 C.

Raise temp. to 60°C @1.5°C/min process and linear dosing of caustic for 10 min

Raise temp. to 70°C @1.5°C/min process and linear dosing of H2O2 for 10 min.

Raise temp. to 105°C @1.5°C/min and run the process for 40 min.

Cooling the bath @1.5°C/min and drain at 80°C and then drain

Fill the bath with hot water from reserve tank and wash at 95°C for 10 min. then drain thebath and normal wash.

Apply peroxide killer and run at 70° C for 10 min then drain & wash the fabric.

Acetic acid dosing and pH check (4.5-5) and run 10 min. Then inject enzyme at 55°C and runfor 40 min

Raise temp. to 80°C and run 10 min which is called enzyme hot

Then drop the bath and wash for 2 times

Dyeing Section

Industrial Attachment 81 | P a g e

Dyeing:

After-treatment:

Fill the bath and raise the temp. At 45°C apply acetic acid and check pH to 5

Inject Sequestering agent, Ant-creasing agent, Leveling agent run 10 min.

½ of total Salt dosing at 45°C for 10 min with linear dosing and run 10 min

Rest ½ Salt dosing at 45°C for 10 min with linear dosing and run 10 min

Dye linear dosing at 45°C for 40 min and after 20 min salt is sample checked.

If salt sample is ok then soda progressive dosing for 50 min at 450 C.

After 20 min soda sample is checked and color steam is given to 600 C

Sample checked after 10, 30, 40 min & after 10 min B.D. sample is checked

Then cooling the bath & rinse for 10 min & drain the bath

Fill the bath and raise temp. to 45°C and dosing acetic acid. Run 10 min then drain.

Unload the fabric from machine.

Fill the bath and raise temperature to 40°C and dosing softener. Fabric is treated for 20 min& sample is checked.

Fill the bath & apply soaping agent. Raise temp. to 95°C. Run 10 min and then drain

Dyeing Section

Industrial Attachment 82 | P a g e

Figure 7. 7: Dyeing Curve

After-treatment

Wetting agent=0.5g/lSequestering agent=o.1g/lH2O2 stabilizer=0.4g/lAnt creasing agent=0.8g/l

LA=Caustic 3g/lB=H2O2 2.75g/lC=A.A. 1g/lx10’D=Enzyme 0.3g/l

E

Acetic Acid 0.2g/lSequestering agent 0.1g/lAnt-creasing agent 0.8g/lLeveling agent 1g/l

F= Acetic acid 1g/lG=soaping agent0.6g/lH= softener 7%

1-8= sampletaken for shadedevelopment

washRinse10’

1050Cx40’

B

A

C D E Dyes

Sodaash

Salt

40

50

60

110

70

80

90

100

0 50 100 150 200 250 300 350 400 450 500 550

DrainEn

zym

e ho

t

10’ 10’ 40’ 20’ 50’20’

1 2

3 4 5 6

F

G

H

Drain DrainDrainDrain &Unload

7

8

Coo

ling

Drain

nL

Fabric run 10’

Hotwash

Time (min)

Tem

pera

ture

(0 C )

H2O

2ki

ller

0.5

g/l

Dyeing30

G

Pre-treatment

Dyeing Section

Industrial Attachment 83 | P a g e

Shade development :

Note:

When shade of one stage is ok then go for next stage (usually at 600C).

But, when color is already close to target shade at 600C after 10 min then, temp raiseto 700C and run for 10 min. Another shade will be checked after 10 min at 700C and ifshade is ok then bath drop.

When shade is light then color is added to the dye bath and run until required shade isobtained.

In above cases shade development swatch with time will be different.

Bath drop sample should be darker than the target shade & depending on the shadesoaping decision will be taken.

After 20’ of colordosing (Salt sample)

After 10 min of sodadosing (color steam

sample)

600aC x 10 min 600C x 30 min

Target Swatch

600C x 40 min orBD sample

After Acid After Soaping After Softener

Dyeing Section

Industrial Attachment 84 | P a g e

7.16. Process Flow Chart for Knit Dyeing: For Black color

Fabric : 1x1 Rib Quantity : 1000 kg