Indian Flour Mill Final (1)

-

Upload

visitmoorthy -

Category

Documents

-

view

255 -

download

2

Transcript of Indian Flour Mill Final (1)

-

7/25/2019 Indian Flour Mill Final (1)

1/21

This case has been authored by Professor Amit Kapoor and has received the Ruth Greene Memorial Award from NorthAmerican Case Research Organization. You can contact Professor Amit Kapoor at [email protected]

Case - Indian Flour Mill 1

Indian Flour Mill

In 1982 when we were making our decision to invest in a flour millingenterprise we thought that India being an agriculture economy, with growingpopulation would always have a great opportunity in food. No industry couldreally match its growth and profitability potential. The world over food has beenone of the most profitable industries and most of global food giants that haveemerged have fundamentally been wheat millers. The most profitable and largestcompanies in the world are also food companies like Nestle, Kraft General Food,Cargill etc.(See Exhibit 1 for Map of India)

This is what Vinod Kumar (Managing Partner) said who was in an extremely pensivemood, as the unit was not performing well and it was getting more and tougher to stay overboard.The company had come a long way since 1997 wherein it had record profits that the ownershiphad always expected after being in this business (Exhibit 2 and 3). However, the last few yearshad been very miserable in terms of performance for the company as there were huge losses andcapital was eroding at a very fast pace. In the financial year of 2000 2001

1 the companysuffered a loss of Rupees 4 million2.

This problem was further compounded, as there were certain changes in the environmentsuch as the entry of giants as Hindustan Levers, Cargill etc. The industry was also suffering fromovercapacities, unpredictable supply of wheat, and unpredictability of prices. With eroding capitalthere were certain tough decisions at hand Kumar had to take. He was not very sure as to howthese forces would affect industry and the company. Kumar scheduled to meet his businesspartners in about two weeks time from now scheduled to make a presentation on possibly thebest course of action for the firm.

Industry Background

This industry can be categorized into two sectors the organized sector comprisingRoller Flour Mills involved in commercial milling operations and unorganized sector consisting ofmainly Chakkis3. In 1950, there were 54,000 Chakkis in India producing about 5 million tones ofwheat products; today the number is expected to be more than 2.8 million Chakkis producingmore than 35 million tones of wheat products, primarily Atta4.

Around 800 large Flour Mills5in the country convert about 10.5 Million Tons of wheat intowheat products i.e., Coarse Flour, Flour, Semolina, Bran & Wheat Germ. The installed capacity ofFlour Mills is more than 21 Million Metric Tons (Exhibit 4). Roller Flour Milling sector processesaround 1215 per cent of the total wheat consumed in the country, the balance being processedthrough Stone Chakkis. A major part of the flour milling industry is in the small-scale sector6.

Started almost a century ago the Roller Flour Filling industry is one of the oldestestablished industries in the country. The majority of units have an average installed capacity of70 tons per day and only around 10 per cent of the mills are above the capacity of 120 Tons perday. The flour milling industry in India has grown to become over the years the largest organized

sector for utilization of wheat in the country. The number of mills has more than doubled from 454

1Financial year in India is from April through March

2US$ 1 = About Rupees 47

3Small Flour Mills based on stone grinding technology

4Coarse Flour

5Capacity greater than 70 tons per day

6Any manufacturing venture with investment of upto Rs.10 million in plant and machinery is defined as small

scale venture of India.

-

7/25/2019 Indian Flour Mill Final (1)

2/21

This case has been authored by Professor Amit Kapoor and has received the Ruth Greene Memorial Award from NorthAmerican Case Research Organization. You can contact Professor Amit Kapoor at [email protected]

Case - Indian Flour Mill 2

in 1985 to 812 in 1997. Added in it are another 100 units that are about to start operations. Thishas made the competition intense and capacity utilization to a level of 40 percent.

The location of the industry is not only in the wheat belt 7 but well spread across thecountry (Exhibit 5). Karnataka, which is one of the farthest states from the wheat belt, housesnearly 8 per cent of the Flour Mills in the country. The largest concentration of Flour Mills in thecountry is in the states of Uttar Pradesh, Punjab and Haryana.

The flour milling industry is highly working capital intensive. Moreover, it is a low marginlow value addition business. The operations are in very price sensitive wherein even a slightupward movement prices attracts government intervention. The economic policy after 1991 led toa number of foreign collaborations and units to come up in this sector such as Godrej Pillsbury,Cargill, Hindustan Levers etc.

The History

Flour Milling Industry has seen several policy led ups and downs. Broadly we can dividethe growth of the industry into three phases: Viz. licensed regime, deregulated period and postliberalization era. Prior to 1986 the Industry was highly regulated. To start a flour-milling unit alicense was required. With improvement in wheat production the industry was delicensed /deregulated. After 1986 it was possible for the millers to procure wheat directly from the market.After 1991, with the begining of the liberalization process, the Industry entered a new era whereinthe competition was to be with large conglomerates including a few global companies.

Situation prior to the 1986 deregulation

Before 1986, entire wheat both domestic and imported supplied to the mills was only fromFood Corporation of India (FCI)8. The millers did not have the choice over the type and quality ofwheat received. The wheat given was named as Fair Average Quality (FAQ) i.e., wheat that wasfit for human consumption. The price of the wheat was fixed by the FCI with little regard for qualityor type of wheat. The millers were not allowed to purchase wheat in excess of the daily licensedcapacity. There were restrictions on storing wheat at the mills location.

The wheat Roller Milling industry was governed by special regulations under theIndustries Development and Regulation Act. Reserved for the small scale sector, even wheatRoller Flour Milling units were required to obtain two licenses under this Act if they wereemploying 50 or more than 50 workers. Though the mills were privately owned they could not bebuilt or operated without the prior approval and license from the Food Corporation of India. Thepolicy of the government did not allow setting up a mill with more than 60 tons capacity per day.The Food Corporation of India dictated the location of the mill in effect as it only gave licenses fornew milling capacity where it felt there was a need.

The products made at the flour mill were picked up by Food Corporation of India whichpaid a fixed price for these products (Cost of Wheat + Milling Margin). The Food Corporation ofIndia was solely responsible for distribution and sale of wheat flour to bakers, consumers or otherend users. There was no link between the consumers and the individual millers.

The quality specifications for flour were those established by the Pure Food Standards.They were quite strict with respect to sanitary and nutritional standards but quite loose withrespect to end use quality. Millers could go to jail for selling flour that did not meet standards, yetit was usually impossible to do so given the poor quality of the wheat that was being supplied for

7Northern part of India comprising the states of Punjab, Haryana and Uttar Pradesh 8The agency that exacts this levy and, in general, executes GOI food policies is the Food Corporation of

India, established by Parliament in 1965 under the Food Corporation Act 1964.

-

7/25/2019 Indian Flour Mill Final (1)

3/21

This case has been authored by Professor Amit Kapoor and has received the Ruth Greene Memorial Award from NorthAmerican Case Research Organization. You can contact Professor Amit Kapoor at [email protected]

Case - Indian Flour Mill 3

milling. Due to their restrictive policies the trade led had a flourishing black market for both wheatand flour.

1986: Deregulation

Since 1986-87 all the restrictions on establishment of new Roller Flour Mills or expansion

in the capacity of existing units were removed, including reservation of the industry to the smallscale sector. No license is now required for manufacture of wheat products. There are no controlson price and distribution of wheat products. The mills are free to obtain their requirements ofwheat from any source and sell to anyone.

The Main effect of deregulation was that the market for domestic wheat was opened forfree trade. The millers were allowed to buy wheat from the farmer or through the private graintrader. The Food Corporation of India reoriented its strategy towards food security, which madethese changes possible. Food Corporation of India reduced its procurement to a level designed tocover its strategic food reserve (Buffer stock of Wheat). The government distributed subsidizedfood through its Public Distribution System (PDS) that targeted the low-income families ratherthan the rich ones.

The import of wheat however, was not open. Food Corporation of India was the sole

agency, which could import wheat in the shortage years and later distribute amongst the massesunder the PDS.

There was no change in the ownership pattern of the mills. It continued to be in the small-scalesector after deregulation. Though licensing was still required but it became a lot easier for theentrepreneur to obtain them. It became possible to have larger capacity mills i.e., beyond the 60tons per day, the maximum capacity set prior to deregulation. The existing millers were allowed toexpand their capacity and entrepreneur could decide the location of the mill.

The Food Corporation of India was no longer in the flour business. The millers were freeto operate as per the market dictate. For the first time in decades they had to face customer andpush the demand for their products. The price of flour was decided / negotiated between thebuyer and seller and hence was influenced by the demand and supply situation and as well by

the quality of the product.

One of the positive changes that took place after deregulation was that freedom to themillers to decide on the quality of wheat brought by him. It was no longer the question of fairaverage quality wheat as sold by Food Corporation of India. It became easier for the miller tocontrol the quality of the product and meet standards of end products as stated by the Pure FoodStandards.

The net effect of the deregulation was manifested in terms of free market competitionamongst the millers. A miller could no longer depend on the government income built into the oldsystem. Food Corporation of India did not dictate the selling price of the product but it wasdecided by the prevailing demand and supply situation. The black marketing in the end productsstopped, as the product was available in abundance. The most important change was the power

that rested with the consumer. He could decide on the product he wanted to buy. The tradecertainly moved from sellers market to buyers market. The consumer became the key tosurvival. The essence of the change was that If you could not satisfy the customer, you could gobroke .

1991: Liberalization

The millers have achieved prominence from a trading community to an industrialcommunity only in the last two decades. This industry was relatively traditional and served a smallshare of the nations population by mainly grinding wheat provided to it by the government. But in

-

7/25/2019 Indian Flour Mill Final (1)

4/21

This case has been authored by Professor Amit Kapoor and has received the Ruth Greene Memorial Award from NorthAmerican Case Research Organization. You can contact Professor Amit Kapoor at [email protected]

Case - Indian Flour Mill 4

the last ten to fifteen years flour consumption and production has exploded. Along with theincrease in production and consumption the countrys domestic wheat production as also themilling capacity has increased considerably.

The situation now is very different for the industry that has worked under licenses, quotasand controls. The raw material supply & prices were regulated and the quality was not the majorconcern as it was the supplies market. Moreover the distribution was also limited and there werelimits on everything including how much raw material and finished goods stock can be stored. Itwas a happy scenario as the number of the firms was limited, making sure that everyone mademoney due to the restricted competition.

The scenario today has become even more unusual with the government easingrestrictions on foreign players setting up production units in India and that too without anyrestriction. Although the present milling capacity is estimated to be around 21.8 million tonnes,only around 11 million tones of wheat is being milled by the Roller Flour Mills. This is due to thefact that most of the mills do not operate even at 50 per cent of their rated capacities.

Regulators Role in the Open Market

The Government of India authorizes Food Corporation of India to offload wheat in the

open market for sale to trade and industry during lean season either to work as a pricestabilization effort in times of shortages or to offload surplus wheat stocks. This policy has been invogue on more or less regular basis since industrys liberalization of 1986. From October 1993 ithas been virtually on a continuous basis. Prior to industrys liberalization, the State Governmentsdepending upon the milling expenses and extraction percentages fixed the price of wheatproducts. From 1986, only the price of wheat was fixed and there was no price fixation ofproducts. Whenever the Government offered wheat for sale the same was sold by tender /auction.

From November 1993, FCI started selling wheat on fixed prices from month to month oreffective whenever changed. The prices fixed were on state wise basis from November 93 toOctober 95. From November 95, the prices were changed from state basis to 34 center basis.This was done to bring it in conformity with the open market trends in a free market competitive

environment economy and to reduce the subsidy burden on the Government. Between November1995 March 1997, the period till, which the practice continued, the center wise pricing wasmade to conform to the open market price mechanism. The price at Chandigarh was Rs. 490 perquintal whereas in Trivandrum it was Rs. 790 per quintal. The policy was discontinued with effectfrom 1st April 1997 and it was reverted back to the November 1993 situation. In 2000 theGovernment fixed the APL issue price for wheat at Rs. 900. The Government suddenlyannounced the lowering of Issue prices from Rs. 900 to Rs.750 and subsequently to Rs. 682 inthe month of July 2000.

The Market for Products

Around eighty per cent of the total Roller Flour Mill / Chakki output is consumed directlyby the household sector for preparation of various types of India breads and other dishes. The

balance output is consumed by the secondary and tertiary sector, which produce bakery andconfectionery products (breads, biscuits and other products), pasta products (macaroni, spaghettietc.) breakfast foods and other instant foods (See Exhibit 6 for Prices of Products at VariousLocations).

Maida (Flour)

Bread & Biscuits manufacturers, households, Sweet makers, confectioners, protein richfood manufacturers primarily use Maida. All these customers, to make these products, require

-

7/25/2019 Indian Flour Mill Final (1)

5/21

This case has been authored by Professor Amit Kapoor and has received the Ruth Greene Memorial Award from NorthAmerican Case Research Organization. You can contact Professor Amit Kapoor at [email protected]

Case - Indian Flour Mill 5

flour with different characteristics. While an automatic bakery plant may make bread out of poorquality flour yet the smaller baker may not be able to make good bread out of the same.

Different end users need different qualities of flour produced from different varieties ofwheat classified as hard and soft wheat. These varieties are available but not segregated in themarket. The bread manufacturer is looking for flour with high protein content

9, high water

absorption10, gas production capacity of flour and gas retaining capacity of flour to make dough ofuniform consistency. The biscuit manufacturer is looking for flour, which has greater extensibilitybut lower resistance to make biscuits. The confectioners are looking for low ash, low gluten flourto make fluffy products. Cereal based breakfast food manufacturers / protein rich foodmanufacturers desire to have high protein flour with lesser starch damage. The householdconsumer / restaurant user goes to the retailer and buys flour available on the shelf.

Suji / Rawa / Cheroti (Semolina)

Semolina, Suji & Rawa are all names of the same item, Suji, in general is bold Semolinawhere as Rawa is fine / medium Semolina. The Consumer profile is similar to that of flour i.e.,industrial, for pasta manufacturing or in the quick food manufacturing units. Pasta productmanufacturing units have preference for semolina of hard wheat where as the other end-userscan do with semolina of any wheat.

The household consumer is primarily in south where Suji is used as a regular rawmaterial for making breakfast items like Idli, Dosa that has a large per capita consumption. Theconsumer in north consumes Rawa primarily on festive occasions to make sweet items, thefavorite being Halwa.

Whole Wheat Flour / Coarse Flour (Atta)

Atta is primarily consumed in North India by all sections of society at least twice a day, ifnot more, to make chapattis. It primarily has a household usage and the people prefer to get thewheat floured in the Chakkis to get the consistent quality they want to have. These customers areserved by a large number of milling units springing up in the country, specializing in producingwhole meal Atta and not venturing into other products.

Bran

Bran is used as cattle feed and its consumer profile is similar to that of flour andSemolina i.e., traders who specialize in direct sales to local dairies, both big and small. Thevariations in bran prices are dependent on alternative sources of cattle feed availability in theregion and the price.

The Wheat Market

Wheat Growing Regions

Wheat is grown primarily in five states of the country. These states contribute to the

extent of 90 % of the total wheat grown in the country. The wheat grown in these states are takenas Fair Average Quality (FAQ) and no efforts are taken to segregate wheat according to its corecharacteristics. The wheat is purchased as is by the Governmental Agencies, end consumer andFlour Millers. Single largest purchaser of wheat is the Food Corporation of India which procureswheat to the extent of 15 million tons.

9Gluten quantity and quality

10Depends on starch damage that happens during the processing of wheat

-

7/25/2019 Indian Flour Mill Final (1)

6/21

This case has been authored by Professor Amit Kapoor and has received the Ruth Greene Memorial Award from NorthAmerican Case Research Organization. You can contact Professor Amit Kapoor at [email protected]

Case - Indian Flour Mill 6

Indian Wheat Production Top 5 StatesState 5 Year* Average Production

Uttar Pradesh 35%

Punjab 21%

Haryana 12%

Madhya Pradesh 11%Rajasthan 8%

* Years 1994 - 1998

Pricing of Wheat

During the third five-year plan (1961-62 to 1965-66) the Government of India formulatedits food policy. One of the objectives was to ensure a reasonable minimum support price that willencourage the farmer to adopt improved methods of cultivation for increasing production and toensure that consumer prices do not rise unduly. As an outcome of this in 1965, Agricultural Pricecommission (APC) was setup with presumably long-term goals in view. The APC (presentlyCommission for Agriculture Cost and Pricing (CACP)) is an advisory body and all the decision-making powers rest unquestionably with the Government. The APC was entrusted with the

responsibility of evolving a balanced and integrated price structure in the perspective of theoverall needs of the economy and with due regards to the interests of the producers and theconsumers.

The terms of reference to the Commission refer not only to the need for price incentivesfor promoting agricultural growth but also to the need to ensure rational utilization of land, otherproduction resources and to the likely effect of price policy on the rest of the economy, particularlyon the cost of living, industrial cost structure etc.

Support

Support price may be regarded as an offer price at which the Government is willing tobuy any amount of grain from the farmers in years of good harvest when, in the absence of the

support operation, the market price may fall below the cost of production. A logical corollary to theconcept of the minimum support price is that ofmaximum or ceiling price the rational for whichlies in two factors. First, protecting from losses in years of abundance through purchase by theGovernment at minimum prices. Second, a maximum price would imply protection of consumersinterests in years of crop failure. Thus there seem to be two notions, one of price control within acertain range and the other of support to farm incomes along with some degree of protection ofnon-farm incomes

The other issue before the Government is of achieving procurement targets to ensuresufficient food stocks. Procurement of grain becomes increasingly difficult under conditions ofscarcity, local or global. It implies that procurement price has to remain close to market price at allthe times. The CACP recommended in 1998 that there shouldnt be any increase in the price ofwheat for next 3 years but the prices were increased by the central Government due to the

political compulsions prevailing in the country.

Minimum Support Price of Wheat

Year MSP in Rupees

199192 225.00

199293 275.00

199394 330.00

199495 350.00

-

7/25/2019 Indian Flour Mill Final (1)

7/21

This case has been authored by Professor Amit Kapoor and has received the Ruth Greene Memorial Award from NorthAmerican Case Research Organization. You can contact Professor Amit Kapoor at [email protected]

Case - Indian Flour Mill 7

199596 360.00

199697 380.00

199798 475.00

199899 510.00

199900 550.00

200001 580.00

200102 610.00Source: Roller Flour Millers Federation of India

Central Issue Price

Food Corporation of India distributes food grains to poor under several governmentprograms e.g. Targeted Public Distribution System (TPDS), the Jawahar Rozgar Yojna (JRY, afood for work Program), nutrition / feeding programs, schedule castes, schedule tribes andbackward class hostels, below poverty line food processing units, mid day meals program andthe World Food Program projects.

Issue Price of WheatYear MSP

(in rupees)

Issue Price *

(in rupees)

199192 225.0 280.0

199293 275.0 280.0

199394 330.0 330.0

199495 350.0 402.0

199596 360.0 402.0

199697 380.0 402.0

199798 475.0 250.0

199899 510.0 250.0

199900 550.0 250.0

200001 580.0 415.0

200102 610.0 -The APL Price for the Year 199798 was Rs.450 and for 199899 was Rs.650.

Source: Compiled from Economic Surveys of 1992 to 1999.

The TPDS, which is upon the most important operation of the FCI, was launched closerto in 1997 with the intention of improving upon the operations of old PDS. It segregates BelowPoverty Line (BPL) and Above Poverty Line (APL) households. The APL prices are intended tobe closer to the market prices, with unrestricted access. The APL prices and the BPL prices arethe same across the country and the wheat is procured by the flour mills in the non growingstates through the Governmental agency at the declared price.

The Sale and Distribution of Wheat

FCI implements the rice and wheat price support program through its procurement

operations. It also handles, stores and distributes rice and wheat for the Targeted PublicDistribution System and other Government of India (GOI) food programs and stabilizes domesticfood grain prices through buffer stock operations, open market sales and external trade. StateCivil Supplies Departments and other State procurement and distribution agencies assist FCI intheir tasks. GOI covers the difference between FCIs selling price (called the issue price) and itsprocurement price plus costs of handling, storage etc. through a central food subsidy.

Whether public or private, wheat marketing follows identical parallel tradingarrangements, with the private sector handling from 30 to 50 percent of the grain that is traded.

-

7/25/2019 Indian Flour Mill Final (1)

8/21

This case has been authored by Professor Amit Kapoor and has received the Ruth Greene Memorial Award from NorthAmerican Case Research Organization. You can contact Professor Amit Kapoor at [email protected]

Case - Indian Flour Mill 8

The rest moves through the public channel FCI and other state agencies. Purchases by privatetraders and FCI agents take place in regulated wholesale markets and other trading centers.Farmers who sell voluntarily to FCI receive pre announced uniform procurement prices i.e., theminimum support price. FCIs wheat is then distributed to the consumers without furtherprocessing through fair price shops and other government programs at below market prices. Mostprivate-sector wheat is also directly sold to consumers for subsequent custom milling atneighborhood Chakkis (small scale traditional grinding units), although private flour mills take asmaller but increasing share. Once milled, flour is sold to wheat product manufacturers (e.g.Bakeries, and biscuit manufacturers) or to wholesalers for domestic distribution through retailersto consumers).

Freight Equalization / Subsidy

The government doesnt give a direct subsidy to the flourmills. To regulate the priceacross the country beyond the Public Distribution System (PDS) the government regulates theprice of wheat through FCI and keeping a uniform sale price across the country, which translatesinto an in built freight subsidy for the millers. In the process flour millers in wheat belt are not ableto exploit the advantage they possess being nearer to the source of principal raw material. (SeeExhibit 7 for freight of Wheat from Panchkula to Various Locations)

Purchase Tax and Other Procurement Expenses on Wheat

Although several Government Ministries oversee the functioning of the food grainmarketing system, the Ministry of Food and Consumer Affairs (MOF) has the primaryresponsibility for managing the food economy. It is charged with the formulation andimplementation of national polices on procurement, movement, distribution and stocking of foodgrains, provision of storage facilities for the food grains strategic reserves and control overexternal trade of food grains. The MOF oversees the operations of the FCI. The Ministry of FoodProcessing Industries facilitates the rice and wheat milling industries, while the Department ofRural Development of the Ministry of Rural Areas and Development, works with stategovernments in fostering the growth and development of regulated markets system through StateAgricultural Marketing Boards levying market fees, and Rural Development Fund. These leviesvary from state to state. These taxes are payable once the flour miller is purchasing wheat for

processing in the unit but in case a farmer wants to take the wheat out of the state he is not topay any of these taxes and Cess to the Government. The commission to the Pucca Arthiya andKuchha Arthiya are also decided by the stricture from the Government (Exhibit 8).

Taxes on Wheat Declared by State Governments

Punjab Haryana Delhi Chandigarh UP

Purchase / Product Tax 4% 4% 0% 2% 4%Market fee 2 % 2% 1% 1% 2%Rural Development Fund 2 % 2 % 0% 0% 0%Pucca Arthiya Commission 1% 1% 1% 1% 1%Kuchha Arthiya Commission 2.5% 2.5% 2% 2.5% 2%Mandi Expenses 1% 1% 1% 1% 1%Infrastructure Cess 1% 0% 0% 0% 0%

Total 13.5% 12.5% 5% 7.5% 10%Source: Roller Flour Millers Federation of India

Substantial levels of taxes are levied on industry at the procurement stage Punjab andHaryana impose the highest levels of taxes on wheat amongst the North Indian States. The flourmilling industry provides a value addition to the extent of 10 per cent on final products.

-

7/25/2019 Indian Flour Mill Final (1)

9/21

This case has been authored by Professor Amit Kapoor and has received the Ruth Greene Memorial Award from NorthAmerican Case Research Organization. You can contact Professor Amit Kapoor at [email protected]

Case - Indian Flour Mill 9

The Changing Situation

Signing of WTO

It is becoming more and more clear that India cannot remain insulated from theupheavels in the world market. Having signed the General Agreement on Trade and Tariffs

(GATT) and becoming the member of the World Trade Organization (WTO) India has made itclear its resolve to get integrated the world economic structure by 2003. There are certain issuesthat arise under the WTO regime, the most pertinant being the effect of Sanitary Provisions,Wheat Prices and Product Specifications.

Prices of Indian Wheat Vs US Wheat at Mumbai Port(Prices in Rupees)

Year US Wheat Indian Wheat

199192 293 344199293 392 411199394 420 481

199495 442 514199596 700 512199697 594 541199798 610 661199899 559 713199900 607 782200001 575 830

The Competition

Being typically small scale, the flour millers in general tend to focus on branded

processing and meeting the regional demand. The local players try to compete in the marketthrough lower prices by undercutting each other. The prices are also reduced due evasion of taxby a few unethical businessmen.They rarely pay agriculture and procurement taxes.

The Government of India initiated the Liberalization process to exploit resources thecountry has to the fullest and create wealth and move towards the status of a developed nation.Taking advantage of the liberalization policies multinationals started investing in the countrythrough Portfolio Investments or forming joint ventures.

Sensing the opportunity in this segment many large players have also entered the marketincluding two Multinationals Viz. Hindustan Lever Limited (a subsidiary of Unilever), which hasintroduced Kissan Annapoorna brand of coarse flour & salt and Godrej Pillsbury with their brandof PillsburyChakki Fresh Atta. The Indian companies include DCW Home Products (marketing

Atta and other food products under the brand name of Captain Cook) and NEPC Agro(marketing under the brand name of Trupthi). Now, several other international majors and largeIndian corporate are expected to follow suit.

The strategy of most of the large companies is that they concentrate only on marketingonly and help the producers (existing Flour Millers) to revamp their facilities and maintain quality.They have also gone up-stream to help the farmer use better seeds and adopt better farmingpractices. They are also focusing on development of large distribution network and relying heavilyon advertisements to make their presence felt in the market. They are also ensuring off the shelfavailability of products even if they have to incur some losses. (Exhibit 9)

-

7/25/2019 Indian Flour Mill Final (1)

10/21

This case has been authored by Professor Amit Kapoor and has received the Ruth Greene Memorial Award from NorthAmerican Case Research Organization. You can contact Professor Amit Kapoor at [email protected]

Case - Indian Flour Mill 10

Changing Food Habits

Two things disposable are driving changes in food consumption patterns. First, the mostimportant, is the rise in disposable incomes and increasing internationalization and convergenceof food habits. With rising incomes, what is considered good food comes to accommodate greaterdiversity?

It is expected that in the next twenty years, the convergence in peoples consumptionpatterns is likely to be even more rapid because of their factors.. This change is predictable as itmaps the change or the evolution pattern that has been evident in over twenty countries. Studiesshow that countries go through a distinct food consumption evolutionary pattern. In the first stagethe focus is on obtaining basic dietary inputs, the second stage focuses on improving and buildingbasic food, before moving on to the third stage of adding premium food to the diet.

It can be seen that all these stages of food consumption evolution are simultaneouslyapparent in a nation such as India. As some upper income segments of the population move fromBasic to Premium, others in lower income groups may well be moving from Subsistence to Basic.It is the Basic segment that is expected to be central with large population moving into the middle-income segment.

The Retailing Revolution

The growth in the packaged flour and wheat based foods / health foods would make inroads into the households. These would be driven by three factors. The first of these factors andthe one that drives all the others is the rise in disposable incomes.

The second factor that is expected to cause a shift towards packaged products is theincreasing value many Indian households put on time. Currently over 90 per cent of the wheatconsumed in India is eaten as Roti and other forms of bread. Consequenced, bread makingconsumes many hours a week. Consumers buy the wheat grain, sieve it to remove impurities,and then take it to be milled at the local stone mill or Chakki. This process, which was the onlyway of assuring a consistent quality of flour until recently, is labor intensive and time consuming.Perpetuating this system is becoming increasingly difficult in the larger towns due to changing

lifestyles. These changes, typified by the increasing numbers of nuclear families with workingwomen, ensure that time is being perceived as a scarce resource. This trend, coupled withincreasing disposable incomes of such families, changing food habits combine to catalyze thedemand for packaged branded wheat products.

The third factor driving the growth of packaged wheat products is the increasing demandfor improved quality and hygiene. The hygiene levels and quality of locally procured grain and ofthe local Chakkis leaves much to be desired. Both local organized players and large-scaleplayers are beginning to educate the consumer about these issues.

The Bakery Industry (Bread and Biscuit)

The industry was regulated by the Government in 1977 78 and was reserved for the

small-scale industry sector that restricted the entry of large producers. The small andunorganized sector had shared the growth in the industry till 1997 when the sector wasdereserved. In 1998 the market for bread, biscuits and cake was estimated at 3 million tons. In1998, 80 percent of the bread and 60 percent of biscuit were manufactured in the unorganizedsector. The market for bread is estimated to be growing at 7 percent per annum and that forbiscuits and cakes at entry of the 10 percent per annum. The bakery products market is expectedto be 6 million tons with the entry of the organized sector.

-

7/25/2019 Indian Flour Mill Final (1)

11/21

This case has been authored by Professor Amit Kapoor and has received the Ruth Greene Memorial Award from NorthAmerican Case Research Organization. You can contact Professor Amit Kapoor at [email protected]

Case - Indian Flour Mill 11

The Firm

The roots to the venture lie in the year of 1980, when Vinod Kumar shifted toPanchkula11, Haryana where eventually the unit was set up after leaving his job with the ReserveBank of India. An expert in the area of corporate finance he set the ball rolling for setting up of theunit in middle 1979. The unit was completed in 1981 but commenced commercial production in

1982, due to the licensing problems.

The unit was state of the art, using indigenous technology and having a capacity of 30tons per day. The operations at this time were fairly simple. The firm got wheat from FoodCorporation of India and was paid a milling margin for the processing it at the mill.

The unit kept abreast with the changes in the environment and increased its capacity to120 tons per day with the deregulation of the industry in 1986. With a view of reaping benefits ofthe market economy the management thought that the global integration of the Indian economywill present a great opportunity in terms of better purchasing power, changing lifestyles and betterdemand for products in the global market. The management also thought that, with the advent ofopen economy, the market forces would compel the farmer to segregate wheat in terms of theirquality and the industry would graduate towards being more customers oriented. Keeping allthese in view the unit started taking certain strategic steps which they felt would give them anedge in a competitive but a dynamic market.

Differentiation

The firm tried to focus its energies on differentiating their product offering. The strategywas focused towards the industrial segment wherein a certain quality of flour was guaranteed.The unit started focusing on being the best in the region for giving flour to the bakery units. Thisgave the unit acceptance in the bakery industry and a few majors like Britannia, Bakemans,Harvest Gold, Seetha Foods started buying from the unit, for the quality that it produced.

In the industry where there is no segregation of wheat at the farm level in terms of qualityor breed. It took a lot of effort on the part of Indian Flour Mill to find the right blend for themanufacture of their flour with a consistent the quality. The mill had a team of 6 people who were

constantly in touch with the market trying to know about the quality coming into the wholesalemarkets (mandis) and testing it for its suitability for manufacturing the quality of flour promised.

New Product Introduction

With increasing awareness levels of the consumer and changing demand pattern therewere introduced into the market. New products like Wheat Germ and Wheat based BreakfastCereals had been introduced. The company in collaboration with Micronutrient Initiative ofCanada started manufacturing and selling fortified Atta.

With the changing attitude of the consumer the company thought it as an appropriatestep to introduce Maida and Suji in consumer packs. The various products introduced were premixes and 3 types of Suji each catering to a specific end use namely Rava for making Upma, Suji

for making Idlis and Cheroti for making Halwa.

Developing Distribution Network

The company understood the importance of distribution and went on to increase its reachin the market. The company had harnessed around 1500 retail outlets in the states of Punjab,Haryana and the Cities of Delhi and Chandigarh.

11Town next to Chandigarh, the capital of the state of Haryana

-

7/25/2019 Indian Flour Mill Final (1)

12/21

This case has been authored by Professor Amit Kapoor and has received the Ruth Greene Memorial Award from NorthAmerican Case Research Organization. You can contact Professor Amit Kapoor at [email protected]

Case - Indian Flour Mill 12

Capacity Expansion

After its success in the financial year of 1996 97 the company thought of going into theexpansion of its capacity. The capacity was increased from about 120 tons per day to 185 tonsper day. This was done keeping in view the booming market and acceptance of the core product

Maida by the industrial user and being branded as the best manufacturer of flour in the country.

The Future

The time to decide was very less hence Kumar thought of taking help from the report thatwas prepared by its Research Bureau (Exhibit 10) in 1998. The Bureau was later closed downdue to huge losses the firm incurred. Kumar was extremely worried as to what his decision shouldbe and how he should approach to analyze the problem as saw the sun going down on a gloomyday and maybe for the future of the firm. He was looking at the possibilities of closure of the firm,relocating the plant, enter new markets as the South Indian market or continue to lobby with theGovernment. He wasnt too sure what was in store for him in the future.

-

7/25/2019 Indian Flour Mill Final (1)

13/21

This case has been authored by Professor Amit Kapoor and has received the Ruth Greene Memorial Award from NorthAmerican Case Research Organization. You can contact Professor Amit Kapoor at [email protected]

Case - Indian Flour Mill 13

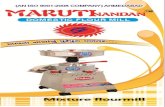

Exhibit 1 Map of India

-

7/25/2019 Indian Flour Mill Final (1)

14/21

This case has been authored by Professor Amit Kapoor and has received the Ruth Greene Memorial Award from NorthAmerican Case Research Organization. You can contact Professor Amit Kapoor at [email protected]

Case - Indian Flour Mill 14

Exhibit 2 Balance Sheet of Indian Flour Mill (in Rupees)

1996* 1997* 1998* 1999* 2000*

Capital and Liabilities

Capital 709460 8968863 1787927 2262699 2496601

Reserves 1085274 1085274 1085274 1085274 1085274Secured Loans 11841072 13335142 11557242 7141428 9424272

Unsecured Loans 1923935 1505203 2578250 2605250 2977536

Current Liabilities and Provisions 1531186 2579971 2215287 2017370 2071423

Total 17090928 27474453 19223981 15112021 18055105

Properties and Assets

Fixed Assets 2370505 4892899 5301764 4202634 3973314

Investments 332402 332402 332402 332402 332402

Inventory 5201965 5990389 7005822 5876637 4241304

Receivables 8187363 12177693 5181438 3431654 8341504Deposits and Advances 734429 3518291 792717 804491 840310

Cash and Bank Balance 264263 562779 609836 464202 326272

Total 17090928 27474453 19223981 15112021 18055105

The figures are for year ending March 31, 19XX

-

7/25/2019 Indian Flour Mill Final (1)

15/21

This case has been authored by Professor Amit Kapoor and has received the Ruth Greene Memorial Award from NorthAmerican Case Research Organization. You can contact Professor Amit Kapoor at [email protected]

Case - Indian Flour Mill 15

Exhibit 3Income and Expenditure Statement for Indian Flour Mill (in Rupees)

1996 1997 1998 1999 2000

Income

Sales* 112117714 226827397 102477933 87386457 92846834

ExpenditureManufacturing Expenses** 104281537 207881294 97059161 81558857 87215132

Administrative and Selling 4320921 5497317 3500656 2822562 3129646

Interest and Bank Charges 2170230 3157992 2305461 2307582 1738638

Depreciation 393880 865913 756333 640074 603711

Total Expenditure 111166568 217402516 103621611 87329075 92687127

Profit / Loss for the Year 951146 9424881 -1143678 57382 159707

The statement is for the period of one year with year ending March 31, 19XX. The profit of loss is transferred to thebalance sheet and its effect is on the Capital Account. If the figures for two years dont match that is because partners

might have invested or divested money from the f irm.

* The Sales figures includes sales from other sources, which include sales of assets, packingmaterial etc.

Other Income 269574 277956 488426 888938 325386

**Manufacturing Expenses include the cost of wheat consumed during the year

Raw Material Consumed 94131771 188238178 88049715 73403026 80323051

-

7/25/2019 Indian Flour Mill Final (1)

16/21

This case has been authored by Professor Amit Kapoor and has received the Ruth Greene Memorial Award from NorthAmerican Case Research Organization. You can contact Professor Amit Kapoor at [email protected]

Case - Indian Flour Mill 16

Exhibit 4 Number and Capacity of Flour Mills

Year Number Yearly Capacity(Million Tons)

1968 202 4.53

1969 206 5.13

1970 211 5.411971 218 5.50

1972 221 5.68

1973 232 5.95

1974 232 5.95

1975 232 5.95

1976 232 5.95

1977 232 5.95

1978 232 5.95

1979 232 5.95

1980 234 5.95

1981 306 7.41

1982 310 7.49

1983 365 7.85

1984 426 8.59

1985 454 8.91

1986 464 8.99

1987 496 9.80

1988 557 10.21

1989 580 10.39

1990 605 11.00

1991 623 12.89

1992 702 16.00

1993 710 16.001994 750 17.72

1995 774 19.10

1996 800 21.00

1997 812 21.80

Source: Roller Flour Millers Federation of India

-

7/25/2019 Indian Flour Mill Final (1)

17/21

This case has been authored by Professor Amit Kapoor and has received the Ruth Greene Memorial Award from NorthAmerican Case Research Organization. You can contact Professor Amit Kapoor at [email protected]

Case - Indian Flour Mill 17

Exhibit 5Number of Roller Flour Mills in Different States

State Number of MillsAndhra Pradesh 58Assam 40Bihar 58Chandigarh 5

Delhi 18Goa 2Gujrat 34Haryana 47Himachal Pradesh 15Jammu and Kashmir 19Karnataka 60Kerela 27Madhya Pradesh 42Maharashtra 63Manipur 1Meghalaya 2Nagaland 4Orissa 19

Pondicherry 3Punjab 46Rajasthan 10Sikkim 3Tamil Nadu 60Tripura 2Uttar Pradesh 125West Bengal 49

Total 812Source: Roller Flour Millers Federation of India

Exhibit 6 Price of Wheat and Wheat Products as on May 18, 2001 at various locations

Panchkula Delhi Bangalore

Wheat 650 580 682

Maida 650 640 1000

Suji 660 660 1050

Atta 620 570 NA

Bran 500 500 NA

The wheat price is for one quintal (100 Kgs) whereas the selling price of products is for 90 Kgs. The wheatprocured contains foreign particles to the extent of 58 percent

-

7/25/2019 Indian Flour Mill Final (1)

18/21

This case has been authored by Professor Amit Kapoor and has received the Ruth Greene Memorial Award from NorthAmerican Case Research Organization. You can contact Professor Amit Kapoor at [email protected]

Case - Indian Flour Mill 18

Exhibit 7Cost of Transporting Wheat and Wheat Products from Panchkula as on May 18, 2001

City Price / Cost

(In Rupees)

Delhi 30

Mumbai 120

Calcutta 120

Bangalore 230

Trivandrum 300

Exhibit 8 Structure of Indian Wheat Trade

Farmer Kuchha Arthiya Pucca Arthiya Broker

Located At Farm Village Main Mandis Towns

Role Grow Crop Agent Agent Links PuccaArthiya

Consolidatesproduce of localfarmers

Consolidatesstocks of KuchhaArthiya

Gets informationfrom all Mandis

Often financesfarmer and settlescrop against dues

Margins 2.5 per cent 1 per cent 1 per centInterest (> 36 percent per annum)

Exhibit 9 Cargill in Milling Sector

Internationally, Cargill is one of the largest processors of food grains with integrated operations. InIndia, Cargill had a small beginning with sunflower seeds near Bangalore. This was a part of thearrangement with ITC Agro Tech to whom the sunflowers were to be sold for producing oil. There weremajor agitations against the company due to the promised yields not coming through. In some odd cases theIndian farmers agitated against the prices of the seeds.

In wheat milling sector, it started with a 300 tons per day plant at Ghaziabad, near Delhi, forprocessing wheat. As soon as the 300 ton per day plant was operational, the work started on another 500ton per day plant on the same location with the single objective of feeding the Delhi market and becomingthe most cost effective producer of the same.

Another strategic plant was put into place to take the villages nearby under its umbrella, and start

educating them about better techniques of farming as also providing them with better seeds. The objective isto simply take them into confidence so that they sell the produce back to Cargill for processing. This wouldhelp Cargill maintain a strict vigil on quality of the wheat milled in its mills and fetch a better price in themarket. Internationally, Cargill operates only in the bulk institutional market and not in the retail market. Thesame strategy is being followed in India, and this explains its entry near the biggest flour market of India,Delhi. Simultaneously it started building up large storage silos for wheat and wheat products so that it canstore enough supplies for one to two months. This coincided with the Government allowing the companies toset up their own storage spaces for the storage of food grain. Overall, more than Rs.15 crores have alreadybeen invested into the development of the mills.

-

7/25/2019 Indian Flour Mill Final (1)

19/21

This case has been authored by Professor Amit Kapoor and has received the Ruth Greene Memorial Award from NorthAmerican Case Research Organization. You can contact Professor Amit Kapoor at [email protected]

Case - Indian Flour Mill 19

Exhibit 10 The Research Bureaus Report

The Food Sector in Developed Nations

Successful food companies around the world are typically very large. Indeed they are oftenamongst the largest of companies. In stark contrast to rest of the world, Ind ias food companies are verysmall despite India being a giant in food production. This is clearly reflected in the industry structure. Over75% of food players in India are in the small scale or unorganized sector, the remaining 25%, which thegovernment classified as the large-scale player, are again quite small by international standards. Theaverage size of top 20 Indian food companies is $ 125 million, i.e., 1/80

thof the US Average. The largest

food companies in India have revenue of only $600 million, less than 1/30thof Cargill.

The second way that the Indian food chain differs from those in more developed economies is interms of the presence of range of different players, all of whom help drive the process of integration andreduction of inefficiencies. These players include large retailers, branded processors, commodityprocessors, transportation companies, co-operative, and agricultural input manufacturers. Indian food chain,by contrast, reveals that some of the classes of companies are either nascent or altogether missing. Theclasses that are missing or in the nascent stage of development include large scale commodity processors,large-scale retailers and seed companies.

Commodity Processors are an important part of most developed food chains, these are companiesthat produce high volumes low value added commodity products such as wheat flour, edible oils, andprocessed and frozen meat products, they tend to be amongst the largest food companies in mostdeveloped nations and are rapidly emerging in less developed countries. Large commodity processors,because they handle very high volumes (e.g. Millions of tones of grains), Invest in infrastructure and systemthat have wide spread impact on the development of food chain. In India commodity processors are nascent.Large commodity processors dominate developed food chains. The most pertinent examples being that ofCargill and ADM in wheat milling, Con Agra in vegetables, oils and meat processing, Tyson and Gold Kist infruit juices and Hudson in poultry processing in United States.

Commodity processors are also playing an important role in less developed countries like Brazil,Thailand and Indonesia. Thailand is well known for its large poultry producing companies, Indonesia hassome of the worlds largest wheat processors like Bogasari flourmills and Indofood, which in recent years

have invested in ships, docks, Storage silos and automated wheat mills. In contrast, India has few largecommodity processors today. In India even wheat, which in most countries is a sector that is normallydominated by large commodity processors, has only a handful of players with revenues of over $10 million.

Technology does not Impact Scale and Cost Structure

Roller Flour Milling technology linking with cost structure may vary upto a minimum economic sizecapacity of around 80 tons per day capacity. Beyond this capacity level, the technology has very minor flowvariations from plant to plant. By virtue of wheat quality parameters, from different streams, the millingindustry can cater to individual end use. The upgradation of capacities has been done either by replicatingthe units or by expanding by adding similar machines with additional equipments in the process. Theexpanding capacities however did reduce the costs very marginally, if located with same premises, in termsof fixed cost contribution. The direct costs were not affected by such expansions since major contributor todirect costs was energy consumed for processing wheat products. Besides this, manual operations ofloading, unloading, bagging etc. still continue and their costs do not change downwards with increasing

production. The Roller Flour Milling Directory indicates that the daily capacities all across the country havebeen from 50 tons per day to 250 MTS per day in a single occasion. The millers also confirmed that thetechnology remains the same but plants sourced from different sources indicate different energyconsumption. Plants sourced from the same source even though varying in size have more or less uniformenergy consumption basis, hence operating costs remain the same. The plants are sourced indigenouslyand imported from erstwhile Soviet block countries and Europe. Increasing interest burden because ofadditional costs one has to bear on imported plants neutralizes the power savings achieved by sourcing itfrom foreign sources. The cost of erecting a same size plant through imported machinery was 8 times that ofthe indigenous plant.

-

7/25/2019 Indian Flour Mill Final (1)

20/21

This case has been authored by Professor Amit Kapoor and has received the Ruth Greene Memorial Award from NorthAmerican Case Research Organization. You can contact Professor Amit Kapoor at [email protected]

Case - Indian Flour Mill 20

Growth Patterns in Developed Nations

The growth of the industry in various developed nations have followed quite a similar path. Theyhave moved from a highly regulated industry environment to a liberalized one, large number of players toconsolidated world level players, changing ownership patterns i.e., from entrepreneurial startups toprofessionally managed firms and from small players to integrated food companies.

The US Wheat Industry. The industry in US moved from a highly fragmented to one which ishighly consolidated and profitable. There were distinct phases in the growth of the industry wherein it hasgone on to become the most efficient setups in the world. The wheat value chain is a benchmark forefficiency in the grain processing industry around the world. The Industry has grown to have players whohave become conglomerates. There was also the buildup of integrated food firms i.e., firms that operatealong the complete value chain i.e., agricultural inputs, agricultural production, procurement and processing.

The industry went through a cyclical process of growth that saw the firms following a similar patternand emerging as large players. The pattern followed by the industry was movement from fragmented, togrowing and a mature industry. The strategies followed by the firms were well timed and consisted of effortsto consolidate by mergers and takeovers, integrating along the value chains, entering global markets andbuilding infrastructure to reduce wastage levels.

An interesting point comes out that in USA there has been a significant change in the demand

pattern. This had been led by the changing consumption patterns of the consumers. There has been anexplosion in the demand of pasta in some ethnic communities and now the demand is rising for Tortillas -Mexican Chapattis and variety breads is rising.

The Canadian Wheat Industry. The industry attracted a lot of attention and in a short period oftime and it started suffering from Chronic over capacities. This made the competition intense and wasprimarily dominated by the strategy of undercutting prices and hence suffering huge losses, whichaccounted to the closure of a number of mills due to sickness. There was a major shakeout in the industryas there were large-scale takeovers, which transformed the companies from single unit enterprises to multiunit enterprises with units situated at various locations in the country. There was a major shift in the kind ofpeople who managed the flourmills, the management drifted from entrepreneurs to professional managers.In the past the flour millers were having a short-term perspective, till the time there were entrepreneurs whobecame the major players in the industry. With the advent of conglomerates taking over the businesses itbecame more of long-term orientation in planning. The industry is in the mature stage of the life cycle andthe competition between the players is on gaining the market share.

The Australian Wheat Industry. The Australian Milling Industry has grown like in any otherdeveloped nation. There were 137 units in 1956, which have come down to 37 in 1998. The Average millingcapacity has also increased from 2.5 tons flour per hour to 8 tons of flour per hour. The consolidation over aperiod of over 40 years has helped in reducing the spare capacity and increasing the efficiencies in the flourmilling industry.Today 100 per cent of the flour mills in Australia are privately owned and 90 per cent of thetrade is controlled by 3 companies. The 37 flour mills in the country extract 1.8 million tons of flour per yearover the grinding of 2.35 million tons of wheat per year. The average mill size in Australia is 750 tons perday that is very close the world average of 850 tons per day. Another feature of the Australian Industry isthat there is a clear-cut segmentation of the market. The flour is consumed in distinct categories which canbe divided into segments as to be used for Bread, Gluten, Pastry Cookies, Biscuits, Domestic and Premixes,Food Manufacturers and Pasta.

A distinctive but similar pattern emerges in the Australian industry that it went from large number ofplayers to a market controlled by 3 players and emergence of niche segments which cater to different

demands of consumer and this has been made possible through a well managed infrastructure.

-

7/25/2019 Indian Flour Mill Final (1)

21/21

This case has been authored by Professor Amit Kapoor and has received the Ruth Greene Memorial Award from NorthAmerican Case Research Organization. You can contact Professor Amit Kapoor at [email protected]

Performance Analysis of Flour Mills in Various Indian Locations

1992 1993 1994 1995 1996 1997

Indian Flour MillCost of Wheat at Mill 287.78 321.45 358.89 386.48 410.80 425.74

Milling Costs of wheat 30.82 44.26 49.09 51.09 48.87 51.54

Financial Costs 10.51 12.00 9.68 11.40 10.84 9.53

Revenue Realized by Miller 324.33 384.69 415.25 453.00 471.50 492.29

Ahmedabad Flour Mill

Cost of Wheat at Mill 285.69 340.21 388.02 413.88 437.63 437.14

Milling Costs of wheat 27.31 29.5 28.63 38.1 38.76 35.95Financial Costs 10.57 10.2 10.19 6.48 5.68 5.28

Revenue Realized by Miller 329.37 393.78 451.28 471.51 488.21 488.21

Bangalore Flour Mill

Cost of Wheat at Mill 331.65 416.76 457.71 466.94 466.83 553.03

Milling Costs of wheat 23.85 22.47 27.24 30.55 41.1 50.26

Financial Costs 8.46 6.03 8.94 9.19 9.8 6.23

Revenue Realized by Miller 377.97 455.12 514.45 520.32 591.79 583.74

Calcutta Flour Mill

Cost of Wheat at Mill 297.41 396.54 412.18 442.66 460.62 499.44

Milling Costs of wheat 34.16 49.64 32.05 35.15 36.49 36.31

Financial Costs 2.09 3.01 2.01 1.93 3.49 2.77

Revenue Realized by Miller 336.9 461.18 455.95 482.12 505.55 541.44

The figures are for year ending March 31, 19XX. All calculations are in Rupees and for One Quintal (100 Kgs) of Wheat

The production pattern generally followed by the mills is 60 % Flour, 20 22 % Coarse Flour and 1820percent Bran. The production of Semolina can be upto the extent of 18 % but the demand is fairly regional orcyclical. The nature of demand is cyclical in North and peaks up during the festival season that is during themonths of October and November whereas the demand for Semolina in South is fairly regular as it forms a

part of their daily diet. Wheat Germ is a miniscule part of the production about 4 5 Kgs per ton of wheatmilled and is sold at a premium and is generally used by the pharmaceutical companies or as breakfast foodin North India. Flour fetches the best price after Germ, Atta is sold at the price that is very near to theprevailing price of wheat and Bran is generally the lowest in price.