In Dl Safety

-

Upload

kaushik-sreenivas -

Category

Documents

-

view

216 -

download

0

description

Transcript of In Dl Safety

-

Dr. K. MuthukumarDGMSafety ManagementINDUSTRIAL SAFETY & ACCIDENT PREVENTION

-

Skillful Planning Maximum Production. Minimum cost. Quality Control. Morale of Personnel. General Efficiency.

-

Men Machine Material if any a accident or injury to these tools, everyone segment the operation will be affected.

-

SAFETYis the Controlof AccidentalLosses to

PeopleEquipmentMaterialsEnvironment

LIFE EmployeesContractorsVisitors/ customersCommunity

PROPERTY Share holdersInsurance companyFinancial institutionNational wealthCustomers productsENVIRONMENT What we owe to our futuregeneration

-

Mechanical hazardsChemical hazardsPhysical hazardsBiological hazardsErgonomic hazardsEnvironmental hazards

-

Chemical HazardsSolids, liquids, vapours, gases, dusts, fumes or mistsFlammables, corrosives, toxics, compressed gases, oxidizers

Physical HazardsNoise, vibration, energy, electricity, radiation, pressure, moving mechanical parts, extreme heat and cold

-

Biological HazardsBacteria, viruses, insects, plants, birds, animals, and humans. These sources can cause a variety of health effects ranging from skin irritation and allergies to infections (e.g., tuberculosis), cancer

Ergonomic HazardsRepetitive motions, awkward postures, manual material handling, excessive forces

-

Environmental HazardsComfort factors (temperature and humidity), poor indoor air quality, inadequate ventilation, inadequate or excessive illuminationE.g. mould, dirty ceiling vents, dirty/dusty floors, no ventilation, heavy perfumes

-

Unsafe acts: violation of safety rules and regulations in practice. Unsafe condition: the working area is fully in hazardous condition and cause any accident at any time

-

Substandard Work PracticesWorking in a poorly ventilated areaUsing defective equipment Using equipment improperlyNot wearing P.P.EHorseplay

-

1

2

3

4

5

6

-

Inadequate guards or barriers Inadequate or improper protective equipmentDefective tools, equipment or materials Lack of proper tools & equipmentFire and explosion hazardsLoose MaterialsOpen holes

-

1

2

3

-

Lack of knowledge. Lack of skill. Physical impairment. Improper attitude.

-

Urgency negligence. Lack of experience. Over confidence. Adamant. Worries. Shortcut MethodsNon wearing of safety equipment.

-

Major injury accident Minor injury accident

-

1 -- Major injury / fatal

29 -- Minor injury

300 -- No injury

can we predict the instance of that one accident with major injury amongst 330 ? to avoid the major injury / fatal stop all the unsafe acts.

-

1 -- Disablining injury

10 -- Minor injury

30 -- Property damage

600 -- Near mises

-

Management:

Provide a safe work place & environment. Prescribe safe work practices & procedures. Provide adequate training & supervision. Designate responsibility & delegate authority.

-

Train personnel in proper work practices. Supervise the proper practicesTake corrective action for unsafe acts and unsafe condition Maintain safe equipments tools and safe working environment..

-

Observe safe work practices. Report the hazards that exist in the area to the supervisors. Use protective devices and safety equipments.

-

Direct CostsIndirectCosts Unseen costs can sink the ship!

-

Direct cost Medical compensationIndirect cost Damage to machinery, damage to material, damage to equipment, Loss of production time training to new employee

-

Loss of trained and experienced person Expenses on disabled persons and their dependents. Scarcity of the products and higher prices.

-

Injury Loss of limb Pain Worries Expenditure Finance deficit Borrowing Loss of income Family future

-

Loss skilled workerWorriesLoss of prestigeSelection and training of new workerLoss of outputWeakened morale of workers

-

LOSS LOSSLOSSACCIDE ACCIDENTFAULT OF PERSONPERSONAL BEHAVIOR ON SOCIAL ENVIRON-MENT UNSAFE ACT & UNSAFE CONDITION

-

Educate. Teach. Train. Inspire Assigning job to physically capable.

-

What is personal protective equipment ?

-

Personal Protective equipment is a simple device which protect the employee from Injury (the result of an Accident). or Prevent injury to the employee

-

Personal Protective equipment may give 100% Protection in some accidents.

In some accidents the severity of the injury will be reduced.

Accident will not be prevented by the PPE.

-

Personal Protective Equipments are classified in to two

Respiratory Protection

Non Respiratory Protection

-

NON RESPIRATORY PROTECTION

-

Non Respiratory ProtectionHead ProtectionEye ProtectionEar ProtectionFace ProtectionBody ProtectionHand ProtectionLeg and Foot Protection

-

HEAD PROTECTION

-

Crash Helmets- IS 4151

-

HEAD PROTECTION EQUIPMENT

-

FACE PROTECTION

-

FACE PROTECTION

-

EYE PROTECTIONkm

-

EYE PROTECTION EQUIPMENTkm

-

EAR PROTECTION

-

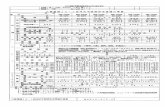

TLV for noise is 90 dB for 8 hours workIncrease in 5db will reduce the working hours to half

90 dB-8 hours95dB-4 100 dB-2 105 dB-1 hour110 dB- 115 dB-

-

EAR PROTECTION EQUIPMENTEAR MUFFEAR PLUG

-

BODY PROTECTION

-

BODY PROTECTION EQUIPMENT

-

HAND PROTECTION

-

HAND PROTECTION EQUIPMENTkm

-

FOOT / LEG PROTECTION

-

SAFETY SHOESGUM BOOTWELDER BOOTSLIPON TYPE SHOESALUMINISED SHOESASBESTOS SHOESFOOT PROTECTION EQUIPMENTLEG GUARDkm

-

RESPIRATORY PROTECTION

-

Respiratory protectionHazardAir pollution - Dust- Chemical fumesOxygen deficiency

Respiratory protection equipmentAir purifying equipmentAir supplying equipmentSelf contained breathing apparatus

-

Air purifying equipmentsDust respirator - Disposable paper type - Cloth type - Cup type

Cartridge respirator- Light fume - Heavy fume

Gas mask - Half mask - Full vision face mask - Canister gas mask

-

Canister Gas mask

Black- Organic vapourWhite- Acid fumesYellow- Organic and AcidsGreen- AmmoniaBrown- Organic , Acid, AmmoniaRed - UniversalBlue- Carbon monoxideWhite with green strip - Hydro cyanic acidWhite with yellow strip - Chlorine

-

Air supplying equipments equipments are to be used if the area is oxygen deficient and the contaminant level is more than 2 % by volume.

Air supplying equipmentsSuction hose maskPressure hose maskAir line respirator

-

RESPIRATORSkm