IMPLEMENTATION OF 5S TECHNIQUES IN MAJESTIC …IMPLEMENTATION OF 5S TECHNIQUES IN MAJESTIC MACHINE...

Transcript of IMPLEMENTATION OF 5S TECHNIQUES IN MAJESTIC …IMPLEMENTATION OF 5S TECHNIQUES IN MAJESTIC MACHINE...

IMPLEMENTATION OF 5S TECHNIQUES IN MAJESTIC MACHINE WORKS,

COIMBATORE

1Dr.R.Vinayagasundaram,

2Dr. P.K.Giridharan,

1Associate Professor, Department of Management,

Kumaraguru College of Technology, Coimbatore, Tamil Nadu, India.

2Professor, Department of Mechanical Engineering,

Kumaraguru College of Technology, Coimbatore, Tamil Nadu, India.

ABSTRACT:

This research paper aims at providing the perfect workplace in an organisation for the

employees by means of implementing the 5 S principles. The research focuses on

understanding the problems faced by the employees in accessing the materials from the store

,to change the layout in order to improve productivity and to implement sort and set in order

to understand the effectiveness in 5s implementation .The need for the implementation of

„5S‟ is because of unorganized warehouse materials, uncomfortable space in the stores and

excessive wastes . The study concludes that introducing the 5S rules bring the great changes

in the company.

Key words:5S, productivity, seiri, seiton, seiso, seiketsu, shitsuke.

About the study

SORT Seiri When in doubt move it out- red tag

technique

SET IN ORDER Seiton A place for everything and everything

in its place

SHINE Seiso Clean and inspect or inspect through

cleaning

International Journal of Pure and Applied MathematicsVolume 119 No. 17 2018, 2285-2304ISSN: 1314-3395 (on-line version)url: http://www.acadpubl.eu/hub/Special Issue http://www.acadpubl.eu/hub/

2285

STANDARDISE Seiketsu Make up the rules, follow and enforce

them

SUSTAIN Shitsuke Part of daily work and it becomes a

habit

1. 5S in majestic machine works

The 5S initiative was done by majestic machine works in its production Muvasharkhan

T. Jenaliyev (2017), unit and was not able to succeed as there was no awareness or training

given to employees. So when an audit on 5S implementation was done by the company was

not able to achieve the standards ,so the implementation was to be done perfectly by staring

with the understanding of 5 S and a training program given by kansen institute asia- pacific

and coindia.

2. Implementation of 5S

The implementation of 5S requires the understanding of all the employees,

supervisors and managers related.

The planning phase is important when considering the success of 5S implementation.

First of all, the entire implementation begins with choosing a leader. The project

leader should have a thorough understanding of 5S and experience of leading such a

project and managing personnel.

The team members should be a mix of employees that work in the area, performing

different tasks.

After choosing the team, it is extremely important to train the team, in order for the 5S

program to fully succeed.

The training in majestic machine works are given by a team from coindia , kansen

institute asia – pacific limited who are involved in small scale development industries

To improve the ultimate goal a action plan has been framed which consists of a gantt

chart with schedules distinguished into 5 phases for effective implementation of 5s principles.

The documentation of the phases and action plan is shown below.

International Journal of Pure and Applied Mathematics Special Issue

2286

3. Scope of the study

The scope of the study is to improve the effectiveness of the various process taking

place in a warehouse by implementing 5S technique.

4. Statement of the problem

The raw material storage in the organisation has many components and they are not

proper arranged

Improper utilization of storage space for raw material

Wastage of time in searching the raw material due to non-permanent location for

storage of raw material

No well defined space for storing the unwanted or rejected material. „

5. Objectives of the study

Primary Objective

To study the problems faced by the employees in accessing the materials from the

store and to improve the process by implementing 5s.

Secondary Objective

To analyse the practises followed by majestic machine works and to change the layout

in order to improve productivity

International Journal of Pure and Applied Mathematics Special Issue

2287

To implement sort and set in order in majestic machine works

To find the effect on implementation of 1s and 2s

6. Sampling technique:

The study contains the 27 workers who are in charge of the store activities in majestic

pumps. The type of sampling used is convenient sampling.

7. Tools used for analyzing data

The following tools are used for this study

Descriptive statistics

Anova

Sample t test

Correlation

Percentage analysis

Descriptive statistics

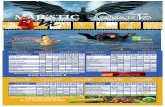

SORT FACTOR MEAN

Unwanted materials 3.37037

Finding materials 2.703704

Red tag 1.074074

Unnecessary items from store 2.37037

SET IN ORDER Products organised 2.111111

Materials are stored in proper racks 2

Labelling items 1.518518

SHINE Surface free from dusts 2.925926

Right substrates 3.111111

Scheduled cleaning 2.888889

STANDARD-ISE Team established 2.555556

5S agreement 2.222222

SUSTAIN 5s concept 1.346154

Effort 2.153846

International Journal of Pure and Applied Mathematics Special Issue

2288

11

89

0 50 100

YES

NO

BINS

Series1

Percentage analysis

Bins

Space

Shine

8. ANOVA

Easy accessibility

Source of

Variation Df F P-value F crit

Between Groups 2 4.426724 0.015101 3.113792

Within Groups 78

Total 80

33.3

66.7

0 50 100

YES

NO

SPACE

Series1

0 7.4

22.2 55.6

14.8

Strongly…

Neutral

Strongly…

0 50 100

SHINE

Series1

International Journal of Pure and Applied Mathematics Special Issue

2289

Time consumption

Source of

Variation Df F P-value F crit

Between Groups 2 20.78531 5.81E-08 3.113792

Within Groups 78

Total 80

Clean the workplace

Source of

Variation Df F P-value F crit

Between Groups 2 6.193133 0.003189 3.113792

Within Groups 78

Total 80

9. Paired t-test

Material picking

t-Test: Paired Two Sample for Means

Variable 1 Variable 2

Mean 4.111111 1.407407

Variance 0.717949 0.250712

Observations 27 27

Pearson Correlation 0.25182

Hypothesized Mean

Difference 0

Df 26

t Stat 16.16857

P(T<=t) one-tail 2.2E-15

t Critical one-tail 1.705618

P(T<=t) two-tail 4.4E-15

t Critical two-tail 2.055529

International Journal of Pure and Applied Mathematics Special Issue

2290

Material picking by contract employees

t-Test: Paired Two Sample for Means

Variable 1 Variable 2

Mean 5.111111 1.62963

Variance 0.410256 0.549858

Observations 27 27

Pearson Correlation 0.251936

Hypothesized Mean

Difference 0

Df 26

t Stat 21.30783

P(T<=t) one-tail 2.75E-18

t Critical one-tail 1.705618

P(T<=t) two-tail 5.49E-18

t Critical two-tail 2.055529

Labour footprints

t-Test: Paired Two Sample for Means

Variable 1 Variable 2

Mean 8.148148 4.444444

Variance 1.823362 0.410256

Observations 27 27

Pearson Correlation -0.43481

Hypothesized Mean

Difference 0

Df 26

t Stat 11.13759

P(T<=t) one-tail 1.07E-11

t Critical one-tail 1.705618

P(T<=t) two-tail 2.15E-11

t Critical two-tail 2.055529

International Journal of Pure and Applied Mathematics Special Issue

2291

Correlation

Factors Correlation value

Set in order Vs time consumed for taking materials -0.104533272

Sort Vs accessibility -0.21615

10. 1S IMPLEMENTATION

To implement the first S the Red-Tag process is commonly employed.The Red-Tag

strategy helps to identify unwanted items anddetermine their usefulness. There are six steps

involvedin creating a successful Red-Tagging process.

Step 1: Launch the Red-Tag Project

This is done by creating holding areas and planning for the disposal of unwanteditems

using the Red-Tag form.

Step 2: Identify the Red-Tag Targets

Specify the type of items and the physical work areas to beevaluated.

Step 3: Set Red-Tag Criteria

Questions need to be asked to determine if an item is necessary for that area or not.

Step 4 : Attach the Tag.

The Red-Tagging event must be quick and decisive. The target scopemust be

completed before the 5S Launch.

Step 5 : Evaluate Red-Tagged Items

Red tagis done as a first step in 1s where the items are segregated and are taken care

as per the below table.

International Journal of Pure and Applied Mathematics Special Issue

2292

Treatment Description

Throw it

away

Dispose of as scrap or incinerate items that are useless or unneeded for

any purpose.

Sell Sell off to other companies items that are useless or unneeded for nay pur-

pose.

Return Return items to the supply company.

Lend out Lend items to other sections of the company that can use them on a tem-

porary basis.

Distribute Distribute items to another part of the company on a permanent basis.

Central red-

tag area

Send items to the central red-tag hold-ing area for redistribution, storage,

or disposal.

Before implementation of 1S

In the above picture shown , all the components are mixed with the rusted

components and no proper sorting has been taken place.

After implementation

International Journal of Pure and Applied Mathematics Special Issue

2293

When Red-Tagging is completed and action taken the workflow is reduced,

communication between workers isimproved and productivity is enhanced. The elimination

of unnecessary itemsin the workplace is an excellent technique to transform acluttered

workplace layout into an effective area to improve efficiencyand safety.

11. Benefits of 1 S

Necessary items are identified and positioned in the right workplace and location.

Unwanted items are eliminated.

Searching time is reduced.

Working environment is improved.

Space utilisation is maximised

12. 2S IMPLEMENTATION

The second S reflects a very popular saying: “A place for everything and everything

in it‟s place”. It emphasises safety, efficiency and effective storage and consequently

improves the appearance of the workplace.

International Journal of Pure and Applied Mathematics Special Issue

2294

Before implementation

After the red tag has been applied the components were yet to be placed in the correct

bins and labelled

After implementation

The bins have been labelled and components placed in their respective bins.

Each of the rows were documented and named , and it was pasted on the racks for

easy access of the materials.

International Journal of Pure and Applied Mathematics Special Issue

2295

The racks are labelled with the components available in each rows , so that the

components could be easily accessible. The bin cards are placed in each of the bins to know

the availability of the number of components both old and new.

Setting up awareness boards

Awareness board were set on sort and set in order on walls of the stores.

13. Benefits of 2 S

Items easily returned to its designated location after use.

Required items easily located, stored and retrieved.

Retrieval time is reduced.

Right Item, Right Place, Right Quantity and Right Method are in place.

International Journal of Pure and Applied Mathematics Special Issue

2296

Existing layout of store

The existing layout of the store is very small as a segregation is made in between fo

keeping The A class items and another room is made for a discussion, but the discussion

room is not being used and space is wasted. Another problem in the store is that there is no

order of items and bins which are placed and it takes time to collect the materials as more

than 2 bins contain the same item far away from each other.

Proposed layout

In the proposed layout the racks are set in such a way that A class items are placed far

behind and could be accessed only when required. The other frequently and sometimes used

materials are placed near for easy access. A trolley is to be engaged in the material handling

process where the movement could take place as follows,

International Journal of Pure and Applied Mathematics Special Issue

2297

The trolly is to be introduced and the movement of the trolly is shown as above, when

the A class materials need not be fetched then a shorter route is taken as indicated by the

arrows and time will be much reduced as all racks will be labelled and easy tracking of

materials could be achieved.

14. FINDINGS

Sort

From the descriptive statistics performed on the input materials lying on the floor it is

clear that the mean value = 3.37037 which is equal to 4, where 4 implies that most of

the input materials are lying on the floor

From the descriptive statistics on the easy access of materials it is clear that the mean

value = 2.703704 which is equal to 3, where 3 implies that few of the materials are

easily found

From the descriptive statistics on implementation of red tag it is clear that the mean

value = 1.074074 which is equal to 1, where 1 implies that red tag has not been done

From the descriptive analysis on whether the unwanted materials are ying on the floor

or not it is clear that the mean value = 2.37037 which is equal to 2, where 2 implies

that some of the unwanted materials are removed from the store.

International Journal of Pure and Applied Mathematics Special Issue

2298

From anova test it is clear that there is significant difference in finding the materials

on time, so sorting of the materials and labelling each bin is needed

From correlation it is seen that the value is -0.21615 this shows that there exists a

strong negative correlation between ratings of the sort and the materials easy

accessibility . This indicated that when the sort ratings increases ie when a proper red

tag system introduced, all materials sorted, no materials lying on the floor and

materials easily found then the difficulty level in accessing the warehouse materials

becomes low and vice versa. Thus a negative correlation is applied.

Set in order

From the table it is clear that the mean value = 2.111111 which is equal to 2, where 2

implies that some of the materials are not organised properly

From the table it is clear that the mean value = 2.0 which is equal to 2, where 2

implies that some of the materials are stored in proper racks

From the table it is clear that the mean value = 1.518 which is equal to 2, where 2

implies that some of the materials are labelled properly

Correlation = -0.104533272, from this it implies that it is negatively correlated stating

that as the ratings of set in order increases the time consumed in finding the materials

decreases and vice versa.

From the bar chart , 89% of the respondents indicate that each and every bins are not

always used, and 11% of the respondents indicate that all the bins are used all the

time. So in order to rectify this problem , all the materials should be in correct bins

and to be labelled.

Shine

From the descriptive analysis it is clear that mean value = 2.925926 which implies as

neutral stating that the floors , walls , stairs and surface are partially clean from dusts ,

oil and grease. Thus proper cleaning should be done on scheduled time to clean the

place and monitor

From the descriptive analysis it is clear that mean value = 3.111111 which implies as

neutral stating that the right substrates are partially used to clean the place. Thus

proper cleaning should be done on scheduled time to clean the place and monitor,

these materials should be placed in a proper manner in the store for easy access

International Journal of Pure and Applied Mathematics Special Issue

2299

From the descriptive analysis it is clear that mean value = 2.888889 which implies as

neutral stating that the a schedule in the evening is made all day to clean the work

place and the store before leaving. Thus in order to increase the efficiency a new

system of a 15 mins bell is indicated morning and evening to clean the workplace.

From anova it is clear that there is significant difference in time taken to keep the

store clean , usually the store cleaning is done in the evenings and so the remaining

hours the store is not maintained properly. So a 15 mins alarm to be set in the morning

and evening for cleaning

From the chart it is seen that majority of the respondents 55.6% have replied that they

disagree to the statement that the floors and stairs are free of dust, and the next 22.2%

respondents are neutral to the reply that there are dusts in some places.

Standardise

From the table it is clear that mean value = 2.555556 which implies as neutral stating

that the documents are prepared for sort and set in order and shine is yet to be done .

Both sort and set in order are in place in the stores and now the management has

planned to implement both in the production unit too followed by shine , standardise

and sustain throughout the organisation.

From the descriptive analysis it is clear that mean value = 2.2222 which implies as

agree, stating that the 5S agreement is in place and all the employees know about it.

Awareness sheets has been displayed regarding 5 S.

Sustain

From the table it is clear that mean value = 1.346154 which implies as strongly agree,

stating that the workers understand the concept of 5 S as special training and

awareness program was conducted by external audits such as coindia and kansen

institute asia-pacific private limited.

From the above table it is clear that mean value = 2.153846 which implies as agree,

stating that the workers put in effort to understand the 5 S concepts and to make it

sustain.

International Journal of Pure and Applied Mathematics Special Issue

2300

Layout

From the chart , 66.7% of the respondents indicate that there is no proper space to

walk around in the store to get the materials, and 33.3% of the respondents indicate

that there is adequate space. So in order to rectify this problem , layout change has to

be done.

From Anova performed on the accessibility level of the materials in the store there is

significant difference,so the layout of the store is changed for easy accessibility

After implementation

From paired test there is significant difference between the time taken by the

permanent employees for material picking after the implementation of 5s principles,

which implies the effectiveness of implementing sort and set in order

From paired t test there is significant difference between the time taken by the

contract employees for material picking after the implementation of 5s principles

From paired t test , there is significant difference between the time taken by labour

footprints after the implementation of 5s principles

Suggestion

1. A trolly is to be introduced as a material handling device so that the movement of the

materials from the store to production area is easy

2. For shine to be implemented all the materials and places are to be kept clean, usually

the cleaning would take place in the evening now a new system is to be implemented

where a 15 mins bell is given both morning 10am and in the evening by 4pm. Now

sort and set in order has been implemented in stores, the same is going to be done in

the production unit and finally the organisation is going to perform shine, standardise

and sustain.

3. For 4s to be implemented a daily check list is to be followed where the following is to

be considered

The specific procedure was followed.

All obligatory rules in the company are obeyed.

Rules and regulations of the company were followed.

International Journal of Pure and Applied Mathematics Special Issue

2301

Establishment of Rules and Standard Operation Procedure (SOP)

Improvement in operation and workflow.

4. When all the 4s has been implemented in order to sustain as the final principle of 5s,

by increasing the awareness, improvement of inter human relations, inspection of 5s

activities

15. CONCLUSION

Thus the sort and set in order was analysed and implemented in majestic machine

works, where the company has good knowledge on 5s techniques as the company has gone

through a training and awareness program on 5s principles. The proposed layout change

would limit the time consumed and easy tracking is possible. Suggestions for shine,

standardise and sustain was given so the company could follow the same for its production

unit too

16. References

[1] Abhishek jain, Rajbir bhatti, harwinder singh,(2014), “Productivity Improvement

Through 5S Implementation in Indian Manufacturing Industries”, Proceedings of the

International Conference on Research and Innovations in Mechanical Engineering,

pp.535-545, DOI: 10.1007/978-81-322-1859-3_49

[2] Alberto Bayo‐ Moriones, Alejandro Bello‐ Pintado, Javier Merino‐ Díaz de Cerio,

(2010) "5S use in manufacturing plants: contextual factors and impact on operating

performance", International Journal of Quality & Reliability Management, Vol. 27

Issue: 2, pp.217-230, doi: 10.1108/02656711011014320

[3] J. Michalska , D. Szewieczek, (2007),” The 5S methodology as a tool for improving

the organisation”, VOLUME 24 ISSUE 2 October 2007

[4] K.R. Dushyanth Kumar, Dr.G.S Shiva Shankar , Rajeshwar S.

Kadadevaramutt,(2016), “Process Efficiency Improvement in Small Organization

International Journal of Pure and Applied Mathematics Special Issue

2302

through Lean Supply Chain Approach”, IOSR Journal of Business and Management

(IOSR-JBM) e-ISSN: 2278-487X, p-ISSN: 2319-7668. Volume 18, Issue 6 .Ver. I

(Jun. 2016), PP 61-68

[5] Mohd Nizam Ab Rahman, Nor Kamaliana Khamis, Rosmaizura Mohd Zain, Baba Md

Deros and Wan Hasrulnizzam Wan Mahmood,(2010)” ,Implementation of 5S

Practices in the Manufacturing Companies”, American Journal of Applied Sciences 7

(8): 1182-1189, 2010 ISSN 1546-9239© 2010 Science Publications

[6] Muvasharkhan T. Jenaliyev (2017), “Loaded Parabolic Equations And Boundary

Value Problems Of Heat Conduction In Non-Cylindrical Degenerating Domains”,

International Journal of Pure and Applied Mathematics, vol, 113, no. 4 - 527-537.

[7] N. Khamis, M. N. Ab Rahman, K.R. Jamaludin, A.R. Ismail, J.A. Ghani, R. Zulkifli,

(2009),” Development of 5S Practice

International Journal of Pure and Applied Mathematics Special Issue

2303

2304