I-line photoresist evaluation for A 0.5 micron technology

-

Upload

thomas-fischer -

Category

Documents

-

view

213 -

download

0

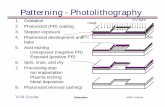

Transcript of I-line photoresist evaluation for A 0.5 micron technology

Microelectronic Engineering 17 (1992) 299-302 Elsevier 299

I-LINE PHOTORESIST EVALUATION FOR A 0.5 MICRON TECHNOLOGY

Thomas Fischer and Holger Moritz IBM Plant Sindelfingen, Dpmts 0374 and 6377, Bldg 7030-47, PO-Box 266, D-7030 Boblingen

Abstract

The lithographic performance of IBM Spectralith, Hoechst AZ 7110, and Hoechst AZ 5214E in image reversal mode was evaluated on a Nikon body 7 0.45NA i-line stepper. All 3 resists are capable of resolving 0.45 pm lines and spaces, printing linearly down to 0.45 pm with zero bias, and show at least 1.5 pm depth of focus. The photospeed of Spectralith and AZ 7110 is around 150 mJ/cm2, and their exposure latitude is 32 %, for 0.5 pm lines/spaces. AZ 5214E in image reversal mode is 3 times faster, prints 0.5 pm patterns to nominal at only 45 mJ/cm2, and also shows a significantly wider exposure latitude of 52 % (again for 0.5 pm patterns). In conclusion a 0.5 pm technology can be run on today’s i-line steppers with these resists.

1. Introduction

During 1989 all major photoresist manufacturers introduced new positive working materials, claiming their superiority for i-line exposure (“i-line” is the 365 MI wavelength line of the mercury spectrum, widely used in step-and-repeat exposure tools). At that time we did an extensive study, to understand the differences among the various resists. The result was, that - provided, each material’s processing parameters are individually optimized - there are no significant differences. This is not surprising, since they all are based on a novolak variety as the matrix resin, and a diazonaphtoquinone as the photoactive compound.

The good results encouraged us to investigate the potential of the new 0.45 NA Nikon body 7 steppers, which were installed in early 1990. This report describes in detail the procedures and results. Of course, we were curious to again test image reversal, now with 0.5 pm minimum features. The other two resists, Spectralith and AZ 7110, had been evaluated in East Fishkill in February 1990, with slight advantages for AZ 7110 (photospeed and exposure latitude). Ref.1 gives the complete report.

2. Results

2.1 Swing Curves

Since the i-line steppers use only the mercury i-line for exposure, in other words time - coherent monochromatic light, interference effects influence strongly the energy incoupling into the resist film. The first step is therefore always to measure so-called “swing curves”. They plot some energy sensitive quantity, such as critical dimension, or time to clear the exposed resist film, versus resist film thickness. Wafers were coated with incrementally decreasing spin speed to produce a series of increasing film thickness. The thicknesses were measured on a calibrated Tencor Alphastep 200 surface profiler (optical thickness measurement tools would need prior knowledge of the complex refractive index). They were all exposed with the same dose and equally pre- and post exposure baked prior to development. A development endpoint detector was used to measure the time to clear, which is plotted on the y-axis. The fitted function follows from two beam thin film interference, taking into account primary and secondary reflections at the resist surfaces. Table 1 summarizes the results. We do see significant differences in the refractive index. This has to be taken into account, as one compares photospeed.

0167-9317/92/$0.5.00 0 1992 - Elsevier Science Publishers B.V. All rights reserved.

300 T. Fischer, H. Moritz / i-line photoresist evaluation

Spectralith AZ 7110

Fit Correlation 97%

refractive index n 1.728 optimum resist

thickness 1105 nm

Swing Curve Period 105.6 MI 112.2 nm 108.4 nm RLDn MUWESS (Hua*nol)

Table 1: Evaluation of the Suing-Curve Data

2.2 Optical Properties

Fig 1. Swing Curve of Spectralith

For reference and for readers wanting to do modeling we include here the optical constants, which had been measured earlier. These are the refractive indices obtained from swing curves, and the Dill constants A, B, and C. The units are l/urn for A and B, and cm2/mJ for C.

Resist n A B C Nlkon body 7. 0.46 NA Iilne

Contraal (Imax - Imlnl/(lmax + lmln)

TNS 4210 1.735 0.57 0.06 0.015

MacDermid 1024 1.706 0.57 0.06 0.013

AZ 5214 E 1.683 0.59 0.07 0.011

AZ 5214 DI 1.683 0.61 0.36 0.017

Spectralith 1.728 0.55 0.02 0.015 0 600 ,000 ,600 2000 Bpatld Frqua.zy

AZ 7110 1.627 0.48 0.16 0.007 - Theory Idqal 8y.t.m - Nlkon on 8, - Nlbn on ARC

Fig 2. Contrast Transfer Function of the Stepper

The spectralith Dill parameters were measured by Robert Wood, IBM. The AZ 7110 Dill parameters were supplied by Wolfgang Zahn of Hoechst. All others are our own measurements.

2.3 Resolution

With all three resists 0.45 pm lines and spaces were cleanly resolved. This result shows, that all three resists show high contrast, i.e. they transform a sinusoidal image of low modulation into a square wave resist pattern. This represents an aspect ratio (height over width) of 2.4 for Spectralith and AZ 7110, and 3.3 for AZ 5214 E in image reversal mode. In Figure 2 is shown the contrast in the images of the Nikon body 7 stepper, measured recently by A. Grassmann. From it we read 52 % modulation for k = 0.55 images.

2.4 Exposure Latitude

With monochromatic exposure tools such as the Nikon i-line stepper, exposure latitude is of prime importance: minute deviations of the resist film thickness as well as any other underlying transparent films will cause significant changes in the energy coupled into the resist during a set exposure time. This is clearly visible in the swing curves. A widely accepted definition of exposure latitude is the percentage of tolerable change in dose, which will change the critical dimension (CD) not more than f10 %.

Thus the linewidth versus exposure dose data from the focus - expose matrices is normalized to

T. Fischer, H. Moritz I l-line photoresist evaluation 301

the dose to print the nominal width of the critical dimension, here a 0.5 urn space. At optimum focus one obtains a plot such as Figure 3.

The shape of the curves is the square root of the logarithm of the dose, which has been derived in ref. 4. This follows directly from the shape of the aerial image intensity profile, which can be approximated with the Gaussian distribution function.

Spectralith and AZ 7110 fall almost on top of each other, showing 32 % exposure latitude.

AZ 5214E in reversal mode shows more latitude at the high end, giving a total of 52 %. The key results are summarized in table 3:

Spectralith AZ 7110 AZ 5214E

Nominal Exposure for 0.5 pm lines 260 ms 340 ms 80 ms

Resolution 0.45 pm 0.45 um 0.45 pm

Printing Linearity down to 0.45 pm 0.45 l.lm 0.45 pm

Focus Latitude 1.8 p 1.5 pm 1.8 pm

Exposure Latitude for 0.5 pm L/S 32 % 32 % 52 % Exposure Smlkty of SPECTRAIJTH. M 5214 E and AZ 7110

05 pm lines/spaces. 365 nm. NA=O45. coherence 05

Table 3: Key Performance Results Fig 3. Exposure Latitude Plot

Comparison of Theory and Experiment

Raising and lowering dose will increase and decrease the final developed space in the resist film. If one characterises the total lithographic process by means of a process threshold, one can read the expected exposure latitude from Figure 4. Here is plotted the relative dose, (relative to the dose, which prints the nominal space), necessary to increase and decrease the space width by 10 %. The aerial image in turn was calculated for an ideal projection system. The result is, that the exposure latitude should be 48 %. The experiment however gave Figure 3 32% and 52% respectively.

Recently A. Grassmann measured the contrast in the aerial images as a function of linewidth, Figure 2. He found a significant decrease as compared to an ideal imaging system. There can be a multitude of reasons for it; Burn Lin in particular has analysed the effect of straylight, vibrations, substrate reflections, topology etc. on contrast in a number of papers (e.g. ref.2). One can emulate the image degradation by calculating the aerial image for a certain amount of defocus: 0.65 pm defocus gives a faily good approximation for the actually measured image contrast. Figure 5 gives the corresponding aerial image of a nominally 0.5 pm space. The resultant exposure latitude is now only 31 %, in good agreement with our own measurement, as well as with others; in ref.1 30 % latitude was measured; W. Zahn reported 36 % (with a GCA 0.45 NA i-line stepper).

In conclusion: the exposure latitude is limited by the optical imaging system, not the resist, nor the resist process.

302 T. Fischer, H. Moritz I I-line photoresist evaluation

Protith Computation of the A&l Image Intensity in Best Focus

Uinimum and M&mum Exp0a.w Dose fa i/7 10 X CO - VatiM

I&, = 0.81 ?Y,, . 5, = 129 E,, --> Built-in Latitude = 48 X

Pm!& Camputation of the k&l Image Intensity in 0.65 pm Defocus

htinimvm and Mtimum Exposure Dose for +/- 10 Z CD - Variation

& = 0.65 b . E_, = 1.16 b --> Built-in Latitude = 31 X

Fig 4. Built-in Latitude of an ideal Lens Fig 5 Built-in Latitude at 0.65 pm defocus

3. Conclusions

Due to the differences in the chemistry applied with different resists, the resist processing needs individual tayloring. Once that is done, all three resist show excellent performance.

A 0.5 pm technology can be run on 0.45 NA i-line steppers, such as the Nikon body 7. All three resists tested do not limit the resolution, linearity, depth of focus, and exposure latitude.

The exposure latitude is even significantly extended with the image reversal process. Also, photospeed is at least three times faster.

4. Acknowledgments

It is a pleasure to acknowledge the many useful and enlightening discussions with the East Fishkill resist team, in particular Robert Wood and Chris Lyons, and their help with everything concerning Spectralith. M. Reuhman and F. Vollenbroeck (Philips research) provided excellent data on image reversal and many fruitful suggestions. Stimulating input was also received from W. Zahn (Hoechst), S. Wittekoek (ASM-L), and N. Ittner (Zeiss). 0. Groeger did most of the measurements, H. Brommer and D. Pietsch supported the stepper work.

S.Refereuces

1.

2.

3.

C.Lyons, W. Montgomery: I-Line Photoresist Evaluations - AZ WA1059 and IBM Spectralith IBM internal report dated 3/12/90 B.J. Lin: Methods to Print Optical Images at Low-k1 Factors, SPIE Optical/Laser Microlithography III, 1990, San Jose P. Trefonas, T. Fisher and J. Lachowski: What is the optimum Exposure Dose for a positive Resist containing Poly-Functional Photoactive Compound (Poly-PAC)?