How to Meet 2017/2020 Energy RegulationsE2%80...How to Meet 2017/2020 Energy Regulations U.S....

Transcript of How to Meet 2017/2020 Energy RegulationsE2%80...How to Meet 2017/2020 Energy Regulations U.S....

How to Meet 2017/2020 Energy Regulations

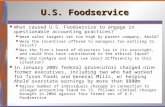

U.S. Commercial Foodservice

Ani JayanthFoodservice Marketing ManagerEmerson

Brian BuynacekSenior Refrigeration Engineer and Marketing ConsultantEmerson

This presentation is intended to highlight changing developments in the law and industry topics. The law is frequently evolving and information and publications in this presentation may not reflect the latest changes in the law or legal interpretations. The statements and information provided in this presentation should not be construed as legal advice or legal opinion regarding any specific facts or circumstances, but is intended for general informational purposes only. The views and statements expressed during this presentation are the personal opinions of the presenter and do not those of Emerson Climate Technologies, Inc. or its affiliated companies. You should consult an attorney about your situation and specific facts and you should not act on any of the information in this presentation as the information may not be applicable to your situation. Although all statements and information contained herein are believed to be accurate and reliable, they are presented without warranty of any kind. Information provided herein does not relieve the user from the responsibility of carrying out its own tests and experiments. Statements or suggestions concerning the use of materials and processes are made without representation or warranty that any such use is free of patent infringement and are not recommendations to infringe on any patents. This presentation may not be copied or redistributed without the express written consent of Emerson Climate Technologies, Inc.

Disclaimer

DOE Equipment Regulations Survey

3

Source: Department of Energy

• Effective January 2020 on new equipment

• WICF measured in three major components

• AWEF measured using AHRI-1250 testing standard–Each equipment class assigned

equation–Variable: Q = system capacity

• Effective March 2017 on new equipment

• CRE measured in kWh/24-hour day–Each equipment class assigned

equation–Variable: Total Display Area (TDA)

or volume

Industry Reach-In Solid Door Refrigerator Energy Draw

• Effective January 2018 on new equipment

• ACIM measured in kWh/100 lbs ice– Each equipment class assigned

equation– Variable: H = harvest rate in

pounds per 24 hours

Commercial refrigeration equipment

Walk-in coolers and freezers (WICF)

Automatic commercialice makers

From 20% to 50% energy reduction required for systems, depending on class 5% to 25% energy reduction required

EPA’s Final Rule, July 20, 2015, and September 26, 2016Changed listing status of certain HFCs*

*Abbreviated – For complete listing, see EPA Final Rule; go to: https://www.gpo.gov/fdsys/pkg/FR-2015-07-20/pdf/2015-17066.pdfSee proposed rule; go to: https://www.gpo.gov/fdsys/pkg/FR-2016-04-18/pdf/2016-08163.pdf

Final Rule: July 20, 2015 Final Rule: September 26, 2016

Phase-outrefrigerant

Super-market(New**)

Super-market

(Retrofit***)

Remote condensing unit(New)

Remote condensing unit

(Retrofit***)

Stand-Alone Refrigerated food

processing and dispensingequipment

(New)

Cold storage

warehouses (New)

Ice machines

(New)

Verylow-temp

refrigeration(New)

MT < 2,200 BTU/hr. and not contain flooded

evap. (New)

MT ≥ 2,200 BTU/hr. with or without flooded

evap. (New)

LT(New)

LT and MT

(Retrofit***)

R-404A/507A Jan. 1, 2017 July 20, 2016 Jan. 1,

2018July 20,

2016 Jan. 1, 2019 Jan. 1, 2020 Jan. 1, 2020 July 20,2016 Jan. 1, 2021 ^Jan. 1, 2023 OK OK

R-410A OK - OK - Jan. 1, 2019 Jan. 1, 2020 Jan. 1, 2020 - Jan. 1, 2021 ^Jan. 1, 2023 OK OK

R-407A/C/F OK OK OK OK Jan. 1, 2019 Jan. 1, 2020 Jan. 1, 2020 OK ^Jan. 1, 2021R-407C/F OK

R-407A:^Jan. 1, 2023

OK R-407C only

HFC-134a OK OK OK OK Jan. 1, 2019 Jan. 1, 2020 OK OK OK OK OK -Likely alternatives(Emerson perspective)

R-448A/449A OK OK OK OK

Neither SNAP-approved, nor

banned

Neither SNAP-approved, nor

bannedOK OK for

LT only - - OK -

R-450A/513A OK OK OK OK OK OK OK OK OK OK OK -

R-290 - - - - OK OK OK - - - OK OK

R-744 OK - OK - OK OK OK - OK OK - OK

R-717OK

(in primary loop of secondary

system)

-

OK (In primary

loop of secondary system)

-OK

(in primary loop ofsecondary system)

OK (in primary loop ofsecondary system)

OK (in primary

loop ofsecondary system)

OK (in primary

loop ofsecondary system)

OK (in primary loop ofsecondary system)

OK OK -

** Includes ice machines connected to a supermarket rack refrigeration system.*** EPA uses term “retrofit” to indicate the use of a refrigerant in an appliance that was designed for and originally operated using a different refrigerant.

Term does not apply to upgrades to existing equipment where the refrigerant is not changed.

4

12

Compliance Will Not Be Easy

Opportunity to Comply With One Design Cycle Change

EPA Refrig.

DOE Energy

2017 2018 2019 2020 2021Supermarket (Rack)

Walk-In (Remote CDU)CoolerFreezer

Reach-In (Stand-Alone)Cooler <2,200 BTU

>2,200 BTUFreezer

Ice Machine

Dispensing

<2,500 GWP

<2,500 GWP

20–40%

<600 GWP

<600 GWP<1,500 GWP

30–50%

5–15%

1/1/17

1/1/18

3/27/17

1/1/18R-290 Approved

1/1/20

1/1/19

1/1/20

20–30%

Awaiting FinalASRAC

<1,500 GWP

EnergyEnvironment

EconomicsEquipment

5

Yes52%

Not yet44%

OEM Preparedness to Meet Compliance Dates

Level of Preparedness: Level of Preparedness:

Equipment Passes DOE Regulations:Equipment Passes EPA Regulations:

EPA Plan in Place DOE Plan in Place

Very prepared Somewhat prepared Only slightly prepared Not at all prepared

(mean)48%

(mean)74%

Yes57%

Not yet36%

Over Half Have a Plan in Place and Are Prepared to Meet Compliance Dates. This Leaves Quite a Few Companies Not Ready for the Change.

6

13% 52% 15% 17% 15% 45% 19% 17%

OEM-Specific Preparations for Meeting DOE Regulations

We’re lab testing as a way to prepare.

We’re seeking guidance on how to be better prepared.

We have a product road map.

We’re communicating our plans to customers.

Other

62%

49%

43%

32%

13%

End use customers

Aftermarket/wholesalers/distributors

Contractors

Other

87%

47%

20%

13%DOE preparations

Communicating plan to … (among those communicating plans to customers)

Seeking guidance from … (among those seeking guidance to prepare)

Component manufacturers

Consultants

End use customers

Other

87%

35%

22%

9%

While 62% Are Lab Testing to Prepare for DOE Regulations, the Remaining Two in Five Are Not.Many customers are still seeking guidance on becoming better prepared.

7

Agreement With Statements Related to Regulatory Changes

Top-2 Box

I expect some componentswill change.

I expect some of our productsto become obsolete.

I expect component costs to increase.

89%

63%

73%

5 = Completely Agree 4 3 2 1 = Completely

Disagree

77%

53%

51%

12%

10%

22%

10%

14%

20%

2%

10%

4%

14%

4%

The Majority Expect Components Will Change Based on the Regulations. This, in Turn, Will Impact Cost Negatively.

Top-2 Box

8

Source: Department of Energy

Commercial Refrigeration Equipment Equipment Classes

Low- or Medium-Temperature

Vertical, Semi-Vertical, Horizontal or Service

Over Counter

Self-Contained or Remote Condensing

With or Without Solid/Transparent Doors

Commercial Refrigerator and Freezer

Equ

ipm

ent A

ffect

ed

33+ Classes of Equipment20+ Sizes/Eqp. Class

Buffet Tables, Salad Bars, Prep Tables Not Affected Depending Upon Refrigeration Construction

9

Buffet Tables, Salad Bars, Prep Tables BeyondScope of Energy Mandates

Source: Department of Energy

10

RegulatedTop Rail

BottomStorage

Regulated Not RegulatedNot RegulatedAirflow Airflow

CRE Prep and Buffet Tables Architectures and Compliance Note

Source: Department of Energy

Top Rail Bottom Storage Certification Required Criteria

Power Supply No Power Supplied or From Common Supply With Top

See Refrigeration Requirements Single Energy Source

Power Supply Power Supply Yes Dual Energy Source With Single Source Requirement

Top Rail Bottom Storage Certification Required Criteria

Refrigerated: Cold Wall or Forced Air

Dry –Non-Refrigerated No Regular Buffet/Prep Construction –

No Classification

Refrigerated: Cold Wall or Forced Air With Heat Being Rejected Directly

Into Lower Section

Refrigerated: Air In Lower Section Coming

in Direct ContactWith Top Rail and Single Condensing

Unit

No

Heat From Upper Rail Is Being Absorbed Directly Into Lower Section Refrigeration System With Single Energy Source and

Single Refrigeration System

Refrigerated: Cold Wall or Forced Air With No Direct

Contact With Lower Section

Refrigerated: Cold Wall or Forced Air With No Direct

Contact With Rail Section and Single Condensing Unit

Yes

Heat From Upper Rail Is Not Being Absorbed Directly Into Lower Section

Refrigeration System With Single Energy Source and Single Refrigeration System

Refrigerated: Cold Wall or Forced Air

With Its Own Condensing Unit

Refrigerated: Cold Wall or Forced Air

With Its Own Condensing Unit

YesDual Refrigeration System With Single

Refrigeration System Requirement, Single or Dual Energy Source

Can

Be

Test

ed

w/D

OE

Te

st P

roce

dure

Can

’t Be

Tes

ted

w/D

OE

Test

Pro

cedu

re

There Are No Exemptions From the Energy Standard for Commercial Refrigeration Equipment. However, There Are Some EquipmentTypes That Do Not Have a Test Procedure and Therefore Do Not Have to be Certified at This Time.

11

CRE Equipment DOE Analysis and Equations

Source: Department of Energy

• X-axis: size of equipment ft3• Y-axis: energy draw kWh/day• Equation format: Y = m(x) + b• kWh = m(ft3) + b

• 33 classes of equipment• Remote condensing and self-contained open

cases will not require major efficiency improvement challenges

• Self-contained vertical reach-ins will require significant efficiency improvement changes

2010 2012 2017 2010 2012 2017 % Delta 2010 2012 2017 % DeltaVOP.RC.M 0.82 x TDA + 4.07 0.64 x TDA + 4.07 4.07 4.07 0% 0.82 0.64 -22%VOP.RC.L 2.27 x TDA + 6.85 2.2 x TDA + 6.85 6.85 6.85 0% 2.27 2.2 -3%SVO.RC.M 0.83 x TDA + 3.18 0.66 x TDA + 3.18 3.18 3.18 0% 0.83 0.66 -20%SVO.RC.L 2.27 x TDA + 6.85 2.2 x TDA + 6.85 6.85 6.85 0% 2.27 2.2 -3%HZO.RC.M 0.35 x TDA + 2.88 0.35 x TDA + 2.88 2.88 2.88 0% 0.35 0.35 0%HZO.RC.L 0.57 x TDA + 6.88 0.55 x TDA + 6.88 6.88 6.88 0% 0.57 0.55 -4%VCT.RC.M 0.22 x TDA + 1.95 0.15 x TDA + 1.95 1.95 1.95 0% 0.22 0.15 -32%VCT.RC.L 0.56 x TDA + 2.61 0.49 x TDA + 2.61 2.61 2.61 0% 0.56 0.49 -13%HCT.RC.M 0.16 x TDA + 0.13 0.16 x TDA + 0.13 0.13 0.13 0% 0.16 0.16 0%HCT.RC.L 0.34 x TDA + 0.26 0.34 x TDA + 0.26 0.26 0.26 0% 0.34 0.34 0%VCS.RC.M 0.11 x V + 0.26 0.1 x V + 0.26 0.26 0.26 0% 0.11 0.1 -9%VCS.RC.L 0.23 x V + 0.54 0.21 x V + 0.54 0.54 0.54 0% 0.23 0.21 -9%HCS.RC.M 0.11 x V + 0.26 0.1 x V + 0.26 0.26 0.26 0% 0.11 0.1 -9%HCS.RC.L 0.23 x V + 0.54 0.21 x V + 0.54 0.54 0.54 0% 0.23 0.21 -9%SOC.RC.M 0.51 x TDA + 0.11 0.44 x TDA + 0.11 0.11 0.11 0% 0.51 0.44 -14%SOC.RC.L 1.08 x TDA + 0.22 0.93 x TDA + 0.22 0.22 0.22 0% 1.08 0.93 -14%VOP.SC.M 1.74 x TDA + 4.71 1.69 x TDA + 4.71 4.71 4.71 0% 1.74 1.69 -3%VOP.SC.L 4.37 x TDA + 11.82 4.25 x TDA + 11.82 1.82 1.82 0% 4.37 4.25 -3%SVO.SC.M 1.73 x TDA + 4.59 1.7 x TDA + 4.59 4.59 4.59 0% 1.73 1.7 -2%SVO.SC.L 4.34 x TDA + 11.51 4.26 x TDA + 11.51 1.51 1.51 0% 4.34 4.26 -2%HZO.SC.M 0.77 x TDA + 5.55 0.72 x TDA + 5.55 5.55 5.55 0% 0.77 0.72 -6%HZO.SC.L 1.92 x TDA + 7.08 1.9 x TDA + 7.08 7.08 7.08 0% 1.92 1.9 -1%VCT.SC.M 0.12 V + 3.34 0.1 x V + 0.86 3.34 0.86 -74% 0.12 0.1 -17%VCT.SC.L 0.75 V + 4.10 0.29 x V + 2.95 4.1 2.95 -28% 0.75 0.29 -61%VCS.SC.M 0.10 V + 2.04 0.05 x V + 1.36 2.04 1.36 -33% 0.10 0.05 -50%VCS.SC.L 0.40 V + 1.38 0.22 x V + 1.38 1.38 1.38 0% 0.40 0.22 -45%

Equations y-Intercept Slope

12

CRE Equipment DOE Analysis and Equations

13

Source: Department of Energy

Comparing 2017 vs. 20101. Improvement reduces relatively for larger size machines

• VCT.SC.M2. Improvement increases substantially for larger size machines

• VCT.SC.L• VCS.SC.L

3. Improvement levels out for larger machines• VCT.SC.L• VCS.SC.L• VCS.SC.M

VCT.SC.M

VCT.SC.L

VCS.SC.M

VCS.SC.L

25%

28%

31%

34%

37%

40%

43%

46%

49%

52%

55%

58%

61%

64%

67%

70%

5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

2017

v. 2

010

Ener

gy R

educ

tion

Diff

eren

ce %

Size ft3

Source: Department of Energy

VCT.SC.M VCT.SC.L VCS.SC.M VCS.SC.L

2010 kWh = 0.12(V) + 3.34

0.75(V) + 4.10

0.10(V) + 2.04

0.40(V) + 1.38

2017 kWh = 0.10(V) + 0.86

0.29(V) + 2.95

0.05(V) + 1.36

0.22(V) + 1.38

Y-intercept % change -74% -28% -33% 0%

Slope % change -17% -61% -50% -45%

Walk-in Coolers and Freezers (WICF)Equipment Classes

Medium- or Low-Temp

Multiplex Condensing

Recip. Hermetic, Semi-Hermetic Recip. or Scroll Compression

<9K BTU/h or >= 9K BTU/h

Indoor or Outdoor

Medium- or Low-Temp

Dedicated Condensing

• Dedicated– Single walk-in feed

– A packaged dedicated system where the unit cooler and condensing unit are integrated into a single piece of equipment

– A split dedicated system with separate unit cooler and condensing unit sections

• Multiplex– Unit coolers matched to

multiplex condensing rack system

14

Source: Department of Energy

WICF AWEF Improvement Design Option CostsDedicated Condensing MT/LT by BTU/h

6000 9000 54000 72000 18000 54000 6000L M

DCI - HER $1,528 $1,648 $2,130 $1,448I - SCR $1,754 $1,873 $6,754 $2,348 $3,575 $6,233I - SEM $1,993 $4,653 $2,588 $4,103 $4,242O - HER $1,558 $1,678 $2,160 $1,479O - SCR $1,785 $1,903 $6,819 $2,379 $3,615 $6,289O - SEM $2,024 $2,154 $7,246 $9,133 $2,618 $4,143 $4,286

$0

$2,000

$4,000

$6,000

$8,000

$10,000

$12,000

$14,000

$16,000

Average Costs

9000 6000 54000 72000 18000 54000 6000L M

DCI - HER $2,171 $2,370I - SCR $2,365 $2,204 $7,568I - SEM $2,452 $7,571 $4,387 $4,568O - HER $2,494O - SCR $9,668 $2,682 $3,978 $7,003O - SEM $10,530 $13,706 $4,603 $4,771

$0

$2,000

$4,000

$6,000

$8,000

$10,000

$12,000

$14,000

$16,000

New Costs for Meeting AWEF

Source: Department of Energy

$3,269 $4,684 +43%

15

Automatic Commercial Ice MakersOverview

16

Source: Department of Energy

• Affecting batch ice machines also known as “cubers”• Affecting continuous ice machines also known as “flakers” or “nuggets”

Air or water cooled

Self-contained or remote

condensingVarious harvest

rates

• Frozen carbonated beverage machines not affected

Polling Question 1

What is this audience’s level of understanding, channel constituent collaboration and preparedness to address these regulatory challenges?

A. Didn’t even know about thisB. Haven’t started engaging the channel on getting preparedC. Getting prepared to engage the channel nowD. I’m ready and have communicated to all stakeholders in my channel

17

Commercial Refrigeration EquipmentDesign option vs. cost

18Source: Department of Energy

$0

$10

$20

$30

$40

$50

$60

$70

$80

$90

0% 5% 10% 15% 20% 25%

Higher Eff Compr

Hot-Gas Antisweat

ECM Cond Fan 0.5 year

1.0 year

2.0 yearsBPM Compr Mtr

VS Compr

Better Insulation

Payback

$ OEM Cost Adder

% Energy Saving

Solid-Door Reach-In Refrigerator(DOE/ADL Study)

ECM Evap Fan

kWh/Day

kWh/day = comp. energy draw + lighting + fan + controls + others

Total System Measurement Based on Equipment Type; CDU Is Treated as Component

Better insulation BPM motor

vs. comp.

System Compressor CDU component

ECM evaporator / condenser fan

High-effy. comp.

Hot gas anti-sweat

LED lighting

Reach-ins: Energy Considerations

19

• DOE 2017 compliance very challenging, especially self-contained with doors– ENERGY STAR promotes even higher

efficiency levels

• Design challenge compounded with high-GWP HFC phase-down by 2020

• Requires evaluation of multiple options:– Compressor– Condensing unit– Fan motors– Control– Future refrigerant planning

Walk-in Coolers and Freezers (WICF)Annual Walk-in Energy Factor (AWEF)

• AWEF values calculated using AHR-1250 calculator with plugged-in assumptions for factors

• Can be simulated in the absence of full system build

Source: Department of Energy

20

DOE Design Options to Meet AWEF Summary

Floating Head Pressure

Modulating Evaporator Fans

Electronically Commutated

Motors

Improved Evaporator Fan

Blades

Improved Condenser Fan

BladesImproved CoilHot Gas Defrost

Temperature-initiated,

Temperature-terminated Defrost

Variable Speed Compressor

Variable Speed Condenser Fans

Variable Speed Evaporator Fans

Ambient Sub-cooling

Source: Department of Energy

21

Floating Head Pressure vs. Fixed

22

Source: Emerson

Taking Advantage of Low Ambient

23

Source: Emerson

Automatic Commercial Ice MakersCycle Understanding

Start• 30/110• 15% Run Time

Stabilize• 15/115• 70%

Finish• 0/105• 10%

Harvest• 45/95• 5%

Ice

Mac

hine

Tra

nsie

nt M

odel

Ice Machine Improvement Levers

Continuous BothBatch

24

Total Walk-ins Reach-ins

Ice/FCB/SS

Racks

75% 74% 64% 83%

75% 74% 55% 75%

56% 71% 46% 75%

69% 60% 55% 67%

44% 37% 27% 50%

50% 17% 18% 50%

38% 37% 18% 25%

50% 20% 9% 17%

56% 20% 0% 50%

44% 14% 9% 33%

Measures Being Taken to Increase Energy Efficiency

71%

69%

65%

59%

35%

31%

29%

26%

26%

18%

Switching to more efficient fanmotors

Switching to more efficientcompressors

Using LED lighting

Using more electronic controls

Using larger heat exchangers

Switching to electronicexpansion valves

Improving the amount ofinsulation

Switching to scroll compressors

Using adaptive electric defrost

Using floating head pressures

More Efficient Fan Motors and Compressors, Along With LED Lighting and Electronic Controls, Are Being Used to Increase Energy Efficiency and Provide the Best ROI.

Top energy efficiency

improvements that will

provide the best return on

investment

25

37,616CRE

797ACIM

1,673WICF

• Google “DOE CCMS” or …– https://www.regulations.doe.gov/ccms

• DOE enforcement mechanism– Fines have been imposed

• Annual certification required by submitting new CCMS and supplemental testing forms each year

Current Number of Models Listed

Source: Department of Energy

26

Polling Question 2In what way would you describe these regulatory challenges?

A. Negative: It’s going to hurt my business.B. Positive: It’s going to be an opportunity for me to differentiate and lead.

27

Questions?

DISCLAIMERAlthough all statements and information contained herein are believed to be accurate and reliable, they are presented without guarantee or warranty of any kind, expressed or implied. Information provided herein does not relieve the user from the responsibility of carrying out its own tests and experiments, and the user assumes all risks and liability for use of the information and results obtained. Statements or suggestions concerning the use of materials and processes are made without representation or warranty that any such use is free of patent infringement and are not recommendations to infringe on any patents. The user should not assume that all toxicity data and safety measures are indicated herein or that other measures may not be required.

Thank You!