Honda CB 500 recostrucci+¦n de culata - Ingles

-

Upload

joao-moreira -

Category

Documents

-

view

133 -

download

3

Transcript of Honda CB 500 recostrucci+¦n de culata - Ingles

cam Honda. Don't even start the tear-down, though, without a copy of thefactory's Honda CB 500 Shop Man-ual; your dealer can get one for youfor less than $ 1 0. There's a few finedetail parts that make these enginesthe jewel-like machines they are andthe manual will show you just wherethey fit together.

When you're tearing an engineapart, and particularly one with asmany pieces as a four-cylinder, it paysto have a few housewife-style cookingsheets padded with a layer of cleanrags. Lay each of the parts on thecookie sheet in the order you took itoff, with separate pans for the cylinderhead, barrel and piston parts, andcrankcase pieces to keep them insome kind of order for reassembly.

The outside of the engine should, ofcourse, be completely clean and dryand you'll enjoy the work more if youwash off each of the parts as you goin gasoline.

Surprisingly, for an engine thatseems so complex, you won't needany special tools to take it apart orto get it back together again. The 500Four, like any other four-stroke, willrequire a valve spring compressor togain access to the valves and you'llneed both a torque wrench and aPhillips-bit impact wrench; the restwill come apart nicely with just anassortment of metric wrenches, asoft-headed hammer and screw-drivers. You will need special Hondapullers to get at the works of the ACgenerator or the transmission's

If your 500 Four isailing inside, this ishow to get at it.

What do you do when you havethe "Gem" of the motorcycle mar-ket's engines? Well, Honda just madetheir 500 that much nicer, mechani-cally, than their previous showpiece750. The bulk, weight and, of course,the displacement of the Honda 500Four engine is a third less than the750 but the half-liter is even nicerinside. It's a complicated engine ifyou're used to working on two-strokesbut anyone with any overhead-valveengine experience should have fewproblems in getting into the overhead

49. The edges of thetransmission's shifting forks areone of the most likely wearpoints in the unit. If they'rehighly polished that's fine but, ifthey show any wear marksdeeper than the thickness of abusiness card, that fork should hereplaced.

50. Remove the bolts that retainthe end of the primary shaft onthe side opposite the oilpump—the shaft will come outthis end later.

51 & 52. Remove thePhillips-head screws that retainthe oil pump and lift the pumpstraight away from the side of thecrankcase and the primary shaftinside.

53. Tap out the primary shaftfrom the oil pump side. Thecrankshaft-driven primarysprocket and starter clutch willremain in the case as a singleunit; they can he lifted away fromthe primary chain once theprimary shaft is out.

54. Auto parts stores sell aspecial clearance gauge called a"Plasti Gauge" that is placedbetween the crankshaft bearingsand the crankshaft. If there ismore than .0031-inches clearancebetween any of the crankshaftbearings and their Journals in thecase the bearing will have to bereplaced and the crankshaftre-ground. The factory workshopmanual describes the procedurefor picking the proper bearings.

55. The primary chain can bewiggled about off the end of thecrankshaft without removing therods if you have to replace it. Thebig ends of the rods should bechecked for wear too. If there ismore than .0031-inches clearancebetween the bearing and crank,the bearing will have to bereplaced and, most often, thecrankshaft throw re-ground. Therod's big end bolts should betightened to 14.46 to 15.91 footpounds of torque. The "PlastiGauge," again, is needed to getan accurate reading on the bigend bearing's clearances.

primary shaft, however, if either ofthese components is ailing. Yourdealer is the best man to recut thevalve seats, if they need it, so thosetools won't be required either. You'dbe best off, in fact, if you'd entrusta dealer with any valve replacementwork; just hand him the head and afew small bills and he'll return thehead to you in a few days ready tobolt back in place. Valve removal,valve seat recutting, valve grinding,'valve spring tension-equalization andreassembling the valves, springs andkeepers are things that can be donequicker and, in the long run cheaper,by a well-equipped Honda dealer'sservice department. The rest you canhandle with a bit of help from themanual.

1. Disconnect the exhaust pipes,the fuel lines and the electricalconnections to the engine.Remove the drive chain and theengine-mounting bolts and it canbe lifted onto your workbench.One man can handle the 500,barely, but it's safer with two.You can disconnect thecarburetors from the engine andjust leave them in the frame stillattached to their cables if youwish.

2 & 3. Loosen each of the fourcarburetor-to-cylinder headflexible hoses' clamping screwsand carefully pry off the fourcarburetors as a single unit. Afew drops of water will help toease them back on later.

4. An impact driver is a must formost modern engines. Use it,here, to loosen the screws thatretain the cylinder head cover.Turn each screw only aquarter-turn, at first, to equalizethe tension so the cover won'twarp. Work in a criss-crosspattern. Tighten the screwsgradually, too, when the engine isreassembled.

5 & 6. There's a breather coverover the center of the cylinderhead cover piece that has to beremoved to gain access to thescrews holding the cylinder headcover. Remove the breather andloosen the four remaining screwsbelow it.

CYCLE MECHANICS QUARTERLY 41

7. The eight individual tappetadjustment plugs are bestremoved before you lift thecylinder head cover so you'll havethe entire engine for leverage.Remove all eight of them andplace them in order on one ofthose padded cookie sheets. Theycan stay off until the engine isback in the chassis ready for thevalves to be adjusted.

8. Use the impact screwdriver,again, to loosen and remove thescrew that retains each of theside covers and remove them.

9. There are, in addition to all thePhillips-head screws, four boltswith copper washers beneath thatretain the cylinder head cover.Remove them and the cover canbe lifted away from the engine.

10. The cylinder head cover alsocontains the rocker arms and theirshafts. Screw a long bolt into theend of each shaft (they're tappedto accept a 6mm bolt) and pullthe four separate shafts fromeach end of the cylinder headcover. Inspect the rubbing facesof each of the rocker arms forany signs of the scrapes and pitsthat indicate excessive wear.Replace any worn rocker armsbefore reassembling the engine.

11. One of the jewel-like qualitiesof the Honda 500 is the gasket inthe cylinder head cover. It's aspecially-molded and shapedO-ring style neoprene seal thatis oil-tight without the bother ofgasket cement. Lift it gently fromits groove in the cover. If there'sany sign of cracking or wearing,replace the gasket.

12. Loosen the cam chaintensioner's outer lock nut andinner slotted adjusting screw ifyou're only going to remove thecylinder head. If the barrel, too,will be removed you can unscrewboth the nut and screw.

14. There are twelve nuts thathold the cylinder head but theycannot be removed until thecamshaft is out of the way. Thetwo 6mm bolts at the center ofboth front and back of the barrelare the ones you're likely toforget, though; they can beremoved now.

13. The bolt immediately abovethe cam chain tensioner is theone that actually holds thetensioner in the cylinder head.You must remove it to removethe cylinder head. Leave theactual tensioner in place for now(it can stay in place if you're onlyworking on the head).

15. Remove the cover over thecontact points so you can turnthe engine over with a wrench onthe central crankshaft nut (youcould also use the kickstarterlever if you wish). Rotate theengine so you can easily reachthe two bolts that attach thecamshaft sprocket.

16 & 17. Remove both of thecamshaft sprocket's retainingnuts. The hole in the sprocket iselongated to clear the tabs on thecenter of the camshaft. Pry thechain off the gear with yourfingers first, then slide the camthrough the chain and through theelongated holes in the sprocket.It's a good idea to tie a wire tothe chain and another to thesprocket so they don't drop downinto the crankcase.

18. Inspect each of the camshaftbearings for wear or thepebbly-surfaces that indicategalling from lack of lubrication. Ifthere's more than .004-inchclearance between the cam andthe cylinder head bearings thehead must be replaced. Removethe four small rubber caps overthe four center cylinder headhold-down nuts.

19. Loosen the 12 8mm cylinderhold-down nuts a quarter-turn at atime to evenly relieve thepressure on the head so it won'twarp. When the engine isreassembled follow the samepattern, torquing each nut tobetween 14.46 and 16.63foot-pounds with a torquewrench.

20 & 21. The cylinder headshould be free to be lifted awayby hand; if it's tight, replace thespark plugs and crank it over—thevalves are all closed and thecompression should be enough tobreak the head gasket's seal. Liftthe head and gently pry away thehead gasket.

22. You need a plethora ofspecial tools to properly reworkthe cylinder head including avalve spring compressor, specialseat-cutting tools and a springtension-equalizer. If the valvesneed reworking or there's muchcarbon buildup in the exhauststake it into a Honda dealer.

24. There are several rubberO-rings and aligning pins in boththe cylinder head and barrel(another reason for having thefactory workshop manual handy).Remove these oil passage O-ringsfrom the cylinder barrel, forexample, so you don't losethem. Remember to replace them!

23. The adjusting screw and thetop bolt that retain the cam chaintensioner were removed earlier.The tensioner must be rotated 90degrees so its integral guide pinswill clear the chain slot in thecylinders and it can be lifted fromthe cylinder barrel. The chainstays for now.

26. There are O-rings around thehollow oil passage dowel rings atthe top of the crankcase too, setthem aside for replacement later.The barrel is easy enough to liftbut it's devilishly difficult to getFOUR sets of piston ringscompressed when you replace it.Discount auto parts stores sellring compressors for less thantwo-dollars that'll make it easierto reassemble the barrel over thepistons and rings.

25. You'll likely need to tap thesides of the barrel to break thebase gasket seal. Use a rubber orfiber-headed hammer and tap onlyon the solid portions of the barrel,not the fins. A few light taps onall four sides should be enough toloosen the barrel.

27 & 28. Stuff a rag around thebase of each cylinder so youdon't drop any parts down intothe crankcase. Honda sells aspecial piston ring clip removaltool but you can do the job withan ice pick and a pair ofneedlenose pliers. Pry the edge ofthe clip loose with the pick andlift it free with the needlenosepliers.

29. The piston pins should justslide out of the pistons. Removethe rings and check their end gapby inserting each of them in theirrespective cylinders. It should beless than .027-inches or the ringsneed replacing. If they're badlyworn check their clearancetop-to-bottom in the ring slots ofthe piston. The MAXIMUMclearance between the ring andthe groove is .007-inches for thetop ring and .005 for the bottomtwo. If the piston-to-boreclearance exceeds .010-inchesyou're due for a rebore. If thepistons are smaller than2.198-inches anywhere around thering area diameter they'll have tobe replaced. When you replacethe rings be sure to stagger theirgaps one-third of the way aroundAND be sure that none of thegaps are in line with the pistonpin OR the long edges of frontand backs of the piston skirts.Use new pin clips even if youreplace the old pistons or rings.The maximum allowable diameteron the piston pin hole in thepiston is .593-inches, if it's largerreplace the piston.

32 & 33. Remove the kickstarterlever and the clutch cover plate.The clutch itself can remain intactunless it, too, requires replacingor rebuilding.

30 & 31. Remove the generatorcover using an impact screwdriverto loosen the Phillips-headedscrews. A puller (number07011-21601 from Honda) isneeded to pull the generator rotorif you're having troubles with it.You don't have to remove therotor, however, to remove thecrankshaft or to split thecrankcases for access to thetransmission.

34 & 35. Remove thePhillips-head screws from theextreme outer edges of thecontact point backing plate thenloosen the nut on the end of thecrankshaft that retains thecontact point cam. Remove thenut, the spark advancemechanism and the completecontact point assembly.

36 & 37. Loosen the two boltsthat hold the starter motor inplace and pull the completestarter motor straight out of theside of the crankcase.

38 & 39. Loosen and remove allof the 6mm and 8mm bolts thathold the top of the transmissionand crankcase together—there areabout 16 more 6mm bolts and 13more 8mm ones on the bottombut we'll get those later.

40. The crankcase can now beturned upside down to gainaccess to the bolts and parts onthe bottom side. Remove thecentral bolt that retains the oilfitter and lift both filter andelement away.

41. You can now begin looseningthe bolts that hold the crankcasehalves together. Start with thetwo center bolts and work yourway out towards both ends,turning each about a half-turn at atime to avoid warping the cases.

42. Watch the head of each bolt,as you remove it, for a number.There are two special 8mm boltson the generator end marked"9"—each and every part of theengine, including the bolts, nutsand screws, should go backexactly as it was.

43. Remove the ten bolts thatretain the finned oil pan andcarefully tap the edges of thepan, if necessary, to free it.There's another 6mm bolt insidethe transmission (shown) as wellas three others along its backedge. When reassembling thecases, the 8mm bolts should betightened with a torque wrench tobetween 16.63 and 18.08 footpounds.

44. The crankcases should now be ready to be split apart. Youmay have to tap the edges with a soft-head hammer and pry, butoh-so-lightly, on some of the edges to get them apart. If theyseem stubborn, look around for a bolt or nut you forgot—it doesn'ttake much effort to split the 500's cases. The bottom half islifted away leaving the top half with the crankshaft andcountershaft in the case and, the transmission mainshaft in thebottom half of the case.

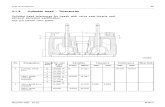

45. The countershaft will liftaway from the top half of thecrankcase. Take a close look ateach and every gear for signs ofexcessive wear. The drawingillustrates the order of assemblyof each of the gears, keepers andwashers if you do have to replaceany of the gears.

46. Pull the clutch-actuating rodand the mainshaft's one bearingwill lift out of the hollowmainshaft if you need to gainaccess to any of the transmissiongears on the mainshaft.

47. The complete clutch andmainshaft can also be liftedgently from the crankcase tophalf (the clutch-actuating rod canremain inside).